Exploring Flexible OLED Encapsulation in Consumer Electronics

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized the consumer electronics industry over the past decade, enabling the development of bendable, foldable, and rollable display devices. The evolution of this technology can be traced back to the early 2000s when researchers first demonstrated the potential of creating displays on flexible substrates. Since then, significant advancements have been made in materials science, manufacturing processes, and device architectures to enhance the performance and durability of flexible OLEDs.

The critical challenge in flexible OLED technology lies in the encapsulation process. Unlike traditional rigid displays, flexible OLEDs require specialized encapsulation techniques to protect the organic materials from environmental factors such as oxygen and moisture while maintaining flexibility. Early encapsulation methods relied on glass barriers, which limited flexibility and were prone to cracking under mechanical stress. This limitation prompted the development of thin-film encapsulation (TFE) technologies, which have become the industry standard for flexible displays.

The technical evolution trajectory shows a clear shift from single-layer barrier films to multi-layer structures combining organic and inorganic materials. These hybrid approaches have significantly improved the barrier properties while preserving mechanical flexibility. Recent innovations include atomic layer deposition (ALD) techniques for creating ultra-thin barrier layers and the integration of nanocomposite materials to enhance moisture resistance.

The primary objective of current flexible OLED encapsulation research is to develop barrier technologies that can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while withstanding repeated bending cycles exceeding 200,000 times without performance degradation. Additionally, researchers aim to reduce the thickness of encapsulation layers to below 10 micrometers to enhance overall device flexibility and form factor.

Another critical goal is to develop cost-effective manufacturing processes that can be scaled for mass production. Current encapsulation technologies often require complex vacuum deposition systems and specialized equipment, contributing significantly to the high cost of flexible OLED devices. Innovations in solution-processable barrier materials and roll-to-roll manufacturing techniques are being explored to address this challenge.

Looking forward, the industry is moving toward encapsulation technologies that not only protect the OLED materials but also provide additional functionalities such as enhanced optical properties, improved heat dissipation, and self-healing capabilities. These multifunctional encapsulation systems represent the next frontier in flexible display technology, potentially enabling entirely new categories of consumer electronic devices with unprecedented form factors and user experiences.

The critical challenge in flexible OLED technology lies in the encapsulation process. Unlike traditional rigid displays, flexible OLEDs require specialized encapsulation techniques to protect the organic materials from environmental factors such as oxygen and moisture while maintaining flexibility. Early encapsulation methods relied on glass barriers, which limited flexibility and were prone to cracking under mechanical stress. This limitation prompted the development of thin-film encapsulation (TFE) technologies, which have become the industry standard for flexible displays.

The technical evolution trajectory shows a clear shift from single-layer barrier films to multi-layer structures combining organic and inorganic materials. These hybrid approaches have significantly improved the barrier properties while preserving mechanical flexibility. Recent innovations include atomic layer deposition (ALD) techniques for creating ultra-thin barrier layers and the integration of nanocomposite materials to enhance moisture resistance.

The primary objective of current flexible OLED encapsulation research is to develop barrier technologies that can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while withstanding repeated bending cycles exceeding 200,000 times without performance degradation. Additionally, researchers aim to reduce the thickness of encapsulation layers to below 10 micrometers to enhance overall device flexibility and form factor.

Another critical goal is to develop cost-effective manufacturing processes that can be scaled for mass production. Current encapsulation technologies often require complex vacuum deposition systems and specialized equipment, contributing significantly to the high cost of flexible OLED devices. Innovations in solution-processable barrier materials and roll-to-roll manufacturing techniques are being explored to address this challenge.

Looking forward, the industry is moving toward encapsulation technologies that not only protect the OLED materials but also provide additional functionalities such as enhanced optical properties, improved heat dissipation, and self-healing capabilities. These multifunctional encapsulation systems represent the next frontier in flexible display technology, potentially enabling entirely new categories of consumer electronic devices with unprecedented form factors and user experiences.

Market Demand Analysis for Flexible Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven primarily by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible display market is projected to reach $42.85 billion by 2027, growing at a CAGR of 28.1% from 2020. This substantial growth trajectory underscores the significant market potential for flexible OLED technologies, particularly those with advanced encapsulation solutions.

Consumer electronics manufacturers are increasingly adopting flexible displays across various product categories. Smartphones represent the largest application segment, accounting for approximately 63% of the flexible display market in 2021. Major smartphone manufacturers have introduced foldable devices featuring flexible OLED displays, with Samsung's Galaxy Z series and Huawei's Mate X series leading the market penetration. These products command premium pricing, indicating consumers' willingness to pay for innovative form factors.

Beyond smartphones, wearable devices constitute the fastest-growing segment for flexible display technologies, with a projected CAGR of 32.4% through 2026. Smartwatches, fitness trackers, and emerging wearable healthcare devices are driving demand for flexible displays that can conform to the human body while maintaining durability and performance.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, holding 58% market share in 2021. This dominance stems from the concentration of display manufacturers and consumer electronics companies in countries like South Korea, Japan, and China. North America and Europe follow with 22% and 16% market shares respectively, with growth primarily driven by early technology adoption and premium consumer segments.

Consumer preference surveys indicate that device thinness, durability, and novel form factors are the primary drivers for flexible display adoption. Approximately 72% of smartphone users express interest in foldable or rollable devices, provided they offer meaningful functionality improvements and acceptable durability. This highlights the critical importance of effective encapsulation technologies that can protect sensitive OLED materials while maintaining flexibility.

Industry forecasts suggest that as encapsulation technologies mature and production costs decrease, flexible displays will expand beyond premium devices into mid-range consumer electronics. This market expansion depends critically on solving the technical challenges of flexible OLED encapsulation, particularly regarding moisture and oxygen barrier properties, mechanical durability during repeated flexing, and cost-effective manufacturing processes.

Consumer electronics manufacturers are increasingly adopting flexible displays across various product categories. Smartphones represent the largest application segment, accounting for approximately 63% of the flexible display market in 2021. Major smartphone manufacturers have introduced foldable devices featuring flexible OLED displays, with Samsung's Galaxy Z series and Huawei's Mate X series leading the market penetration. These products command premium pricing, indicating consumers' willingness to pay for innovative form factors.

Beyond smartphones, wearable devices constitute the fastest-growing segment for flexible display technologies, with a projected CAGR of 32.4% through 2026. Smartwatches, fitness trackers, and emerging wearable healthcare devices are driving demand for flexible displays that can conform to the human body while maintaining durability and performance.

Regional analysis reveals Asia-Pacific as the dominant market for flexible display technologies, holding 58% market share in 2021. This dominance stems from the concentration of display manufacturers and consumer electronics companies in countries like South Korea, Japan, and China. North America and Europe follow with 22% and 16% market shares respectively, with growth primarily driven by early technology adoption and premium consumer segments.

Consumer preference surveys indicate that device thinness, durability, and novel form factors are the primary drivers for flexible display adoption. Approximately 72% of smartphone users express interest in foldable or rollable devices, provided they offer meaningful functionality improvements and acceptable durability. This highlights the critical importance of effective encapsulation technologies that can protect sensitive OLED materials while maintaining flexibility.

Industry forecasts suggest that as encapsulation technologies mature and production costs decrease, flexible displays will expand beyond premium devices into mid-range consumer electronics. This market expansion depends critically on solving the technical challenges of flexible OLED encapsulation, particularly regarding moisture and oxygen barrier properties, mechanical durability during repeated flexing, and cost-effective manufacturing processes.

Current Encapsulation Technologies and Challenges

Flexible OLED encapsulation technology has evolved significantly over the past decade, with several approaches currently dominating the market. The most widely adopted method is the thin-film encapsulation (TFE) technique, which involves alternating layers of inorganic and organic materials. The inorganic layers, typically composed of silicon nitride (SiNx) or aluminum oxide (Al2O3), provide excellent barrier properties against moisture and oxygen, while the organic layers offer flexibility and stress relief during bending. This multi-layer approach has proven effective in achieving both barrier performance and mechanical flexibility.

Another prominent technology is atomic layer deposition (ALD), which enables the creation of ultra-thin, highly uniform barrier films with excellent moisture resistance. ALD allows for precise control over film thickness at the atomic level, making it particularly valuable for flexible displays where every nanometer matters. However, the relatively slow deposition rate of ALD presents challenges for high-volume manufacturing environments.

Glass-based encapsulation solutions, including ultra-thin glass (UTG) technology, have also gained traction. UTG offers superior barrier properties while maintaining a degree of flexibility when thinned to approximately 30-100 micrometers. Companies like Corning and Schott have developed specialized flexible glass products specifically for OLED encapsulation applications.

Despite these advancements, significant challenges persist in flexible OLED encapsulation. The foremost challenge is achieving an optimal balance between barrier performance and flexibility. As displays become increasingly bendable and even foldable, encapsulation layers must withstand repeated mechanical stress without compromising their barrier properties. Current solutions often face degradation after thousands of folding cycles, particularly at the folding axis where stress concentration is highest.

Manufacturing scalability presents another major hurdle. High-quality encapsulation processes like ALD are often time-consuming and expensive, creating bottlenecks in production. The industry continues to seek more efficient deposition methods that maintain barrier quality while improving throughput.

Edge sealing remains particularly problematic for flexible displays. The perimeter of the display is especially vulnerable to moisture and oxygen ingress, requiring specialized edge sealing techniques that can maintain integrity during bending. Current solutions often involve additional protective materials or structures around the display edges, adding complexity to the manufacturing process.

Temperature sensitivity during the encapsulation process also poses challenges. Many organic materials in OLEDs degrade at temperatures above 100°C, limiting the processing window for encapsulation techniques. This constraint eliminates many traditional high-temperature deposition methods that might otherwise provide excellent barrier properties.

Another prominent technology is atomic layer deposition (ALD), which enables the creation of ultra-thin, highly uniform barrier films with excellent moisture resistance. ALD allows for precise control over film thickness at the atomic level, making it particularly valuable for flexible displays where every nanometer matters. However, the relatively slow deposition rate of ALD presents challenges for high-volume manufacturing environments.

Glass-based encapsulation solutions, including ultra-thin glass (UTG) technology, have also gained traction. UTG offers superior barrier properties while maintaining a degree of flexibility when thinned to approximately 30-100 micrometers. Companies like Corning and Schott have developed specialized flexible glass products specifically for OLED encapsulation applications.

Despite these advancements, significant challenges persist in flexible OLED encapsulation. The foremost challenge is achieving an optimal balance between barrier performance and flexibility. As displays become increasingly bendable and even foldable, encapsulation layers must withstand repeated mechanical stress without compromising their barrier properties. Current solutions often face degradation after thousands of folding cycles, particularly at the folding axis where stress concentration is highest.

Manufacturing scalability presents another major hurdle. High-quality encapsulation processes like ALD are often time-consuming and expensive, creating bottlenecks in production. The industry continues to seek more efficient deposition methods that maintain barrier quality while improving throughput.

Edge sealing remains particularly problematic for flexible displays. The perimeter of the display is especially vulnerable to moisture and oxygen ingress, requiring specialized edge sealing techniques that can maintain integrity during bending. Current solutions often involve additional protective materials or structures around the display edges, adding complexity to the manufacturing process.

Temperature sensitivity during the encapsulation process also poses challenges. Many organic materials in OLEDs degrade at temperatures above 100°C, limiting the processing window for encapsulation techniques. This constraint eliminates many traditional high-temperature deposition methods that might otherwise provide excellent barrier properties.

Current Encapsulation Solutions for Flexible OLEDs

01 Multilayer encapsulation structures for flexible OLEDs

Multilayer encapsulation structures are used to enhance the flexibility of OLED devices while maintaining effective barrier properties against moisture and oxygen. These structures typically consist of alternating inorganic and organic layers, where the inorganic layers provide barrier properties and the organic layers provide flexibility and stress relief. The combination allows the encapsulation to bend without cracking while maintaining protection for the sensitive OLED components.- Multilayer encapsulation structures for flexible OLEDs: Multilayer encapsulation structures combine inorganic barrier layers with organic buffer layers to provide both effective moisture/oxygen protection and mechanical flexibility. The inorganic layers (such as silicon nitride, aluminum oxide, or silicon oxide) provide barrier properties while the organic layers (such as polymers or resins) accommodate bending stress. This alternating structure prevents crack propagation through the entire encapsulation system when the device is flexed, maintaining barrier properties even under deformation.

- Thin film encapsulation with stress relief features: Specialized stress relief features are incorporated into the encapsulation structure to enhance flexibility while maintaining barrier properties. These features include engineered patterns, grooves, or islands in the encapsulation layers that can absorb or redistribute mechanical stress during bending. Some designs incorporate elastic interlayers or stress-buffering zones at critical points where stress concentration occurs during flexing. These features allow the encapsulation to withstand repeated bending cycles without developing cracks or delamination.

- Advanced barrier materials for flexible encapsulation: Novel materials with inherent flexibility and excellent barrier properties are used in OLED encapsulation. These include hybrid organic-inorganic materials, nanocomposites, and specially formulated polymers with enhanced barrier properties. Some approaches use materials that can be deposited at low temperatures compatible with flexible substrates. Certain materials feature self-healing properties that can repair minor defects that occur during flexing, maintaining the integrity of the encapsulation barrier over time.

- Edge sealing techniques for flexible OLEDs: Specialized edge sealing methods prevent moisture and oxygen ingress at the vulnerable perimeter of flexible OLED devices. These techniques include reinforced edge structures, gradient encapsulation designs that are thicker at edges, and specialized adhesive systems that maintain flexibility while providing strong edge seals. Some approaches incorporate additional protective layers specifically at the edges or use laser sealing methods that create strong but flexible perimeter barriers, preventing delamination during bending.

- Encapsulation deposition methods for enhanced flexibility: Specialized deposition techniques are used to create encapsulation layers with superior flexibility characteristics. These include atomic layer deposition (ALD) for ultra-thin, conformal barrier layers, plasma-enhanced chemical vapor deposition (PECVD) with modified process parameters to reduce internal stress, and solution-based processes that create inherently flexible layers. Some methods incorporate gradient deposition approaches where the composition or density of the encapsulation layer changes throughout its thickness to better accommodate mechanical stress during bending.

02 Thin film encapsulation techniques for flexibility

Thin film encapsulation (TFE) techniques are employed to create ultra-thin barrier layers that can withstand bending and folding while protecting OLED devices. These techniques involve depositing thin layers of materials such as silicon nitride, aluminum oxide, or hybrid materials using methods like atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD). The thinness of these films allows them to flex without developing defects that would compromise their barrier properties.Expand Specific Solutions03 Stress-relieving structures in OLED encapsulation

Various stress-relieving structures are incorporated into flexible OLED encapsulation to prevent cracking and delamination during bending. These include buffer layers, stress-relief patterns, mesh structures, and engineered interfaces between different materials. These structures help to absorb and distribute mechanical stress during flexing, preventing the propagation of cracks and maintaining the integrity of the barrier layers.Expand Specific Solutions04 Novel materials for flexible encapsulation

Advanced materials are being developed specifically for flexible OLED encapsulation, including hybrid organic-inorganic composites, nanocomposites, and specially formulated polymers. These materials combine high barrier properties with mechanical flexibility, allowing them to maintain their protective function even under repeated bending cycles. Some materials also feature self-healing properties to repair minor defects that may occur during flexing.Expand Specific Solutions05 Edge sealing techniques for flexible OLEDs

Specialized edge sealing techniques are employed to ensure that the perimeter of flexible OLED displays remains protected during bending and flexing. These techniques include flexible adhesives, reinforced edge structures, and gradient material transitions that prevent edge-initiated failure. Proper edge sealing is critical for flexible OLEDs as the edges are particularly vulnerable to moisture ingress and mechanical stress during bending operations.Expand Specific Solutions

Key Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation market in consumer electronics is currently in a growth phase, with an estimated market size exceeding $2 billion and projected to expand at a CAGR of 15-20% through 2028. The competitive landscape is dominated by Asian manufacturers, with BOE Technology, LG Display, and Samsung SDI leading technological innovation. Chinese players including TCL China Star Optoelectronics and Visionox are rapidly advancing their capabilities, while established companies like Applied Materials provide critical manufacturing equipment. The technology maturity varies significantly across players, with Korean and Japanese firms demonstrating more advanced thin-film encapsulation techniques, while Chinese companies are closing the gap through aggressive R&D investments and government support. Collaboration between display manufacturers and materials specialists like LG Chem is accelerating innovation in barrier films and hybrid encapsulation solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative flexible OLED encapsulation solution called "Hybrid Barrier Multilayer" (HBM) technology. This approach combines inorganic silicon nitride and aluminum oxide layers deposited via plasma-enhanced chemical vapor deposition with proprietary organic polymer interlayers. BOE's encapsulation structure achieves water vapor transmission rates below 5×10^-6 g/m²/day while maintaining flexibility for bend radii down to 3mm. Their process incorporates a unique "stress-relief pattern" in the inorganic layers, using photolithography to create microscopic structures that prevent crack propagation during bending. BOE has also pioneered a room-temperature deposition process for certain barrier layers, reducing thermal stress on the OLED materials and improving overall yield. Their latest innovation includes integrating quantum dot materials directly into the encapsulation structure, enhancing color performance while maintaining barrier properties. This comprehensive approach has enabled BOE to achieve encapsulation thicknesses of approximately 15μm while ensuring device lifetimes exceeding 40,000 hours in high-humidity environments.

Strengths: Cost-effective manufacturing process suitable for large-scale production; innovative stress-relief patterns improving mechanical durability; compatibility with existing manufacturing equipment. Weaknesses: Slightly thicker encapsulation layer compared to industry leaders; more limited bend radius capabilities; higher defect rates in extremely large display applications.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced "Hybrid Barrier Film" (HBF) technology specifically for flexible OLED encapsulation. Their approach utilizes a proprietary combination of inorganic barrier layers created through atomic layer deposition and specialized organic interlayers with enhanced crosslinking properties. LG Chem's barrier films achieve water vapor transmission rates below 10^-6 g/m²/day while maintaining flexibility for bend radii down to 2mm. Their innovation includes a unique "nanocomposite interlayer" containing dispersed ceramic nanoparticles that create tortuous paths for moisture penetration while maintaining mechanical flexibility. LG Chem has also pioneered a roll-to-roll manufacturing process for certain encapsulation layers, significantly reducing production costs while maintaining quality. Their latest development incorporates transparent gas-barrier adhesives that simplify the lamination process while enhancing overall barrier performance. This technology enables LG Chem to provide encapsulation solutions with total thicknesses of approximately 20μm that can withstand over 150,000 bend cycles without significant barrier degradation.

Strengths: Excellent mass production capabilities through roll-to-roll processing; superior adhesion between layers preventing delamination; comprehensive material ecosystem including specialized adhesives. Weaknesses: Slightly thicker overall encapsulation structure; moderate bend radius limitations compared to leading competitors; higher material costs for specialized nanocomposite formulations.

Critical Patents and Innovations in Barrier Technologies

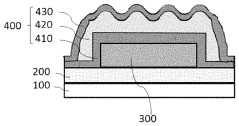

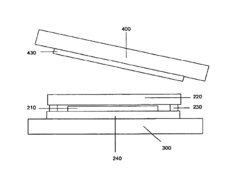

Flexible organic light-emitting diode (OLED) device of reduced stess at bending place and fabrication method thereof

PatentActiveUS11258038B2

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, formed by thermal stress differences, increasing contact area and reducing stress on the outer inorganic layer, and an optically clear adhesive is used to level the configuration.

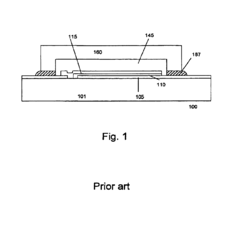

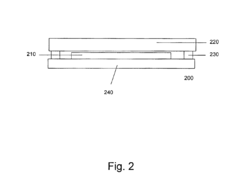

Procedure for encapsulation of electronic devices

PatentInactiveUS6803245B2

Innovation

- A specialized encapsulation procedure using a substrate holder and lid holder with adhesive release tape that loses adhesion after treatment, combined with UV-curable or thermal-curable sealants, allows for precise placement and hermetic sealing of thin flexible OLED devices without breaking, achieving a thin and flexible cavity structure.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible OLED encapsulation technologies represents a critical consideration as consumer electronics increasingly adopt these advanced display solutions. Traditional encapsulation methods often rely on glass barriers and metal foils that present significant end-of-life disposal challenges. These materials typically require energy-intensive recycling processes or contribute to electronic waste when improperly discarded. In contrast, newer thin-film encapsulation (TFE) approaches utilizing organic and inorganic multilayers offer potential sustainability advantages through reduced material usage and improved recyclability profiles.

Manufacturing processes for flexible OLED encapsulation currently involve energy-intensive vacuum deposition techniques and the use of rare earth elements in certain barrier compositions. The environmental footprint of these processes includes substantial energy consumption, greenhouse gas emissions, and the extraction impacts associated with specialized materials. Industry leaders are actively researching alternative deposition methods such as solution-based processes that operate at lower temperatures and atmospheric pressure, potentially reducing energy requirements by 30-45% compared to conventional approaches.

Chemical composition of encapsulation materials presents another environmental consideration. Many current barrier films contain fluorinated compounds and other persistent chemicals that may pose long-term ecological risks. Recent innovations focus on developing bio-based alternatives and environmentally benign barrier materials that maintain performance while reducing toxicity. Several research institutions have demonstrated promising results with cellulose-derived barrier films that offer comparable water vapor transmission rates to synthetic alternatives while being biodegradable.

The extended product lifecycle enabled by flexible, durable encapsulation technologies may offset some environmental impacts through reduced replacement frequency. Studies indicate that flexible devices with effective encapsulation can maintain functionality for 40-60% longer than rigid alternatives in certain use cases, potentially reducing overall electronic waste generation. However, this benefit must be balanced against the increased complexity of separating and recycling multilayer encapsulation systems at end-of-life.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced electronics manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in Asia and North America are driving manufacturers toward more sustainable encapsulation solutions. Industry consortia have established voluntary standards for environmental performance in flexible electronics, creating market incentives for continued innovation in green encapsulation technologies.

Manufacturing processes for flexible OLED encapsulation currently involve energy-intensive vacuum deposition techniques and the use of rare earth elements in certain barrier compositions. The environmental footprint of these processes includes substantial energy consumption, greenhouse gas emissions, and the extraction impacts associated with specialized materials. Industry leaders are actively researching alternative deposition methods such as solution-based processes that operate at lower temperatures and atmospheric pressure, potentially reducing energy requirements by 30-45% compared to conventional approaches.

Chemical composition of encapsulation materials presents another environmental consideration. Many current barrier films contain fluorinated compounds and other persistent chemicals that may pose long-term ecological risks. Recent innovations focus on developing bio-based alternatives and environmentally benign barrier materials that maintain performance while reducing toxicity. Several research institutions have demonstrated promising results with cellulose-derived barrier films that offer comparable water vapor transmission rates to synthetic alternatives while being biodegradable.

The extended product lifecycle enabled by flexible, durable encapsulation technologies may offset some environmental impacts through reduced replacement frequency. Studies indicate that flexible devices with effective encapsulation can maintain functionality for 40-60% longer than rigid alternatives in certain use cases, potentially reducing overall electronic waste generation. However, this benefit must be balanced against the increased complexity of separating and recycling multilayer encapsulation systems at end-of-life.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced electronics manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in Asia and North America are driving manufacturers toward more sustainable encapsulation solutions. Industry consortia have established voluntary standards for environmental performance in flexible electronics, creating market incentives for continued innovation in green encapsulation technologies.

Manufacturing Scalability and Cost Analysis

The scalability of flexible OLED encapsulation technologies represents a critical factor in their commercial viability within consumer electronics markets. Current manufacturing processes for thin-film encapsulation (TFE) face significant challenges in scaling to mass production levels while maintaining consistent quality. The atomic layer deposition (ALD) method, widely recognized for its superior barrier properties, suffers from relatively slow deposition rates that limit throughput in high-volume manufacturing environments. This creates a production bottleneck that directly impacts unit economics.

Cost analysis reveals that encapsulation represents approximately 15-20% of the total manufacturing cost for flexible OLED displays. The multi-layer approach combining inorganic and organic materials (often referred to as the "dyad" structure) requires specialized equipment and precise process control, driving capital expenditure requirements upward. Material costs for high-performance barrier films, particularly those utilizing aluminum oxide and silicon nitride, remain substantially higher than traditional rigid encapsulation solutions.

Yield rates present another critical economic challenge, with current industry averages for flexible encapsulation processes ranging between 70-85%, significantly lower than the 90%+ yields achieved in mature rigid OLED manufacturing. Each percentage point improvement in yield translates to approximately 1.2-1.5% reduction in overall production costs, highlighting the economic importance of process optimization.

Recent innovations in roll-to-roll (R2R) processing show promise for dramatically improving throughput. Early implementations demonstrate potential capacity increases of 3-5x compared to traditional batch processing methods, though maintaining uniform barrier quality across large substrate areas remains technically challenging. Several major display manufacturers have invested in pilot R2R lines, with full production implementation expected within 2-3 years.

Equipment amortization represents a significant cost factor, with specialized encapsulation tools requiring substantial capital investment ranging from $15-30 million per production line. The expected useful life of such equipment (typically 5-7 years) must be balanced against rapidly evolving technology that may render systems obsolete before full depreciation.

Labor costs contribute minimally to the overall economics, as encapsulation processes are highly automated. However, specialized engineering talent for process development and optimization commands premium compensation, adding to the indirect cost structure. As manufacturing scales, these fixed costs become distributed across larger production volumes, improving unit economics.

Cost analysis reveals that encapsulation represents approximately 15-20% of the total manufacturing cost for flexible OLED displays. The multi-layer approach combining inorganic and organic materials (often referred to as the "dyad" structure) requires specialized equipment and precise process control, driving capital expenditure requirements upward. Material costs for high-performance barrier films, particularly those utilizing aluminum oxide and silicon nitride, remain substantially higher than traditional rigid encapsulation solutions.

Yield rates present another critical economic challenge, with current industry averages for flexible encapsulation processes ranging between 70-85%, significantly lower than the 90%+ yields achieved in mature rigid OLED manufacturing. Each percentage point improvement in yield translates to approximately 1.2-1.5% reduction in overall production costs, highlighting the economic importance of process optimization.

Recent innovations in roll-to-roll (R2R) processing show promise for dramatically improving throughput. Early implementations demonstrate potential capacity increases of 3-5x compared to traditional batch processing methods, though maintaining uniform barrier quality across large substrate areas remains technically challenging. Several major display manufacturers have invested in pilot R2R lines, with full production implementation expected within 2-3 years.

Equipment amortization represents a significant cost factor, with specialized encapsulation tools requiring substantial capital investment ranging from $15-30 million per production line. The expected useful life of such equipment (typically 5-7 years) must be balanced against rapidly evolving technology that may render systems obsolete before full depreciation.

Labor costs contribute minimally to the overall economics, as encapsulation processes are highly automated. However, specialized engineering talent for process development and optimization commands premium compensation, adding to the indirect cost structure. As manufacturing scales, these fixed costs become distributed across larger production volumes, improving unit economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!