The Role of Catalyst Additions in Flexible OLED Encapsulation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Technology in OLED Encapsulation: Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized the display industry over the past two decades, offering superior visual performance, flexibility, and energy efficiency compared to traditional LCD displays. The evolution of OLED technology has been marked by continuous improvements in materials science, manufacturing processes, and device architecture. Particularly, flexible OLED displays have emerged as a groundbreaking innovation, enabling the development of foldable smartphones, rollable televisions, and wearable devices.

One of the critical challenges in OLED technology, especially for flexible applications, is the degradation caused by environmental factors such as moisture and oxygen. These elements can significantly reduce the operational lifetime of OLED devices by causing oxidation of the organic materials and deterioration of the cathode. This vulnerability has necessitated the development of effective encapsulation technologies to protect the sensitive organic layers from environmental exposure.

Encapsulation technologies have evolved from rigid glass barriers to thin-film encapsulation (TFE) methods that maintain flexibility while providing adequate protection. The thin-film encapsulation approach typically involves alternating layers of inorganic and organic materials to create a multi-layer barrier that prevents moisture and oxygen permeation. However, traditional TFE methods often require high processing temperatures or extended curing times, which can damage the underlying OLED structure or reduce manufacturing efficiency.

Catalyst technology has emerged as a promising solution to address these limitations. By incorporating specific catalysts into the encapsulation process, manufacturers can achieve faster curing times, lower processing temperatures, and enhanced barrier properties. These catalysts facilitate chemical reactions that accelerate the formation of dense, defect-free barrier layers, thereby improving the overall encapsulation performance while maintaining compatibility with flexible substrates.

The primary objective of catalyst technology in OLED encapsulation is to enhance the barrier properties against moisture and oxygen while preserving the flexibility of the display. Additionally, catalysts aim to reduce processing time and energy consumption, contributing to more cost-effective and environmentally friendly manufacturing processes. The development of novel catalyst systems specifically designed for OLED encapsulation represents a significant opportunity for advancing flexible display technology.

Recent technological trends indicate a growing interest in metal-organic catalysts, photocatalysts, and enzyme-inspired catalytic systems that can operate under mild conditions. These innovative approaches are expected to overcome current limitations and enable the next generation of ultra-thin, highly flexible, and durable OLED displays. The continuous evolution of catalyst technology is closely aligned with the broader industry goal of developing fully flexible, rollable, and even stretchable display devices for diverse applications.

One of the critical challenges in OLED technology, especially for flexible applications, is the degradation caused by environmental factors such as moisture and oxygen. These elements can significantly reduce the operational lifetime of OLED devices by causing oxidation of the organic materials and deterioration of the cathode. This vulnerability has necessitated the development of effective encapsulation technologies to protect the sensitive organic layers from environmental exposure.

Encapsulation technologies have evolved from rigid glass barriers to thin-film encapsulation (TFE) methods that maintain flexibility while providing adequate protection. The thin-film encapsulation approach typically involves alternating layers of inorganic and organic materials to create a multi-layer barrier that prevents moisture and oxygen permeation. However, traditional TFE methods often require high processing temperatures or extended curing times, which can damage the underlying OLED structure or reduce manufacturing efficiency.

Catalyst technology has emerged as a promising solution to address these limitations. By incorporating specific catalysts into the encapsulation process, manufacturers can achieve faster curing times, lower processing temperatures, and enhanced barrier properties. These catalysts facilitate chemical reactions that accelerate the formation of dense, defect-free barrier layers, thereby improving the overall encapsulation performance while maintaining compatibility with flexible substrates.

The primary objective of catalyst technology in OLED encapsulation is to enhance the barrier properties against moisture and oxygen while preserving the flexibility of the display. Additionally, catalysts aim to reduce processing time and energy consumption, contributing to more cost-effective and environmentally friendly manufacturing processes. The development of novel catalyst systems specifically designed for OLED encapsulation represents a significant opportunity for advancing flexible display technology.

Recent technological trends indicate a growing interest in metal-organic catalysts, photocatalysts, and enzyme-inspired catalytic systems that can operate under mild conditions. These innovative approaches are expected to overcome current limitations and enable the next generation of ultra-thin, highly flexible, and durable OLED displays. The continuous evolution of catalyst technology is closely aligned with the broader industry goal of developing fully flexible, rollable, and even stretchable display devices for diverse applications.

Market Analysis for Flexible OLED Encapsulation Solutions

The flexible OLED encapsulation market has experienced remarkable growth, with a global valuation reaching approximately $1.2 billion in 2022 and projected to exceed $3.5 billion by 2028, representing a compound annual growth rate of 19.7%. This growth is primarily driven by the expanding adoption of flexible displays in smartphones, wearables, and emerging applications such as foldable devices and automotive displays.

Consumer electronics remains the dominant application segment, accounting for over 65% of the market share. Within this segment, smartphones represent the largest sub-segment due to the increasing integration of flexible OLED displays in premium and mid-range devices by manufacturers like Samsung, Apple, and Chinese OEMs. The wearable technology segment is experiencing the fastest growth rate at 24.3% annually, fueled by the rising popularity of smartwatches and fitness trackers with curved displays.

Geographically, Asia-Pacific dominates the market with approximately 78% share, attributed to the concentration of display manufacturers and electronics production facilities in South Korea, Japan, China, and Taiwan. North America and Europe collectively account for about 19% of the market, with growing demand for premium consumer electronics and automotive applications.

The catalyst-enhanced encapsulation solutions sub-segment is emerging as a high-growth area, currently representing about 12% of the overall flexible OLED encapsulation market but expected to grow at 27.5% annually through 2028. This accelerated growth is driven by the superior performance characteristics of catalyst-assisted thin-film encapsulation (TFE) technologies, particularly in extending device lifespans and enabling ultra-thin form factors.

Market demand is increasingly focused on solutions that can provide superior moisture and oxygen barrier properties while maintaining flexibility and optical transparency. End-users are willing to pay premium prices for encapsulation technologies that can demonstrably extend device lifetime, with surveys indicating that manufacturers would accept a 15-20% cost increase for solutions that double the effective barrier lifetime.

The competitive landscape features both established materials companies and emerging startups. Traditional players like 3M, Samsung SDI, and LG Chem hold significant market share, while specialized firms focusing exclusively on catalyst-enhanced encapsulation technologies are gaining traction through strategic partnerships with display manufacturers. Recent market consolidation through mergers and acquisitions signals the growing importance of proprietary catalyst technology in competitive differentiation.

Consumer electronics remains the dominant application segment, accounting for over 65% of the market share. Within this segment, smartphones represent the largest sub-segment due to the increasing integration of flexible OLED displays in premium and mid-range devices by manufacturers like Samsung, Apple, and Chinese OEMs. The wearable technology segment is experiencing the fastest growth rate at 24.3% annually, fueled by the rising popularity of smartwatches and fitness trackers with curved displays.

Geographically, Asia-Pacific dominates the market with approximately 78% share, attributed to the concentration of display manufacturers and electronics production facilities in South Korea, Japan, China, and Taiwan. North America and Europe collectively account for about 19% of the market, with growing demand for premium consumer electronics and automotive applications.

The catalyst-enhanced encapsulation solutions sub-segment is emerging as a high-growth area, currently representing about 12% of the overall flexible OLED encapsulation market but expected to grow at 27.5% annually through 2028. This accelerated growth is driven by the superior performance characteristics of catalyst-assisted thin-film encapsulation (TFE) technologies, particularly in extending device lifespans and enabling ultra-thin form factors.

Market demand is increasingly focused on solutions that can provide superior moisture and oxygen barrier properties while maintaining flexibility and optical transparency. End-users are willing to pay premium prices for encapsulation technologies that can demonstrably extend device lifetime, with surveys indicating that manufacturers would accept a 15-20% cost increase for solutions that double the effective barrier lifetime.

The competitive landscape features both established materials companies and emerging startups. Traditional players like 3M, Samsung SDI, and LG Chem hold significant market share, while specialized firms focusing exclusively on catalyst-enhanced encapsulation technologies are gaining traction through strategic partnerships with display manufacturers. Recent market consolidation through mergers and acquisitions signals the growing importance of proprietary catalyst technology in competitive differentiation.

Current Catalyst Technologies and Challenges in OLED Encapsulation

Current catalyst technologies for flexible OLED encapsulation primarily focus on enhancing the thin-film barrier deposition process. Metal-based catalysts, particularly those containing platinum, palladium, and ruthenium, have demonstrated significant efficacy in accelerating cross-linking reactions in silicone-based encapsulation materials. These catalysts operate by reducing activation energy barriers and promoting faster polymerization at lower temperatures, which is crucial for temperature-sensitive flexible substrates.

Organometallic catalysts have emerged as a promising category, with tin-based compounds showing excellent performance in moisture-resistant layer formation. Research indicates that these catalysts can reduce curing times by up to 60% while maintaining barrier integrity. Additionally, photoactive catalysts that respond to UV exposure have gained traction for their ability to enable selective curing without thermal stress, preserving the mechanical flexibility of OLED devices.

Despite these advancements, several critical challenges persist in catalyst technology for OLED encapsulation. Catalyst migration remains a significant issue, where catalyst particles can diffuse into adjacent functional layers, potentially compromising device performance and longevity. Studies have shown that even trace amounts of catalyst contamination can reduce luminance efficiency by 5-15% over time.

Thermal stability presents another major challenge, particularly for flexible applications. Many effective catalysts begin to degrade at temperatures above 80°C, limiting their compatibility with certain manufacturing processes. This degradation can lead to incomplete polymerization and subsequent barrier defects, creating pathways for moisture and oxygen penetration.

Uniformity of catalyst distribution across large-area substrates remains problematic, especially as the industry moves toward larger flexible displays. Non-uniform distribution leads to inconsistent barrier properties, with some areas exhibiting excellent protection while others become vulnerable to environmental ingress. Current deposition technologies struggle to maintain homogeneity beyond 15-inch diagonal dimensions.

Catalyst compatibility with flexible substrates presents additional complications. Some highly effective catalysts that work well with glass substrates can induce stress or chemical degradation in polymer-based flexible substrates. This incompatibility has forced manufacturers to compromise between catalyst efficiency and substrate integrity.

The cost factor cannot be overlooked, as precious metal-based catalysts significantly impact production economics. Current platinum-based catalyst systems add approximately $8-12 per square meter to manufacturing costs, creating barriers to mass-market adoption of flexible OLED technologies. Alternative catalyst systems using more abundant metals show promise but currently lag in performance metrics.

Organometallic catalysts have emerged as a promising category, with tin-based compounds showing excellent performance in moisture-resistant layer formation. Research indicates that these catalysts can reduce curing times by up to 60% while maintaining barrier integrity. Additionally, photoactive catalysts that respond to UV exposure have gained traction for their ability to enable selective curing without thermal stress, preserving the mechanical flexibility of OLED devices.

Despite these advancements, several critical challenges persist in catalyst technology for OLED encapsulation. Catalyst migration remains a significant issue, where catalyst particles can diffuse into adjacent functional layers, potentially compromising device performance and longevity. Studies have shown that even trace amounts of catalyst contamination can reduce luminance efficiency by 5-15% over time.

Thermal stability presents another major challenge, particularly for flexible applications. Many effective catalysts begin to degrade at temperatures above 80°C, limiting their compatibility with certain manufacturing processes. This degradation can lead to incomplete polymerization and subsequent barrier defects, creating pathways for moisture and oxygen penetration.

Uniformity of catalyst distribution across large-area substrates remains problematic, especially as the industry moves toward larger flexible displays. Non-uniform distribution leads to inconsistent barrier properties, with some areas exhibiting excellent protection while others become vulnerable to environmental ingress. Current deposition technologies struggle to maintain homogeneity beyond 15-inch diagonal dimensions.

Catalyst compatibility with flexible substrates presents additional complications. Some highly effective catalysts that work well with glass substrates can induce stress or chemical degradation in polymer-based flexible substrates. This incompatibility has forced manufacturers to compromise between catalyst efficiency and substrate integrity.

The cost factor cannot be overlooked, as precious metal-based catalysts significantly impact production economics. Current platinum-based catalyst systems add approximately $8-12 per square meter to manufacturing costs, creating barriers to mass-market adoption of flexible OLED technologies. Alternative catalyst systems using more abundant metals show promise but currently lag in performance metrics.

Current Catalyst Addition Methods for Flexible OLED Protection

01 Encapsulation techniques for catalyst protection

Various encapsulation methods are used to protect catalysts from deactivation and extend their lifespan. These techniques involve coating catalyst particles with protective materials that allow reactants to diffuse through while shielding the catalyst from harsh reaction conditions. Encapsulation can improve catalyst stability, prevent leaching, and enable catalyst recovery and reuse in various chemical processes.- Encapsulation techniques for catalyst protection: Various encapsulation methods are used to protect catalysts from deactivation and extend their lifespan. These techniques involve coating catalyst particles with protective materials that allow reactants to diffuse through while shielding the catalyst from harsh reaction conditions. Encapsulation can improve catalyst stability, prevent agglomeration, and enable controlled release of catalytic species during reactions.

- Polymer-based catalyst encapsulation systems: Polymer matrices are utilized to encapsulate catalysts, providing a flexible framework that can be tailored for specific applications. These systems often incorporate polymers with controlled permeability to regulate access of reactants to the catalyst surface. The polymer encapsulation can be designed with various functional groups to enhance catalyst performance, improve dispersion, and facilitate recovery of the catalyst after reaction.

- Metal-organic frameworks for catalyst encapsulation: Metal-organic frameworks (MOFs) provide a highly ordered structure for catalyst encapsulation, offering precise control over pore size and chemical environment. These crystalline materials can host catalytic species within their pores or have catalytic sites integrated into their framework. The well-defined structure of MOFs allows for selective molecular access to catalytic sites while providing protection from deactivation mechanisms.

- Core-shell structures for catalyst stabilization: Core-shell architectures feature a catalytic core surrounded by a protective shell layer that controls access to the active sites. These structures can be designed with various shell materials including silica, alumina, or polymers, with controlled porosity to allow selective diffusion of reactants. The shell provides mechanical and chemical protection while maintaining catalytic activity, and can be functionalized to enhance selectivity or activity.

- Stimuli-responsive catalyst encapsulation systems: Advanced encapsulation systems that respond to external stimuli such as temperature, pH, or light allow for controlled release or activation of catalysts. These smart materials can protect catalysts during storage or transport and release them only under specific reaction conditions. The responsive nature enables precise control over catalytic reactions, improved efficiency, and the ability to recycle or deactivate catalysts on demand.

02 Polymer-based catalyst encapsulation systems

Polymer matrices are utilized to encapsulate catalysts, providing controlled release and protection. These systems involve incorporating catalytic materials within polymer structures that can be designed with specific porosity and permeability characteristics. The polymer encapsulation allows for tunable catalyst activity, improved handling properties, and enhanced performance in various reaction environments including polymerization processes.Expand Specific Solutions03 Metal-organic frameworks for catalyst encapsulation

Metal-organic frameworks (MOFs) serve as advanced materials for catalyst encapsulation, offering high surface area and tunable pore structures. These crystalline materials can host catalytic species within their framework, providing size-selective catalysis and enhanced stability. The encapsulated catalysts benefit from the unique environment of the MOF structure, which can influence selectivity and activity in various chemical transformations.Expand Specific Solutions04 Core-shell structures for catalyst performance enhancement

Core-shell architectures are designed to enhance catalyst performance by creating a protective outer layer around catalytic core materials. This approach allows for the combination of different functional materials, where the shell can provide selectivity, stability, or additional catalytic functions while the core maintains primary catalytic activity. These structures can be tailored for specific reactions and offer improved catalyst longevity and selectivity.Expand Specific Solutions05 Catalyst addition methods for polymerization processes

Specialized techniques for adding catalysts to polymerization reactions involve controlled delivery systems that optimize catalyst distribution and activity. These methods include staged addition, pre-activation processes, and the use of supported catalyst systems. By carefully managing how catalysts are introduced to reaction environments, manufacturers can control polymer properties, reaction rates, and product quality while minimizing catalyst consumption.Expand Specific Solutions

Key Industry Players in OLED Encapsulation Materials

The flexible OLED encapsulation market is currently in a growth phase, with catalyst additions emerging as a critical technological advancement. The global market size is expanding rapidly, driven by increasing demand for flexible displays in smartphones, wearables, and automotive applications. Technologically, the field is approaching maturity with key players like Samsung Display, BOE Technology, and LG Chem leading innovation. Chinese manufacturers including TCL China Star Optoelectronics and Tianma Microelectronics are rapidly closing the technology gap. Universal Display Corporation and Industrial Technology Research Institute provide significant catalyst technology contributions, while companies like Merck Patent GmbH and 3M Innovative Properties focus on specialized encapsulation materials. The competitive landscape shows regional clusters with South Korean, Chinese, and Western companies each bringing distinct technological approaches to catalyst-enhanced OLED encapsulation.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a proprietary catalyst-enhanced thin-film encapsulation system called "FlexSeal" specifically designed for their flexible OLED production lines. Their approach utilizes a combination of metal-organic catalysts (primarily zinc and aluminum complexes) incorporated into both inorganic and organic layers of their multi-layer barrier structure. The catalysts significantly enhance the reaction kinetics during plasma-enhanced ALD deposition of aluminum oxide and silicon nitride layers, enabling complete film formation at temperatures below 90°C. BOE's technology features a gradient catalyst distribution optimized through machine learning algorithms that predict the ideal catalyst concentration for each specific layer based on its position in the stack and functional requirements. This approach has enabled them to achieve WVTR values below 5×10^-6 g/m²/day while maintaining excellent mechanical properties with bending radii down to 1.5mm. Additionally, BOE has developed catalyst-containing nanocomposite materials that combine barrier properties with stress-relief functionality, critical for preventing delamination during repeated bending cycles.

Strengths: Optimized catalyst distribution through AI-driven process control; excellent combination of barrier properties and mechanical durability; fully integrated with existing production lines. Weaknesses: Complex multi-layer structure increases production time and cost; requires sophisticated in-line monitoring systems; slightly higher defect sensitivity compared to rigid encapsulation technologies.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative catalyst-enhanced hybrid encapsulation system specifically designed for flexible OLED applications. Their technology employs organotitanium and organotin catalysts incorporated into siloxane-based polymer matrices to create highly effective barrier films. The catalysts significantly accelerate the condensation polymerization reactions of the siloxane precursors, enabling rapid curing at temperatures below 100°C compatible with flexible plastic substrates. LG Chem's approach utilizes a gradient catalyst concentration across the film thickness, with higher catalyst loading near the substrate interface to promote adhesion and lower concentrations near the surface to optimize barrier properties. This gradient structure minimizes stress during thermal cycling and mechanical bending. Their encapsulation system achieves WVTR values of approximately 10^-6 g/m²/day while maintaining flexibility for bending radii down to 1mm. Additionally, LG Chem has incorporated UV-activated catalysts that enable selective curing through photomasks, allowing patterned encapsulation structures.

Strengths: Excellent adhesion to various substrate materials; gradient catalyst structure optimizes both barrier properties and mechanical flexibility; compatible with roll-to-roll manufacturing processes. Weaknesses: UV-activated catalysts require additional processing steps; potential for catalyst leaching during extended device operation; barrier performance slightly lower than some vacuum-deposited alternatives.

Critical Patents and Research on Catalyst-Enhanced Encapsulation

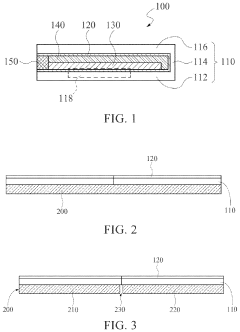

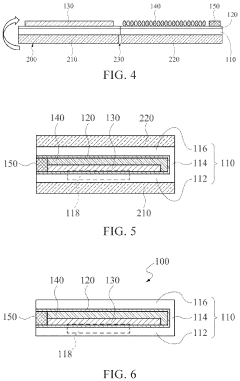

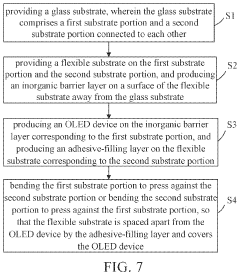

Flexible OLED substrate and encapsulation method thereof

PatentActiveUS20230200111A1

Innovation

- A flexible OLED substrate with an inorganic barrier layer and an adhesive-filling layer, along with a border adhesive, is used to enclose the OLED device, where the inorganic barrier layer is made of materials like aluminum oxide or silicon oxide, and the adhesive-filling and border adhesives provide additional water-resistant properties, simplifying the encapsulation process and enhancing protection.

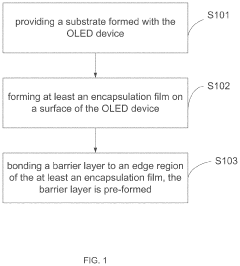

Encapsulation method of organic light emitting diode device and encapsulation structure encapsulated using same

PatentActiveUS20200083476A1

Innovation

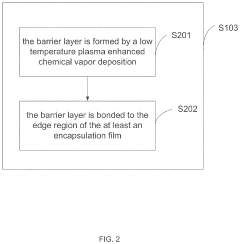

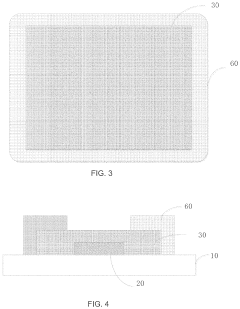

- A method involving a pre-formed ring-shaped barrier layer made of inorganic materials like silicon nitride or aluminum oxide, bonded to the edge region of the encapsulation film using low temperature plasma enhanced chemical vapor deposition and rolling or vacuum bonding processes, which improves moisture and oxygen resistance.

Environmental Impact of Catalyst Materials in Display Manufacturing

The environmental impact of catalyst materials used in flexible OLED encapsulation processes represents a growing concern as display manufacturing scales globally. Catalysts, while essential for enhancing reaction rates and enabling lower processing temperatures in thin-film encapsulation (TFE), introduce significant environmental considerations throughout their lifecycle. Metal-based catalysts containing platinum, palladium, and ruthenium are particularly problematic due to their extraction processes, which often involve extensive mining operations resulting in habitat destruction, soil degradation, and water contamination.

During manufacturing, catalyst materials generate hazardous waste streams that require specialized treatment. The synthesis of organometallic catalysts frequently involves volatile organic compounds (VOCs) and toxic precursors that contribute to air pollution and pose occupational health risks. Studies indicate that for every kilogram of catalyst produced, approximately 25-100 kilograms of waste materials may be generated, highlighting the disproportionate environmental footprint of these specialized materials.

Energy consumption presents another environmental challenge, as catalyst preparation often requires high-temperature processes and energy-intensive purification steps. The carbon footprint associated with catalyst production for OLED manufacturing is estimated to be 5-10 times higher per unit weight than standard electronic materials, contributing significantly to the industry's overall greenhouse gas emissions.

Water usage in catalyst preparation and purification processes is substantial, with estimates suggesting 200-500 liters of ultrapure water may be consumed per gram of high-purity catalyst produced. In regions facing water scarcity, this intensive consumption pattern raises serious sustainability concerns for expanded manufacturing operations.

End-of-life considerations for catalyst-containing OLED displays present additional environmental challenges. The complex integration of catalysts within multi-layer encapsulation structures complicates recycling efforts, often resulting in valuable and potentially toxic materials entering landfills. Current recycling technologies recover less than 15% of precious metals from discarded display components.

Recent regulatory developments in Europe, Asia, and North America are increasingly targeting the environmental impacts of specialty chemicals in electronics manufacturing. The EU's REACH regulations and similar frameworks are expanding to include stricter reporting and management requirements for catalyst materials, potentially affecting global supply chains and manufacturing strategies for OLED producers.

Industry initiatives are emerging to address these concerns, including green chemistry approaches to catalyst design, closed-loop manufacturing systems, and alternative catalyst systems based on more abundant and less environmentally problematic elements. These developments suggest a growing recognition of environmental impacts as a critical factor in future technology development for flexible OLED encapsulation.

During manufacturing, catalyst materials generate hazardous waste streams that require specialized treatment. The synthesis of organometallic catalysts frequently involves volatile organic compounds (VOCs) and toxic precursors that contribute to air pollution and pose occupational health risks. Studies indicate that for every kilogram of catalyst produced, approximately 25-100 kilograms of waste materials may be generated, highlighting the disproportionate environmental footprint of these specialized materials.

Energy consumption presents another environmental challenge, as catalyst preparation often requires high-temperature processes and energy-intensive purification steps. The carbon footprint associated with catalyst production for OLED manufacturing is estimated to be 5-10 times higher per unit weight than standard electronic materials, contributing significantly to the industry's overall greenhouse gas emissions.

Water usage in catalyst preparation and purification processes is substantial, with estimates suggesting 200-500 liters of ultrapure water may be consumed per gram of high-purity catalyst produced. In regions facing water scarcity, this intensive consumption pattern raises serious sustainability concerns for expanded manufacturing operations.

End-of-life considerations for catalyst-containing OLED displays present additional environmental challenges. The complex integration of catalysts within multi-layer encapsulation structures complicates recycling efforts, often resulting in valuable and potentially toxic materials entering landfills. Current recycling technologies recover less than 15% of precious metals from discarded display components.

Recent regulatory developments in Europe, Asia, and North America are increasingly targeting the environmental impacts of specialty chemicals in electronics manufacturing. The EU's REACH regulations and similar frameworks are expanding to include stricter reporting and management requirements for catalyst materials, potentially affecting global supply chains and manufacturing strategies for OLED producers.

Industry initiatives are emerging to address these concerns, including green chemistry approaches to catalyst design, closed-loop manufacturing systems, and alternative catalyst systems based on more abundant and less environmentally problematic elements. These developments suggest a growing recognition of environmental impacts as a critical factor in future technology development for flexible OLED encapsulation.

Reliability Testing Standards for Catalyst-Enhanced Encapsulation

Reliability testing standards for catalyst-enhanced encapsulation systems in flexible OLED devices have evolved significantly in recent years to address the unique challenges posed by these advanced materials. The incorporation of catalysts in encapsulation layers necessitates specialized testing protocols that differ from conventional barrier evaluation methods.

Standard accelerated aging tests have been modified to specifically target catalyst-enhanced systems, with temperature cycling ranges typically expanded to -40°C to 85°C to account for the potential thermal degradation of catalyst activity. Humidity testing has also been adapted, with the JEDEC JESD22-A101 standard now including specific provisions for catalyst-containing barriers at 85°C/85% RH conditions for extended durations of 1000+ hours.

Mechanical reliability testing has become particularly crucial for flexible OLED applications. The ASTM D4145 standard has been supplemented with mandrel bend tests specifically calibrated for catalyst-enhanced thin films, requiring maintenance of barrier properties after 100,000+ cycles at radii as small as 1mm. These tests must verify that catalyst distribution remains uniform and active throughout the mechanical stress cycles.

Calcium tests, which measure water vapor transmission rates (WVTR), have been refined for catalyst systems with modified optical detection methods that can distinguish between barrier failure and catalyst depletion. The target WVTR for catalyst-enhanced barriers has been established at <1×10^-6 g/m²/day, significantly more stringent than previous standards.

Photostability testing under UV exposure (ASTM G154) has been extended to include spectroscopic analysis of catalyst activity retention, as certain photocatalytic reactions may either enhance or degrade barrier performance over time. This test typically requires 1000+ hours of exposure while maintaining barrier integrity.

Interfacial adhesion testing between catalyst-containing layers has been standardized using modified versions of ASTM D3359, with particular attention to potential catalyst migration between layers during thermal or mechanical stress events.

Chemical compatibility testing has emerged as a critical standard specific to catalyst-enhanced systems, evaluating potential interactions between catalysts and OLED materials through gas chromatography-mass spectrometry (GC-MS) analysis of outgassing compounds during accelerated aging.

These reliability standards continue to evolve as the technology matures, with industry consortia like the Flexible Display Center and SEMI working to establish unified testing protocols specifically addressing the unique challenges of catalyst-enhanced encapsulation systems for next-generation flexible displays.

Standard accelerated aging tests have been modified to specifically target catalyst-enhanced systems, with temperature cycling ranges typically expanded to -40°C to 85°C to account for the potential thermal degradation of catalyst activity. Humidity testing has also been adapted, with the JEDEC JESD22-A101 standard now including specific provisions for catalyst-containing barriers at 85°C/85% RH conditions for extended durations of 1000+ hours.

Mechanical reliability testing has become particularly crucial for flexible OLED applications. The ASTM D4145 standard has been supplemented with mandrel bend tests specifically calibrated for catalyst-enhanced thin films, requiring maintenance of barrier properties after 100,000+ cycles at radii as small as 1mm. These tests must verify that catalyst distribution remains uniform and active throughout the mechanical stress cycles.

Calcium tests, which measure water vapor transmission rates (WVTR), have been refined for catalyst systems with modified optical detection methods that can distinguish between barrier failure and catalyst depletion. The target WVTR for catalyst-enhanced barriers has been established at <1×10^-6 g/m²/day, significantly more stringent than previous standards.

Photostability testing under UV exposure (ASTM G154) has been extended to include spectroscopic analysis of catalyst activity retention, as certain photocatalytic reactions may either enhance or degrade barrier performance over time. This test typically requires 1000+ hours of exposure while maintaining barrier integrity.

Interfacial adhesion testing between catalyst-containing layers has been standardized using modified versions of ASTM D3359, with particular attention to potential catalyst migration between layers during thermal or mechanical stress events.

Chemical compatibility testing has emerged as a critical standard specific to catalyst-enhanced systems, evaluating potential interactions between catalysts and OLED materials through gas chromatography-mass spectrometry (GC-MS) analysis of outgassing compounds during accelerated aging.

These reliability standards continue to evolve as the technology matures, with industry consortia like the Flexible Display Center and SEMI working to establish unified testing protocols specifically addressing the unique challenges of catalyst-enhanced encapsulation systems for next-generation flexible displays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!