Analysis of Flexible OLED Encapsulation and Its Thermal Resistance

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has emerged as a revolutionary advancement in display technology over the past decade. Unlike traditional rigid displays, flexible OLEDs can be bent, folded, and even rolled while maintaining their display functionality, opening new possibilities for device form factors and applications. The evolution of this technology began in the early 2000s with rudimentary prototypes, progressing significantly through the 2010s with commercial implementations in smartphones, wearables, and other consumer electronics.

The encapsulation layer represents one of the most critical components in flexible OLED technology, serving as a protective barrier against environmental factors that can severely degrade organic materials. Traditional glass encapsulation used in rigid OLEDs cannot accommodate the mechanical stress of flexing, necessitating the development of novel thin-film encapsulation (TFE) technologies that maintain flexibility while providing adequate protection against oxygen and moisture permeation.

The technical evolution trajectory shows a clear shift from early single-layer encapsulation methods toward multi-layer hybrid approaches combining inorganic and organic materials. These hybrid structures aim to balance the excellent barrier properties of inorganic layers with the flexibility advantages of organic materials, creating a composite solution that addresses both protection and mechanical requirements.

Thermal resistance represents a particularly challenging aspect of flexible OLED encapsulation. As devices become thinner and more flexible, heat dissipation becomes increasingly problematic. Excessive heat not only accelerates the degradation of organic materials but also can compromise the integrity of the encapsulation layer itself, potentially creating micro-cracks that allow moisture and oxygen ingress.

The primary technical objectives in this field include developing encapsulation solutions that achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining flexibility through thousands of bending cycles. Additionally, these solutions must demonstrate thermal stability across operating temperatures ranging from -40°C to 85°C, with particular emphasis on heat dissipation during peak usage scenarios.

Current research is focused on novel material combinations, atomic layer deposition (ALD) techniques, and nanocomposite structures that can simultaneously address barrier properties, flexibility, and thermal management. The integration of graphene and other 2D materials shows particular promise for enhancing thermal conductivity while maintaining the ultra-thin profile required for flexibility.

The ultimate goal of flexible OLED encapsulation technology development is to enable truly foldable and rollable displays with longevity comparable to traditional displays, while supporting next-generation applications in wearable technology, foldable smartphones, and rollable televisions. This requires overcoming the inherent trade-offs between flexibility, barrier performance, and thermal management that have historically limited the commercial viability of highly flexible display technologies.

The encapsulation layer represents one of the most critical components in flexible OLED technology, serving as a protective barrier against environmental factors that can severely degrade organic materials. Traditional glass encapsulation used in rigid OLEDs cannot accommodate the mechanical stress of flexing, necessitating the development of novel thin-film encapsulation (TFE) technologies that maintain flexibility while providing adequate protection against oxygen and moisture permeation.

The technical evolution trajectory shows a clear shift from early single-layer encapsulation methods toward multi-layer hybrid approaches combining inorganic and organic materials. These hybrid structures aim to balance the excellent barrier properties of inorganic layers with the flexibility advantages of organic materials, creating a composite solution that addresses both protection and mechanical requirements.

Thermal resistance represents a particularly challenging aspect of flexible OLED encapsulation. As devices become thinner and more flexible, heat dissipation becomes increasingly problematic. Excessive heat not only accelerates the degradation of organic materials but also can compromise the integrity of the encapsulation layer itself, potentially creating micro-cracks that allow moisture and oxygen ingress.

The primary technical objectives in this field include developing encapsulation solutions that achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining flexibility through thousands of bending cycles. Additionally, these solutions must demonstrate thermal stability across operating temperatures ranging from -40°C to 85°C, with particular emphasis on heat dissipation during peak usage scenarios.

Current research is focused on novel material combinations, atomic layer deposition (ALD) techniques, and nanocomposite structures that can simultaneously address barrier properties, flexibility, and thermal management. The integration of graphene and other 2D materials shows particular promise for enhancing thermal conductivity while maintaining the ultra-thin profile required for flexibility.

The ultimate goal of flexible OLED encapsulation technology development is to enable truly foldable and rollable displays with longevity comparable to traditional displays, while supporting next-generation applications in wearable technology, foldable smartphones, and rollable televisions. This requires overcoming the inherent trade-offs between flexibility, barrier performance, and thermal management that have historically limited the commercial viability of highly flexible display technologies.

Market Demand Analysis for Thermally Resistant Flexible OLEDs

The flexible OLED display market has witnessed substantial growth in recent years, with increasing demand for thermally resistant encapsulation solutions. According to market research, the global flexible OLED market reached approximately $15.7 billion in 2022 and is projected to grow at a CAGR of 27.3% through 2028, with thermal resistance capabilities being a key driver of this expansion.

Consumer electronics represents the largest application segment for thermally resistant flexible OLEDs, accounting for over 65% of market demand. Smartphones and wearable devices are the primary contributors, with manufacturers increasingly adopting flexible OLED displays to enable innovative form factors such as foldable and rollable devices. The premium smartphone segment has particularly embraced this technology, with major brands launching flagship models featuring flexible displays.

The automotive industry has emerged as a rapidly growing market for thermally resistant flexible OLEDs, with a projected CAGR of 32% through 2027. Advanced driver assistance systems (ADAS) and in-vehicle infotainment systems require displays that can withstand extreme temperature variations, from -40°C to 85°C, creating significant demand for thermally enhanced encapsulation technologies.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices with flexible displays that demonstrate superior durability and thermal resistance. This consumer preference is driving manufacturers to invest in advanced encapsulation technologies that can maintain display integrity under thermal stress conditions.

Regional analysis shows that Asia-Pacific dominates the market with approximately 72% share, led by South Korea, Japan, and China. North America and Europe follow with 15% and 10% market shares respectively, with both regions showing increased adoption in automotive and aerospace applications where thermal performance is critical.

Industry surveys reveal that 87% of device manufacturers consider thermal resistance as a "very important" or "critical" factor in their flexible OLED sourcing decisions. The ability to withstand thermal cycling without degradation ranks as the third most important purchasing criterion after cost and flexibility performance.

The market for thermally resistant encapsulation materials is expected to grow at 31% annually, outpacing the overall flexible OLED market growth. This indicates a clear shift toward higher-performance materials that can address thermal challenges while maintaining the flexibility and optical properties required for next-generation displays.

Consumer electronics represents the largest application segment for thermally resistant flexible OLEDs, accounting for over 65% of market demand. Smartphones and wearable devices are the primary contributors, with manufacturers increasingly adopting flexible OLED displays to enable innovative form factors such as foldable and rollable devices. The premium smartphone segment has particularly embraced this technology, with major brands launching flagship models featuring flexible displays.

The automotive industry has emerged as a rapidly growing market for thermally resistant flexible OLEDs, with a projected CAGR of 32% through 2027. Advanced driver assistance systems (ADAS) and in-vehicle infotainment systems require displays that can withstand extreme temperature variations, from -40°C to 85°C, creating significant demand for thermally enhanced encapsulation technologies.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices with flexible displays that demonstrate superior durability and thermal resistance. This consumer preference is driving manufacturers to invest in advanced encapsulation technologies that can maintain display integrity under thermal stress conditions.

Regional analysis shows that Asia-Pacific dominates the market with approximately 72% share, led by South Korea, Japan, and China. North America and Europe follow with 15% and 10% market shares respectively, with both regions showing increased adoption in automotive and aerospace applications where thermal performance is critical.

Industry surveys reveal that 87% of device manufacturers consider thermal resistance as a "very important" or "critical" factor in their flexible OLED sourcing decisions. The ability to withstand thermal cycling without degradation ranks as the third most important purchasing criterion after cost and flexibility performance.

The market for thermally resistant encapsulation materials is expected to grow at 31% annually, outpacing the overall flexible OLED market growth. This indicates a clear shift toward higher-performance materials that can address thermal challenges while maintaining the flexibility and optical properties required for next-generation displays.

Current Encapsulation Technologies and Thermal Challenges

Flexible OLED encapsulation technology has evolved significantly over the past decade, with several approaches currently dominating the market. Thin-film encapsulation (TFE) represents the most widely adopted solution, typically employing alternating layers of inorganic and organic materials. The inorganic layers (commonly Al2O3, SiO2, or SiNx) provide excellent barrier properties against moisture and oxygen, while organic layers (typically acrylates or epoxy-based polymers) offer flexibility and stress relief. This multi-layer approach creates a tortuous path for permeants, significantly extending diffusion time.

Another prominent technology is atomic layer deposition (ALD), which enables the formation of ultra-thin, highly conformal barrier layers with exceptional uniformity. ALD-deposited Al2O3 films as thin as 20-30nm can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day, meeting the stringent requirements for OLED protection. However, ALD processes typically require longer deposition times, presenting challenges for high-volume manufacturing.

Hybrid encapsulation systems combining glass or metal foil with thin-film barriers have also gained traction. These solutions utilize an ultra-thin glass layer (typically <100μm) or metal foil bonded with adhesives to provide mechanical support while maintaining flexibility. The edge sealing in these configurations remains particularly challenging, often requiring specialized barrier adhesives.

Despite these technological advances, thermal challenges persist as significant obstacles. The primary thermal issue involves the mismatch in coefficient of thermal expansion (CTE) between different encapsulation materials and the OLED stack. During thermal cycling, this mismatch induces mechanical stress that can lead to delamination, crack formation, or barrier failure. For instance, typical polymer substrates have CTEs ranging from 50-100 ppm/K, while inorganic barrier layers exhibit CTEs below 10 ppm/K.

Heat dissipation represents another critical challenge. Unlike rigid OLEDs that can incorporate heat sinks, flexible displays must dissipate heat through the encapsulation layers themselves. The low thermal conductivity of organic materials (typically 0.1-0.3 W/m·K) creates thermal bottlenecks, potentially leading to localized hotspots that accelerate device degradation. Studies have shown that operating temperatures above 60°C can reduce OLED lifetime by 50% or more.

Furthermore, the encapsulation process itself introduces thermal constraints. Many deposition techniques require elevated temperatures that can damage temperature-sensitive OLED materials. For example, plasma-enhanced chemical vapor deposition (PECVD) of SiNx typically operates at 200-300°C, while optimal OLED processing generally requires temperatures below 100°C. This necessitates careful process optimization or the development of low-temperature deposition techniques.

Recent research has focused on developing thermally resilient encapsulation materials, including nanocomposites that combine the barrier properties of inorganic materials with the flexibility of polymers. These materials aim to withstand thermal cycling while maintaining barrier performance, though commercial implementation remains limited.

Another prominent technology is atomic layer deposition (ALD), which enables the formation of ultra-thin, highly conformal barrier layers with exceptional uniformity. ALD-deposited Al2O3 films as thin as 20-30nm can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day, meeting the stringent requirements for OLED protection. However, ALD processes typically require longer deposition times, presenting challenges for high-volume manufacturing.

Hybrid encapsulation systems combining glass or metal foil with thin-film barriers have also gained traction. These solutions utilize an ultra-thin glass layer (typically <100μm) or metal foil bonded with adhesives to provide mechanical support while maintaining flexibility. The edge sealing in these configurations remains particularly challenging, often requiring specialized barrier adhesives.

Despite these technological advances, thermal challenges persist as significant obstacles. The primary thermal issue involves the mismatch in coefficient of thermal expansion (CTE) between different encapsulation materials and the OLED stack. During thermal cycling, this mismatch induces mechanical stress that can lead to delamination, crack formation, or barrier failure. For instance, typical polymer substrates have CTEs ranging from 50-100 ppm/K, while inorganic barrier layers exhibit CTEs below 10 ppm/K.

Heat dissipation represents another critical challenge. Unlike rigid OLEDs that can incorporate heat sinks, flexible displays must dissipate heat through the encapsulation layers themselves. The low thermal conductivity of organic materials (typically 0.1-0.3 W/m·K) creates thermal bottlenecks, potentially leading to localized hotspots that accelerate device degradation. Studies have shown that operating temperatures above 60°C can reduce OLED lifetime by 50% or more.

Furthermore, the encapsulation process itself introduces thermal constraints. Many deposition techniques require elevated temperatures that can damage temperature-sensitive OLED materials. For example, plasma-enhanced chemical vapor deposition (PECVD) of SiNx typically operates at 200-300°C, while optimal OLED processing generally requires temperatures below 100°C. This necessitates careful process optimization or the development of low-temperature deposition techniques.

Recent research has focused on developing thermally resilient encapsulation materials, including nanocomposites that combine the barrier properties of inorganic materials with the flexibility of polymers. These materials aim to withstand thermal cycling while maintaining barrier performance, though commercial implementation remains limited.

Current Thermal Resistance Solutions for Flexible OLEDs

01 Multi-layer encapsulation structures for thermal resistance

Multi-layer encapsulation structures can be designed to enhance thermal resistance in flexible OLEDs. These structures typically consist of alternating inorganic and organic layers that provide effective barriers against moisture and oxygen while maintaining flexibility. The inorganic layers (such as silicon nitride, aluminum oxide) provide barrier properties, while the organic layers (such as polymers) accommodate mechanical stress during bending. This combination helps maintain device integrity under thermal stress conditions.- Multi-layer encapsulation structures for thermal resistance: Multi-layer encapsulation structures can be used to enhance the thermal resistance of flexible OLEDs. These structures typically consist of alternating inorganic and organic layers that provide effective barriers against moisture and oxygen while maintaining flexibility. The inorganic layers (such as silicon nitride, aluminum oxide) provide barrier properties, while the organic layers (such as polymers) accommodate mechanical stress during bending. This combination helps the OLED device withstand thermal cycling and mechanical stress without degradation.

- Thin-film encapsulation with heat-resistant materials: Thin-film encapsulation techniques using heat-resistant materials can significantly improve the thermal stability of flexible OLEDs. These materials include high-temperature resistant polymers, ceramic materials, and specialized barrier films that maintain their protective properties even under elevated temperatures. The thin-film approach allows for flexibility while providing sufficient protection against environmental factors. Advanced deposition methods ensure uniform coverage and strong adhesion between layers, which is critical for maintaining thermal resistance during operation.

- Thermal management systems integrated with encapsulation: Integrating thermal management systems directly with the encapsulation layer can effectively dissipate heat from flexible OLED devices. These systems may include thermally conductive materials, heat spreading layers, or specialized structures that channel heat away from sensitive components. By incorporating heat dissipation features into the encapsulation design, the overall thermal resistance of the device is improved, preventing degradation of organic materials and extending device lifetime under high-temperature operating conditions.

- Edge sealing techniques for thermal stability: Enhanced edge sealing techniques provide improved thermal stability for flexible OLED encapsulation. These methods focus on reinforcing the vulnerable edges of the device where delamination often begins under thermal stress. Specialized edge sealants, frit materials, or laser sealing techniques create robust bonds that maintain integrity during thermal cycling. Some approaches incorporate gradient structures at the edges to accommodate differential thermal expansion between materials, preventing stress concentration and maintaining the barrier properties even under fluctuating temperature conditions.

- Self-healing encapsulation materials for thermal durability: Self-healing encapsulation materials represent an innovative approach to maintaining thermal resistance in flexible OLEDs. These materials contain components that can repair microcracks or damage caused by thermal stress or mechanical bending. When activated by heat or other stimuli, the self-healing mechanism restores the barrier properties of the encapsulation layer. This technology is particularly valuable for flexible applications where repeated bending and thermal cycling might otherwise lead to progressive degradation of the encapsulation barrier, extending the operational lifetime of the device under varying thermal conditions.

02 Thermally resistant adhesive materials for encapsulation

Specialized adhesive materials with high thermal resistance properties can be incorporated into flexible OLED encapsulation structures. These adhesives maintain their bonding strength and barrier properties even under elevated temperature conditions. They often contain thermally stable polymers, cross-linking agents, and inorganic fillers that enhance thermal conductivity while maintaining flexibility. These materials help prevent delamination and maintain encapsulation integrity during thermal cycling.Expand Specific Solutions03 Thin-film encapsulation techniques for thermal stability

Advanced thin-film encapsulation techniques can be employed to improve thermal resistance in flexible OLEDs. These methods include atomic layer deposition, plasma-enhanced chemical vapor deposition, and solution-based processes that create ultra-thin barrier films with excellent thermal stability. The resulting encapsulation layers maintain their protective properties at high temperatures while allowing for the mechanical flexibility required in bendable displays.Expand Specific Solutions04 Edge sealing technologies for thermal protection

Specialized edge sealing technologies can be implemented to enhance thermal resistance at the vulnerable perimeter of flexible OLED devices. These edge seals often utilize thermally resistant materials such as ceramic frits, metal alloys, or specialized polymers that create a robust barrier against moisture and oxygen ingress, particularly at elevated temperatures. The edge sealing techniques help prevent degradation pathways that commonly begin at device edges when exposed to thermal stress.Expand Specific Solutions05 Hybrid encapsulation systems with thermal management layers

Hybrid encapsulation systems incorporate dedicated thermal management layers to improve heat dissipation and thermal resistance in flexible OLEDs. These systems may include thermally conductive materials, heat-spreading layers, or phase-change materials that help regulate temperature distribution across the device. By efficiently managing heat, these encapsulation structures prevent localized thermal stress points and extend device lifetime under various operating conditions.Expand Specific Solutions

Key Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation and thermal resistance market is currently in a growth phase, with increasing adoption across display technologies. The global market size is projected to expand significantly as demand for flexible displays in smartphones, wearables, and automotive applications rises. Technologically, the field is advancing rapidly but remains challenging, with key players at different maturity levels. Samsung Display and LG Display lead with established commercial solutions, while BOE Technology and TCL China Star Optoelectronics are rapidly closing the gap with significant R&D investments. Companies like 3M and LG Chem provide specialized materials critical to encapsulation performance. Chinese manufacturers including Kunshan Govisionox and Everdisplay Optronics are emerging as important competitors, particularly in cost-effective solutions, creating a dynamic competitive landscape where technological innovation and manufacturing scale determine market position.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced multi-barrier encapsulation system for flexible OLEDs featuring alternating inorganic and organic layers. Their technology employs silicon nitride and aluminum oxide inorganic barriers deposited via plasma-enhanced chemical vapor deposition (PECVD) at temperatures below 100°C to maintain substrate integrity. The organic layers utilize proprietary acrylate-based polymers with enhanced thermal stability (decomposition temperature >350°C). BOE's encapsulation incorporates a novel "thermal buffer layer" containing ceramic nanoparticles dispersed in a flexible polymer matrix, achieving thermal conductivity of approximately 1.8 W/m·K while maintaining mechanical flexibility. Their process achieves water vapor transmission rates below 10^-5 g/m²/day and oxygen transmission rates below 10^-3 cc/m²/day. BOE has also pioneered the integration of edge sealing technology specifically designed for flexible displays to prevent lateral moisture ingress, a common failure point in flexible devices.

Strengths: Cost-effective manufacturing process suitable for large-area production; good balance between barrier properties and flexibility; innovative edge sealing technology. Weaknesses: Barrier properties slightly lower than industry leaders; thermal management less advanced than competitors; potential for increased layer thickness affecting overall device flexibility.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered advanced barrier film technology for flexible OLED encapsulation through their Multi-layer Optical Film (MOF) approach. Their system utilizes alternating layers of inorganic oxide barriers (primarily Al2O3 and SiO2) and proprietary polymer layers designed specifically for thermal stability. The inorganic layers are deposited using a modified plasma-enhanced chemical vapor deposition process at temperatures below 80°C, achieving thicknesses of 30-100nm per layer. 3M's innovation lies in their specialized organic interlayers containing proprietary additives that enhance thermal conductivity (1.5-2.0 W/m·K) while maintaining optical clarity and flexibility. Their encapsulation system incorporates a unique "stress-relief" design where specific layers are engineered to absorb thermal expansion mismatch between components. This technology achieves water vapor transmission rates below 10^-5 g/m²/day and oxygen transmission rates below 10^-3 cc/m²/day, while maintaining optical transparency above 90% and flexibility for bending radii down to 3mm.

Strengths: Excellent optical properties with minimal haze; good thermal stability across wide temperature range (-40°C to 85°C); established manufacturing infrastructure for large-scale production. Weaknesses: Slightly lower barrier performance compared to leading display manufacturers; moderate thermal conductivity compared to specialized solutions; limited flexibility for extreme folding applications.

Critical Patents and Innovations in Thermal-Resistant Encapsulation

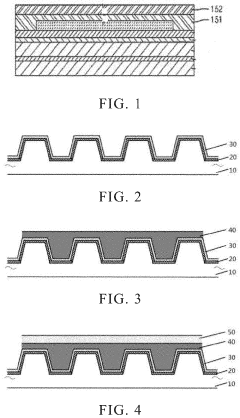

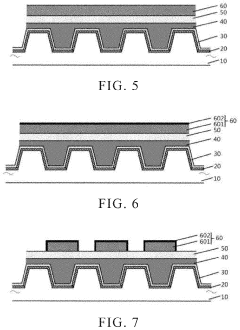

Encapsulation structure and encapsulation method for flexible organic light-emitting diode device

PatentActiveUS20230180509A1

Innovation

- An encapsulation structure comprising an organic matter protective layer, continuous or discontinuous organic flat layers, and inorganic barrier layers, with the outermost organic layers treated with plasma to form a surface hardened layer, creating an organic barrier layer that enhances moisture and oxygen blocking while allowing stress release.

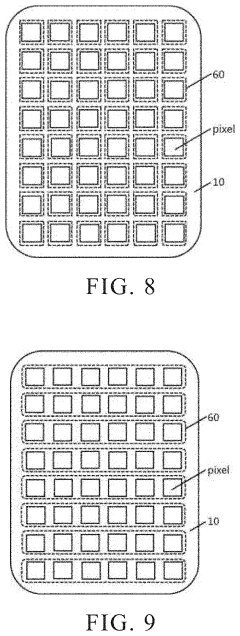

Flexible organic light-emitting diode (OLED) device of reduced stess at bending place and fabrication method thereof

PatentActiveUS11258038B2

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, formed by thermal stress differences, increasing contact area and reducing stress on the outer inorganic layer, and an optically clear adhesive is used to level the configuration.

Materials Science Advancements for Flexible OLED Barriers

Recent advancements in materials science have revolutionized the development of flexible OLED barriers, addressing critical challenges in encapsulation technology. The evolution of barrier materials has progressed from traditional glass-based solutions to sophisticated multi-layer structures that combine organic and inorganic components. These hybrid structures effectively block moisture and oxygen penetration while maintaining the flexibility required for next-generation display applications.

Thin-film encapsulation (TFE) technology represents a significant breakthrough, utilizing alternating layers of inorganic barriers and organic buffer layers. The inorganic layers, typically composed of silicon nitride, aluminum oxide, or silicon oxide, provide excellent barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. Meanwhile, organic layers contribute essential flexibility and stress-relieving properties, preventing crack formation during bending cycles.

Atomic Layer Deposition (ALD) has emerged as a pivotal technique for creating high-quality barrier films with precise thickness control at the atomic level. This method enables the deposition of ultra-thin, defect-free layers that significantly enhance barrier performance while maintaining flexibility. Recent research has demonstrated that ALD-deposited Al₂O₃ layers as thin as 10nm can achieve exceptional barrier properties when properly integrated into multilayer structures.

Nanocomposite materials represent another frontier in flexible barrier technology. By incorporating nanoparticles such as graphene, carbon nanotubes, or metal oxide nanostructures into polymer matrices, researchers have developed barriers with enhanced thermal stability and mechanical resilience. These nanocomposites can withstand temperatures exceeding 200°C while maintaining barrier integrity, addressing the thermal resistance requirements of modern OLED manufacturing processes.

Self-healing materials constitute a promising direction for next-generation barriers. These innovative materials contain microcapsules with healing agents that are released when cracks form, automatically repairing defects in the barrier layer. Preliminary studies show that self-healing barriers can maintain their performance even after multiple bending cycles, potentially extending the operational lifetime of flexible OLEDs significantly.

Transparent conductive oxides (TCOs) with enhanced flexibility, such as indium tin oxide (ITO) alternatives, are being developed to serve dual functions as both barrier layers and electrodes. Materials like silver nanowire networks, PEDOT:PSS, and graphene-based composites demonstrate excellent optical transparency, electrical conductivity, and barrier properties, enabling simplified device architectures and manufacturing processes.

Thin-film encapsulation (TFE) technology represents a significant breakthrough, utilizing alternating layers of inorganic barriers and organic buffer layers. The inorganic layers, typically composed of silicon nitride, aluminum oxide, or silicon oxide, provide excellent barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. Meanwhile, organic layers contribute essential flexibility and stress-relieving properties, preventing crack formation during bending cycles.

Atomic Layer Deposition (ALD) has emerged as a pivotal technique for creating high-quality barrier films with precise thickness control at the atomic level. This method enables the deposition of ultra-thin, defect-free layers that significantly enhance barrier performance while maintaining flexibility. Recent research has demonstrated that ALD-deposited Al₂O₃ layers as thin as 10nm can achieve exceptional barrier properties when properly integrated into multilayer structures.

Nanocomposite materials represent another frontier in flexible barrier technology. By incorporating nanoparticles such as graphene, carbon nanotubes, or metal oxide nanostructures into polymer matrices, researchers have developed barriers with enhanced thermal stability and mechanical resilience. These nanocomposites can withstand temperatures exceeding 200°C while maintaining barrier integrity, addressing the thermal resistance requirements of modern OLED manufacturing processes.

Self-healing materials constitute a promising direction for next-generation barriers. These innovative materials contain microcapsules with healing agents that are released when cracks form, automatically repairing defects in the barrier layer. Preliminary studies show that self-healing barriers can maintain their performance even after multiple bending cycles, potentially extending the operational lifetime of flexible OLEDs significantly.

Transparent conductive oxides (TCOs) with enhanced flexibility, such as indium tin oxide (ITO) alternatives, are being developed to serve dual functions as both barrier layers and electrodes. Materials like silver nanowire networks, PEDOT:PSS, and graphene-based composites demonstrate excellent optical transparency, electrical conductivity, and barrier properties, enabling simplified device architectures and manufacturing processes.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible OLED encapsulation technologies represents a critical consideration in the sustainable development of next-generation display technologies. Traditional encapsulation methods often rely on materials with significant ecological footprints, including rare earth elements and petroleum-based polymers that present end-of-life disposal challenges. The thin-film encapsulation (TFE) processes commonly used for flexible OLEDs require multiple deposition cycles that consume substantial energy and often utilize greenhouse gas-emitting precursors.

Thermal resistance properties of encapsulation layers present both challenges and opportunities for sustainability. Higher thermal resistance materials may extend device lifetimes by protecting sensitive organic layers, thereby reducing electronic waste. However, these same materials often require more energy-intensive manufacturing processes, creating a sustainability trade-off that must be carefully balanced through lifecycle assessment methodologies.

Water vapor transmission rate (WVTR) requirements for flexible OLED encapsulation necessitate barrier materials that are often difficult to recycle or biodegrade. Recent research has focused on developing bio-based alternatives to traditional petroleum-derived polymers for encapsulation sublayers, though these still face challenges in meeting the stringent permeation requirements of <10^-6 g/m²/day.

Manufacturing processes for high-performance encapsulation layers typically involve vacuum deposition techniques that consume significant energy. The industry is increasingly exploring lower-energy alternatives such as solution-processed barrier layers and atomic layer deposition (ALD) at reduced temperatures, which could substantially decrease the carbon footprint of flexible OLED production.

End-of-life considerations remain particularly challenging for flexible OLEDs. The multi-layer composite structure of encapsulation systems, often combining inorganic and organic materials in alternating layers, creates significant barriers to effective recycling. Delamination techniques to separate these materials are currently energy-intensive and not economically viable at scale.

Regulatory frameworks worldwide are increasingly addressing electronic waste management, with particular focus on display technologies. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar legislation in Asia are driving research toward more easily recyclable encapsulation systems that maintain the required barrier properties while facilitating material recovery.

Future sustainable encapsulation solutions will likely focus on circular economy principles, designing materials and processes that enable recovery and reuse of critical elements while minimizing environmental impact throughout the product lifecycle. This may include development of reversible bonding mechanisms in encapsulation layers or designing for disassembly to facilitate more effective recycling processes.

Thermal resistance properties of encapsulation layers present both challenges and opportunities for sustainability. Higher thermal resistance materials may extend device lifetimes by protecting sensitive organic layers, thereby reducing electronic waste. However, these same materials often require more energy-intensive manufacturing processes, creating a sustainability trade-off that must be carefully balanced through lifecycle assessment methodologies.

Water vapor transmission rate (WVTR) requirements for flexible OLED encapsulation necessitate barrier materials that are often difficult to recycle or biodegrade. Recent research has focused on developing bio-based alternatives to traditional petroleum-derived polymers for encapsulation sublayers, though these still face challenges in meeting the stringent permeation requirements of <10^-6 g/m²/day.

Manufacturing processes for high-performance encapsulation layers typically involve vacuum deposition techniques that consume significant energy. The industry is increasingly exploring lower-energy alternatives such as solution-processed barrier layers and atomic layer deposition (ALD) at reduced temperatures, which could substantially decrease the carbon footprint of flexible OLED production.

End-of-life considerations remain particularly challenging for flexible OLEDs. The multi-layer composite structure of encapsulation systems, often combining inorganic and organic materials in alternating layers, creates significant barriers to effective recycling. Delamination techniques to separate these materials are currently energy-intensive and not economically viable at scale.

Regulatory frameworks worldwide are increasingly addressing electronic waste management, with particular focus on display technologies. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar legislation in Asia are driving research toward more easily recyclable encapsulation systems that maintain the required barrier properties while facilitating material recovery.

Future sustainable encapsulation solutions will likely focus on circular economy principles, designing materials and processes that enable recovery and reuse of critical elements while minimizing environmental impact throughout the product lifecycle. This may include development of reversible bonding mechanisms in encapsulation layers or designing for disassembly to facilitate more effective recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!