What Are the Key Challenges in Flexible Microdisplay Manufacturing

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay Technology Evolution and Objectives

Flexible microdisplay technology has evolved significantly over the past two decades, transitioning from rigid display architectures to increasingly flexible and conformable solutions. The journey began in the early 2000s with the development of thin-film transistor (TFT) technologies on plastic substrates, marking the first departure from traditional glass-based displays. This initial breakthrough laid the foundation for subsequent innovations in materials science and manufacturing processes.

By 2010, researchers had developed organic light-emitting diode (OLED) displays with limited flexibility, capable of withstanding moderate bending without performance degradation. The period between 2010 and 2015 saw significant advancements in substrate materials, with polyimide emerging as a preferred option due to its thermal stability and mechanical robustness. These developments enabled the first commercial flexible displays in smartphones and wearable devices.

The evolution accelerated from 2015 onwards with the introduction of quantum dot displays and microLED technologies adapted for flexible applications. These technologies offered superior brightness, color gamut, and energy efficiency compared to earlier flexible display solutions. Concurrently, advances in thin-film encapsulation techniques addressed critical challenges related to moisture and oxygen sensitivity in flexible display components.

Recent years have witnessed the emergence of stretchable display technologies, representing the next frontier beyond mere flexibility. These displays incorporate novel materials such as elastomeric substrates and stretchable conductors to achieve both bending and stretching capabilities. The integration of self-healing materials has also begun to address durability concerns in flexible microdisplays.

The primary technical objectives in flexible microdisplay development center around several key parameters. First, achieving ultra-thin form factors (below 10 microns) while maintaining structural integrity during repeated mechanical deformation. Second, developing manufacturing processes that enable high-resolution pixel densities (exceeding 1000 PPI) on non-rigid substrates. Third, ensuring consistent electrical performance across the entire display area during bending, folding, or stretching operations.

Additional objectives include enhancing operational lifetime under mechanical stress, reducing power consumption for mobile applications, and developing scalable manufacturing techniques compatible with existing display production infrastructure. The ultimate goal is to create microdisplays that can conform to any surface while delivering visual performance comparable to or exceeding that of rigid displays.

The technology trajectory points toward fully conformable, high-resolution microdisplays that can be integrated into various form factors, from curved automotive dashboards to medical devices that conform to human anatomy. This evolution represents a fundamental shift in display technology paradigms, moving from displays as rigid components to displays as adaptable, integrated elements of product design.

By 2010, researchers had developed organic light-emitting diode (OLED) displays with limited flexibility, capable of withstanding moderate bending without performance degradation. The period between 2010 and 2015 saw significant advancements in substrate materials, with polyimide emerging as a preferred option due to its thermal stability and mechanical robustness. These developments enabled the first commercial flexible displays in smartphones and wearable devices.

The evolution accelerated from 2015 onwards with the introduction of quantum dot displays and microLED technologies adapted for flexible applications. These technologies offered superior brightness, color gamut, and energy efficiency compared to earlier flexible display solutions. Concurrently, advances in thin-film encapsulation techniques addressed critical challenges related to moisture and oxygen sensitivity in flexible display components.

Recent years have witnessed the emergence of stretchable display technologies, representing the next frontier beyond mere flexibility. These displays incorporate novel materials such as elastomeric substrates and stretchable conductors to achieve both bending and stretching capabilities. The integration of self-healing materials has also begun to address durability concerns in flexible microdisplays.

The primary technical objectives in flexible microdisplay development center around several key parameters. First, achieving ultra-thin form factors (below 10 microns) while maintaining structural integrity during repeated mechanical deformation. Second, developing manufacturing processes that enable high-resolution pixel densities (exceeding 1000 PPI) on non-rigid substrates. Third, ensuring consistent electrical performance across the entire display area during bending, folding, or stretching operations.

Additional objectives include enhancing operational lifetime under mechanical stress, reducing power consumption for mobile applications, and developing scalable manufacturing techniques compatible with existing display production infrastructure. The ultimate goal is to create microdisplays that can conform to any surface while delivering visual performance comparable to or exceeding that of rigid displays.

The technology trajectory points toward fully conformable, high-resolution microdisplays that can be integrated into various form factors, from curved automotive dashboards to medical devices that conform to human anatomy. This evolution represents a fundamental shift in display technology paradigms, moving from displays as rigid components to displays as adaptable, integrated elements of product design.

Market Demand Analysis for Flexible Display Solutions

The flexible microdisplay market is experiencing unprecedented growth driven by increasing consumer demand for wearable technology, augmented reality (AR), virtual reality (VR), and foldable smart devices. Market research indicates that the global flexible display market is projected to reach $15.1 billion by 2026, growing at a CAGR of 35% from 2021. This remarkable growth trajectory is primarily fueled by the expanding applications across multiple industries and changing consumer preferences toward more portable, lightweight, and versatile display solutions.

Consumer electronics remains the dominant sector driving demand for flexible microdisplays. The rising popularity of smartwatches, fitness trackers, and other wearable devices has created a substantial market for small, flexible displays that can conform to the human body while delivering high-resolution visual information. Major smartphone manufacturers are increasingly incorporating flexible display technology into their flagship products, with foldable smartphones representing a rapidly growing segment expected to capture 5% of the premium smartphone market by 2025.

Healthcare applications present another significant growth area for flexible microdisplays. Medical wearables for patient monitoring, surgical assistance displays, and advanced diagnostic equipment all benefit from lightweight, conformable displays that can be integrated into various medical devices. The healthcare flexible display market segment is expected to grow at 40% annually through 2027, outpacing most other application areas.

Military and defense sectors are also driving substantial demand for flexible display solutions, particularly for head-mounted displays (HMDs) and augmented reality systems for battlefield information delivery. These applications require displays that are not only flexible but also extremely durable, energy-efficient, and capable of operating in harsh environmental conditions.

Consumer preference surveys indicate that 78% of potential buyers consider display quality and flexibility as "very important" factors when purchasing next-generation wearable devices. This consumer sentiment is pushing manufacturers to prioritize flexible display technology in their product development roadmaps.

Regional analysis shows that Asia-Pacific currently leads the market with 45% share, followed by North America at 30% and Europe at 20%. China and South Korea are emerging as manufacturing powerhouses for flexible display technology, while North America leads in technology innovation and patent development.

Despite strong market demand, significant price premiums remain a barrier to mass adoption. Current flexible microdisplays cost approximately 3-4 times more than their rigid counterparts, limiting penetration in mid-range and budget device segments. Industry analysts predict that manufacturing innovations and economies of scale will reduce this price gap to 1.5x by 2028, potentially triggering explosive market growth across all consumer segments.

Consumer electronics remains the dominant sector driving demand for flexible microdisplays. The rising popularity of smartwatches, fitness trackers, and other wearable devices has created a substantial market for small, flexible displays that can conform to the human body while delivering high-resolution visual information. Major smartphone manufacturers are increasingly incorporating flexible display technology into their flagship products, with foldable smartphones representing a rapidly growing segment expected to capture 5% of the premium smartphone market by 2025.

Healthcare applications present another significant growth area for flexible microdisplays. Medical wearables for patient monitoring, surgical assistance displays, and advanced diagnostic equipment all benefit from lightweight, conformable displays that can be integrated into various medical devices. The healthcare flexible display market segment is expected to grow at 40% annually through 2027, outpacing most other application areas.

Military and defense sectors are also driving substantial demand for flexible display solutions, particularly for head-mounted displays (HMDs) and augmented reality systems for battlefield information delivery. These applications require displays that are not only flexible but also extremely durable, energy-efficient, and capable of operating in harsh environmental conditions.

Consumer preference surveys indicate that 78% of potential buyers consider display quality and flexibility as "very important" factors when purchasing next-generation wearable devices. This consumer sentiment is pushing manufacturers to prioritize flexible display technology in their product development roadmaps.

Regional analysis shows that Asia-Pacific currently leads the market with 45% share, followed by North America at 30% and Europe at 20%. China and South Korea are emerging as manufacturing powerhouses for flexible display technology, while North America leads in technology innovation and patent development.

Despite strong market demand, significant price premiums remain a barrier to mass adoption. Current flexible microdisplays cost approximately 3-4 times more than their rigid counterparts, limiting penetration in mid-range and budget device segments. Industry analysts predict that manufacturing innovations and economies of scale will reduce this price gap to 1.5x by 2028, potentially triggering explosive market growth across all consumer segments.

Current Manufacturing Limitations and Technical Barriers

Flexible microdisplay manufacturing faces significant technical barriers that currently limit mass production capabilities and commercial viability. The transition from rigid to flexible display technologies introduces complex challenges across multiple manufacturing stages. Traditional fabrication processes developed for rigid substrates cannot be directly applied to flexible materials without substantial modifications.

Temperature sensitivity represents one of the most critical limitations. Flexible substrates typically have lower thermal stability compared to glass or silicon, with maximum processing temperatures often restricted to 200-300°C. This constraint eliminates many conventional high-temperature processes used in traditional display manufacturing, including certain annealing steps and deposition techniques that require temperatures exceeding 400°C.

Material compatibility issues further complicate manufacturing processes. The interaction between flexible substrates and functional materials often results in poor adhesion, delamination, and reduced device performance. Chemical incompatibilities between substrate materials and processing chemicals can lead to degradation of the flexible base, compromising both mechanical and optical properties essential for display functionality.

Dimensional stability during processing presents another significant challenge. Flexible substrates experience greater thermal expansion and contraction compared to rigid alternatives, causing misalignment between layers during multi-step fabrication processes. This dimensional instability directly impacts yield rates and device uniformity, particularly as display resolution increases and pixel sizes decrease.

Handling and transport mechanisms designed for rigid substrates prove inadequate for flexible materials. Conventional robotic systems and conveyor mechanisms can introduce mechanical stress, causing substrate deformation or damage. The development of specialized handling equipment adds significant cost and complexity to manufacturing lines, limiting scalability.

Encapsulation and protection of flexible displays from environmental factors remains technically challenging. Effective barrier layers must simultaneously prevent oxygen and moisture ingress while maintaining flexibility and optical transparency. Current barrier technologies often represent a compromise between flexibility and protection, with few solutions achieving the permeation rates below 10^-6 g/m²/day required for long-term device stability.

Yield management becomes increasingly difficult with flexible substrates. Defect rates typically increase by 30-50% compared to rigid display manufacturing, primarily due to particle contamination, mechanical damage during handling, and process variations. These challenges are magnified when scaling to larger substrate sizes or implementing roll-to-roll processing techniques that could potentially reduce manufacturing costs.

Temperature sensitivity represents one of the most critical limitations. Flexible substrates typically have lower thermal stability compared to glass or silicon, with maximum processing temperatures often restricted to 200-300°C. This constraint eliminates many conventional high-temperature processes used in traditional display manufacturing, including certain annealing steps and deposition techniques that require temperatures exceeding 400°C.

Material compatibility issues further complicate manufacturing processes. The interaction between flexible substrates and functional materials often results in poor adhesion, delamination, and reduced device performance. Chemical incompatibilities between substrate materials and processing chemicals can lead to degradation of the flexible base, compromising both mechanical and optical properties essential for display functionality.

Dimensional stability during processing presents another significant challenge. Flexible substrates experience greater thermal expansion and contraction compared to rigid alternatives, causing misalignment between layers during multi-step fabrication processes. This dimensional instability directly impacts yield rates and device uniformity, particularly as display resolution increases and pixel sizes decrease.

Handling and transport mechanisms designed for rigid substrates prove inadequate for flexible materials. Conventional robotic systems and conveyor mechanisms can introduce mechanical stress, causing substrate deformation or damage. The development of specialized handling equipment adds significant cost and complexity to manufacturing lines, limiting scalability.

Encapsulation and protection of flexible displays from environmental factors remains technically challenging. Effective barrier layers must simultaneously prevent oxygen and moisture ingress while maintaining flexibility and optical transparency. Current barrier technologies often represent a compromise between flexibility and protection, with few solutions achieving the permeation rates below 10^-6 g/m²/day required for long-term device stability.

Yield management becomes increasingly difficult with flexible substrates. Defect rates typically increase by 30-50% compared to rigid display manufacturing, primarily due to particle contamination, mechanical damage during handling, and process variations. These challenges are magnified when scaling to larger substrate sizes or implementing roll-to-roll processing techniques that could potentially reduce manufacturing costs.

Current Manufacturing Approaches and Process Solutions

01 Substrate and material challenges for flexible displays

Manufacturing flexible microdisplays requires specialized substrate materials that can maintain display functionality while being bent or flexed. Challenges include developing substrate materials with appropriate mechanical properties, thermal stability, and compatibility with display components. Polymer-based substrates are commonly used, but they present challenges in terms of dimensional stability during manufacturing processes that involve high temperatures. Additionally, the interface between flexible substrates and rigid electronic components must be carefully engineered to prevent delamination or cracking during flexing.- Substrate and material challenges for flexible displays: Manufacturing flexible microdisplays requires specialized substrate materials that can maintain display functionality while being bent or flexed. Challenges include developing substrates with appropriate mechanical properties, thermal stability, and compatibility with display components. Polymer-based substrates offer flexibility but present difficulties in terms of dimensional stability during high-temperature processing steps. Material selection must balance flexibility requirements with durability and resistance to environmental factors.

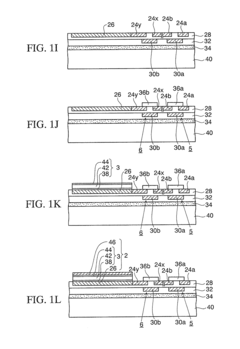

- Thin film transistor (TFT) fabrication on flexible substrates: Creating high-performance thin film transistors on flexible substrates presents significant manufacturing challenges. Traditional semiconductor fabrication processes often involve high temperatures that can damage flexible materials. Low-temperature deposition techniques must be developed while maintaining transistor performance and reliability. Additionally, ensuring uniform electrical characteristics across a bendable surface requires specialized manufacturing approaches to prevent defects during flexing.

- Encapsulation and protection technologies: Flexible displays require effective encapsulation to protect sensitive electronic components from moisture, oxygen, and mechanical damage. Traditional rigid encapsulation methods are unsuitable for flexible applications. Developing thin, flexible barrier layers that maintain integrity during bending while providing sufficient environmental protection is a major manufacturing challenge. Multi-layer barrier films and specialized sealing techniques are needed to ensure display longevity under repeated flexing conditions.

- Integration and interconnect challenges: Connecting components within flexible displays presents unique manufacturing difficulties. Traditional rigid interconnects can crack or fail when bent, requiring the development of stretchable or inherently flexible connection technologies. Challenges include creating reliable interfaces between different materials with varying mechanical properties, maintaining electrical connectivity during flexing, and developing manufacturing processes that accommodate dimensional changes during bending without compromising circuit integrity.

- Testing and quality control for flexible displays: Ensuring quality and reliability in flexible microdisplays requires specialized testing methodologies. Traditional display testing equipment is designed for rigid panels and may not adequately assess flexible display performance. Manufacturers must develop new testing protocols that evaluate display functionality under various bending conditions, assess durability during repeated flexing cycles, and identify potential failure modes specific to flexible technologies. In-line testing during production presents additional challenges due to the handling requirements of flexible substrates.

02 Thin film transistor (TFT) fabrication on flexible substrates

Manufacturing TFTs on flexible substrates presents unique challenges compared to traditional rigid substrates. The lower temperature tolerance of flexible materials requires adaptation of conventional semiconductor processing techniques. Low-temperature deposition methods must be developed for semiconductor layers, dielectrics, and electrodes. Additionally, maintaining precise alignment during multiple photolithography steps becomes more difficult due to the dimensional instability of flexible substrates. These challenges affect transistor performance, uniformity, and yield in flexible microdisplay manufacturing.Expand Specific Solutions03 Encapsulation and protection technologies

Flexible microdisplays require effective encapsulation to protect sensitive electronic components from environmental factors such as moisture and oxygen. Traditional rigid encapsulation methods are not suitable for flexible displays as they would restrict the flexibility. Developing thin, flexible barrier layers that maintain their protective properties during repeated bending cycles is a significant manufacturing challenge. Multi-layer barrier films and atomic layer deposition techniques are being explored to create ultra-thin encapsulation layers that can flex without compromising their barrier properties.Expand Specific Solutions04 Integration of display components in flexible form factors

Integrating various display components such as light-emitting materials, color filters, and driving circuits in a flexible form factor presents significant manufacturing challenges. These components must maintain their functionality while being subjected to mechanical stress during flexing. The interconnections between different layers of the display stack must be designed to accommodate bending without breaking. Additionally, achieving uniform display performance across the entire flexible surface requires precise control of layer thicknesses and material properties during manufacturing.Expand Specific Solutions05 Testing and quality control for flexible displays

Testing and quality control processes for flexible microdisplays require specialized equipment and methodologies different from those used for rigid displays. Evaluating display performance under various bending conditions, detecting defects in flexible substrates, and ensuring reliability during repeated flexing cycles are key challenges. Automated optical inspection systems must be adapted to account for the non-planar nature of flexible displays during testing. Additionally, accelerated life testing protocols need to be developed to predict the long-term reliability of flexible displays under real-world usage conditions.Expand Specific Solutions

Leading Companies in Flexible Microdisplay Ecosystem

The flexible microdisplay manufacturing landscape is currently in a growth phase, with the market expanding rapidly due to increasing demand for wearable devices and AR/VR applications. Major players include established electronics giants like Samsung Electronics, LG Display, and BOE Technology Group, who leverage their extensive display manufacturing expertise to overcome key technical challenges. Chinese manufacturers such as TCL China Star Optoelectronics and Tianma Microelectronics are rapidly gaining market share through aggressive R&D investments. Technical maturity varies significantly across different technologies, with E Ink leading in e-paper displays while OLED flexible displays from LG and Samsung demonstrate higher commercial readiness. Research institutions like Industrial Technology Research Institute and Arizona State University are driving fundamental innovations, though mass production challenges related to yield rates and durability remain significant barriers to widespread adoption.

LG Display Co., Ltd.

Technical Solution: LG Display has developed advanced flexible OLED microdisplay technology utilizing plastic substrates instead of traditional glass. Their manufacturing process involves a proprietary low-temperature polysilicon (LTPS) backplane technology combined with thin-film encapsulation (TFE) that enables ultra-thin, bendable displays. The company employs a roll-to-roll (R2R) manufacturing process that allows for continuous production of flexible displays, significantly improving throughput compared to traditional batch processes. LG's solution addresses key challenges in flexible microdisplay manufacturing through their "Tandem OLED" structure, which stacks two OLED layers to enhance brightness and extend lifetime - critical for microdisplay applications in AR/VR headsets where high brightness and durability are essential[1][3]. Their process also incorporates specialized barrier films to protect sensitive OLED materials from oxygen and moisture degradation.

Strengths: Industry-leading OLED technology with established mass production capabilities; proprietary TFE technology enables ultra-thin form factors; tandem structure provides superior brightness and lifetime. Weaknesses: Higher manufacturing costs compared to rigid displays; yield challenges at smaller microdisplay sizes; limited flexibility compared to emerging technologies like microLED.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered flexible microdisplay manufacturing through their "Active Matrix on Plastic" (AMoP) technology platform. Their approach utilizes ultra-thin flexible glass substrates (under 100μm thickness) that provide both flexibility and superior barrier properties against moisture and oxygen. BOE's manufacturing process incorporates laser release techniques to separate the display from rigid carriers during production, allowing for precise fabrication while enabling flexibility in the final product. For microdisplay applications specifically, BOE has developed high pixel-density (over 2000 PPI) OLED microdisplays on flexible substrates using their proprietary oxide TFT backplane technology[2]. Their solution addresses yield challenges through an automated optical inspection system that identifies defects at multiple production stages. BOE has also implemented specialized encapsulation technology using alternating inorganic/organic layers that maintain barrier properties even when the display is bent, addressing one of the most significant challenges in flexible microdisplay durability[4].

Strengths: Extensive manufacturing infrastructure with high volume capabilities; advanced oxide TFT technology provides superior electron mobility for high-resolution microdisplays; proprietary multi-layer encapsulation technology. Weaknesses: Higher production costs compared to conventional displays; challenges with consistent yield at mass production scales; limited extreme flexibility compared to emerging technologies.

Key Patents and Innovations in Flexible Display Fabrication

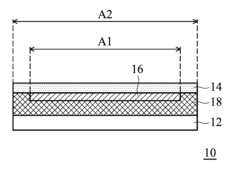

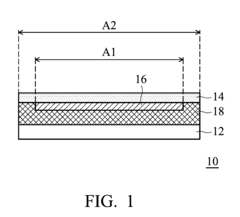

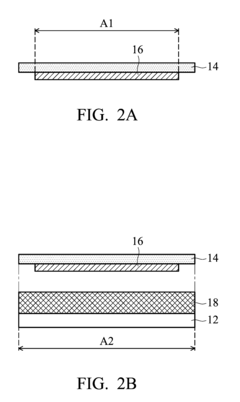

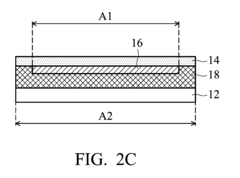

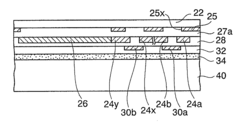

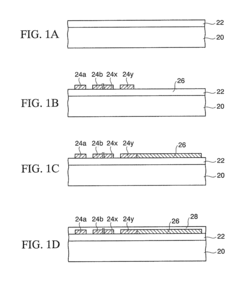

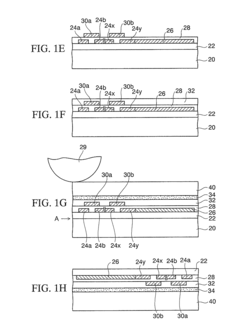

Substrate structures applied in flexible electrical devices and fabrication method thereof

PatentInactiveUS8182892B2

Innovation

- A substrate structure comprising a carrier, a flexible substrate, a release layer, and an adhesive layer, where the adhesive layer has a greater adhesion force than the release layer, allowing for secure immobilization of the flexible substrate during processing and easy separation post-processing, using materials like polyimide and parylene with specific adhesion properties.

Flexible display and manufacturing method of the same

PatentInactiveUS8143628B2

Innovation

- A method involving the formation of a transfer layer on a heat-resistant substrate with a peelable layer, which is then transferred and inverted onto a plastic film with an adhesive layer, allowing for the formation of organic TFTs and EL layers using mask vapor deposition and ink jet methods, avoiding direct photolithography on the plastic film.

Materials Science Advancements for Flexible Displays

The evolution of flexible display technology has been significantly propelled by breakthroughs in materials science. Traditional rigid display materials like glass substrates and silicon-based semiconductors have given way to innovative flexible alternatives. Polyimide has emerged as a leading substrate material due to its exceptional thermal stability, mechanical flexibility, and chemical resistance properties. These characteristics allow displays to bend repeatedly without degradation in performance, addressing one of the fundamental challenges in flexible microdisplay manufacturing.

Organic semiconductors represent another critical advancement, enabling the development of OLED (Organic Light Emitting Diode) displays that can conform to curved surfaces. These materials offer advantages in power efficiency and color reproduction while maintaining functionality during flexing operations. However, their sensitivity to oxygen and moisture necessitates sophisticated encapsulation technologies.

Barrier films have evolved substantially to protect sensitive display components from environmental factors. Multi-layer thin film encapsulation (TFE) technologies now achieve water vapor transmission rates below 10^-6 g/m²/day, extending the operational lifetime of flexible displays from months to years. These films combine organic and inorganic layers to create tortuous paths that prevent moisture penetration while maintaining flexibility.

Transparent conductive materials have progressed beyond traditional indium tin oxide (ITO), which tends to crack under bending stress. Silver nanowires, graphene, PEDOT:PSS, and metal mesh structures now provide conductivity comparable to ITO while withstanding thousands of bending cycles. These materials maintain optical transparency above 85% while offering sheet resistance below 100 ohms/square, essential metrics for touch functionality in flexible displays.

Stretchable electronics represent the frontier of materials science in this field. Novel composite materials incorporating liquid metals within elastomeric matrices can maintain conductivity even when stretched to double their original length. This advancement points toward truly conformable displays that can adapt to complex three-dimensional surfaces rather than merely bending along a single axis.

Adhesive technologies have also evolved to address the unique requirements of laminating multiple flexible layers. Optically clear adhesives (OCAs) now combine high transparency with viscoelastic properties that accommodate the different thermal expansion coefficients of display components, preventing delamination during thermal cycling and mechanical stress.

Organic semiconductors represent another critical advancement, enabling the development of OLED (Organic Light Emitting Diode) displays that can conform to curved surfaces. These materials offer advantages in power efficiency and color reproduction while maintaining functionality during flexing operations. However, their sensitivity to oxygen and moisture necessitates sophisticated encapsulation technologies.

Barrier films have evolved substantially to protect sensitive display components from environmental factors. Multi-layer thin film encapsulation (TFE) technologies now achieve water vapor transmission rates below 10^-6 g/m²/day, extending the operational lifetime of flexible displays from months to years. These films combine organic and inorganic layers to create tortuous paths that prevent moisture penetration while maintaining flexibility.

Transparent conductive materials have progressed beyond traditional indium tin oxide (ITO), which tends to crack under bending stress. Silver nanowires, graphene, PEDOT:PSS, and metal mesh structures now provide conductivity comparable to ITO while withstanding thousands of bending cycles. These materials maintain optical transparency above 85% while offering sheet resistance below 100 ohms/square, essential metrics for touch functionality in flexible displays.

Stretchable electronics represent the frontier of materials science in this field. Novel composite materials incorporating liquid metals within elastomeric matrices can maintain conductivity even when stretched to double their original length. This advancement points toward truly conformable displays that can adapt to complex three-dimensional surfaces rather than merely bending along a single axis.

Adhesive technologies have also evolved to address the unique requirements of laminating multiple flexible layers. Optically clear adhesives (OCAs) now combine high transparency with viscoelastic properties that accommodate the different thermal expansion coefficients of display components, preventing delamination during thermal cycling and mechanical stress.

Scalability and Cost Reduction Strategies

Achieving commercial viability for flexible microdisplays requires significant advancements in scalability and cost reduction strategies. Current manufacturing processes remain largely experimental or small-batch oriented, creating substantial barriers to mass market adoption. The transition from laboratory-scale production to high-volume manufacturing represents one of the industry's most pressing challenges.

Production yield rates for flexible microdisplays currently hover between 60-70%, substantially lower than the 90%+ yields achieved in conventional rigid display manufacturing. This yield gap directly translates to higher unit costs and represents a critical area for improvement. Implementing statistical process control and advanced defect detection systems could potentially increase yields by 15-20% within existing production frameworks.

Material costs constitute approximately 40-45% of total production expenses for flexible microdisplays. The specialized substrates, organic semiconductors, and encapsulation materials required for flexibility and durability command premium prices due to limited supplier networks and proprietary formulations. Developing alternative material sources and standardizing material specifications across the industry could drive significant cost reductions.

Equipment utilization efficiency presents another opportunity for cost optimization. Current flexible display production lines typically operate at 65-75% efficiency compared to 85-90% for conventional display manufacturing. This inefficiency stems from longer process times, more frequent calibration requirements, and specialized handling procedures necessitated by the delicate nature of flexible substrates.

Roll-to-roll (R2R) processing technology offers perhaps the most promising pathway to scalability. This continuous manufacturing approach, adapted from the printing industry, could potentially reduce production costs by 30-40% compared to current sheet-based processes. However, R2R implementation for microdisplays faces significant technical hurdles, particularly in maintaining precise alignment and preventing substrate deformation during processing.

Modular manufacturing architectures represent another strategic approach to scalability. By designing production systems with standardized, interchangeable process modules, manufacturers can more easily scale capacity incrementally and incorporate technological improvements without complete line redesigns. This approach has successfully reduced capital expenditure requirements by 25-30% in adjacent electronics manufacturing sectors.

Automation and process integration will be crucial for sustainable cost reduction. Current flexible display manufacturing involves numerous discrete steps with manual handling between processes, increasing both labor costs and defect rates. Integrated production systems with minimal human intervention could reduce labor costs by 40-50% while simultaneously improving yield consistency.

Production yield rates for flexible microdisplays currently hover between 60-70%, substantially lower than the 90%+ yields achieved in conventional rigid display manufacturing. This yield gap directly translates to higher unit costs and represents a critical area for improvement. Implementing statistical process control and advanced defect detection systems could potentially increase yields by 15-20% within existing production frameworks.

Material costs constitute approximately 40-45% of total production expenses for flexible microdisplays. The specialized substrates, organic semiconductors, and encapsulation materials required for flexibility and durability command premium prices due to limited supplier networks and proprietary formulations. Developing alternative material sources and standardizing material specifications across the industry could drive significant cost reductions.

Equipment utilization efficiency presents another opportunity for cost optimization. Current flexible display production lines typically operate at 65-75% efficiency compared to 85-90% for conventional display manufacturing. This inefficiency stems from longer process times, more frequent calibration requirements, and specialized handling procedures necessitated by the delicate nature of flexible substrates.

Roll-to-roll (R2R) processing technology offers perhaps the most promising pathway to scalability. This continuous manufacturing approach, adapted from the printing industry, could potentially reduce production costs by 30-40% compared to current sheet-based processes. However, R2R implementation for microdisplays faces significant technical hurdles, particularly in maintaining precise alignment and preventing substrate deformation during processing.

Modular manufacturing architectures represent another strategic approach to scalability. By designing production systems with standardized, interchangeable process modules, manufacturers can more easily scale capacity incrementally and incorporate technological improvements without complete line redesigns. This approach has successfully reduced capital expenditure requirements by 25-30% in adjacent electronics manufacturing sectors.

Automation and process integration will be crucial for sustainable cost reduction. Current flexible display manufacturing involves numerous discrete steps with manual handling between processes, increasing both labor costs and defect rates. Integrated production systems with minimal human intervention could reduce labor costs by 40-50% while simultaneously improving yield consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!