Why Standardization Matters in Flexible OLED Encapsulation Process

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Evolution and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has evolved significantly over the past two decades, transforming from a laboratory curiosity to a commercial reality that powers cutting-edge displays in smartphones, wearables, and other consumer electronics. The evolution of flexible OLED encapsulation processes represents one of the most critical technological developments in this journey, as it directly impacts device longevity, performance, and manufacturing scalability.

The encapsulation process for flexible OLEDs emerged as a response to the fundamental vulnerability of organic materials to moisture and oxygen. Early OLED devices in the 1990s suffered from rapid degradation due to environmental exposure, with lifetimes measured in mere hours. The initial encapsulation solutions involved rigid glass barriers with desiccants, which effectively protected the organic materials but eliminated any possibility of flexibility.

By the mid-2000s, the development of thin-film encapsulation (TFE) technologies marked a pivotal advancement, enabling the first truly flexible OLED prototypes. This approach utilized alternating layers of inorganic and organic materials to create effective moisture barriers while maintaining flexibility. The subsequent evolution saw the introduction of atomic layer deposition (ALD) techniques around 2010, which allowed for the creation of ultra-thin barrier films with exceptional barrier properties.

The primary objective of flexible OLED encapsulation technology has consistently been to achieve the perfect balance between barrier performance and flexibility. This balance must be maintained while simultaneously addressing manufacturing challenges related to throughput, yield, and cost-effectiveness. The Water Vapor Transmission Rate (WVTR) target has progressively become more stringent, moving from 10^-4 g/m²/day in early applications to current requirements of 10^-6 g/m²/day for long-lifetime flexible displays.

Recent technological objectives have expanded beyond mere protection to include enhanced optical performance, reduced thickness, improved mechanical durability during repeated flexing, and compatibility with emerging form factors such as foldable and rollable displays. These objectives reflect the growing consumer demand for increasingly versatile and durable flexible display products.

The standardization of flexible OLED encapsulation processes has emerged as a critical industry objective, as it promises to address several persistent challenges. These include inconsistent quality across manufacturers, difficulties in comparing performance metrics between different technologies, and barriers to supply chain integration. Standardization aims to establish common testing methodologies, performance benchmarks, and process parameters that can accelerate innovation while reducing manufacturing costs.

Looking forward, the technological roadmap for flexible OLED encapsulation is focused on developing solutions that can support next-generation display applications, including stretchable displays, transparent displays, and displays integrated into non-traditional surfaces. These applications will require encapsulation technologies with unprecedented combinations of barrier performance, optical clarity, and mechanical flexibility.

The encapsulation process for flexible OLEDs emerged as a response to the fundamental vulnerability of organic materials to moisture and oxygen. Early OLED devices in the 1990s suffered from rapid degradation due to environmental exposure, with lifetimes measured in mere hours. The initial encapsulation solutions involved rigid glass barriers with desiccants, which effectively protected the organic materials but eliminated any possibility of flexibility.

By the mid-2000s, the development of thin-film encapsulation (TFE) technologies marked a pivotal advancement, enabling the first truly flexible OLED prototypes. This approach utilized alternating layers of inorganic and organic materials to create effective moisture barriers while maintaining flexibility. The subsequent evolution saw the introduction of atomic layer deposition (ALD) techniques around 2010, which allowed for the creation of ultra-thin barrier films with exceptional barrier properties.

The primary objective of flexible OLED encapsulation technology has consistently been to achieve the perfect balance between barrier performance and flexibility. This balance must be maintained while simultaneously addressing manufacturing challenges related to throughput, yield, and cost-effectiveness. The Water Vapor Transmission Rate (WVTR) target has progressively become more stringent, moving from 10^-4 g/m²/day in early applications to current requirements of 10^-6 g/m²/day for long-lifetime flexible displays.

Recent technological objectives have expanded beyond mere protection to include enhanced optical performance, reduced thickness, improved mechanical durability during repeated flexing, and compatibility with emerging form factors such as foldable and rollable displays. These objectives reflect the growing consumer demand for increasingly versatile and durable flexible display products.

The standardization of flexible OLED encapsulation processes has emerged as a critical industry objective, as it promises to address several persistent challenges. These include inconsistent quality across manufacturers, difficulties in comparing performance metrics between different technologies, and barriers to supply chain integration. Standardization aims to establish common testing methodologies, performance benchmarks, and process parameters that can accelerate innovation while reducing manufacturing costs.

Looking forward, the technological roadmap for flexible OLED encapsulation is focused on developing solutions that can support next-generation display applications, including stretchable displays, transparent displays, and displays integrated into non-traditional surfaces. These applications will require encapsulation technologies with unprecedented combinations of barrier performance, optical clarity, and mechanical flexibility.

Market Demand Analysis for Standardized OLED Encapsulation

The global OLED display market has been experiencing robust growth, with flexible OLED technology emerging as a key driver. Market research indicates that the flexible OLED segment is projected to grow at a CAGR of 35% through 2026, significantly outpacing rigid OLED alternatives. This accelerated growth is primarily fueled by increasing adoption in premium smartphones, wearable devices, and emerging applications in automotive displays and foldable electronics.

Encapsulation technology, critical for protecting OLED materials from moisture and oxygen degradation, represents approximately 15-20% of the total manufacturing cost for flexible OLED panels. The lack of standardization in this process has created significant market inefficiencies, with manufacturers developing proprietary solutions that limit economies of scale and increase production costs.

Consumer electronics manufacturers have expressed growing demand for standardized encapsulation processes to ensure consistent quality and reliability across suppliers. Survey data from major OEMs indicates that 78% consider standardized encapsulation a "high priority" for their supply chain management, citing concerns about variable lifespans and performance characteristics between different panel suppliers.

The automotive sector represents an emerging high-value market for flexible OLED displays, with projected integration in 40% of premium vehicles by 2025. This sector demands particularly stringent reliability standards, with expected operational lifespans of 10+ years under varying temperature and humidity conditions. Standardized encapsulation processes would facilitate qualification processes and accelerate adoption in this conservative but lucrative market.

Regional analysis reveals varying levels of market readiness for standardized encapsulation. East Asian markets, particularly South Korea and China, demonstrate the highest demand due to their concentrated OLED manufacturing base. North American and European markets show growing interest driven by automotive and medical device applications where reliability standards are paramount.

The economic impact of standardization extends beyond manufacturing efficiencies. Supply chain analysis indicates potential cost reductions of 12-18% through standardized material specifications, testing protocols, and quality assurance processes. These savings could accelerate price normalization for flexible OLED displays, expanding addressable markets beyond premium segments.

Consumer research highlights that end-users increasingly value device longevity and durability, with 65% of smartphone buyers citing "screen durability" as a top-five purchase consideration. Standardized encapsulation directly addresses these concerns by ensuring consistent protection against environmental factors that cause display degradation.

Encapsulation technology, critical for protecting OLED materials from moisture and oxygen degradation, represents approximately 15-20% of the total manufacturing cost for flexible OLED panels. The lack of standardization in this process has created significant market inefficiencies, with manufacturers developing proprietary solutions that limit economies of scale and increase production costs.

Consumer electronics manufacturers have expressed growing demand for standardized encapsulation processes to ensure consistent quality and reliability across suppliers. Survey data from major OEMs indicates that 78% consider standardized encapsulation a "high priority" for their supply chain management, citing concerns about variable lifespans and performance characteristics between different panel suppliers.

The automotive sector represents an emerging high-value market for flexible OLED displays, with projected integration in 40% of premium vehicles by 2025. This sector demands particularly stringent reliability standards, with expected operational lifespans of 10+ years under varying temperature and humidity conditions. Standardized encapsulation processes would facilitate qualification processes and accelerate adoption in this conservative but lucrative market.

Regional analysis reveals varying levels of market readiness for standardized encapsulation. East Asian markets, particularly South Korea and China, demonstrate the highest demand due to their concentrated OLED manufacturing base. North American and European markets show growing interest driven by automotive and medical device applications where reliability standards are paramount.

The economic impact of standardization extends beyond manufacturing efficiencies. Supply chain analysis indicates potential cost reductions of 12-18% through standardized material specifications, testing protocols, and quality assurance processes. These savings could accelerate price normalization for flexible OLED displays, expanding addressable markets beyond premium segments.

Consumer research highlights that end-users increasingly value device longevity and durability, with 65% of smartphone buyers citing "screen durability" as a top-five purchase consideration. Standardized encapsulation directly addresses these concerns by ensuring consistent protection against environmental factors that cause display degradation.

Current Standardization Status and Technical Barriers

Despite the rapid advancement of flexible OLED technology, the standardization landscape for encapsulation processes remains fragmented and underdeveloped. Currently, several industry bodies including the International Electrotechnical Commission (IEC), Society for Information Display (SID), and the Flexible Display Alliance have proposed partial standards, but a comprehensive, universally accepted framework is notably absent. This lack of cohesive standardization creates significant barriers to industry-wide adoption and technological advancement.

The existing standards primarily focus on basic performance metrics such as water vapor transmission rate (WVTR) and oxygen transmission rate (OTR), but fail to address the complex interplay of materials, processes, and environmental factors specific to flexible OLED encapsulation. For instance, while IEC 62341-6-3 covers some aspects of OLED display durability, it doesn't adequately address the unique challenges posed by flexible substrates and their encapsulation requirements.

Technical barriers to standardization are multifaceted. First, measurement methodologies for ultra-low WVTR values (below 10^-6 g/m²/day) required for flexible OLEDs lack consistency across the industry, with different manufacturers employing proprietary testing protocols. This creates difficulties in comparing performance claims and establishing baseline requirements.

Second, the rapid evolution of encapsulation technologies—from early glass-based solutions to advanced hybrid approaches combining inorganic and organic layers—has outpaced standardization efforts. The diversity of approaches, including atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-processed barrier films, complicates the establishment of universal standards.

Third, there exists a significant knowledge gap regarding long-term reliability testing. While accelerated aging tests are common, their correlation with real-world performance remains contentious, particularly for flexible displays that experience mechanical stress alongside environmental exposure.

Regional disparities in standardization approaches further complicate the landscape. Asian manufacturers, particularly in South Korea and China, have developed internal standards that often differ from those proposed by European and American entities, creating potential market fragmentation and interoperability issues.

The absence of standardized terminology also impedes progress, with inconsistent definitions for key performance indicators and testing conditions making cross-industry communication challenging. This semantic barrier extends to material specifications, process parameters, and quality control metrics, further hindering collaborative advancement in the field.

The existing standards primarily focus on basic performance metrics such as water vapor transmission rate (WVTR) and oxygen transmission rate (OTR), but fail to address the complex interplay of materials, processes, and environmental factors specific to flexible OLED encapsulation. For instance, while IEC 62341-6-3 covers some aspects of OLED display durability, it doesn't adequately address the unique challenges posed by flexible substrates and their encapsulation requirements.

Technical barriers to standardization are multifaceted. First, measurement methodologies for ultra-low WVTR values (below 10^-6 g/m²/day) required for flexible OLEDs lack consistency across the industry, with different manufacturers employing proprietary testing protocols. This creates difficulties in comparing performance claims and establishing baseline requirements.

Second, the rapid evolution of encapsulation technologies—from early glass-based solutions to advanced hybrid approaches combining inorganic and organic layers—has outpaced standardization efforts. The diversity of approaches, including atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-processed barrier films, complicates the establishment of universal standards.

Third, there exists a significant knowledge gap regarding long-term reliability testing. While accelerated aging tests are common, their correlation with real-world performance remains contentious, particularly for flexible displays that experience mechanical stress alongside environmental exposure.

Regional disparities in standardization approaches further complicate the landscape. Asian manufacturers, particularly in South Korea and China, have developed internal standards that often differ from those proposed by European and American entities, creating potential market fragmentation and interoperability issues.

The absence of standardized terminology also impedes progress, with inconsistent definitions for key performance indicators and testing conditions making cross-industry communication challenging. This semantic barrier extends to material specifications, process parameters, and quality control metrics, further hindering collaborative advancement in the field.

Mainstream Encapsulation Standardization Approaches

01 Thin film encapsulation techniques for flexible OLEDs

Thin film encapsulation (TFE) is a critical process for flexible OLEDs that involves depositing alternating inorganic and organic layers to create a barrier against moisture and oxygen. This technique allows for the flexibility required in bendable displays while maintaining effective protection of the sensitive OLED materials. The standardized process typically includes plasma-enhanced chemical vapor deposition (PECVD) for inorganic layers and inkjet printing or vapor deposition for organic layers, creating a multi-layer structure that combines the barrier properties of inorganic materials with the flexibility of organic materials.- Thin film encapsulation techniques for flexible OLEDs: Thin film encapsulation (TFE) is a critical process for protecting flexible OLED devices from moisture and oxygen. This technique involves depositing alternating inorganic and organic layers to create a barrier with excellent moisture resistance while maintaining flexibility. The standardized process typically includes plasma-enhanced chemical vapor deposition (PECVD) for inorganic layers and inkjet printing or vapor deposition for organic layers. This multi-layer approach provides effective protection while allowing the OLED to remain flexible.

- Barrier film materials and structures for encapsulation: The selection and standardization of barrier film materials is essential for effective OLED encapsulation. Common inorganic materials include silicon nitride, aluminum oxide, and silicon oxide, which provide excellent barrier properties against moisture and oxygen. Organic materials like parylene and acrylic polymers offer flexibility and stress relief between inorganic layers. Standardized structures typically involve alternating layers with specific thickness ratios to optimize both barrier performance and flexibility. The arrangement and composition of these layers significantly impact the lifetime and performance of flexible OLED devices.

- Encapsulation process monitoring and quality control: Standardized monitoring and quality control procedures are crucial for consistent flexible OLED encapsulation. These include in-situ thickness monitoring during deposition, optical inspection for defects, and calcium tests to evaluate barrier performance. Advanced techniques like ellipsometry and atomic force microscopy help characterize layer properties. Standardized testing protocols involve accelerated aging under controlled temperature and humidity conditions to predict long-term reliability. These quality control measures ensure that the encapsulation process meets the required specifications for commercial production.

- Edge sealing and terminal connection protection: Edge sealing is a critical aspect of flexible OLED encapsulation standardization, as edges are particularly vulnerable to moisture ingress. Standardized approaches include extending the barrier layers beyond the active area, using specialized edge sealants, and implementing mechanical protection structures. Terminal connection areas require special consideration with standardized designs that maintain electrical connectivity while ensuring proper sealing. These techniques often involve additional protective layers or specialized geometries to prevent moisture penetration at these critical interfaces.

- Equipment and process parameters standardization: Standardization of equipment specifications and process parameters is essential for consistent flexible OLED encapsulation. This includes vacuum levels for deposition chambers, gas flow rates, substrate temperatures, and plasma power settings. Automated systems with precise control over deposition rates and layer transitions help ensure reproducibility. Standardized cleaning procedures for equipment and handling protocols for substrates minimize contamination. The establishment of these standardized parameters enables scaling up production while maintaining quality across different manufacturing facilities.

02 Hybrid encapsulation methods for improved barrier properties

Hybrid encapsulation combines multiple techniques to achieve superior barrier properties for flexible OLEDs. These methods typically integrate thin film encapsulation with additional protective elements such as edge sealants, getter materials, or supplementary barrier films. The standardized process involves precise control of deposition parameters, material selection, and interface engineering to minimize defects and pinholes. This approach creates a comprehensive barrier system that addresses the limitations of individual encapsulation methods, resulting in improved device lifetime and reliability under mechanical stress.Expand Specific Solutions03 Roll-to-roll encapsulation processes for mass production

Roll-to-roll (R2R) encapsulation processes enable continuous, high-throughput manufacturing of flexible OLEDs. This approach standardizes the encapsulation of large-area flexible substrates by implementing in-line deposition systems for barrier layers. The process includes substrate handling mechanisms, tension control, alignment systems, and synchronized deposition stations. Standardization focuses on maintaining consistent layer thickness, minimizing contamination, and ensuring uniform coverage across the substrate. This manufacturing method significantly reduces production costs and enables scalable production of flexible OLED displays.Expand Specific Solutions04 Advanced materials for flexible OLED encapsulation

The development and standardization of advanced materials is crucial for effective flexible OLED encapsulation. These materials include high-performance barrier films, low-temperature processable inorganic layers, flexible organic interlayers, and novel composite structures. Standardization efforts focus on material compatibility, deposition parameters, curing conditions, and quality control metrics. Materials such as silicon nitride, aluminum oxide, parylene, and specialized acrylates are being optimized for their barrier properties, flexibility, transparency, and processability to meet the demanding requirements of flexible OLED devices.Expand Specific Solutions05 Quality control and testing standards for encapsulation

Standardized quality control and testing protocols are essential for ensuring the reliability of flexible OLED encapsulation. These standards include water vapor transmission rate (WVTR) measurements, accelerated lifetime testing, mechanical flexibility tests, and optical inspection methods. The standardization process establishes acceptance criteria, testing frequencies, and statistical analysis methods for production environments. Advanced techniques such as calcium tests, laser scanning, and electrical monitoring are being incorporated into standardized procedures to detect defects and predict long-term performance of encapsulation barriers in flexible OLED devices.Expand Specific Solutions

Key Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation process standardization landscape is currently in a growth phase, with the market expanding rapidly as display manufacturers seek to improve production efficiency and yield rates. Major players like BOE Technology, LG Display, and TCL China Star Optoelectronics are driving technological advancement in this field, with varying degrees of technical maturity. While established companies such as Applied Materials and LG Chem have developed sophisticated encapsulation solutions, emerging players like Visionox and Everdisplay Optronics are gaining ground with innovative approaches. The competition is intensifying as Chinese manufacturers invest heavily in OLED technology, though standardization remains fragmented across different technical approaches including thin-film encapsulation and hybrid solutions, creating both challenges and opportunities for industry-wide adoption.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive standardization framework for flexible OLED encapsulation that integrates thin-film encapsulation (TFE) with multi-layer barrier structures. Their approach combines inorganic layers (typically SiNx and Al2O3) with organic interlayers in a precisely controlled deposition process. BOE's standardized encapsulation protocol includes rigorous parameter controls for layer thickness uniformity (±2nm tolerance), deposition temperature stability (±5°C), and vacuum level consistency (10^-6 Torr). Their process incorporates in-line quality monitoring with automated optical inspection and laser-based defect detection systems that can identify particles as small as 0.3μm. BOE has also standardized their Water Vapor Transmission Rate (WVTR) testing methodology to ensure consistent barrier performance below 10^-6 g/m²/day across production lines, enabling reliable mass production of flexible OLED displays with lifespans exceeding 10,000 hours.

Strengths: Industry-leading production scale allows for extensive data collection and statistical process control; integrated supply chain enables comprehensive standardization across materials and processes. Weaknesses: Proprietary standards may limit industry-wide adoption; higher implementation costs compared to rigid display manufacturing processes.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the "Integrated Encapsulation Solution" platform specifically designed to address standardization challenges in flexible OLED manufacturing. Their approach centers on equipment standardization with their Producer® platform that enables precise multi-layer deposition with chamber-to-chamber and tool-to-tool matching within ±3% for critical parameters. Applied Materials' standardization framework includes comprehensive process recipes with defined parameters for plasma pre-treatment, inorganic layer deposition, and interface optimization. Their system incorporates advanced process control with real-time monitoring of plasma characteristics, gas flow precision (±0.1 sccm), and temperature uniformity (±1°C across 2500mm² substrates). The company has established a material qualification protocol that ensures consistent performance across material batches and suppliers, with standardized testing for impurity levels, stoichiometry, and barrier properties. Their encapsulation technology achieves WVTR performance below 5×10^-7 g/m²/day with demonstrated consistency across multiple production sites globally.

Strengths: Equipment-centric approach ensures hardware standardization across the industry; strong position as supplier to multiple display manufacturers enables cross-industry standardization. Weaknesses: Limited control over downstream manufacturing processes; dependence on customer implementation of recommended standards.

Critical Patents and Technical Literature Review

Flexible organic light-emitting diode (OLED) device and fabrication method thereof

PatentActiveUS20210336206A1

Innovation

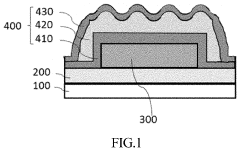

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, increasing contact area and reducing stress, formed spontaneously due to thermal stress differences between layers.

Flexible OLED substrate and encapsulation method thereof

PatentActiveUS20230200111A1

Innovation

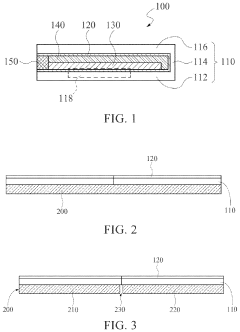

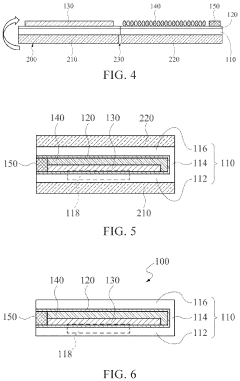

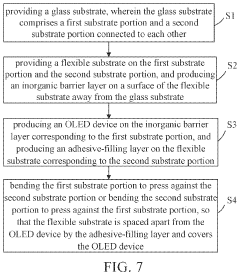

- A flexible OLED substrate with an inorganic barrier layer and an adhesive-filling layer, along with a border adhesive, is used to enclose the OLED device, where the inorganic barrier layer is made of materials like aluminum oxide or silicon oxide, and the adhesive-filling and border adhesives provide additional water-resistant properties, simplifying the encapsulation process and enhancing protection.

Quality Control Metrics and Testing Protocols

Quality control in flexible OLED encapsulation processes requires robust metrics and standardized testing protocols to ensure consistent performance and reliability. The industry has developed several key measurement parameters that serve as benchmarks for evaluating encapsulation quality. Water vapor transmission rate (WVTR) stands as the primary metric, with acceptable standards typically requiring levels below 10^-6 g/m²/day for adequate OLED protection. Oxygen transmission rate (OTR) serves as another critical parameter, with threshold requirements generally below 10^-5 cc/m²/day.

Calcium test methods have emerged as industry standards for ultra-barrier evaluation, offering visual and quantitative assessment of barrier performance through the monitoring of calcium oxidation rates. Electrical calcium tests provide enhanced sensitivity for detecting microscopic defects that might compromise barrier integrity. These methods are complemented by laser-based defect detection systems that can identify pinhole defects as small as 1μm in diameter.

Adhesion strength testing between encapsulation layers utilizes standardized peel tests and cross-hatch methods to quantify interfacial bonding quality. The industry has established minimum adhesion strength requirements of 8-10 N/mm² for reliable flexible OLED encapsulation. Bend testing protocols simulate real-world mechanical stress, with standardized procedures requiring encapsulation to maintain integrity through 100,000+ bending cycles at radii between 1-5mm.

Accelerated aging tests expose encapsulated samples to elevated temperature (85°C) and humidity (85% RH) conditions for periods ranging from 500 to 1000 hours, with pass criteria requiring less than 5% degradation in critical performance parameters. These tests are essential for predicting long-term reliability in various environmental conditions.

Optical performance metrics include standardized measurements of light transmission (>90% in visible spectrum), haze (<0.5%), and color shift (ΔE < 1.0) before and after encapsulation. These parameters ensure that the protective layers do not compromise the display's visual quality.

The implementation of statistical process control (SPC) methodologies enables manufacturers to monitor process variations and establish control limits for critical parameters. Six Sigma methodologies have been widely adopted, with process capability indices (Cpk) targets exceeding 1.33 for key quality metrics to ensure consistent production quality.

Calcium test methods have emerged as industry standards for ultra-barrier evaluation, offering visual and quantitative assessment of barrier performance through the monitoring of calcium oxidation rates. Electrical calcium tests provide enhanced sensitivity for detecting microscopic defects that might compromise barrier integrity. These methods are complemented by laser-based defect detection systems that can identify pinhole defects as small as 1μm in diameter.

Adhesion strength testing between encapsulation layers utilizes standardized peel tests and cross-hatch methods to quantify interfacial bonding quality. The industry has established minimum adhesion strength requirements of 8-10 N/mm² for reliable flexible OLED encapsulation. Bend testing protocols simulate real-world mechanical stress, with standardized procedures requiring encapsulation to maintain integrity through 100,000+ bending cycles at radii between 1-5mm.

Accelerated aging tests expose encapsulated samples to elevated temperature (85°C) and humidity (85% RH) conditions for periods ranging from 500 to 1000 hours, with pass criteria requiring less than 5% degradation in critical performance parameters. These tests are essential for predicting long-term reliability in various environmental conditions.

Optical performance metrics include standardized measurements of light transmission (>90% in visible spectrum), haze (<0.5%), and color shift (ΔE < 1.0) before and after encapsulation. These parameters ensure that the protective layers do not compromise the display's visual quality.

The implementation of statistical process control (SPC) methodologies enables manufacturers to monitor process variations and establish control limits for critical parameters. Six Sigma methodologies have been widely adopted, with process capability indices (Cpk) targets exceeding 1.33 for key quality metrics to ensure consistent production quality.

Supply Chain Implications of Standardization

Standardization in flexible OLED encapsulation processes creates significant ripple effects throughout the entire supply chain ecosystem. When manufacturers adopt uniform standards, component suppliers can optimize production volumes and reduce customization requirements, leading to economies of scale and lower unit costs. This standardization enables suppliers to focus on perfecting specific components rather than developing multiple variations to accommodate different manufacturers' specifications.

The absence of standardization currently forces suppliers to maintain diverse inventory systems and production lines, increasing operational complexity and capital expenditure. Material suppliers must produce multiple formulations of encapsulation materials with slight variations in chemical composition, thickness, or application methods to meet different OEMs' requirements. This fragmentation prevents the development of specialized equipment optimized for high-volume production.

Standardized encapsulation processes would streamline quality control procedures across the supply chain. Currently, each variation in process requires unique testing protocols and equipment, creating redundancies and inefficiencies. With standardization, testing equipment manufacturers could develop more sophisticated, specialized tools applicable across multiple production environments, improving detection capabilities while reducing costs.

From a logistics perspective, standardization simplifies inventory management and reduces warehousing requirements. The current fragmented approach necessitates maintaining safety stocks of multiple component variations, increasing working capital requirements and storage costs. Standardized components allow for just-in-time delivery systems and more efficient supply chain planning.

Standardization also facilitates more transparent pricing structures throughout the supply chain. When components and processes are standardized, cost comparisons become more straightforward, fostering healthy competition among suppliers. This transparency typically drives innovation in manufacturing processes rather than in proprietary formulations, benefiting the entire ecosystem through continuous improvement initiatives.

For emerging market participants, standardization lowers barriers to entry by reducing the technical complexity required to integrate into established supply chains. New suppliers can focus on meeting clearly defined specifications rather than navigating multiple proprietary systems, potentially increasing competition and innovation in the component supply market.

The absence of standardization currently forces suppliers to maintain diverse inventory systems and production lines, increasing operational complexity and capital expenditure. Material suppliers must produce multiple formulations of encapsulation materials with slight variations in chemical composition, thickness, or application methods to meet different OEMs' requirements. This fragmentation prevents the development of specialized equipment optimized for high-volume production.

Standardized encapsulation processes would streamline quality control procedures across the supply chain. Currently, each variation in process requires unique testing protocols and equipment, creating redundancies and inefficiencies. With standardization, testing equipment manufacturers could develop more sophisticated, specialized tools applicable across multiple production environments, improving detection capabilities while reducing costs.

From a logistics perspective, standardization simplifies inventory management and reduces warehousing requirements. The current fragmented approach necessitates maintaining safety stocks of multiple component variations, increasing working capital requirements and storage costs. Standardized components allow for just-in-time delivery systems and more efficient supply chain planning.

Standardization also facilitates more transparent pricing structures throughout the supply chain. When components and processes are standardized, cost comparisons become more straightforward, fostering healthy competition among suppliers. This transparency typically drives innovation in manufacturing processes rather than in proprietary formulations, benefiting the entire ecosystem through continuous improvement initiatives.

For emerging market participants, standardization lowers barriers to entry by reducing the technical complexity required to integrate into established supply chains. New suppliers can focus on meeting clearly defined specifications rather than navigating multiple proprietary systems, potentially increasing competition and innovation in the component supply market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!