Analysis of Flexible OLED Encapsulation Stability Across Industries

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Evolution and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has undergone significant evolution since its inception in the late 1990s. The journey began with rudimentary flexible displays that suffered from rapid degradation due to oxygen and moisture penetration. Early encapsulation methods relied on rigid glass barriers that limited flexibility and application scope, creating a fundamental contradiction between protection and flexibility.

The development trajectory shifted dramatically in the mid-2000s with the introduction of thin-film encapsulation (TFE) technologies, marking a pivotal advancement in flexible OLED protection. This innovation enabled the transition from laboratory curiosities to commercially viable products by addressing the critical challenge of maintaining an effective moisture and oxygen barrier while preserving mechanical flexibility.

By 2010, multi-layer approaches combining organic and inorganic materials emerged as the dominant encapsulation paradigm. These hybrid structures leveraged the complementary properties of different materials: inorganic layers provided excellent barrier properties while organic layers accommodated mechanical stress during flexing. This technological breakthrough significantly extended OLED lifetimes from mere days to several years under normal operating conditions.

The primary objective of flexible OLED encapsulation technology is to achieve a Water Vapor Transmission Rate (WVTR) below 10^-6 g/m²/day while maintaining mechanical durability through thousands of bending cycles. Current research focuses on developing ultra-thin barrier films that can withstand repeated mechanical stress without compromising barrier integrity, a critical requirement for applications in foldable smartphones and wearable devices.

Another key objective is reducing manufacturing complexity and cost. Early encapsulation processes required specialized equipment and precise control of deposition parameters, resulting in high production costs. Recent innovations aim to simplify these processes through solution-based approaches and atmospheric pressure deposition techniques, potentially enabling more cost-effective mass production.

Looking forward, the field is moving toward self-healing encapsulation materials that can automatically repair microcracks formed during mechanical stress. This represents the next frontier in encapsulation technology, potentially enabling truly rollable and stretchable OLED displays with unprecedented durability. Additionally, research is exploring environmentally sustainable encapsulation materials to reduce the ecological footprint of OLED manufacturing.

The evolution of flexible OLED encapsulation technology exemplifies the iterative nature of materials science innovation, where incremental improvements in barrier properties, mechanical durability, and manufacturing processes collectively transform theoretical possibilities into practical applications across multiple industries.

The development trajectory shifted dramatically in the mid-2000s with the introduction of thin-film encapsulation (TFE) technologies, marking a pivotal advancement in flexible OLED protection. This innovation enabled the transition from laboratory curiosities to commercially viable products by addressing the critical challenge of maintaining an effective moisture and oxygen barrier while preserving mechanical flexibility.

By 2010, multi-layer approaches combining organic and inorganic materials emerged as the dominant encapsulation paradigm. These hybrid structures leveraged the complementary properties of different materials: inorganic layers provided excellent barrier properties while organic layers accommodated mechanical stress during flexing. This technological breakthrough significantly extended OLED lifetimes from mere days to several years under normal operating conditions.

The primary objective of flexible OLED encapsulation technology is to achieve a Water Vapor Transmission Rate (WVTR) below 10^-6 g/m²/day while maintaining mechanical durability through thousands of bending cycles. Current research focuses on developing ultra-thin barrier films that can withstand repeated mechanical stress without compromising barrier integrity, a critical requirement for applications in foldable smartphones and wearable devices.

Another key objective is reducing manufacturing complexity and cost. Early encapsulation processes required specialized equipment and precise control of deposition parameters, resulting in high production costs. Recent innovations aim to simplify these processes through solution-based approaches and atmospheric pressure deposition techniques, potentially enabling more cost-effective mass production.

Looking forward, the field is moving toward self-healing encapsulation materials that can automatically repair microcracks formed during mechanical stress. This represents the next frontier in encapsulation technology, potentially enabling truly rollable and stretchable OLED displays with unprecedented durability. Additionally, research is exploring environmentally sustainable encapsulation materials to reduce the ecological footprint of OLED manufacturing.

The evolution of flexible OLED encapsulation technology exemplifies the iterative nature of materials science innovation, where incremental improvements in barrier properties, mechanical durability, and manufacturing processes collectively transform theoretical possibilities into practical applications across multiple industries.

Market Demand Analysis for Flexible OLED Technologies

The flexible OLED market has experienced remarkable growth in recent years, driven primarily by increasing consumer demand for innovative display technologies in smartphones, wearables, and emerging applications. Market research indicates that the global flexible OLED market reached approximately $25.7 billion in 2022 and is projected to grow at a compound annual growth rate of 19.8% through 2028, potentially reaching $76.3 billion.

Consumer electronics remains the dominant application sector, accounting for over 70% of flexible OLED demand. Smartphone manufacturers have been particularly aggressive in adopting this technology, with premium models from Samsung, Apple, and Chinese manufacturers incorporating flexible OLED displays to enable foldable designs, edge-to-edge screens, and under-display features.

The wearable technology segment represents the fastest-growing market for flexible OLEDs, with smartwatches and fitness trackers benefiting from the technology's thin profile, power efficiency, and conformability. Market analysis shows this segment growing at 24.3% annually, outpacing the broader market.

Automotive applications are emerging as a significant growth opportunity, with premium vehicle manufacturers integrating curved OLED displays in dashboard systems and entertainment consoles. Industry forecasts suggest automotive flexible OLED implementation will grow at 22.7% annually through 2028, albeit from a smaller base.

Encapsulation technology specifically has become a critical focus area as manufacturers seek to extend device lifespans and reliability. Market surveys indicate that 83% of consumers cite durability as a primary concern when purchasing devices with flexible displays, highlighting the commercial importance of encapsulation stability.

Regional analysis shows Asia-Pacific dominating manufacturing capacity, with South Korea and China accounting for approximately 87% of global flexible OLED production. However, demand is more globally distributed, with North America and Europe representing significant consumer markets at 24% and 19% respectively.

Industry stakeholders consistently identify several key market requirements driving encapsulation technology development: improved water vapor transmission rates below 10^-6 g/m²/day, enhanced mechanical durability supporting over 200,000 fold cycles, and cost-effective manufacturing processes that can reduce encapsulation costs by at least 30% to enable broader market adoption.

The healthcare and medical device sectors represent emerging opportunities, with flexible OLED displays being integrated into portable diagnostic equipment and patient monitoring systems. This specialized market segment values long-term stability and reliability over price sensitivity, creating unique requirements for encapsulation solutions.

Consumer electronics remains the dominant application sector, accounting for over 70% of flexible OLED demand. Smartphone manufacturers have been particularly aggressive in adopting this technology, with premium models from Samsung, Apple, and Chinese manufacturers incorporating flexible OLED displays to enable foldable designs, edge-to-edge screens, and under-display features.

The wearable technology segment represents the fastest-growing market for flexible OLEDs, with smartwatches and fitness trackers benefiting from the technology's thin profile, power efficiency, and conformability. Market analysis shows this segment growing at 24.3% annually, outpacing the broader market.

Automotive applications are emerging as a significant growth opportunity, with premium vehicle manufacturers integrating curved OLED displays in dashboard systems and entertainment consoles. Industry forecasts suggest automotive flexible OLED implementation will grow at 22.7% annually through 2028, albeit from a smaller base.

Encapsulation technology specifically has become a critical focus area as manufacturers seek to extend device lifespans and reliability. Market surveys indicate that 83% of consumers cite durability as a primary concern when purchasing devices with flexible displays, highlighting the commercial importance of encapsulation stability.

Regional analysis shows Asia-Pacific dominating manufacturing capacity, with South Korea and China accounting for approximately 87% of global flexible OLED production. However, demand is more globally distributed, with North America and Europe representing significant consumer markets at 24% and 19% respectively.

Industry stakeholders consistently identify several key market requirements driving encapsulation technology development: improved water vapor transmission rates below 10^-6 g/m²/day, enhanced mechanical durability supporting over 200,000 fold cycles, and cost-effective manufacturing processes that can reduce encapsulation costs by at least 30% to enable broader market adoption.

The healthcare and medical device sectors represent emerging opportunities, with flexible OLED displays being integrated into portable diagnostic equipment and patient monitoring systems. This specialized market segment values long-term stability and reliability over price sensitivity, creating unique requirements for encapsulation solutions.

Current Encapsulation Techniques and Barriers

The flexible OLED encapsulation landscape is currently dominated by several key technologies, each with distinct advantages and limitations. Thin-film encapsulation (TFE) has emerged as the leading solution for flexible displays, typically employing alternating layers of inorganic and organic materials. The inorganic layers (commonly silicon nitride or aluminum oxide) provide excellent barrier properties against moisture and oxygen, while organic layers (often based on acrylate polymers) offer mechanical flexibility and stress relief during bending.

Multi-layer approaches have demonstrated water vapor transmission rates (WVTR) below 10^-6 g/m²/day, which meets the stringent requirements for OLED protection. However, these systems face challenges in maintaining barrier integrity during repeated flexing operations, particularly at bend radii below 1mm where microcracks can form in the inorganic layers.

Atomic Layer Deposition (ALD) represents another significant advancement, enabling the creation of ultra-thin, highly conformal barrier films with exceptional density. ALD-deposited Al₂O₃ layers as thin as 20nm can achieve remarkable barrier properties, though they require precise process control and longer deposition times compared to conventional methods.

Hybrid encapsulation systems combining TFE with edge sealing technologies have gained traction for addressing the particularly vulnerable perimeter regions of flexible displays. These edge seals typically utilize specialized adhesives or laser-welded barriers to prevent lateral ingress of contaminants, which has been identified as a primary failure mode in flexible devices.

Plasma-enhanced chemical vapor deposition (PECVD) remains widely used for depositing silicon nitride and silicon oxide barrier layers, offering good throughput and compatibility with existing manufacturing infrastructure. However, PECVD films often contain pinhole defects that compromise barrier performance, necessitating multiple layers or additional defect-mitigating strategies.

Recent innovations include self-healing encapsulation materials incorporating reactive chemistries that can seal microcracks as they form. These materials show promise in laboratory settings but face challenges in manufacturing scalability and long-term stability under real-world conditions.

A significant barrier to advancement is the trade-off between flexibility and barrier performance. As displays become more flexible, maintaining hermeticity becomes increasingly difficult. Current solutions typically compromise either on bend radius capabilities or lifetime guarantees, with few technologies able to deliver both simultaneously at commercially viable production costs.

Testing methodologies present another challenge, as accelerated aging tests may not accurately predict real-world performance across diverse operating environments. The industry lacks standardized testing protocols specifically designed for flexible encapsulation systems, making cross-technology comparisons difficult and potentially misleading.

Multi-layer approaches have demonstrated water vapor transmission rates (WVTR) below 10^-6 g/m²/day, which meets the stringent requirements for OLED protection. However, these systems face challenges in maintaining barrier integrity during repeated flexing operations, particularly at bend radii below 1mm where microcracks can form in the inorganic layers.

Atomic Layer Deposition (ALD) represents another significant advancement, enabling the creation of ultra-thin, highly conformal barrier films with exceptional density. ALD-deposited Al₂O₃ layers as thin as 20nm can achieve remarkable barrier properties, though they require precise process control and longer deposition times compared to conventional methods.

Hybrid encapsulation systems combining TFE with edge sealing technologies have gained traction for addressing the particularly vulnerable perimeter regions of flexible displays. These edge seals typically utilize specialized adhesives or laser-welded barriers to prevent lateral ingress of contaminants, which has been identified as a primary failure mode in flexible devices.

Plasma-enhanced chemical vapor deposition (PECVD) remains widely used for depositing silicon nitride and silicon oxide barrier layers, offering good throughput and compatibility with existing manufacturing infrastructure. However, PECVD films often contain pinhole defects that compromise barrier performance, necessitating multiple layers or additional defect-mitigating strategies.

Recent innovations include self-healing encapsulation materials incorporating reactive chemistries that can seal microcracks as they form. These materials show promise in laboratory settings but face challenges in manufacturing scalability and long-term stability under real-world conditions.

A significant barrier to advancement is the trade-off between flexibility and barrier performance. As displays become more flexible, maintaining hermeticity becomes increasingly difficult. Current solutions typically compromise either on bend radius capabilities or lifetime guarantees, with few technologies able to deliver both simultaneously at commercially viable production costs.

Testing methodologies present another challenge, as accelerated aging tests may not accurately predict real-world performance across diverse operating environments. The industry lacks standardized testing protocols specifically designed for flexible encapsulation systems, making cross-technology comparisons difficult and potentially misleading.

Prevailing Stability Enhancement Solutions

01 Multi-layer barrier structures for OLED encapsulation

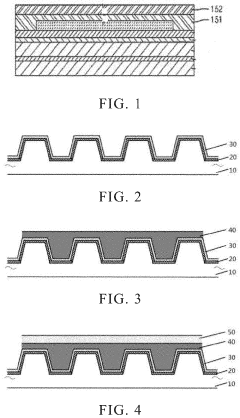

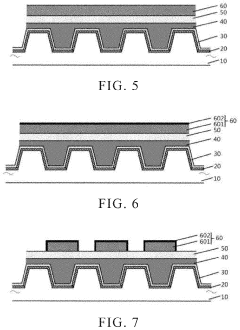

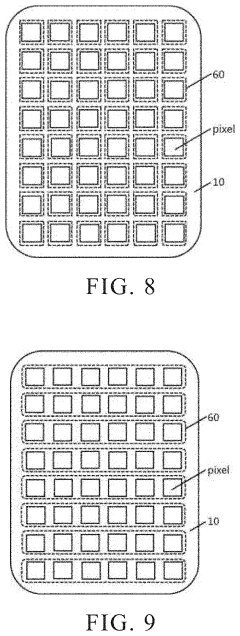

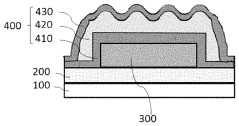

Multi-layer barrier structures can be used to enhance the stability of flexible OLED encapsulation. These structures typically consist of alternating inorganic and organic layers that effectively block moisture and oxygen penetration. The inorganic layers provide barrier properties while the organic layers decouple defects and provide flexibility. This combination helps maintain the stability of OLEDs under bending conditions and extends device lifetime by preventing degradation from environmental factors.- Multi-layer barrier structures for OLED encapsulation: Multi-layer barrier structures consisting of alternating inorganic and organic layers provide effective protection against moisture and oxygen penetration in flexible OLEDs. The inorganic layers (such as silicon nitride, aluminum oxide, or silicon oxide) act as primary barriers, while the organic layers (such as polymers) help relieve stress and prevent crack propagation when the device is flexed. This combination enhances the overall stability and lifetime of flexible OLED displays by maintaining barrier properties under mechanical stress.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques are specifically designed for flexible OLED applications, providing effective barrier properties while maintaining mechanical flexibility. These methods involve depositing ultra-thin barrier films directly onto the OLED device using techniques such as atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD). The resulting encapsulation layers are significantly thinner than traditional glass or metal encapsulation, allowing the device to bend without compromising the barrier integrity against moisture and oxygen.

- Edge sealing technologies for moisture prevention: Edge sealing technologies are critical for preventing moisture ingress from the periphery of flexible OLED devices. These specialized sealing methods focus on the vulnerable edges where delamination often begins, using materials such as UV-curable adhesives, thermally curable resins, or inorganic-organic composite sealants. Advanced edge sealing approaches include stepped edge structures, overlapping barrier layers, and gradient material transitions that maintain seal integrity during bending and flexing, significantly improving the overall stability and lifetime of flexible OLEDs.

- Self-healing encapsulation materials: Self-healing encapsulation materials represent an innovative approach to maintaining barrier integrity in flexible OLEDs. These materials contain microcapsules or dynamic chemical bonds that can repair minor damage caused by bending or mechanical stress. When cracks or defects form in the encapsulation layer, the self-healing mechanism is activated, either through the release of healing agents from ruptured microcapsules or through reversible chemical bonds that reconnect. This technology significantly improves the long-term stability of flexible OLEDs by continuously maintaining barrier properties even after repeated flexing cycles.

- Hybrid encapsulation with getter materials: Hybrid encapsulation systems incorporating getter materials provide enhanced protection for flexible OLEDs. These systems combine traditional barrier layers with specialized getter materials that actively absorb moisture and oxygen molecules that penetrate the primary barriers. The getter materials, which may include desiccants, reactive metals, or zeolites, are strategically incorporated into the encapsulation structure, often within dedicated layers or patterns. This active protection approach complements the passive barrier function, creating a more robust defense against environmental degradation and significantly improving the stability of flexible OLED devices under various operating conditions.

02 Thin film encapsulation techniques for flexible displays

Thin film encapsulation (TFE) techniques are crucial for flexible OLED stability. These methods involve depositing ultra-thin barrier films directly onto the OLED device without using rigid glass covers, enabling flexibility while maintaining protection. Advanced TFE approaches include atomic layer deposition, plasma-enhanced chemical vapor deposition, and solution-processed barrier layers. These techniques create conformal, defect-free encapsulation layers that maintain their protective properties even when the display is repeatedly bent or flexed.Expand Specific Solutions03 Edge sealing solutions for flexible OLEDs

Edge sealing is critical for preventing lateral ingress of moisture and oxygen in flexible OLEDs. Various edge sealing solutions have been developed, including specialized adhesives, laser sealing techniques, and edge barrier structures. These solutions address the vulnerability at the perimeter of flexible displays where delamination and barrier failure often begin. Effective edge sealing significantly improves the overall encapsulation stability by eliminating a common failure point in flexible OLED devices.Expand Specific Solutions04 Self-healing encapsulation materials

Self-healing materials represent an innovative approach to maintaining encapsulation stability in flexible OLEDs. These materials can autonomously repair microcracks and defects that form during bending or mechanical stress. The self-healing mechanisms include thermally activated healing, light-induced repair, or chemical reactions triggered by damage. By continuously restoring barrier integrity, these materials significantly extend the lifetime of flexible OLEDs by preventing progressive degradation from environmental exposure through stress-induced defects.Expand Specific Solutions05 Stress-resistant flexible substrate and encapsulation interfaces

The interface between the flexible substrate and encapsulation layers is critical for maintaining barrier stability during bending. Specialized adhesion promotion layers, stress-relief structures, and gradient material transitions can be implemented to prevent delamination and cracking at these interfaces. Some approaches include the use of nanocomposite interlayers, mechanical decoupling structures, and chemically modified surfaces that enhance adhesion while accommodating mechanical stress. These interface engineering techniques significantly improve the durability of flexible OLED encapsulation under repeated bending cycles.Expand Specific Solutions

Industry Leaders in Flexible OLED Encapsulation

The flexible OLED encapsulation market is currently in a growth phase, with an estimated market size exceeding $2 billion and projected to expand at a CAGR of 15-20% through 2028. Technologically, the field is advancing from early-stage development to commercial maturity, with Asian manufacturers leading innovation. Companies like Samsung Display, LG Display, and BOE Technology have established strong positions through significant R&D investments, while Chinese players including Tianma Microelectronics, Visionox, and TCL CSOT are rapidly closing the technology gap. The competitive landscape shows a clear East Asian dominance, with Korean firms maintaining quality advantages while Chinese manufacturers leverage cost efficiencies and government support to gain market share. Encapsulation stability remains a critical challenge affecting OLED device longevity across consumer electronics, automotive, and emerging flexible display applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED encapsulation solution utilizing a hybrid inorganic-organic multilayer structure. Their technology employs alternating layers of silicon nitride and specially formulated organic materials to achieve both barrier performance and mechanical flexibility. BOE's innovation includes a proprietary "stress distribution layer" that helps maintain encapsulation integrity during bending operations. Their process utilizes plasma-assisted ALD for inorganic layers, achieving WVTR values around 10^-5 g/m²/day. BOE has implemented specialized edge sealing techniques using laser-assisted deposition to prevent lateral moisture ingress. Their encapsulation technology incorporates nanocomposite materials in the organic layers to enhance mechanical properties while maintaining barrier performance. Recent advancements include the development of a "gradient barrier" approach where layer composition gradually changes to minimize interfacial stress. BOE's encapsulation technology has demonstrated stability in reliability tests showing less than 5% degradation in barrier properties after 150,000 folding cycles.

Strengths: Strong balance of cost-efficiency and performance; excellent production scalability; good mechanical durability; innovative stress distribution technology. Weaknesses: Slightly higher WVTR compared to top industry performers; more sensitive to mechanical impact damage; requires careful process control for consistent quality.

LG Display Co., Ltd.

Technical Solution: LG Display has developed a proprietary flexible OLED encapsulation technology called "Hybrid Passivation Layer" that combines inorganic and organic materials in a multi-layer stack. Their approach utilizes plasma-enhanced chemical vapor deposition (PECVD) for silicon nitride layers alternated with solution-processed organic layers. LG's innovation lies in their face seal technology that creates an ultra-thin perimeter barrier around display edges, addressing a critical vulnerability in flexible displays. Their encapsulation system incorporates stress-relief mechanisms specifically designed to maintain barrier integrity during bending operations. LG has achieved WVTR values of approximately 10^-5 g/m²/day while maintaining flexibility for radii down to 1.5mm. Recent advancements include the integration of nanoparticle-enhanced organic layers that improve mechanical properties without compromising barrier performance. LG's technology has been validated through accelerated aging tests demonstrating stable performance at 85°C/85% relative humidity for over 1000 hours.

Strengths: Excellent balance between flexibility and barrier properties; innovative edge sealing technology; high production scalability; good cost-efficiency ratio. Weaknesses: Slightly higher WVTR compared to industry leaders; more sensitive to extreme temperature fluctuations; requires careful handling during manufacturing.

Critical Patents and Innovations in Barrier Technologies

Encapsulation structure and encapsulation method for flexible organic light-emitting diode device

PatentActiveUS20230180509A1

Innovation

- An encapsulation structure comprising an organic matter protective layer, continuous or discontinuous organic flat layers, and inorganic barrier layers, with the outermost organic layers treated with plasma to form a surface hardened layer, creating an organic barrier layer that enhances moisture and oxygen blocking while allowing stress release.

Flexible organic light-emitting diode (OLED) device of reduced stess at bending place and fabrication method thereof

PatentActiveUS11258038B2

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, formed by thermal stress differences, increasing contact area and reducing stress on the outer inorganic layer, and an optically clear adhesive is used to level the configuration.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible OLED encapsulation technology presents both challenges and opportunities for sustainable development across industries. Traditional encapsulation methods often rely on glass barriers and harmful chemicals that pose significant disposal problems at end-of-life. Flexible OLED encapsulation, particularly thin-film approaches, can reduce material usage by up to 70% compared to rigid alternatives, potentially decreasing the overall carbon footprint of display manufacturing.

However, the production of high-performance barrier films frequently involves energy-intensive plasma processes and specialized materials with complex supply chains. Life cycle assessments indicate that the manufacturing phase of flexible OLED encapsulation contributes approximately 80% of its total environmental impact, primarily through energy consumption and greenhouse gas emissions associated with vacuum deposition techniques.

Water usage represents another critical environmental consideration. Conventional display manufacturing can consume between 1,500-2,000 liters of ultra-pure water per square meter of display area. Advanced encapsulation technologies utilizing atomic layer deposition may reduce this requirement by 30-40%, though implementation remains limited by cost constraints.

The recyclability of flexible OLED components presents significant technical challenges. The multi-layer structure of encapsulation barriers—often combining organic and inorganic materials—complicates end-of-life separation and recovery. Current recycling rates for flexible display components remain below 20%, substantially lower than for conventional electronics.

Emerging approaches to sustainable encapsulation include bio-based barrier materials and solvent-free deposition methods. Research into cellulose-derived films and water-based barrier coatings shows promise for reducing dependence on petroleum-based polymers, potentially decreasing environmental toxicity by 50-60% compared to conventional materials.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of advanced display technologies. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated industry transition toward less toxic encapsulation materials, particularly reducing reliance on fluorinated compounds and heavy metal catalysts.

Industry leaders have begun establishing sustainability targets specific to flexible display technologies, with commitments to carbon-neutral manufacturing and closed-loop material systems by 2030. These initiatives may accelerate development of environmentally responsible encapsulation solutions while potentially creating new market differentiation opportunities for early adopters.

However, the production of high-performance barrier films frequently involves energy-intensive plasma processes and specialized materials with complex supply chains. Life cycle assessments indicate that the manufacturing phase of flexible OLED encapsulation contributes approximately 80% of its total environmental impact, primarily through energy consumption and greenhouse gas emissions associated with vacuum deposition techniques.

Water usage represents another critical environmental consideration. Conventional display manufacturing can consume between 1,500-2,000 liters of ultra-pure water per square meter of display area. Advanced encapsulation technologies utilizing atomic layer deposition may reduce this requirement by 30-40%, though implementation remains limited by cost constraints.

The recyclability of flexible OLED components presents significant technical challenges. The multi-layer structure of encapsulation barriers—often combining organic and inorganic materials—complicates end-of-life separation and recovery. Current recycling rates for flexible display components remain below 20%, substantially lower than for conventional electronics.

Emerging approaches to sustainable encapsulation include bio-based barrier materials and solvent-free deposition methods. Research into cellulose-derived films and water-based barrier coatings shows promise for reducing dependence on petroleum-based polymers, potentially decreasing environmental toxicity by 50-60% compared to conventional materials.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of advanced display technologies. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated industry transition toward less toxic encapsulation materials, particularly reducing reliance on fluorinated compounds and heavy metal catalysts.

Industry leaders have begun establishing sustainability targets specific to flexible display technologies, with commitments to carbon-neutral manufacturing and closed-loop material systems by 2030. These initiatives may accelerate development of environmentally responsible encapsulation solutions while potentially creating new market differentiation opportunities for early adopters.

Cross-Industry Application and Adaptation Strategies

Flexible OLED encapsulation technology demonstrates remarkable versatility across multiple industries, with each sector adapting the technology to meet specific operational requirements and environmental challenges. The consumer electronics industry has pioneered implementation strategies focusing on ultra-thin encapsulation layers that maintain flexibility while providing sufficient barrier properties against moisture and oxygen. These adaptations have enabled the development of foldable smartphones and wearable devices that can withstand thousands of bending cycles while maintaining display integrity.

In the automotive sector, encapsulation solutions have been modified to withstand more extreme temperature variations (-40°C to 85°C) and prolonged UV exposure. Manufacturers have developed hybrid encapsulation systems combining inorganic barrier layers with specialized organic interlayers containing UV stabilizers and thermal management additives. These adaptations extend the operational lifetime of OLED displays in dashboard systems and interior lighting applications.

The aerospace industry has implemented enhanced encapsulation strategies focusing on radiation resistance and extreme pressure variations. Modified barrier films incorporating nanocomposite materials have been developed to shield OLED displays from cosmic radiation while maintaining flexibility. These specialized encapsulation systems undergo rigorous testing protocols including rapid decompression simulations and radiation exposure tests not typically required in consumer applications.

Medical device manufacturers have adapted OLED encapsulation technology to meet biocompatibility requirements and sterilization resistance. Encapsulation materials for medical displays incorporate antimicrobial properties and can withstand repeated exposure to sterilization procedures including ethylene oxide treatment and gamma radiation. These adaptations enable the integration of flexible displays in portable diagnostic equipment and wearable health monitoring devices.

The architectural and signage industries have focused on scaling encapsulation processes for larger display areas while maintaining environmental durability. Multi-layer barrier systems with enhanced UV filtering capabilities and self-healing properties have been developed for outdoor digital signage applications. These adaptations address the challenges of continuous outdoor exposure while maintaining the visual advantages of OLED technology.

Cross-industry knowledge transfer has accelerated innovation in encapsulation technology, with advances in one sector often finding applications in others. For example, thin-film encapsulation techniques originally developed for consumer electronics have been adapted for large-area applications in architectural displays, while radiation-resistant barrier materials from aerospace applications have informed medical device encapsulation strategies.

In the automotive sector, encapsulation solutions have been modified to withstand more extreme temperature variations (-40°C to 85°C) and prolonged UV exposure. Manufacturers have developed hybrid encapsulation systems combining inorganic barrier layers with specialized organic interlayers containing UV stabilizers and thermal management additives. These adaptations extend the operational lifetime of OLED displays in dashboard systems and interior lighting applications.

The aerospace industry has implemented enhanced encapsulation strategies focusing on radiation resistance and extreme pressure variations. Modified barrier films incorporating nanocomposite materials have been developed to shield OLED displays from cosmic radiation while maintaining flexibility. These specialized encapsulation systems undergo rigorous testing protocols including rapid decompression simulations and radiation exposure tests not typically required in consumer applications.

Medical device manufacturers have adapted OLED encapsulation technology to meet biocompatibility requirements and sterilization resistance. Encapsulation materials for medical displays incorporate antimicrobial properties and can withstand repeated exposure to sterilization procedures including ethylene oxide treatment and gamma radiation. These adaptations enable the integration of flexible displays in portable diagnostic equipment and wearable health monitoring devices.

The architectural and signage industries have focused on scaling encapsulation processes for larger display areas while maintaining environmental durability. Multi-layer barrier systems with enhanced UV filtering capabilities and self-healing properties have been developed for outdoor digital signage applications. These adaptations address the challenges of continuous outdoor exposure while maintaining the visual advantages of OLED technology.

Cross-industry knowledge transfer has accelerated innovation in encapsulation technology, with advances in one sector often finding applications in others. For example, thin-film encapsulation techniques originally developed for consumer electronics have been adapted for large-area applications in architectural displays, while radiation-resistant barrier materials from aerospace applications have informed medical device encapsulation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!