Standards and Certifications Relevant to Flexible OLED Encapsulation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized display applications by enabling bendable, foldable, and rollable screens that were once confined to science fiction. The evolution of this technology can be traced back to the early 2000s when researchers first demonstrated the potential for creating displays on flexible substrates. Since then, the field has witnessed remarkable advancements, particularly in addressing the critical challenge of encapsulation.

Encapsulation technology for flexible OLEDs has evolved from rigid glass-based solutions to ultra-thin film barriers that maintain flexibility while providing essential protection against moisture and oxygen. This progression has been driven by the fundamental vulnerability of organic materials used in OLEDs, which degrade rapidly when exposed to environmental elements. The technical trajectory shows a clear shift from early single-layer encapsulation methods to sophisticated multi-layer barrier films and hybrid approaches.

The primary technical objective in flexible OLED encapsulation is to achieve an optimal balance between barrier performance and mechanical flexibility. Specifically, the industry aims to develop encapsulation solutions that maintain water vapor transmission rates (WVTR) below 10^-6 g/m²/day while withstanding thousands of bending cycles without degradation. This represents a significant engineering challenge that continues to drive innovation in materials science and deposition techniques.

Recent technological trends indicate growing interest in atomic layer deposition (ALD) for creating ultra-thin barrier layers, alongside the development of organic-inorganic hybrid encapsulation systems that combine the advantages of both material types. These approaches aim to overcome the inherent limitations of traditional encapsulation methods when applied to flexible substrates.

The standardization landscape for flexible OLED encapsulation is still evolving, with organizations like the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) working to establish unified testing protocols and performance metrics. These standards are crucial for industry advancement as they provide common benchmarks for evaluating encapsulation effectiveness across different technologies and manufacturers.

Looking forward, the technical roadmap for flexible OLED encapsulation is focused on developing solutions that not only meet current performance requirements but also anticipate the demands of next-generation devices featuring extreme form factors such as stretchable displays and conformable electronics. This forward-looking approach is essential for supporting the broader trend toward increasingly versatile and adaptable display technologies.

Encapsulation technology for flexible OLEDs has evolved from rigid glass-based solutions to ultra-thin film barriers that maintain flexibility while providing essential protection against moisture and oxygen. This progression has been driven by the fundamental vulnerability of organic materials used in OLEDs, which degrade rapidly when exposed to environmental elements. The technical trajectory shows a clear shift from early single-layer encapsulation methods to sophisticated multi-layer barrier films and hybrid approaches.

The primary technical objective in flexible OLED encapsulation is to achieve an optimal balance between barrier performance and mechanical flexibility. Specifically, the industry aims to develop encapsulation solutions that maintain water vapor transmission rates (WVTR) below 10^-6 g/m²/day while withstanding thousands of bending cycles without degradation. This represents a significant engineering challenge that continues to drive innovation in materials science and deposition techniques.

Recent technological trends indicate growing interest in atomic layer deposition (ALD) for creating ultra-thin barrier layers, alongside the development of organic-inorganic hybrid encapsulation systems that combine the advantages of both material types. These approaches aim to overcome the inherent limitations of traditional encapsulation methods when applied to flexible substrates.

The standardization landscape for flexible OLED encapsulation is still evolving, with organizations like the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) working to establish unified testing protocols and performance metrics. These standards are crucial for industry advancement as they provide common benchmarks for evaluating encapsulation effectiveness across different technologies and manufacturers.

Looking forward, the technical roadmap for flexible OLED encapsulation is focused on developing solutions that not only meet current performance requirements but also anticipate the demands of next-generation devices featuring extreme form factors such as stretchable displays and conformable electronics. This forward-looking approach is essential for supporting the broader trend toward increasingly versatile and adaptable display technologies.

Market Demand Analysis for Flexible OLED Displays

The flexible OLED display market has experienced remarkable growth in recent years, driven by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible OLED market reached approximately $18.2 billion in 2022 and is projected to grow at a CAGR of 35.3% through 2028. This exceptional growth trajectory is primarily fueled by the expanding adoption of flexible displays in smartphones, wearables, and emerging applications in automotive and IoT devices.

Consumer electronics manufacturers are increasingly prioritizing flexible OLED technology due to its ability to enable differentiated product designs. The smartphone segment currently dominates market demand, accounting for over 65% of flexible OLED applications. Major smartphone manufacturers have transitioned their flagship models to incorporate flexible OLED displays, with foldable smartphones representing the fastest-growing sub-segment within this category.

Wearable technology represents another significant growth driver, with smartwatches and fitness trackers increasingly adopting flexible OLED displays. The automotive industry is also emerging as a promising market, with premium vehicle manufacturers integrating curved OLED displays in dashboard systems and entertainment consoles to enhance user experience and interior aesthetics.

Regional analysis reveals that Asia-Pacific dominates the flexible OLED market, with South Korea, China, and Japan leading in both production and consumption. North America and Europe follow as significant markets, primarily driven by high consumer purchasing power and early technology adoption trends.

The demand for improved encapsulation technologies is directly correlated with market growth, as effective barrier solutions are critical for ensuring the longevity and reliability of flexible OLED devices. Industry surveys indicate that consumers prioritize durability and lifespan when purchasing premium devices with flexible displays, making advanced encapsulation solutions a key differentiator for manufacturers.

Supply chain analysis reveals increasing investments in encapsulation technology development, with material suppliers and equipment manufacturers expanding their R&D efforts to meet growing demand. The market for encapsulation materials alone is projected to grow at a CAGR of 28% through 2027, highlighting the critical importance of this component in the flexible OLED ecosystem.

Consumer preference trends indicate growing acceptance of flexible display technology, with willingness to pay premium prices for devices featuring advanced flexible displays increasing by 22% year-over-year. This trend is particularly pronounced in the high-end smartphone and wearable segments, where design differentiation and user experience innovations drive purchasing decisions.

Consumer electronics manufacturers are increasingly prioritizing flexible OLED technology due to its ability to enable differentiated product designs. The smartphone segment currently dominates market demand, accounting for over 65% of flexible OLED applications. Major smartphone manufacturers have transitioned their flagship models to incorporate flexible OLED displays, with foldable smartphones representing the fastest-growing sub-segment within this category.

Wearable technology represents another significant growth driver, with smartwatches and fitness trackers increasingly adopting flexible OLED displays. The automotive industry is also emerging as a promising market, with premium vehicle manufacturers integrating curved OLED displays in dashboard systems and entertainment consoles to enhance user experience and interior aesthetics.

Regional analysis reveals that Asia-Pacific dominates the flexible OLED market, with South Korea, China, and Japan leading in both production and consumption. North America and Europe follow as significant markets, primarily driven by high consumer purchasing power and early technology adoption trends.

The demand for improved encapsulation technologies is directly correlated with market growth, as effective barrier solutions are critical for ensuring the longevity and reliability of flexible OLED devices. Industry surveys indicate that consumers prioritize durability and lifespan when purchasing premium devices with flexible displays, making advanced encapsulation solutions a key differentiator for manufacturers.

Supply chain analysis reveals increasing investments in encapsulation technology development, with material suppliers and equipment manufacturers expanding their R&D efforts to meet growing demand. The market for encapsulation materials alone is projected to grow at a CAGR of 28% through 2027, highlighting the critical importance of this component in the flexible OLED ecosystem.

Consumer preference trends indicate growing acceptance of flexible display technology, with willingness to pay premium prices for devices featuring advanced flexible displays increasing by 22% year-over-year. This trend is particularly pronounced in the high-end smartphone and wearable segments, where design differentiation and user experience innovations drive purchasing decisions.

Current Standards and Technical Challenges in OLED Encapsulation

The flexible OLED encapsulation industry currently faces a fragmented standards landscape, with several organizations developing relevant specifications. The International Electrotechnical Commission (IEC) has established standards such as IEC 62341 series specifically for OLED displays, with sections addressing encapsulation requirements and testing methodologies. Meanwhile, the Society for Information Display (SID) provides technical guidelines focusing on barrier performance metrics for flexible displays.

ASTM International has developed testing protocols for water vapor transmission rates (WVTR) and oxygen transmission rates (OTR) that are critical for evaluating encapsulation effectiveness. These include ASTM F1249 for WVTR measurement and ASTM D3985 for OTR assessment, though these standards were not originally designed for the ultra-high barrier requirements of OLEDs.

The technical challenges in OLED encapsulation are substantial and multifaceted. The primary challenge remains achieving consistently low WVTR values below 10^-6 g/m²/day while maintaining flexibility. Current testing equipment struggles to accurately measure such low permeation rates, creating verification difficulties. This measurement limitation represents a significant barrier to standardization efforts.

Mechanical durability presents another major challenge, as encapsulation layers must withstand thousands of bending cycles without developing microcracks that compromise barrier properties. The industry lacks standardized testing protocols for evaluating this critical aspect of flexible encapsulation performance under dynamic conditions.

Temperature and humidity resistance standards are also inadequate for next-generation flexible OLEDs. While IEC 60068 provides environmental testing guidelines, specific parameters for flexible OLED encapsulation under extreme conditions remain undefined. This gap is particularly problematic for automotive and outdoor applications where devices experience significant temperature fluctuations.

Edge sealing represents another standardization challenge, with no unified approach for evaluating edge permeation in flexible displays. This is critical as edge effects often dominate overall device failure rates in commercial products.

Manufacturing consistency poses additional difficulties, as current standards do not adequately address process validation for high-volume production of encapsulation systems. The industry needs standardized methodologies to ensure batch-to-batch consistency in barrier properties across large substrate areas.

Accelerated lifetime testing standards also remain underdeveloped. While JEDEC standards exist for general electronic component reliability, specific protocols for predicting long-term encapsulation performance in flexible OLEDs are lacking, creating uncertainty in lifetime predictions.

ASTM International has developed testing protocols for water vapor transmission rates (WVTR) and oxygen transmission rates (OTR) that are critical for evaluating encapsulation effectiveness. These include ASTM F1249 for WVTR measurement and ASTM D3985 for OTR assessment, though these standards were not originally designed for the ultra-high barrier requirements of OLEDs.

The technical challenges in OLED encapsulation are substantial and multifaceted. The primary challenge remains achieving consistently low WVTR values below 10^-6 g/m²/day while maintaining flexibility. Current testing equipment struggles to accurately measure such low permeation rates, creating verification difficulties. This measurement limitation represents a significant barrier to standardization efforts.

Mechanical durability presents another major challenge, as encapsulation layers must withstand thousands of bending cycles without developing microcracks that compromise barrier properties. The industry lacks standardized testing protocols for evaluating this critical aspect of flexible encapsulation performance under dynamic conditions.

Temperature and humidity resistance standards are also inadequate for next-generation flexible OLEDs. While IEC 60068 provides environmental testing guidelines, specific parameters for flexible OLED encapsulation under extreme conditions remain undefined. This gap is particularly problematic for automotive and outdoor applications where devices experience significant temperature fluctuations.

Edge sealing represents another standardization challenge, with no unified approach for evaluating edge permeation in flexible displays. This is critical as edge effects often dominate overall device failure rates in commercial products.

Manufacturing consistency poses additional difficulties, as current standards do not adequately address process validation for high-volume production of encapsulation systems. The industry needs standardized methodologies to ensure batch-to-batch consistency in barrier properties across large substrate areas.

Accelerated lifetime testing standards also remain underdeveloped. While JEDEC standards exist for general electronic component reliability, specific protocols for predicting long-term encapsulation performance in flexible OLEDs are lacking, creating uncertainty in lifetime predictions.

Current Encapsulation Solutions and Certification Processes

01 Multi-layer barrier structures for OLED encapsulation

Multi-layer barrier structures are used to protect flexible OLEDs from moisture and oxygen penetration. These structures typically consist of alternating inorganic and organic layers that provide effective barrier properties while maintaining flexibility. The inorganic layers (such as metal oxides) provide the primary barrier function, while the organic layers help to decouple defects between the inorganic layers and improve flexibility. This approach significantly enhances the lifetime and reliability of flexible OLED devices.- Multi-layer encapsulation structures for flexible OLEDs: Multi-layer encapsulation structures are used to protect flexible OLEDs from moisture and oxygen penetration while maintaining flexibility. These structures typically consist of alternating inorganic barrier layers (such as silicon nitride, aluminum oxide) and organic buffer layers. The inorganic layers provide excellent barrier properties while the organic layers accommodate bending stress and prevent crack propagation, resulting in improved device lifetime and mechanical durability.

- Thin-film encapsulation techniques for flexible displays: Thin-film encapsulation (TFE) techniques are specifically designed for flexible OLED applications where traditional rigid encapsulation methods cannot be used. These techniques involve depositing ultra-thin barrier films directly onto the OLED device using methods such as atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD). TFE provides excellent barrier properties against moisture and oxygen while maintaining the flexibility required for bendable displays.

- Edge sealing methods for flexible OLED encapsulation: Edge sealing methods are critical for preventing lateral diffusion of moisture and oxygen into flexible OLED devices. These techniques involve applying specialized sealants or barrier structures around the perimeter of the display to create a complete encapsulation system. Advanced edge sealing approaches include laser sealing, UV-curable adhesives, and hybrid organic-inorganic materials that maintain flexibility while providing excellent barrier properties at the vulnerable edges of the device.

- Hybrid encapsulation using inorganic-organic materials: Hybrid encapsulation approaches combine the advantages of both inorganic and organic materials to create effective barriers for flexible OLEDs. Inorganic materials (like metal oxides) provide excellent barrier properties against moisture and oxygen, while organic materials (like polymers) add flexibility and stress-relieving properties. These hybrid structures can be deposited using various techniques including solution processing, vapor deposition, and lamination methods, resulting in encapsulation layers that maintain performance under repeated bending.

- Self-healing encapsulation materials for flexible OLEDs: Self-healing encapsulation materials represent an innovative approach to flexible OLED protection. These materials can autonomously repair microcracks or defects that form during bending or flexing operations. The self-healing mechanism is typically based on dynamic chemical bonds, phase-change materials, or encapsulated healing agents that are released upon damage. This technology significantly improves the longevity of flexible OLEDs by maintaining barrier integrity even after repeated mechanical stress.

02 Thin-film encapsulation techniques

Thin-film encapsulation (TFE) is a key technology for flexible OLEDs that eliminates the need for rigid glass encapsulation. This technique involves depositing ultra-thin barrier films directly onto the OLED device using methods such as atomic layer deposition (ALD) or chemical vapor deposition (CVD). TFE provides excellent barrier properties against moisture and oxygen while maintaining the flexibility of the device. The thinness of these films also contributes to the overall thinness and lightness of flexible OLED displays.Expand Specific Solutions03 Edge sealing methods for flexible OLEDs

Edge sealing is critical for preventing lateral ingress of moisture and oxygen in flexible OLED devices. Various methods are employed, including the use of specialized adhesives, frit sealing, and laser welding techniques. These edge sealing approaches must maintain flexibility while providing a complete hermetic seal around the perimeter of the device. Advanced edge sealing technologies incorporate moisture-absorbing materials to further protect the sensitive OLED components from environmental degradation.Expand Specific Solutions04 Hybrid encapsulation systems

Hybrid encapsulation systems combine different barrier technologies to achieve optimal protection for flexible OLEDs. These systems may incorporate thin-film barriers, laminated films, and desiccant materials in a single encapsulation solution. The combination of different barrier approaches provides redundant protection against moisture and oxygen while addressing the mechanical challenges of flexible displays. Hybrid systems often include self-healing materials that can repair minor damage to maintain barrier integrity during repeated flexing.Expand Specific Solutions05 Flexible substrate and encapsulation integration

The integration of flexible substrates with encapsulation layers is essential for creating truly flexible OLED devices. This approach involves careful material selection and process optimization to ensure compatibility between the substrate and encapsulation layers. Materials such as polyimide, ultra-thin glass, and metal foils are commonly used as flexible substrates. The encapsulation process must be designed to maintain the mechanical properties of these substrates while providing effective barrier protection. Advanced techniques include roll-to-roll processing for high-volume manufacturing of flexible encapsulated OLEDs.Expand Specific Solutions

Key Industry Players and Certification Bodies

The flexible OLED encapsulation market is currently in a growth phase, with an estimated market size exceeding $2 billion and projected to expand significantly as demand for foldable displays increases. The technology maturity varies across players, with Asian manufacturers leading the field. BOE Technology Group and LG Display have established themselves as frontrunners with advanced thin-film encapsulation technologies and significant patent portfolios. China Star Optoelectronics (TCL) and Visionox are rapidly advancing their capabilities, particularly in barrier film technologies. Applied Materials and LG Chem provide critical manufacturing equipment and materials. The competitive landscape is characterized by intensive R&D investment in barrier performance improvement, with standardization efforts primarily led by industry consortia rather than formal regulatory bodies, as companies balance proprietary technology protection with the need for industry-wide compatibility.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered a hybrid encapsulation technology for flexible OLEDs that combines atomic layer deposition (ALD) of Al2O3 barriers with organic interlayers. Their process meets the IEC 61747 standards for liquid crystal and solid-state display devices and adheres to GB/T 38464-2020 Chinese national standards for flexible display devices. BOE's encapsulation technology utilizes plasma-enhanced chemical vapor deposition (PECVD) to create alternating inorganic/organic layers with a total thickness under 10μm[2], allowing for a bend radius of less than 1mm while maintaining barrier properties. Their encapsulation materials and processes comply with RoHS and REACH regulations, ensuring environmental safety. BOE has also obtained certification under ISO 14001:2015 for environmental management systems and ISO 50001 for energy management systems in their manufacturing facilities. Their encapsulation technology has been tested according to IEC 62715-6-1 guidelines for flexible display devices mechanical reliability[4].

Strengths: Excellent flexibility performance with minimal thickness; comprehensive compliance with both international and Chinese national standards; strong integration with mass production capabilities. Weaknesses: Relatively newer to the market compared to Korean competitors; potential challenges with long-term reliability under extreme environmental conditions; higher initial capital investment required for ALD equipment.

LG Display Co., Ltd.

Technical Solution: LG Display has developed advanced thin-film encapsulation (TFE) technology for flexible OLED displays that meets IEC 62341-6-3 standards for organic light emitting diode displays. Their multi-layer encapsulation approach combines inorganic layers (typically SiNx or Al2O3) with organic layers to create an effective moisture and oxygen barrier. LG's technology has been certified to achieve WVTR (Water Vapor Transmission Rate) levels below 10^-6 g/m²/day[1], meeting the stringent requirements of MIL-STD-810G for environmental engineering considerations. Their encapsulation process has also received UL 8752 certification for OLED durability and reliability standards, demonstrating compliance with photobiological safety standards (IEC 62471)[3]. LG Display implements quality management systems compliant with ISO 9001 and ISO 14001 for environmental management in their manufacturing processes.

Strengths: Superior barrier properties with industry-leading WVTR performance; comprehensive certification portfolio including military-grade standards; established mass production capabilities. Weaknesses: Higher manufacturing costs compared to conventional encapsulation; complex multi-layer structure requires sophisticated deposition equipment; potential for mechanical stress at layer interfaces during repeated flexing.

Critical Patents and Technical Literature on OLED Encapsulation

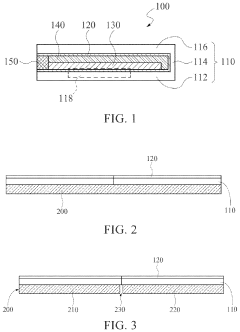

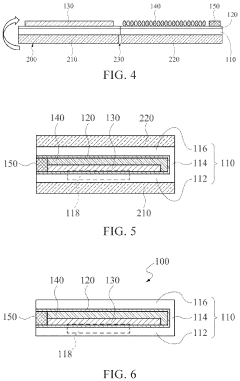

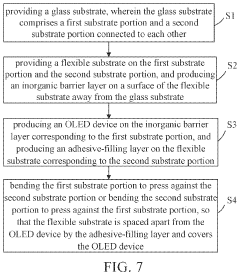

Flexible OLED substrate and encapsulation method thereof

PatentActiveUS20230200111A1

Innovation

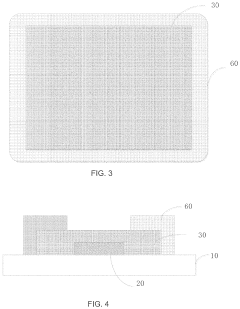

- A flexible OLED substrate with an inorganic barrier layer and an adhesive-filling layer, along with a border adhesive, is used to enclose the OLED device, where the inorganic barrier layer is made of materials like aluminum oxide or silicon oxide, and the adhesive-filling and border adhesives provide additional water-resistant properties, simplifying the encapsulation process and enhancing protection.

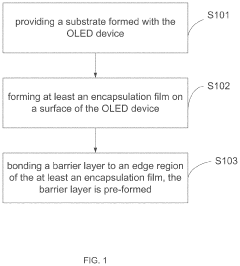

Encapsulation method of organic light emitting diode device and encapsulation structure encapsulated using same

PatentActiveUS20200083476A1

Innovation

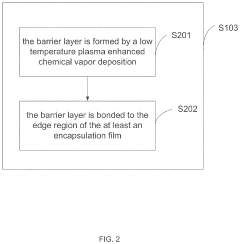

- A method involving a pre-formed ring-shaped barrier layer made of inorganic materials like silicon nitride or aluminum oxide, bonded to the edge region of the encapsulation film using low temperature plasma enhanced chemical vapor deposition and rolling or vacuum bonding processes, which improves moisture and oxygen resistance.

Regulatory Compliance Framework for Flexible Display Technologies

The regulatory landscape for flexible OLED encapsulation technologies encompasses a complex framework of international, regional, and industry-specific standards that manufacturers must navigate to ensure market access and consumer safety. At the international level, the International Electrotechnical Commission (IEC) has established several standards relevant to flexible display technologies, including IEC 62341 for OLED displays and IEC 61747 for flexible display modules, which address electrical safety, performance metrics, and reliability testing methodologies.

The Underwriters Laboratories (UL) certification plays a crucial role in the North American market, with UL 8752 specifically addressing organic light-emitting diode displays. This standard evaluates encapsulation integrity, moisture resistance, and overall durability of flexible OLED components. Similarly, in Europe, compliance with the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations is mandatory, imposing strict limitations on potentially harmful substances in electronic components including encapsulation materials.

For flexible OLED encapsulation specifically, ASTM F1249 and ASTM E96 standards are frequently referenced to measure water vapor transmission rates (WVTR), a critical parameter for evaluating barrier performance. The JEDEC standard JESD22-A101 for temperature cycling and JESD22-A110 for highly accelerated temperature and humidity stress testing (HAST) are essential for validating encapsulation durability under extreme environmental conditions.

In the Asian market, particularly in Japan and South Korea where many OLED manufacturers are based, the Japan Electronics and Information Technology Industries Association (JEITA) and the Korean Agency for Technology and Standards (KATS) have developed region-specific requirements for flexible display technologies. These include detailed specifications for encapsulation materials, testing protocols for mechanical flexibility, and environmental impact assessments.

Industry consortia such as the Flexible Display Center (FDC) and the Society for Information Display (SID) have also established technical guidelines and best practices for flexible OLED encapsulation, though these are not legally binding standards. Nevertheless, they often inform the development of formal certification requirements and are widely respected benchmarks within the industry.

Emerging certification frameworks are beginning to address the unique challenges of flexible displays, including the development of specialized tests for folding endurance, bending radius limitations, and encapsulation integrity under repeated mechanical stress. The International Organization for Standardization (ISO) is currently developing standards specifically for flexible electronic devices under its Technical Committee 119, which will likely include provisions for encapsulation technologies.

The Underwriters Laboratories (UL) certification plays a crucial role in the North American market, with UL 8752 specifically addressing organic light-emitting diode displays. This standard evaluates encapsulation integrity, moisture resistance, and overall durability of flexible OLED components. Similarly, in Europe, compliance with the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations is mandatory, imposing strict limitations on potentially harmful substances in electronic components including encapsulation materials.

For flexible OLED encapsulation specifically, ASTM F1249 and ASTM E96 standards are frequently referenced to measure water vapor transmission rates (WVTR), a critical parameter for evaluating barrier performance. The JEDEC standard JESD22-A101 for temperature cycling and JESD22-A110 for highly accelerated temperature and humidity stress testing (HAST) are essential for validating encapsulation durability under extreme environmental conditions.

In the Asian market, particularly in Japan and South Korea where many OLED manufacturers are based, the Japan Electronics and Information Technology Industries Association (JEITA) and the Korean Agency for Technology and Standards (KATS) have developed region-specific requirements for flexible display technologies. These include detailed specifications for encapsulation materials, testing protocols for mechanical flexibility, and environmental impact assessments.

Industry consortia such as the Flexible Display Center (FDC) and the Society for Information Display (SID) have also established technical guidelines and best practices for flexible OLED encapsulation, though these are not legally binding standards. Nevertheless, they often inform the development of formal certification requirements and are widely respected benchmarks within the industry.

Emerging certification frameworks are beginning to address the unique challenges of flexible displays, including the development of specialized tests for folding endurance, bending radius limitations, and encapsulation integrity under repeated mechanical stress. The International Organization for Standardization (ISO) is currently developing standards specifically for flexible electronic devices under its Technical Committee 119, which will likely include provisions for encapsulation technologies.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible OLED encapsulation technologies represents a critical consideration as these displays become increasingly prevalent in consumer electronics. Traditional encapsulation methods often rely on materials with significant ecological footprints, including rare earth elements and petroleum-based compounds that pose end-of-life disposal challenges. The thin-film barrier layers commonly used in flexible OLED encapsulation frequently contain materials that are energy-intensive to produce and difficult to recycle.

Manufacturing processes for flexible OLED encapsulation typically require high-temperature vacuum deposition and plasma-enhanced chemical vapor deposition (PECVD), consuming substantial energy and potentially releasing greenhouse gases. The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify these environmental impacts from raw material extraction through manufacturing to disposal, with several major display manufacturers publishing sustainability reports that specifically address encapsulation technologies.

Water usage represents another significant environmental concern, as ultra-pure water is required in substantial quantities for cleaning processes during encapsulation layer deposition. Some estimates suggest that producing a single square meter of barrier film may require hundreds of liters of purified water, creating potential sustainability challenges in water-stressed regions where manufacturing facilities operate.

Emerging regulations, particularly in the European Union under the Waste Electrical and Electronic Equipment (WEEE) Directive and Restriction of Hazardous Substances (RoHS) Directive, are driving manufacturers to develop more environmentally friendly encapsulation solutions. These include bio-based barrier materials, water-based deposition processes, and designs that facilitate easier separation of components for recycling at end-of-life.

Several promising sustainable alternatives are under development, including atomic layer deposition (ALD) techniques that use significantly less material while achieving comparable barrier properties. Research into graphene-based encapsulation shows potential for creating ultra-thin barriers with excellent performance using carbon-based materials that may have lower environmental impact than traditional metal oxides and rare earth compounds.

Industry consortia such as the Sustainable Display Initiative (SDI) are establishing voluntary standards for environmental performance in display technologies, including specific metrics for encapsulation materials and processes. These efforts aim to create industry-wide benchmarks for reducing carbon footprints, minimizing hazardous material usage, and improving recyclability of flexible OLED components, with encapsulation technologies receiving particular attention due to their complex material composition.

Manufacturing processes for flexible OLED encapsulation typically require high-temperature vacuum deposition and plasma-enhanced chemical vapor deposition (PECVD), consuming substantial energy and potentially releasing greenhouse gases. The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify these environmental impacts from raw material extraction through manufacturing to disposal, with several major display manufacturers publishing sustainability reports that specifically address encapsulation technologies.

Water usage represents another significant environmental concern, as ultra-pure water is required in substantial quantities for cleaning processes during encapsulation layer deposition. Some estimates suggest that producing a single square meter of barrier film may require hundreds of liters of purified water, creating potential sustainability challenges in water-stressed regions where manufacturing facilities operate.

Emerging regulations, particularly in the European Union under the Waste Electrical and Electronic Equipment (WEEE) Directive and Restriction of Hazardous Substances (RoHS) Directive, are driving manufacturers to develop more environmentally friendly encapsulation solutions. These include bio-based barrier materials, water-based deposition processes, and designs that facilitate easier separation of components for recycling at end-of-life.

Several promising sustainable alternatives are under development, including atomic layer deposition (ALD) techniques that use significantly less material while achieving comparable barrier properties. Research into graphene-based encapsulation shows potential for creating ultra-thin barriers with excellent performance using carbon-based materials that may have lower environmental impact than traditional metal oxides and rare earth compounds.

Industry consortia such as the Sustainable Display Initiative (SDI) are establishing voluntary standards for environmental performance in display technologies, including specific metrics for encapsulation materials and processes. These efforts aim to create industry-wide benchmarks for reducing carbon footprints, minimizing hazardous material usage, and improving recyclability of flexible OLED components, with encapsulation technologies receiving particular attention due to their complex material composition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!