The Effect of Electrode Coatings on Flexible OLED Encapsulation Efficacy

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Background and Objectives

Flexible Organic Light-Emitting Diode (OLED) technology has evolved significantly over the past two decades, transitioning from laboratory curiosity to commercial reality. The journey began in the late 1980s with the discovery of electroluminescence in organic materials, followed by the development of the first practical OLED devices in the 1990s. The progression toward flexible displays gained momentum in the early 2000s, with significant breakthroughs in materials science and manufacturing techniques enabling the creation of bendable and foldable displays.

The encapsulation of flexible OLEDs represents a critical technological challenge that has shaped the industry's development trajectory. Traditional rigid glass encapsulation methods proved incompatible with the flexibility requirements, necessitating innovative approaches to protect the highly moisture and oxygen-sensitive organic materials while maintaining mechanical flexibility. This technological evolution has been driven by the increasing consumer demand for more durable, lightweight, and form-factor versatile display technologies.

Current technological trends point toward multi-layer thin-film encapsulation (TFE) systems that combine inorganic barrier layers with organic interlayers. The electrode-encapsulation interface has emerged as a particularly critical area of focus, as electrode materials and their coatings significantly influence the overall barrier performance and device longevity. Recent research indicates that surface modifications of electrodes can dramatically alter the adhesion, uniformity, and defect density of subsequent encapsulation layers.

The primary objective of this technical research is to comprehensively evaluate how various electrode coating technologies affect the efficacy of flexible OLED encapsulation systems. Specifically, we aim to investigate the relationship between electrode surface properties and encapsulation performance metrics including water vapor transmission rate (WVTR), oxygen transmission rate (OTR), and mechanical durability under repeated flexing conditions.

Secondary objectives include identifying optimal electrode coating materials and processes that can enhance encapsulation performance while remaining compatible with existing manufacturing infrastructure. We also seek to establish quantitative correlations between electrode surface characteristics (such as roughness, hydrophobicity, and chemical functionality) and key encapsulation parameters to develop predictive models for future material development.

The long-term technological goal is to enable the next generation of flexible OLED devices with significantly improved lifetimes under real-world usage conditions, including exposure to varying humidity levels, temperature fluctuations, and mechanical stress. This research directly supports the industry's roadmap toward fully flexible, rollable, and even stretchable display technologies that maintain the visual performance advantages of OLED technology while overcoming current limitations in environmental stability.

The encapsulation of flexible OLEDs represents a critical technological challenge that has shaped the industry's development trajectory. Traditional rigid glass encapsulation methods proved incompatible with the flexibility requirements, necessitating innovative approaches to protect the highly moisture and oxygen-sensitive organic materials while maintaining mechanical flexibility. This technological evolution has been driven by the increasing consumer demand for more durable, lightweight, and form-factor versatile display technologies.

Current technological trends point toward multi-layer thin-film encapsulation (TFE) systems that combine inorganic barrier layers with organic interlayers. The electrode-encapsulation interface has emerged as a particularly critical area of focus, as electrode materials and their coatings significantly influence the overall barrier performance and device longevity. Recent research indicates that surface modifications of electrodes can dramatically alter the adhesion, uniformity, and defect density of subsequent encapsulation layers.

The primary objective of this technical research is to comprehensively evaluate how various electrode coating technologies affect the efficacy of flexible OLED encapsulation systems. Specifically, we aim to investigate the relationship between electrode surface properties and encapsulation performance metrics including water vapor transmission rate (WVTR), oxygen transmission rate (OTR), and mechanical durability under repeated flexing conditions.

Secondary objectives include identifying optimal electrode coating materials and processes that can enhance encapsulation performance while remaining compatible with existing manufacturing infrastructure. We also seek to establish quantitative correlations between electrode surface characteristics (such as roughness, hydrophobicity, and chemical functionality) and key encapsulation parameters to develop predictive models for future material development.

The long-term technological goal is to enable the next generation of flexible OLED devices with significantly improved lifetimes under real-world usage conditions, including exposure to varying humidity levels, temperature fluctuations, and mechanical stress. This research directly supports the industry's roadmap toward fully flexible, rollable, and even stretchable display technologies that maintain the visual performance advantages of OLED technology while overcoming current limitations in environmental stability.

Market Analysis for Electrode-Coated Flexible OLEDs

The flexible OLED market has experienced remarkable growth in recent years, with electrode-coated flexible OLEDs emerging as a pivotal technology in display innovation. Current market valuations indicate that the flexible OLED sector reached approximately 18 billion USD in 2022, with projections suggesting growth to 30 billion USD by 2027, representing a compound annual growth rate of 10.8%.

Consumer electronics remains the dominant application sector, accounting for over 65% of the total market share. Smartphones and wearable devices are the primary drivers, with premium smartphone manufacturers increasingly adopting flexible OLED technology to enable foldable and rollable display designs. The wearable segment shows particularly strong momentum, with smartwatches and fitness trackers incorporating curved displays growing at 15% annually.

Regional analysis reveals that East Asia continues to dominate both production and consumption, with South Korea, China, and Japan collectively representing 78% of global manufacturing capacity. However, North American and European markets are showing accelerated adoption rates in premium consumer segments, particularly in automotive displays and high-end consumer electronics.

The electrode coating segment specifically has seen technological differentiation becoming a key competitive factor. Enhanced encapsulation efficacy through advanced electrode coatings has become a critical selling point, as it directly impacts device longevity and performance reliability. Market research indicates consumers are willing to pay a 15-20% premium for devices with demonstrably longer lifespans and improved durability against environmental factors.

Supply chain analysis reveals increasing vertical integration among major manufacturers, with companies investing in proprietary electrode coating technologies to differentiate their offerings. This trend has created entry barriers for smaller players but has also stimulated specialized innovation in coating materials and application techniques.

Demand forecasting models suggest that electrode coating technologies that effectively extend OLED lifespan beyond 30,000 hours while maintaining flexibility will capture significant market share. The automotive sector represents the fastest-growing potential market, with projected annual growth rates of 22% for flexible OLED integration, particularly in dashboard and entertainment systems requiring enhanced durability.

Customer feedback analysis indicates that transparency in technical specifications regarding encapsulation efficacy is becoming increasingly important in purchase decisions, particularly in premium market segments. This suggests a market opportunity for standardized testing and certification of electrode coating performance in flexible OLED applications.

Consumer electronics remains the dominant application sector, accounting for over 65% of the total market share. Smartphones and wearable devices are the primary drivers, with premium smartphone manufacturers increasingly adopting flexible OLED technology to enable foldable and rollable display designs. The wearable segment shows particularly strong momentum, with smartwatches and fitness trackers incorporating curved displays growing at 15% annually.

Regional analysis reveals that East Asia continues to dominate both production and consumption, with South Korea, China, and Japan collectively representing 78% of global manufacturing capacity. However, North American and European markets are showing accelerated adoption rates in premium consumer segments, particularly in automotive displays and high-end consumer electronics.

The electrode coating segment specifically has seen technological differentiation becoming a key competitive factor. Enhanced encapsulation efficacy through advanced electrode coatings has become a critical selling point, as it directly impacts device longevity and performance reliability. Market research indicates consumers are willing to pay a 15-20% premium for devices with demonstrably longer lifespans and improved durability against environmental factors.

Supply chain analysis reveals increasing vertical integration among major manufacturers, with companies investing in proprietary electrode coating technologies to differentiate their offerings. This trend has created entry barriers for smaller players but has also stimulated specialized innovation in coating materials and application techniques.

Demand forecasting models suggest that electrode coating technologies that effectively extend OLED lifespan beyond 30,000 hours while maintaining flexibility will capture significant market share. The automotive sector represents the fastest-growing potential market, with projected annual growth rates of 22% for flexible OLED integration, particularly in dashboard and entertainment systems requiring enhanced durability.

Customer feedback analysis indicates that transparency in technical specifications regarding encapsulation efficacy is becoming increasingly important in purchase decisions, particularly in premium market segments. This suggests a market opportunity for standardized testing and certification of electrode coating performance in flexible OLED applications.

Current Challenges in Electrode Coating Technologies

Despite significant advancements in flexible OLED technology, electrode coating technologies continue to present substantial challenges that impede optimal encapsulation efficacy. The primary obstacle remains the inherent conflict between flexibility requirements and barrier properties. Traditional rigid electrode materials like indium tin oxide (ITO) offer excellent transparency and conductivity but crack under bending stress, creating pathways for moisture and oxygen penetration that accelerate device degradation.

Alternative transparent conductive materials such as silver nanowires, carbon nanotubes, and PEDOT:PSS demonstrate improved flexibility but suffer from inconsistent electrical conductivity across large areas and inadequate long-term stability under environmental stressors. The trade-off between transparency, conductivity, and flexibility continues to challenge manufacturers seeking to optimize device performance.

Deposition techniques present another significant hurdle. Conventional methods like sputtering and thermal evaporation can damage underlying organic layers through high-energy particle bombardment or excessive heat. Solution-based coating methods offer gentler processing but struggle with uniformity and thickness control, particularly at production scales. This inconsistency leads to variable encapsulation performance across the device area and between production batches.

Interface engineering between electrode coatings and adjacent layers represents a critical challenge. Poor adhesion between these layers creates microscopic voids that become moisture ingress pathways. Chemical incompatibility between electrode materials and encapsulation layers can trigger degradation reactions that compromise barrier integrity over time. The development of compatible interface materials that maintain strong adhesion under repeated flexing remains elusive.

Environmental stability poses persistent difficulties, as many promising electrode materials demonstrate excellent initial performance but degrade rapidly under operational conditions. Silver-based electrodes, while highly conductive and flexible, suffer from oxidation and sulfidation in ambient environments. Carbon-based alternatives show better chemical stability but inferior electrical properties that drift over time, particularly when subjected to temperature and humidity fluctuations.

Manufacturing scalability represents perhaps the most significant barrier to commercialization. Laboratory-scale coating techniques that produce excellent results often fail to translate to high-throughput production environments. Roll-to-roll compatible electrode coating processes frequently result in defects, particulate contamination, and thickness variations that compromise encapsulation integrity. The cost-performance balance remains unfavorable for many advanced electrode materials, with alternatives to ITO typically requiring complex processing steps that increase production costs substantially.

Alternative transparent conductive materials such as silver nanowires, carbon nanotubes, and PEDOT:PSS demonstrate improved flexibility but suffer from inconsistent electrical conductivity across large areas and inadequate long-term stability under environmental stressors. The trade-off between transparency, conductivity, and flexibility continues to challenge manufacturers seeking to optimize device performance.

Deposition techniques present another significant hurdle. Conventional methods like sputtering and thermal evaporation can damage underlying organic layers through high-energy particle bombardment or excessive heat. Solution-based coating methods offer gentler processing but struggle with uniformity and thickness control, particularly at production scales. This inconsistency leads to variable encapsulation performance across the device area and between production batches.

Interface engineering between electrode coatings and adjacent layers represents a critical challenge. Poor adhesion between these layers creates microscopic voids that become moisture ingress pathways. Chemical incompatibility between electrode materials and encapsulation layers can trigger degradation reactions that compromise barrier integrity over time. The development of compatible interface materials that maintain strong adhesion under repeated flexing remains elusive.

Environmental stability poses persistent difficulties, as many promising electrode materials demonstrate excellent initial performance but degrade rapidly under operational conditions. Silver-based electrodes, while highly conductive and flexible, suffer from oxidation and sulfidation in ambient environments. Carbon-based alternatives show better chemical stability but inferior electrical properties that drift over time, particularly when subjected to temperature and humidity fluctuations.

Manufacturing scalability represents perhaps the most significant barrier to commercialization. Laboratory-scale coating techniques that produce excellent results often fail to translate to high-throughput production environments. Roll-to-roll compatible electrode coating processes frequently result in defects, particulate contamination, and thickness variations that compromise encapsulation integrity. The cost-performance balance remains unfavorable for many advanced electrode materials, with alternatives to ITO typically requiring complex processing steps that increase production costs substantially.

Existing Electrode Coating Solutions for Moisture Barriers

01 Polymer-based electrode coatings for enhanced protection

Polymer-based coatings provide effective encapsulation for electrodes, protecting them from environmental factors and extending their operational lifespan. These coatings create a barrier against moisture, chemicals, and mechanical stress while maintaining electrical conductivity. Advanced polymers can be formulated with specific properties to enhance adhesion to electrode surfaces and improve overall device performance. The encapsulation efficacy is measured by the coating's ability to prevent degradation while allowing necessary electrical functions.- Protective encapsulation materials for electrode coatings: Various materials can be used to encapsulate electrodes to protect them from environmental factors and improve their longevity. These materials include polymers, ceramics, and composite materials that form a protective barrier around the electrode. The encapsulation prevents moisture ingress, chemical degradation, and mechanical damage while maintaining electrical conductivity. Effective encapsulation materials must balance protection with minimal interference to electrode performance.

- Encapsulation techniques for battery electrodes: Specialized encapsulation techniques have been developed specifically for battery electrodes to enhance their performance and safety. These techniques include core-shell structures, conformal coatings, and multi-layer encapsulation systems that protect active materials from electrolyte degradation while allowing ion transport. The encapsulation helps prevent capacity fade, improves cycling stability, and enhances the overall battery lifespan by containing electrode expansion and contraction during charge-discharge cycles.

- Electrode coating methods for improved encapsulation efficacy: Various coating methods can significantly impact the efficacy of electrode encapsulation. Techniques such as atomic layer deposition, physical vapor deposition, electrodeposition, and solution-based coating processes offer different advantages in terms of uniformity, thickness control, and conformality. The selection of an appropriate coating method depends on the electrode material, desired properties, and application requirements. Advanced coating techniques can create pinhole-free barriers that effectively protect electrodes while maintaining their electrochemical performance.

- Nanomaterial-enhanced electrode encapsulation: Incorporating nanomaterials into electrode encapsulation systems can significantly enhance their protective properties. Nanomaterials such as graphene, carbon nanotubes, nanoparticles, and nanoscale metal oxides can be integrated into coating formulations to improve mechanical strength, thermal stability, and barrier properties. These nanomaterial-enhanced encapsulations provide superior protection against environmental factors while maintaining or improving electrode conductivity and performance. The high surface area and unique properties of nanomaterials enable thinner yet more effective protective layers.

- Testing and evaluation methods for encapsulation efficacy: Various testing and evaluation methods have been developed to assess the efficacy of electrode encapsulation. These include accelerated aging tests, environmental exposure tests, electrochemical impedance spectroscopy, and advanced imaging techniques. Testing protocols may evaluate moisture resistance, chemical stability, mechanical integrity, and electrical performance over time. Standardized methods help quantify encapsulation performance and predict long-term reliability under various operating conditions, enabling the development of more effective electrode protection strategies.

02 Ceramic and inorganic protective layers for high-temperature applications

Ceramic and inorganic materials serve as effective electrode coatings for applications requiring high-temperature stability and chemical resistance. These materials form dense, adherent layers that protect electrodes from oxidation, corrosion, and thermal degradation. The encapsulation efficacy of these coatings is particularly valuable in harsh operating environments where organic materials would fail. These protective layers can be applied through various deposition techniques to achieve optimal thickness and coverage for specific electrode configurations.Expand Specific Solutions03 Nanostructured coatings for improved electrode performance

Nanostructured coatings significantly enhance electrode encapsulation efficacy through their unique physical and chemical properties. These coatings feature controlled porosity, high surface area, and tailored composition that improve both protection and functionality. By incorporating nanomaterials such as carbon nanotubes, graphene, or metal oxide nanoparticles, these coatings can simultaneously protect electrodes while enhancing their electrochemical performance. The nano-scale architecture allows for better adhesion to electrode surfaces and more effective sealing against environmental contaminants.Expand Specific Solutions04 Multilayer encapsulation systems for enhanced barrier properties

Multilayer encapsulation systems provide superior protection for electrodes by combining complementary materials with different protective properties. These systems typically consist of alternating organic and inorganic layers that work synergistically to block moisture, oxygen, and other contaminants. The efficacy of multilayer coatings stems from their ability to provide redundant protection, where defects in one layer are compensated by adjacent layers. This approach significantly extends electrode lifespan in challenging environments and improves overall device reliability.Expand Specific Solutions05 Self-healing and responsive electrode coatings

Self-healing and responsive coatings represent an advanced approach to electrode encapsulation, offering dynamic protection that responds to environmental changes or damage. These intelligent coatings can repair microcracks, adjust permeability based on external conditions, or release protective agents when needed. The encapsulation efficacy is enhanced through mechanisms that actively maintain coating integrity rather than relying solely on initial barrier properties. These materials often incorporate stimuli-responsive polymers, microcapsules with healing agents, or materials that undergo beneficial phase changes under specific conditions.Expand Specific Solutions

Leading Companies in Flexible OLED Encapsulation

The flexible OLED encapsulation electrode coating market is currently in a growth phase, with an estimated global market size of $3-5 billion and projected annual growth of 15-20%. The technology is approaching maturity but still faces challenges in balancing flexibility with barrier properties. Leading players include Samsung Display and LG Chem, who have established advanced manufacturing capabilities for flexible OLED technologies. BOE Technology and TCL China Star Optoelectronics are rapidly advancing with significant investments in production facilities. Companies like Tianma Microelectronics and Visionox Technology are emerging as strong competitors with innovative approaches to electrode coating technologies that enhance encapsulation efficacy while maintaining flexibility.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed an innovative "Gradient Barrier System" for flexible OLED encapsulation that addresses the critical electrode-encapsulation interface. Their approach utilizes a compositionally graded transition layer between the electrode and main barrier films, gradually changing from electrode-compatible to encapsulation-compatible chemistry. BOE's electrode coating technology employs a proprietary "Nano-Anchor" surface treatment that creates nanoscale features on electrode surfaces, increasing mechanical interlocking with encapsulation materials. Their system incorporates atomic layer deposition of aluminum oxide barriers (approximately 20nm thick) alternated with specially formulated silicone-based organic layers containing reactive silane groups. These silane groups form strong chemical bonds with both the electrode surface and subsequent barrier layers. BOE has also pioneered the use of graphene oxide interlayers between electrodes and encapsulation to improve adhesion while maintaining electrical conductivity. Their latest generation technology achieves water vapor transmission rates of approximately 5×10^-6 g/m²/day while maintaining flexibility for radii down to 3mm. The system demonstrates excellent thermal stability with minimal degradation at operating temperatures up to 85°C.

Strengths: Excellent adhesion due to gradient composition approach; good balance of performance and manufacturing cost; superior thermal stability compared to many competitors. Weaknesses: Slightly less flexible than Samsung's solution; complex manufacturing process requires precise control of multiple deposition parameters; moderate scalability challenges for very large panels.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary "Hybrid Barrier Film" technology for flexible OLED encapsulation that focuses on optimizing electrode-encapsulation interfaces. Their approach utilizes a combination of inorganic barrier layers (typically aluminum oxide and silicon nitride) with specially formulated organic interlayers that enhance adhesion to electrode materials. LG's electrode coating technology incorporates surface-modified ITO (Indium Tin Oxide) with nanoscale roughness control and functional adhesion promoters to create strong chemical bonds with encapsulation layers. Their process includes plasma treatment of electrode surfaces to introduce functional groups that form covalent bonds with the first encapsulation layer. LG Chem has also developed specialized "Hybrid Passivation Technology" that combines atomic layer deposition for inorganic barriers with solution-processed organic layers containing reactive end groups designed to chemically bond with electrode materials. This system achieves water vapor transmission rates of approximately 10^-5 g/m²/day while maintaining flexibility for radii down to 2mm. Recent advancements include self-healing polymer layers that can repair microcracks formed during bending.

Strengths: Excellent adhesion between electrode and encapsulation layers due to chemical bonding approach; cost-effective manufacturing process compared to competitors; self-healing capability in newer generations. Weaknesses: Slightly higher water vapor transmission rates than Samsung's solution; limited flexibility at extreme bending radii; requires precise control of surface chemistry during manufacturing.

Key Patents in Electrode Coating for OLED Encapsulation

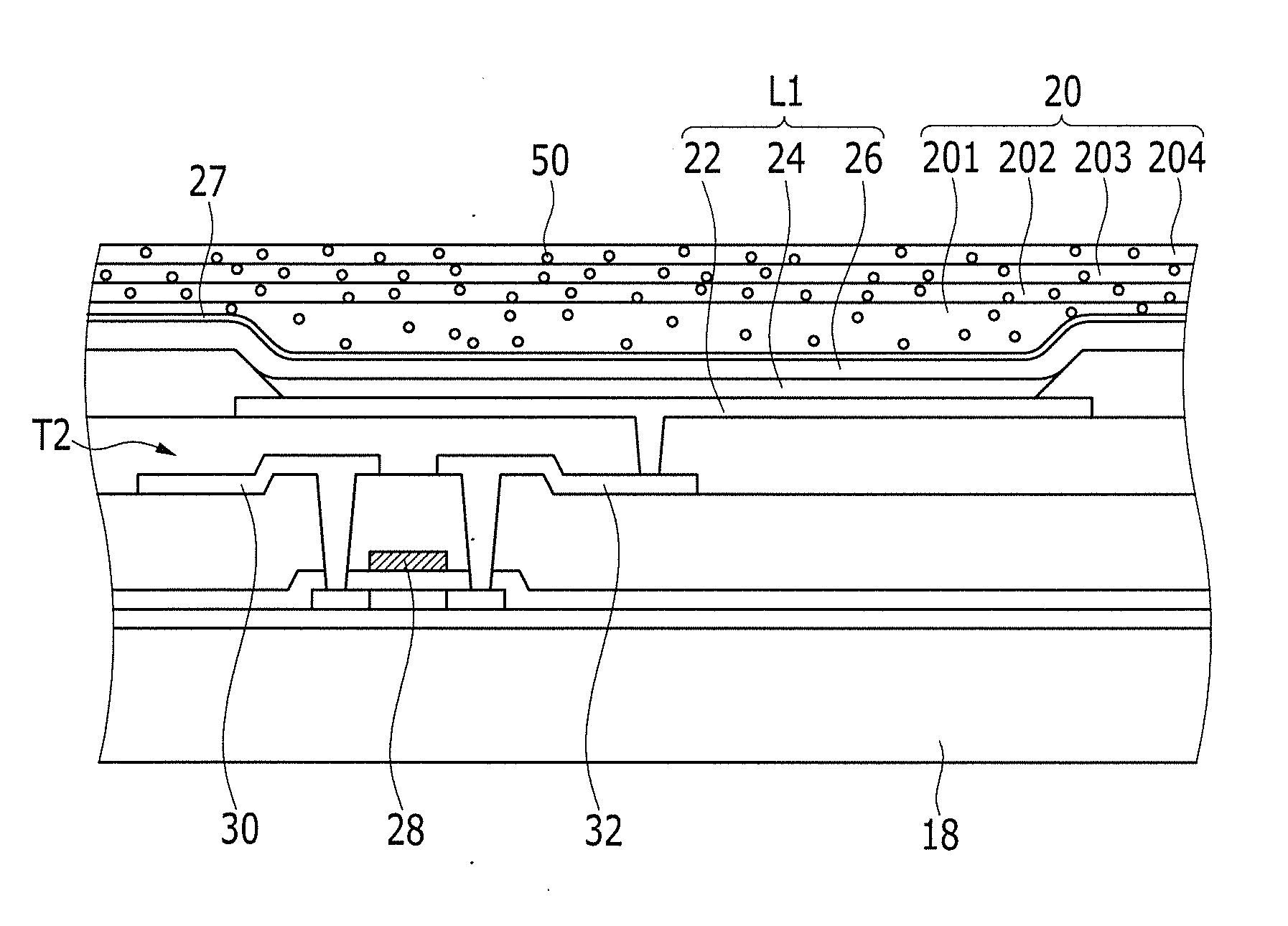

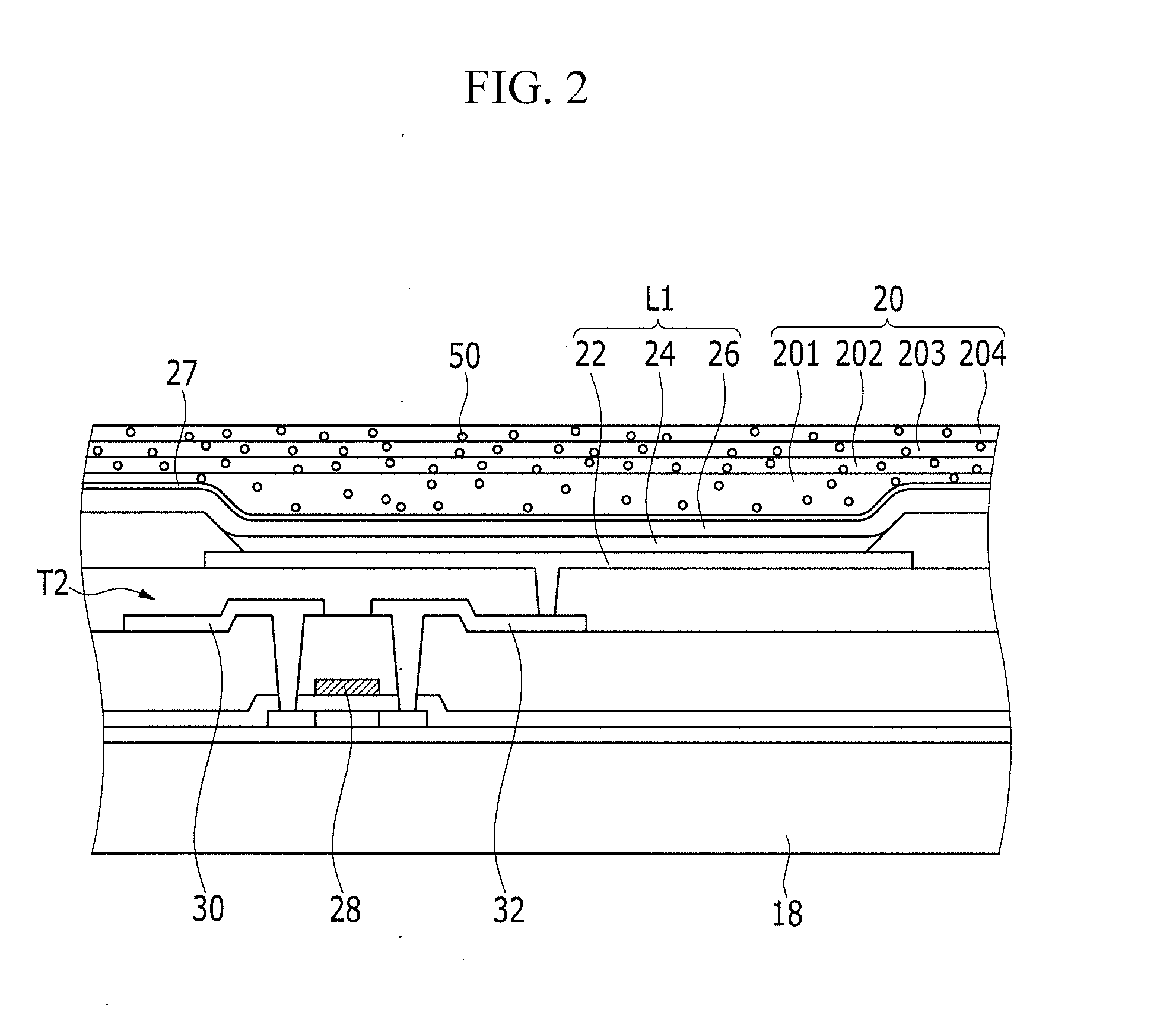

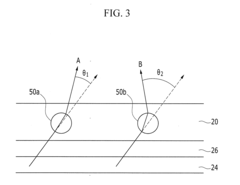

Organic light emitting diode display

PatentActiveUS20120256218A1

Innovation

- Incorporating scattering materials with diameters larger than 1/8 of the emitted light wavelength and refractive indices between 1.5 and 3.0 into the thin film encapsulation layer, specifically in organic and inorganic layers, to scatter light and improve transmission.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in flexible OLED technology represents a growing concern as production volumes increase globally. Traditional encapsulation methods often rely on materials with significant ecological footprints, including rare earth elements, heavy metals, and petroleum-based polymers that pose end-of-life disposal challenges.

Electrode coatings, particularly those containing indium tin oxide (ITO), present notable environmental concerns. The mining and processing of indium is energy-intensive and generates substantial waste. Studies indicate that for every kilogram of indium produced, approximately 600 kg of CO2 equivalent emissions are generated. Alternative electrode coatings being developed, such as silver nanowires and graphene-based materials, show promise for reduced environmental impact while maintaining encapsulation efficacy.

The manufacturing processes for encapsulation materials contribute significantly to their environmental footprint. Thin-film deposition techniques like atomic layer deposition (ALD) and chemical vapor deposition (CVD) consume considerable energy and often utilize precursor chemicals with high global warming potential. Recent advancements in low-temperature plasma-enhanced processes have demonstrated energy reductions of 30-45% while maintaining barrier properties.

Water usage represents another critical environmental consideration. Traditional encapsulation processes can require up to 15 liters of ultra-pure water per square meter of display produced. Newer dry encapsulation techniques being tested with specialized electrode coatings have shown potential to reduce water consumption by up to 80% while improving moisture barrier properties.

End-of-life considerations reveal that most current encapsulation systems create non-recyclable composite materials. The multi-layer structures necessary for effective encapsulation, particularly when combined with specialized electrode coatings, often render separation and recovery of valuable materials economically unfeasible. This contributes to electronic waste challenges, with less than 20% of display materials currently being recovered through recycling processes.

Regulatory frameworks are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain materials in electronic displays. Future regulations may specifically target encapsulation materials with high environmental impact, potentially accelerating the transition to greener alternatives that maintain or improve upon current encapsulation efficacy.

Electrode coatings, particularly those containing indium tin oxide (ITO), present notable environmental concerns. The mining and processing of indium is energy-intensive and generates substantial waste. Studies indicate that for every kilogram of indium produced, approximately 600 kg of CO2 equivalent emissions are generated. Alternative electrode coatings being developed, such as silver nanowires and graphene-based materials, show promise for reduced environmental impact while maintaining encapsulation efficacy.

The manufacturing processes for encapsulation materials contribute significantly to their environmental footprint. Thin-film deposition techniques like atomic layer deposition (ALD) and chemical vapor deposition (CVD) consume considerable energy and often utilize precursor chemicals with high global warming potential. Recent advancements in low-temperature plasma-enhanced processes have demonstrated energy reductions of 30-45% while maintaining barrier properties.

Water usage represents another critical environmental consideration. Traditional encapsulation processes can require up to 15 liters of ultra-pure water per square meter of display produced. Newer dry encapsulation techniques being tested with specialized electrode coatings have shown potential to reduce water consumption by up to 80% while improving moisture barrier properties.

End-of-life considerations reveal that most current encapsulation systems create non-recyclable composite materials. The multi-layer structures necessary for effective encapsulation, particularly when combined with specialized electrode coatings, often render separation and recovery of valuable materials economically unfeasible. This contributes to electronic waste challenges, with less than 20% of display materials currently being recovered through recycling processes.

Regulatory frameworks are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain materials in electronic displays. Future regulations may specifically target encapsulation materials with high environmental impact, potentially accelerating the transition to greener alternatives that maintain or improve upon current encapsulation efficacy.

Durability Testing Standards for Flexible OLEDs

The development of standardized durability testing protocols for flexible OLEDs represents a critical component in evaluating electrode coating effects on encapsulation efficacy. Currently, the industry employs several established testing methodologies that specifically target the unique challenges posed by flexible display technologies.

The International Electrotechnical Commission (IEC) has developed the IEC 62715 series, which outlines environmental and mechanical testing methods for flexible display devices. These standards include specific protocols for measuring barrier properties of encapsulation layers under various bending conditions, directly relevant to evaluating how electrode coatings perform during mechanical stress.

ASTM International contributes complementary standards, particularly ASTM F1249 and ASTM E96, which measure water vapor transmission rates (WVTR) - a critical parameter for assessing encapsulation quality. These tests have been adapted for flexible substrates to account for the unique challenges of maintaining barrier properties during flexing operations.

The Society for Information Display (SID) has established specialized testing protocols focusing on the interface between electrode coatings and encapsulation layers. These tests evaluate adhesion strength, delamination resistance, and interfacial stability during repeated bending cycles, typically requiring 100,000+ cycles for consumer-grade flexible OLEDs.

Temperature-humidity-bias (THB) testing represents another crucial standard, where devices undergo exposure to elevated temperature (85°C) and humidity (85%) while operational. This test has been modified specifically for flexible displays to include concurrent mechanical stress, creating a more realistic evaluation environment for electrode coating performance.

Accelerated aging tests have evolved to include specialized protocols for flexible displays, incorporating cyclic mechanical stress during environmental exposure. The industry standard now requires a minimum of 1,000 hours of testing under combined environmental and mechanical stressors to validate encapsulation efficacy.

Military standards, including MIL-STD-810G, have been adapted for flexible display technologies, providing rigorous protocols for shock, vibration, and environmental extremes that help evaluate electrode coating durability in harsh conditions.

The emergence of specialized testing equipment, such as dynamic mechanical analyzers modified for in-situ barrier property measurement during flexing, has enabled more precise correlation between mechanical stress and encapsulation performance degradation. These advanced testing platforms allow researchers to directly observe how different electrode coating compositions respond to mechanical deformation in real-time.

The International Electrotechnical Commission (IEC) has developed the IEC 62715 series, which outlines environmental and mechanical testing methods for flexible display devices. These standards include specific protocols for measuring barrier properties of encapsulation layers under various bending conditions, directly relevant to evaluating how electrode coatings perform during mechanical stress.

ASTM International contributes complementary standards, particularly ASTM F1249 and ASTM E96, which measure water vapor transmission rates (WVTR) - a critical parameter for assessing encapsulation quality. These tests have been adapted for flexible substrates to account for the unique challenges of maintaining barrier properties during flexing operations.

The Society for Information Display (SID) has established specialized testing protocols focusing on the interface between electrode coatings and encapsulation layers. These tests evaluate adhesion strength, delamination resistance, and interfacial stability during repeated bending cycles, typically requiring 100,000+ cycles for consumer-grade flexible OLEDs.

Temperature-humidity-bias (THB) testing represents another crucial standard, where devices undergo exposure to elevated temperature (85°C) and humidity (85%) while operational. This test has been modified specifically for flexible displays to include concurrent mechanical stress, creating a more realistic evaluation environment for electrode coating performance.

Accelerated aging tests have evolved to include specialized protocols for flexible displays, incorporating cyclic mechanical stress during environmental exposure. The industry standard now requires a minimum of 1,000 hours of testing under combined environmental and mechanical stressors to validate encapsulation efficacy.

Military standards, including MIL-STD-810G, have been adapted for flexible display technologies, providing rigorous protocols for shock, vibration, and environmental extremes that help evaluate electrode coating durability in harsh conditions.

The emergence of specialized testing equipment, such as dynamic mechanical analyzers modified for in-situ barrier property measurement during flexing, has enabled more precise correlation between mechanical stress and encapsulation performance degradation. These advanced testing platforms allow researchers to directly observe how different electrode coating compositions respond to mechanical deformation in real-time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!