Comparative Study on Flexible OLED Encapsulation for Visual Devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized the visual display industry over the past decade, enabling the development of bendable, foldable, and rollable displays that were once confined to science fiction. The evolution of this technology can be traced back to the early 2000s when researchers first demonstrated the possibility of creating OLEDs on flexible substrates. Since then, significant advancements have been made in materials science, manufacturing processes, and device architectures.

The critical challenge in flexible OLED technology has always been encapsulation - the protective barrier that shields the highly sensitive organic materials from environmental factors such as oxygen and moisture. Traditional rigid glass encapsulation, while effective for conventional displays, is incompatible with the mechanical requirements of flexible devices. This technological bottleneck has driven extensive research into alternative encapsulation methods that can maintain barrier properties while accommodating mechanical deformation.

The technological trajectory has moved from early single-layer barrier films toward sophisticated multi-layer architectures and hybrid organic-inorganic systems. Each evolutionary step has addressed specific limitations of previous approaches, gradually improving barrier performance, flexibility, and manufacturing scalability. Recent developments have focused on atomic layer deposition (ALD) techniques, nanocomposite materials, and thin-film encapsulation (TFE) strategies that offer superior protection while maintaining the mechanical properties required for flexible applications.

Market demands have significantly shaped the direction of flexible OLED encapsulation research. The consumer electronics industry's push toward differentiated form factors, including curved smartphones, foldable tablets, and wearable displays, has accelerated investment in this field. Additionally, emerging applications in automotive displays, healthcare monitoring devices, and smart textiles have expanded the potential market for flexible OLED technologies, further driving innovation in encapsulation solutions.

The primary objective of this comparative study is to comprehensively evaluate the current state of flexible OLED encapsulation technologies for visual devices, identifying their relative strengths, limitations, and suitability for various application scenarios. The study aims to establish a technical foundation for strategic decision-making regarding technology adoption, research investment, and product development roadmaps.

Secondary objectives include mapping the intellectual property landscape to identify freedom-to-operate opportunities, assessing manufacturing scalability and cost structures of competing approaches, and forecasting technological trends that may influence future encapsulation solutions. By achieving these objectives, this study will provide actionable insights for positioning within this rapidly evolving technological domain.

The critical challenge in flexible OLED technology has always been encapsulation - the protective barrier that shields the highly sensitive organic materials from environmental factors such as oxygen and moisture. Traditional rigid glass encapsulation, while effective for conventional displays, is incompatible with the mechanical requirements of flexible devices. This technological bottleneck has driven extensive research into alternative encapsulation methods that can maintain barrier properties while accommodating mechanical deformation.

The technological trajectory has moved from early single-layer barrier films toward sophisticated multi-layer architectures and hybrid organic-inorganic systems. Each evolutionary step has addressed specific limitations of previous approaches, gradually improving barrier performance, flexibility, and manufacturing scalability. Recent developments have focused on atomic layer deposition (ALD) techniques, nanocomposite materials, and thin-film encapsulation (TFE) strategies that offer superior protection while maintaining the mechanical properties required for flexible applications.

Market demands have significantly shaped the direction of flexible OLED encapsulation research. The consumer electronics industry's push toward differentiated form factors, including curved smartphones, foldable tablets, and wearable displays, has accelerated investment in this field. Additionally, emerging applications in automotive displays, healthcare monitoring devices, and smart textiles have expanded the potential market for flexible OLED technologies, further driving innovation in encapsulation solutions.

The primary objective of this comparative study is to comprehensively evaluate the current state of flexible OLED encapsulation technologies for visual devices, identifying their relative strengths, limitations, and suitability for various application scenarios. The study aims to establish a technical foundation for strategic decision-making regarding technology adoption, research investment, and product development roadmaps.

Secondary objectives include mapping the intellectual property landscape to identify freedom-to-operate opportunities, assessing manufacturing scalability and cost structures of competing approaches, and forecasting technological trends that may influence future encapsulation solutions. By achieving these objectives, this study will provide actionable insights for positioning within this rapidly evolving technological domain.

Market Analysis for Flexible Visual Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for innovative form factors in visual devices. The global flexible display market was valued at $23.1 billion in 2022 and is projected to reach $42.5 billion by 2027, representing a compound annual growth rate (CAGR) of 13.0%. This growth trajectory underscores the significant market potential for flexible OLED technologies and their encapsulation solutions.

Smartphones currently dominate the application landscape, accounting for approximately 71% of the flexible display market. However, wearable devices, automotive displays, and foldable tablets are emerging as promising growth segments, collectively expected to expand at a CAGR of 18.7% through 2027. This diversification of applications is creating new opportunities for specialized encapsulation technologies tailored to different use cases and environmental requirements.

Regional analysis reveals Asia-Pacific as the dominant market, with South Korea, Japan, and China leading in both production capacity and technological innovation. These countries collectively hold 76% of the global flexible OLED manufacturing capacity. North America and Europe follow as significant markets, primarily driven by high consumer adoption rates of premium devices featuring flexible displays.

Consumer preferences are increasingly favoring thinner, lighter, and more durable visual devices with enhanced form factors. Market surveys indicate that 64% of smartphone users consider display quality and durability as critical purchasing factors, while 57% express interest in foldable or rollable display technologies. This consumer sentiment is pushing manufacturers to invest heavily in advanced encapsulation solutions that can maintain display integrity while enabling flexibility.

The competitive landscape is characterized by intense rivalry among major display manufacturers and their encapsulation technology partners. Samsung Display and LG Display maintain market leadership positions with approximately 45% and 27% market share respectively. However, Chinese manufacturers like BOE and Visionox are rapidly expanding their production capabilities, particularly in thin-film encapsulation technologies, challenging the established market hierarchy.

Supply chain analysis reveals critical dependencies on specialized materials for encapsulation, including barrier films, adhesives, and inorganic deposition materials. The market for these materials is projected to grow at 15.2% CAGR, slightly outpacing the overall flexible display market. This indicates increasing material intensity in advanced encapsulation solutions, particularly as manufacturers strive to balance flexibility with moisture and oxygen barrier properties.

Economic factors including manufacturing scale, yield rates, and material costs significantly impact the commercial viability of different encapsulation approaches. Current production economics favor thin-film encapsulation for high-volume applications, while hybrid approaches maintain advantages in specialized applications requiring exceptional barrier properties.

Smartphones currently dominate the application landscape, accounting for approximately 71% of the flexible display market. However, wearable devices, automotive displays, and foldable tablets are emerging as promising growth segments, collectively expected to expand at a CAGR of 18.7% through 2027. This diversification of applications is creating new opportunities for specialized encapsulation technologies tailored to different use cases and environmental requirements.

Regional analysis reveals Asia-Pacific as the dominant market, with South Korea, Japan, and China leading in both production capacity and technological innovation. These countries collectively hold 76% of the global flexible OLED manufacturing capacity. North America and Europe follow as significant markets, primarily driven by high consumer adoption rates of premium devices featuring flexible displays.

Consumer preferences are increasingly favoring thinner, lighter, and more durable visual devices with enhanced form factors. Market surveys indicate that 64% of smartphone users consider display quality and durability as critical purchasing factors, while 57% express interest in foldable or rollable display technologies. This consumer sentiment is pushing manufacturers to invest heavily in advanced encapsulation solutions that can maintain display integrity while enabling flexibility.

The competitive landscape is characterized by intense rivalry among major display manufacturers and their encapsulation technology partners. Samsung Display and LG Display maintain market leadership positions with approximately 45% and 27% market share respectively. However, Chinese manufacturers like BOE and Visionox are rapidly expanding their production capabilities, particularly in thin-film encapsulation technologies, challenging the established market hierarchy.

Supply chain analysis reveals critical dependencies on specialized materials for encapsulation, including barrier films, adhesives, and inorganic deposition materials. The market for these materials is projected to grow at 15.2% CAGR, slightly outpacing the overall flexible display market. This indicates increasing material intensity in advanced encapsulation solutions, particularly as manufacturers strive to balance flexibility with moisture and oxygen barrier properties.

Economic factors including manufacturing scale, yield rates, and material costs significantly impact the commercial viability of different encapsulation approaches. Current production economics favor thin-film encapsulation for high-volume applications, while hybrid approaches maintain advantages in specialized applications requiring exceptional barrier properties.

Current Encapsulation Technologies and Barriers

The current landscape of flexible OLED encapsulation technologies presents a complex array of solutions, each with distinct advantages and limitations. Thin-film encapsulation (TFE) has emerged as the predominant approach for flexible displays, utilizing alternating layers of inorganic and organic materials. The inorganic layers, typically composed of Al2O3, SiO2, or SiNx, provide excellent barrier properties against moisture and oxygen, while organic layers offer flexibility and stress relief during bending operations.

Traditional glass lid encapsulation, while highly effective for rigid OLEDs with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, proves incompatible with flexible applications due to its inherent rigidity. This limitation has accelerated the development of alternative technologies specifically designed for flexible displays.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic barrier layer formation, enabling the creation of ultra-thin, highly uniform films with exceptional barrier properties. However, ALD processes face challenges related to throughput limitations and relatively high implementation costs, restricting widespread industrial adoption despite their technical superiority.

Plasma-Enhanced Chemical Vapor Deposition (PECVD) offers a more cost-effective alternative for depositing inorganic barrier layers, though the resulting films typically exhibit higher defect densities compared to ALD-produced counterparts. These defects create potential pathways for moisture and oxygen permeation, compromising long-term device reliability.

Hybrid approaches combining multiple encapsulation technologies have gained traction, with multi-layer structures incorporating both inorganic barriers and organic buffer layers showing promising results. These hybrid systems aim to leverage the complementary properties of different materials to achieve optimal barrier performance while maintaining mechanical flexibility.

A significant barrier to advancement in flexible OLED encapsulation remains the inherent trade-off between barrier performance and mechanical flexibility. As layer thickness decreases to accommodate bending requirements, barrier properties often deteriorate, creating a fundamental engineering challenge that continues to drive research efforts.

Accelerated testing methodologies represent another critical challenge, as conventional testing protocols designed for rigid displays may not accurately predict the long-term reliability of flexible encapsulation systems under repeated mechanical stress. This has necessitated the development of specialized testing frameworks that incorporate dynamic mechanical loading during environmental exposure.

Recent innovations in nanocomposite materials and graphene-based barriers show promise for overcoming current limitations, potentially offering unprecedented combinations of barrier performance and mechanical robustness. However, these approaches remain largely experimental, with significant hurdles related to manufacturing scalability and cost-effectiveness yet to be addressed.

Traditional glass lid encapsulation, while highly effective for rigid OLEDs with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, proves incompatible with flexible applications due to its inherent rigidity. This limitation has accelerated the development of alternative technologies specifically designed for flexible displays.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic barrier layer formation, enabling the creation of ultra-thin, highly uniform films with exceptional barrier properties. However, ALD processes face challenges related to throughput limitations and relatively high implementation costs, restricting widespread industrial adoption despite their technical superiority.

Plasma-Enhanced Chemical Vapor Deposition (PECVD) offers a more cost-effective alternative for depositing inorganic barrier layers, though the resulting films typically exhibit higher defect densities compared to ALD-produced counterparts. These defects create potential pathways for moisture and oxygen permeation, compromising long-term device reliability.

Hybrid approaches combining multiple encapsulation technologies have gained traction, with multi-layer structures incorporating both inorganic barriers and organic buffer layers showing promising results. These hybrid systems aim to leverage the complementary properties of different materials to achieve optimal barrier performance while maintaining mechanical flexibility.

A significant barrier to advancement in flexible OLED encapsulation remains the inherent trade-off between barrier performance and mechanical flexibility. As layer thickness decreases to accommodate bending requirements, barrier properties often deteriorate, creating a fundamental engineering challenge that continues to drive research efforts.

Accelerated testing methodologies represent another critical challenge, as conventional testing protocols designed for rigid displays may not accurately predict the long-term reliability of flexible encapsulation systems under repeated mechanical stress. This has necessitated the development of specialized testing frameworks that incorporate dynamic mechanical loading during environmental exposure.

Recent innovations in nanocomposite materials and graphene-based barriers show promise for overcoming current limitations, potentially offering unprecedented combinations of barrier performance and mechanical robustness. However, these approaches remain largely experimental, with significant hurdles related to manufacturing scalability and cost-effectiveness yet to be addressed.

Comparative Analysis of Current Encapsulation Solutions

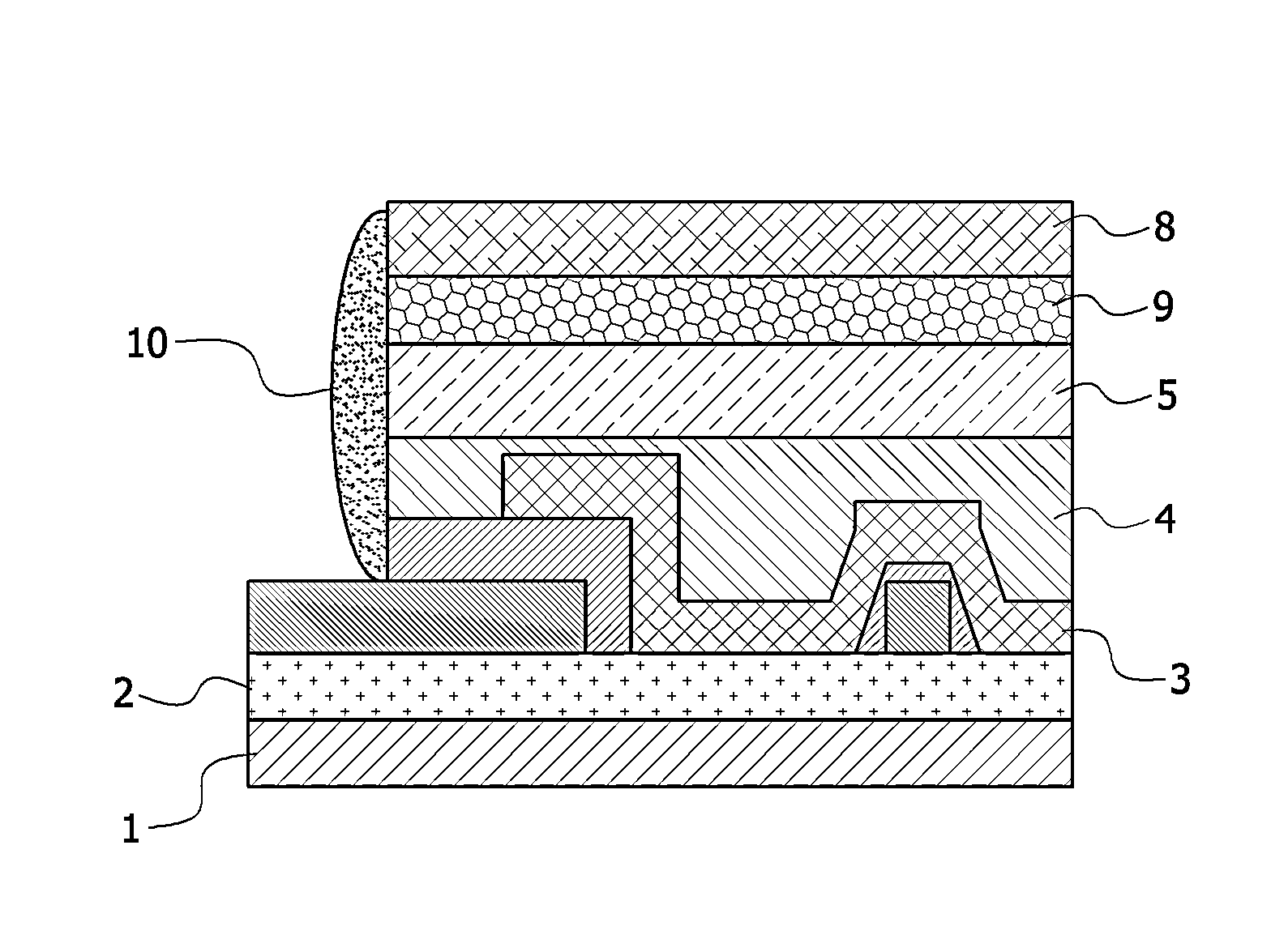

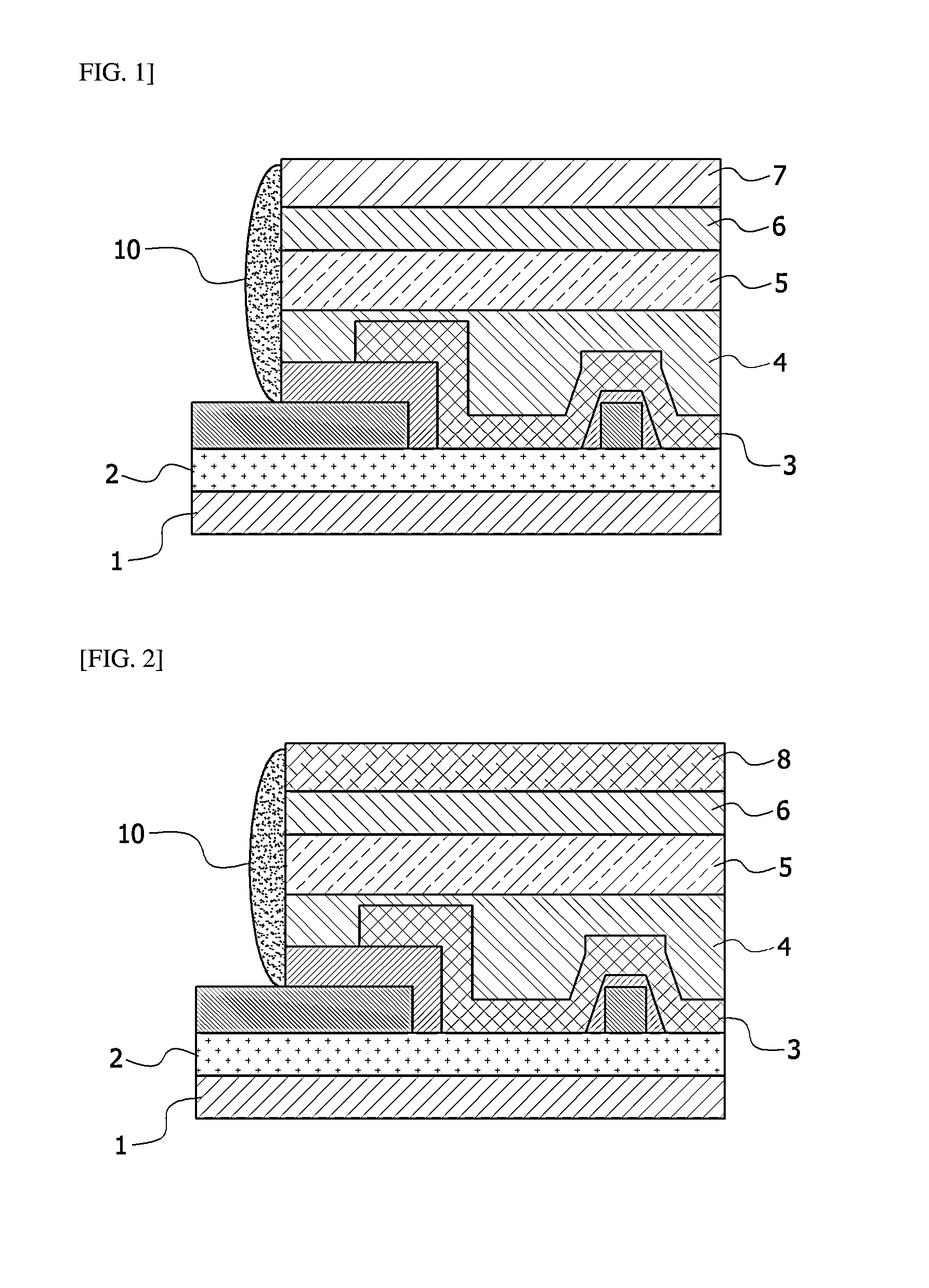

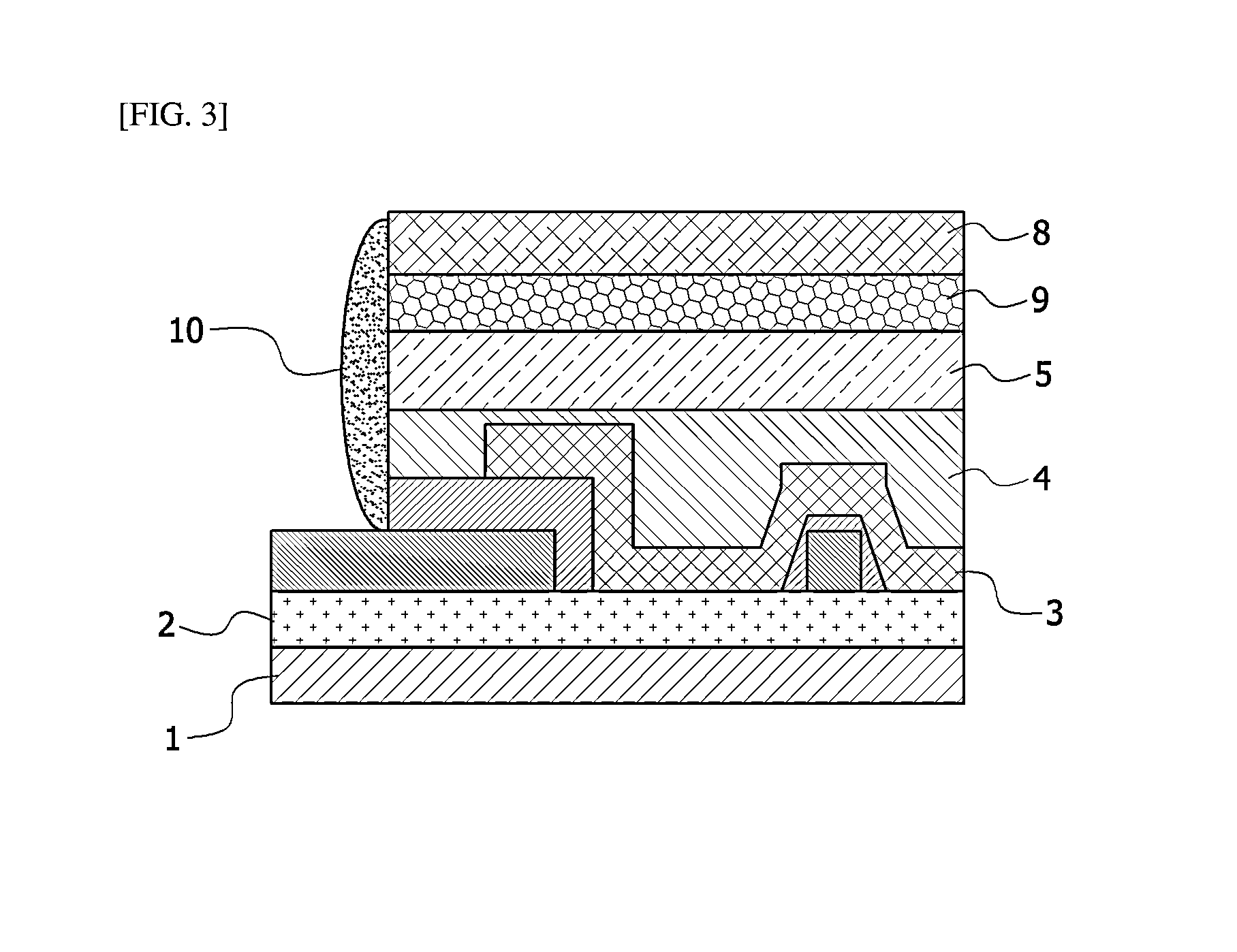

01 Multilayer encapsulation structures for flexible OLEDs

Multilayer encapsulation structures combine inorganic barrier layers with organic buffer layers to provide both effective moisture/oxygen barrier properties and mechanical flexibility. The inorganic layers (such as silicon nitride, aluminum oxide, or silicon oxide) provide excellent barrier properties, while the organic layers (such as polymers or resins) accommodate bending stress and prevent crack propagation. This alternating structure allows the encapsulation to maintain barrier performance even when the OLED device is flexed or bent repeatedly.- Multilayer encapsulation structures for flexible OLEDs: Multilayer encapsulation structures consisting of alternating inorganic and organic layers provide effective barrier properties while maintaining flexibility. The inorganic layers (such as silicon nitride, aluminum oxide) provide moisture and oxygen barrier properties, while the organic layers (such as polymers) accommodate mechanical stress during bending. This combination prevents crack propagation through the entire structure, enhancing the overall flexibility and reliability of OLED devices.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques enable the production of ultra-thin barrier layers that maintain excellent flexibility while protecting OLED devices from environmental degradation. These techniques include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based processes that create conformal, pinhole-free barriers. The reduced thickness of these encapsulation layers significantly improves the bending radius capabilities of flexible OLED displays.

- Stress-relief structures in encapsulation layers: Incorporating specific stress-relief structures within encapsulation layers enhances the mechanical flexibility of OLED devices. These structures include micro-patterns, mesh designs, island-bridge configurations, and engineered interfaces that can effectively distribute and absorb mechanical stress during bending. By preventing stress concentration at specific points, these structures minimize crack formation and propagation, thereby extending the operational lifetime of flexible OLEDs under repeated bending conditions.

- Novel materials for flexible encapsulation: Advanced materials with inherent flexibility properties are being developed for OLED encapsulation. These include hybrid organic-inorganic composites, nanocomposite materials, flexible glass, graphene-based barriers, and specialized polymers with enhanced barrier properties. These materials offer superior combinations of flexibility, transparency, and barrier performance against oxygen and moisture, enabling the production of highly flexible and durable OLED displays.

- Edge sealing techniques for flexible OLEDs: Specialized edge sealing techniques address the vulnerability of flexible OLED edges to moisture and oxygen ingress during bending. These techniques include flexible adhesive systems, laser sealing methods, mechanical interlocking structures, and gradient material transitions at the edges. Effective edge sealing prevents delamination and edge-initiated degradation, which are common failure modes in flexible displays subjected to repeated bending stress.

02 Thin-film encapsulation techniques for flexibility

Thin-film encapsulation (TFE) techniques deposit ultra-thin barrier layers directly onto the OLED device without using rigid glass or metal lids. These techniques include atomic layer deposition (ALD), chemical vapor deposition (CVD), and plasma-enhanced CVD to create conformal, pinhole-free barrier films. The reduced thickness of these encapsulation layers significantly improves flexibility while maintaining barrier properties against moisture and oxygen. TFE enables the production of bendable, rollable, and foldable OLED displays by minimizing the overall thickness of the device structure.Expand Specific Solutions03 Stress-relief structures in encapsulation layers

Specialized stress-relief structures are incorporated into encapsulation layers to accommodate mechanical stress during bending. These include micro-patterned structures, island-bridge configurations, and engineered crack-stopping features that prevent the propagation of defects. Some designs incorporate elastomeric materials or specially designed geometric patterns that can stretch or compress during bending without compromising barrier properties. These structures effectively distribute stress throughout the encapsulation layer, preventing localized failure points when the OLED device is flexed.Expand Specific Solutions04 Self-healing encapsulation materials

Self-healing materials in encapsulation layers can repair microcracks that form during bending or flexing operations. These materials contain reactive components that are released when the encapsulation layer is damaged, filling and sealing cracks before moisture or oxygen can penetrate to the sensitive OLED components. Some approaches use microcapsules containing healing agents, while others employ intrinsically self-healing polymers that can reconnect broken bonds through various mechanisms such as hydrogen bonding or dynamic covalent chemistry. This self-healing capability extends the lifetime of flexible OLED devices by maintaining barrier integrity even after repeated bending cycles.Expand Specific Solutions05 Edge sealing techniques for flexible encapsulation

Specialized edge sealing techniques prevent moisture and oxygen ingress at the vulnerable perimeter of flexible OLED devices. These include advanced adhesive formulations, laser sealing methods, and hybrid organic-inorganic edge sealants that maintain flexibility while providing strong barrier properties. Some approaches use gradient material transitions at the edges to reduce stress concentration during bending. Edge sealing is particularly critical for flexible OLEDs as the edges experience the highest strain during bending operations and are common failure points for encapsulation systems.Expand Specific Solutions

Leading Companies in Flexible OLED Encapsulation

The flexible OLED encapsulation market for visual devices is currently in a growth phase, with increasing adoption across consumer electronics. The market size is expanding rapidly, driven by demand for foldable smartphones and wearable displays. Technologically, the field is approaching maturity with several key players demonstrating advanced solutions. Chinese manufacturers like BOE Technology, TCL China Star, and Tianma Microelectronics are aggressively expanding capabilities, while established players such as LG Display maintain technological leadership. South Korean firms like LG Chem have developed proprietary barrier films, while Applied Materials provides critical manufacturing equipment. The competitive landscape shows regional clustering with Chinese companies focusing on production scale while Korean and international firms emphasize technological innovation in thin-film encapsulation and barrier layer technologies.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered a proprietary flexible OLED encapsulation technology called "BOE-Shield" that employs a hybrid inorganic-organic-inorganic (IOI) structure. Their approach utilizes atomic layer deposition (ALD) for creating ultra-thin aluminum oxide barrier layers (approximately 20-30nm thick) combined with specially formulated organic interlayers that absorb mechanical stress during flexing. BOE's technology incorporates a unique edge sealing method that addresses the vulnerable perimeter of flexible displays, a common failure point in many encapsulation systems. Their process achieves a water vapor transmission rate of approximately 5×10^-6 g/m²/day while maintaining flexibility for over 200,000 bending cycles at a radius of 3mm. BOE has recently enhanced this technology with plasma-assisted ALD processes that improve deposition quality while reducing processing time by approximately 40% compared to conventional methods.

Strengths: Excellent balance between barrier performance and mechanical flexibility; specialized edge sealing technology addressing common failure points; high-volume manufacturing capability with good yield rates. Weaknesses: Relatively higher production costs compared to some competitors; slightly thicker overall encapsulation structure that may impact final device thickness; requires specialized equipment for the plasma-assisted ALD process.

3M Innovative Properties Co.

Technical Solution: 3M has developed an advanced barrier film technology specifically designed for flexible OLED encapsulation called "Barix" multilayer barrier film. This technology utilizes alternating layers of inorganic oxide barriers and polymer layers created through a proprietary vacuum deposition process. The inorganic layers (typically aluminum oxide or silicon nitride) provide the primary moisture and oxygen barrier, while the polymer interlayers decouple defects between adjacent barrier layers and provide mechanical flexibility. 3M's approach achieves an ultra-low water vapor transmission rate of approximately 10^-7 g/m²/day while maintaining optical transparency above 90% in the visible spectrum. A key innovation in their technology is the "dyad" structure where each inorganic-organic pair is optimized for specific barrier and mechanical properties. Recent advancements include the integration of nanocomposite materials in the polymer layers that enhance both barrier properties and mechanical durability, allowing for reliable performance even after 300,000 bending cycles at a 2mm radius.

Strengths: Exceptional barrier properties with industry-leading WVTR values; excellent optical transparency; proven long-term reliability in flexible applications; roll-to-roll manufacturing capability for cost efficiency. Weaknesses: Higher initial material costs compared to direct thin-film encapsulation methods; requires specialized handling during display module integration; slightly thicker overall structure compared to some competing technologies.

Key Patents and Technical Innovations in OLED Barrier Films

Organic light emitting device comprising encapsulating structure

PatentActiveUS20130207093A1

Innovation

- An encapsulating layer comprising a stack of at least two materials such as a water barrier film, glass cap, and metal foil is applied to the entire top surface of the OLED, providing excellent water and oxygen barrier effects while facilitating heat dissipation.

Flexible organic light-emitting diode (OLED) device and fabrication method thereof

PatentActiveUS20210336206A1

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, increasing contact area and reducing stress, formed spontaneously due to thermal stress differences between layers.

Material Science Advancements for Flexible Displays

Material science has undergone remarkable evolution in the realm of flexible display technologies, particularly for OLED applications. Recent advancements in substrate materials have shifted from traditional glass to polyimide films, offering superior flexibility while maintaining dimensional stability under thermal stress. These polymer substrates demonstrate bending radii below 1mm without performance degradation, enabling truly foldable and rollable display configurations.

Barrier materials for encapsulation have seen significant innovation with multi-layer approaches combining inorganic and organic materials. Atomic Layer Deposition (ALD) techniques now allow for ultra-thin aluminum oxide layers with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, essential for protecting sensitive OLED components. Hybrid encapsulation systems utilizing alternating layers of Al₂O₃ and organic polymers have demonstrated superior barrier properties while maintaining flexibility.

Transparent conductive materials have evolved beyond conventional indium tin oxide (ITO), which suffers from brittleness and cracking under repeated bending. Silver nanowire networks, graphene, and PEDOT:PSS formulations now offer sheet resistance below 50 Ω/sq with optical transmittance exceeding 90% while withstanding thousands of bending cycles. These materials maintain conductivity at bend radii below 3mm, critical for foldable device applications.

Self-healing materials represent a frontier development for flexible displays, incorporating microcapsules with healing agents that activate upon mechanical damage. Polyurethane-based self-healing coatings have demonstrated recovery of up to 85% of original properties after damage, potentially extending device lifespans significantly. These materials can autonomously repair microcracks that typically lead to encapsulation failure and device degradation.

Nanocomposite materials combining polymer matrices with nanofillers such as graphene, carbon nanotubes, and ceramic nanoparticles have shown enhanced mechanical properties and barrier performance. These materials exhibit improved thermal stability and reduced coefficient of thermal expansion, addressing challenges in differential expansion between layers during thermal cycling. Graphene-enhanced polymer composites have demonstrated oxygen transmission rates reduced by up to 95% compared to base polymers.

Adhesive and bonding technologies have also progressed with the development of optically clear adhesives maintaining transparency and bonding strength through thousands of folding cycles. These materials feature modulated elastic moduli that change with temperature, providing rigidity during manufacturing while allowing flexibility during device operation.

Barrier materials for encapsulation have seen significant innovation with multi-layer approaches combining inorganic and organic materials. Atomic Layer Deposition (ALD) techniques now allow for ultra-thin aluminum oxide layers with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, essential for protecting sensitive OLED components. Hybrid encapsulation systems utilizing alternating layers of Al₂O₃ and organic polymers have demonstrated superior barrier properties while maintaining flexibility.

Transparent conductive materials have evolved beyond conventional indium tin oxide (ITO), which suffers from brittleness and cracking under repeated bending. Silver nanowire networks, graphene, and PEDOT:PSS formulations now offer sheet resistance below 50 Ω/sq with optical transmittance exceeding 90% while withstanding thousands of bending cycles. These materials maintain conductivity at bend radii below 3mm, critical for foldable device applications.

Self-healing materials represent a frontier development for flexible displays, incorporating microcapsules with healing agents that activate upon mechanical damage. Polyurethane-based self-healing coatings have demonstrated recovery of up to 85% of original properties after damage, potentially extending device lifespans significantly. These materials can autonomously repair microcracks that typically lead to encapsulation failure and device degradation.

Nanocomposite materials combining polymer matrices with nanofillers such as graphene, carbon nanotubes, and ceramic nanoparticles have shown enhanced mechanical properties and barrier performance. These materials exhibit improved thermal stability and reduced coefficient of thermal expansion, addressing challenges in differential expansion between layers during thermal cycling. Graphene-enhanced polymer composites have demonstrated oxygen transmission rates reduced by up to 95% compared to base polymers.

Adhesive and bonding technologies have also progressed with the development of optically clear adhesives maintaining transparency and bonding strength through thousands of folding cycles. These materials feature modulated elastic moduli that change with temperature, providing rigidity during manufacturing while allowing flexibility during device operation.

Reliability Testing Standards for Encapsulation Technologies

Reliability testing standards for encapsulation technologies in flexible OLED displays have evolved significantly to address the unique challenges posed by bendable visual devices. These standards encompass a comprehensive suite of tests designed to evaluate the barrier properties, mechanical durability, and long-term stability of encapsulation systems under various environmental conditions.

The primary reliability testing methodologies include the calcium test, which measures water vapor transmission rate (WVTR) by monitoring the optical changes in calcium films when exposed to moisture. This test has become an industry benchmark due to its high sensitivity, capable of detecting ultra-low WVTR values down to 10^-6 g/m²/day, which is critical for OLED applications.

Temperature-humidity-bias (THB) testing represents another cornerstone standard, where encapsulated devices are subjected to elevated temperature (typically 85°C) and humidity (85% RH) conditions while under electrical bias. This accelerated aging test effectively simulates long-term environmental exposure and helps predict device lifetime in real-world scenarios.

Mechanical reliability standards have gained prominence specifically for flexible displays, including cyclic bending tests at various radii (typically 1-5mm) and frequencies (0.5-3Hz). These tests evaluate the integrity of the encapsulation barrier during repeated flexing operations, often requiring survival of 100,000 to 200,000 bending cycles without significant degradation in barrier properties.

Adhesion strength testing between encapsulation layers and substrates follows standardized protocols such as ASTM D3359 (tape test) and ASTM D4541 (pull-off test). These measurements are crucial as delamination represents a common failure mode in flexible devices.

International standards organizations including IEC, ASTM, and JEDEC have established specific testing protocols for OLED encapsulation. Notable examples include IEC 62341-6-3 for environmental testing of OLED displays and JEDEC JESD22-A101 for accelerated moisture resistance qualification.

Emerging reliability standards are increasingly incorporating combined stress tests that simultaneously apply multiple stressors (mechanical bending, temperature cycling, and humidity exposure) to better simulate real-world usage conditions. These combined tests provide more realistic predictions of encapsulation performance in commercial applications.

The industry is moving toward standardization of lifetime prediction models based on accelerated testing data, with efforts to establish correlation factors between accelerated test results and actual field performance. This trend reflects the growing maturity of flexible OLED technology and the increasing importance of reliable encapsulation solutions for commercial viability.

The primary reliability testing methodologies include the calcium test, which measures water vapor transmission rate (WVTR) by monitoring the optical changes in calcium films when exposed to moisture. This test has become an industry benchmark due to its high sensitivity, capable of detecting ultra-low WVTR values down to 10^-6 g/m²/day, which is critical for OLED applications.

Temperature-humidity-bias (THB) testing represents another cornerstone standard, where encapsulated devices are subjected to elevated temperature (typically 85°C) and humidity (85% RH) conditions while under electrical bias. This accelerated aging test effectively simulates long-term environmental exposure and helps predict device lifetime in real-world scenarios.

Mechanical reliability standards have gained prominence specifically for flexible displays, including cyclic bending tests at various radii (typically 1-5mm) and frequencies (0.5-3Hz). These tests evaluate the integrity of the encapsulation barrier during repeated flexing operations, often requiring survival of 100,000 to 200,000 bending cycles without significant degradation in barrier properties.

Adhesion strength testing between encapsulation layers and substrates follows standardized protocols such as ASTM D3359 (tape test) and ASTM D4541 (pull-off test). These measurements are crucial as delamination represents a common failure mode in flexible devices.

International standards organizations including IEC, ASTM, and JEDEC have established specific testing protocols for OLED encapsulation. Notable examples include IEC 62341-6-3 for environmental testing of OLED displays and JEDEC JESD22-A101 for accelerated moisture resistance qualification.

Emerging reliability standards are increasingly incorporating combined stress tests that simultaneously apply multiple stressors (mechanical bending, temperature cycling, and humidity exposure) to better simulate real-world usage conditions. These combined tests provide more realistic predictions of encapsulation performance in commercial applications.

The industry is moving toward standardization of lifetime prediction models based on accelerated testing data, with efforts to establish correlation factors between accelerated test results and actual field performance. This trend reflects the growing maturity of flexible OLED technology and the increasing importance of reliable encapsulation solutions for commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!