Comparative Evaluation of Flexible OLED Encapsulation in Automotive Displays

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized display applications across various industries, with automotive displays representing one of the most demanding and promising frontiers. The evolution of OLED technology began in the late 1980s, with significant breakthroughs occurring in the early 2000s that enabled practical applications. The trajectory of development has accelerated dramatically over the past decade, with flexible OLED displays transitioning from laboratory curiosities to commercially viable products.

The critical challenge in flexible OLED implementation has consistently been encapsulation - the protective barrier that shields the organic materials from environmental degradation factors such as oxygen and moisture. Traditional rigid glass encapsulation methods, while effective for conventional displays, proved incompatible with the flexibility requirements of next-generation automotive interfaces. This technological bottleneck spurred intensive research into alternative encapsulation methodologies.

The automotive environment presents particularly stringent requirements for display technologies, including extreme temperature variations (-40°C to 85°C), high humidity conditions, prolonged UV exposure, and mechanical stress from vibrations. These factors have historically limited the adoption of OLED technology in vehicles despite its superior visual performance characteristics including perfect blacks, high contrast ratios, and wide viewing angles.

Recent technological advancements in thin-film encapsulation (TFE) have created a pathway for flexible OLED integration into automotive applications. The evolution from early single-layer barriers to sophisticated multi-layer structures incorporating both organic and inorganic materials has dramatically improved the water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) performance metrics critical for long-term OLED stability.

The primary objective of this technical evaluation is to comprehensively assess the current state of flexible OLED encapsulation technologies specifically for automotive display applications. This includes analyzing the performance characteristics, durability, manufacturing scalability, and cost-effectiveness of competing encapsulation methodologies including thin-film encapsulation (TFE), hybrid encapsulation, and emerging atomic layer deposition (ALD) techniques.

Secondary objectives include identifying the technical limitations of current encapsulation solutions, evaluating their compatibility with automotive qualification standards (including AEC-Q100), and forecasting the technological trajectory for the next 3-5 years. This analysis will provide critical insights for strategic R&D investment decisions and potential partnership opportunities in the automotive display supply chain.

The ultimate goal is to determine which encapsulation technologies offer the optimal balance of performance, reliability, and manufacturability for next-generation flexible automotive displays, while identifying potential breakthrough technologies that could disrupt current approaches and accelerate market adoption.

The critical challenge in flexible OLED implementation has consistently been encapsulation - the protective barrier that shields the organic materials from environmental degradation factors such as oxygen and moisture. Traditional rigid glass encapsulation methods, while effective for conventional displays, proved incompatible with the flexibility requirements of next-generation automotive interfaces. This technological bottleneck spurred intensive research into alternative encapsulation methodologies.

The automotive environment presents particularly stringent requirements for display technologies, including extreme temperature variations (-40°C to 85°C), high humidity conditions, prolonged UV exposure, and mechanical stress from vibrations. These factors have historically limited the adoption of OLED technology in vehicles despite its superior visual performance characteristics including perfect blacks, high contrast ratios, and wide viewing angles.

Recent technological advancements in thin-film encapsulation (TFE) have created a pathway for flexible OLED integration into automotive applications. The evolution from early single-layer barriers to sophisticated multi-layer structures incorporating both organic and inorganic materials has dramatically improved the water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) performance metrics critical for long-term OLED stability.

The primary objective of this technical evaluation is to comprehensively assess the current state of flexible OLED encapsulation technologies specifically for automotive display applications. This includes analyzing the performance characteristics, durability, manufacturing scalability, and cost-effectiveness of competing encapsulation methodologies including thin-film encapsulation (TFE), hybrid encapsulation, and emerging atomic layer deposition (ALD) techniques.

Secondary objectives include identifying the technical limitations of current encapsulation solutions, evaluating their compatibility with automotive qualification standards (including AEC-Q100), and forecasting the technological trajectory for the next 3-5 years. This analysis will provide critical insights for strategic R&D investment decisions and potential partnership opportunities in the automotive display supply chain.

The ultimate goal is to determine which encapsulation technologies offer the optimal balance of performance, reliability, and manufacturability for next-generation flexible automotive displays, while identifying potential breakthrough technologies that could disrupt current approaches and accelerate market adoption.

Automotive Display Market Requirements Analysis

The automotive display market is experiencing a significant transformation driven by the integration of advanced technologies, particularly flexible OLED displays. Current market analysis indicates that automotive displays are evolving from mere information interfaces to sophisticated command centers that enhance both functionality and aesthetic appeal of vehicle interiors. The global automotive display market is projected to grow substantially over the next decade, with premium and luxury vehicle segments leading adoption of flexible OLED technology.

Consumer expectations in automotive displays have shifted dramatically, with increasing demands for displays that offer seamless integration with vehicle interiors, curved surfaces that follow dashboard contours, and enhanced visual performance under varying lighting conditions. Automotive OEMs are particularly focused on displays that maintain visibility in direct sunlight while minimizing reflections and glare – a critical requirement where flexible OLED technology with proper encapsulation demonstrates significant advantages.

Durability requirements in automotive environments present unique challenges for display technologies. Displays must withstand extreme temperature variations (-40°C to 85°C), high humidity conditions, and maintain operational integrity over a vehicle's lifecycle (typically 10-15 years). This longevity requirement far exceeds consumer electronics standards, making encapsulation solutions for flexible OLEDs particularly critical in automotive applications. The automotive industry's stringent reliability standards demand failure rates below 10 parts per million, creating significant barriers to entry for new display technologies.

Energy efficiency has become increasingly important as the automotive industry transitions toward electric vehicles. Display systems must minimize power consumption while maintaining brightness levels sufficient for daylight visibility. Flexible OLED technology offers potential advantages in this area, but encapsulation solutions must be optimized to prevent degradation that could increase power requirements over time.

Safety considerations represent another crucial market requirement. Displays must comply with automotive safety standards regarding fragmentation, reflection, and distraction potential. The integration of touch functionality in curved displays introduces additional challenges related to haptic feedback and interaction safety while driving. Encapsulation technologies must therefore not only protect the OLED materials but also maintain optical clarity and touch sensitivity without compromising safety parameters.

Manufacturing scalability and cost considerations remain significant market factors. While premium vehicles can absorb higher costs for advanced display technologies, mass-market adoption requires encapsulation solutions that can be implemented in high-volume production environments without prohibitive cost increases. Current market analysis suggests that flexible OLED displays with effective encapsulation solutions command a price premium of approximately 30-40% compared to conventional automotive displays, a gap that must narrow for broader market penetration.

Consumer expectations in automotive displays have shifted dramatically, with increasing demands for displays that offer seamless integration with vehicle interiors, curved surfaces that follow dashboard contours, and enhanced visual performance under varying lighting conditions. Automotive OEMs are particularly focused on displays that maintain visibility in direct sunlight while minimizing reflections and glare – a critical requirement where flexible OLED technology with proper encapsulation demonstrates significant advantages.

Durability requirements in automotive environments present unique challenges for display technologies. Displays must withstand extreme temperature variations (-40°C to 85°C), high humidity conditions, and maintain operational integrity over a vehicle's lifecycle (typically 10-15 years). This longevity requirement far exceeds consumer electronics standards, making encapsulation solutions for flexible OLEDs particularly critical in automotive applications. The automotive industry's stringent reliability standards demand failure rates below 10 parts per million, creating significant barriers to entry for new display technologies.

Energy efficiency has become increasingly important as the automotive industry transitions toward electric vehicles. Display systems must minimize power consumption while maintaining brightness levels sufficient for daylight visibility. Flexible OLED technology offers potential advantages in this area, but encapsulation solutions must be optimized to prevent degradation that could increase power requirements over time.

Safety considerations represent another crucial market requirement. Displays must comply with automotive safety standards regarding fragmentation, reflection, and distraction potential. The integration of touch functionality in curved displays introduces additional challenges related to haptic feedback and interaction safety while driving. Encapsulation technologies must therefore not only protect the OLED materials but also maintain optical clarity and touch sensitivity without compromising safety parameters.

Manufacturing scalability and cost considerations remain significant market factors. While premium vehicles can absorb higher costs for advanced display technologies, mass-market adoption requires encapsulation solutions that can be implemented in high-volume production environments without prohibitive cost increases. Current market analysis suggests that flexible OLED displays with effective encapsulation solutions command a price premium of approximately 30-40% compared to conventional automotive displays, a gap that must narrow for broader market penetration.

Current Encapsulation Technologies and Barriers

The current landscape of flexible OLED encapsulation technologies for automotive displays is dominated by several key approaches, each with distinct advantages and limitations. Thin-film encapsulation (TFE) represents the most advanced solution, utilizing alternating layers of inorganic (typically silicon nitride or aluminum oxide) and organic materials to create a multi-layer barrier against moisture and oxygen. This technology achieves excellent barrier properties with minimal thickness, making it particularly suitable for flexible applications where maintaining bendability is crucial.

Glass-based encapsulation remains prevalent in premium automotive displays, offering superior barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. However, its inherent rigidity limits application in truly flexible displays, relegating it primarily to fixed-curve implementations where minimal flexibility is required after installation.

Hybrid encapsulation approaches combine aspects of both thin-film and glass technologies, often incorporating ultra-thin glass (UTG) with additional polymer layers. These solutions attempt to balance the superior barrier properties of glass with improved flexibility, though they still face challenges in achieving the extreme bending radii required for certain automotive interior designs.

The primary barrier to effective encapsulation remains the achievement of sufficient moisture protection while maintaining flexibility. Current technologies struggle to consistently achieve WVTR below 10^-5 g/m²/day when subjected to repeated bending cycles, particularly at the elevated temperatures (up to 85°C) and humidity levels (up to 85% RH) common in automotive environments.

Edge sealing represents another critical challenge, as the perimeter of flexible displays remains particularly vulnerable to moisture ingress. Current solutions employ specialized adhesives and barrier materials, but these often become points of failure during thermal cycling and mechanical stress. The automotive requirement for operational lifespans exceeding 10 years (compared to 2-3 years for consumer electronics) exacerbates this challenge.

Manufacturing scalability presents additional barriers, particularly for TFE processes that require precise deposition of nanometer-scale layers. Current production methods face yield challenges when scaled to automotive-grade quality requirements, with defect rates significantly higher than those acceptable for instrument clusters and central information displays.

Cost considerations further complicate implementation, with current encapsulation technologies adding approximately 15-20% to overall display manufacturing costs. This premium becomes particularly problematic for mid-range vehicle segments where price sensitivity is higher but durability requirements remain stringent.

Glass-based encapsulation remains prevalent in premium automotive displays, offering superior barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. However, its inherent rigidity limits application in truly flexible displays, relegating it primarily to fixed-curve implementations where minimal flexibility is required after installation.

Hybrid encapsulation approaches combine aspects of both thin-film and glass technologies, often incorporating ultra-thin glass (UTG) with additional polymer layers. These solutions attempt to balance the superior barrier properties of glass with improved flexibility, though they still face challenges in achieving the extreme bending radii required for certain automotive interior designs.

The primary barrier to effective encapsulation remains the achievement of sufficient moisture protection while maintaining flexibility. Current technologies struggle to consistently achieve WVTR below 10^-5 g/m²/day when subjected to repeated bending cycles, particularly at the elevated temperatures (up to 85°C) and humidity levels (up to 85% RH) common in automotive environments.

Edge sealing represents another critical challenge, as the perimeter of flexible displays remains particularly vulnerable to moisture ingress. Current solutions employ specialized adhesives and barrier materials, but these often become points of failure during thermal cycling and mechanical stress. The automotive requirement for operational lifespans exceeding 10 years (compared to 2-3 years for consumer electronics) exacerbates this challenge.

Manufacturing scalability presents additional barriers, particularly for TFE processes that require precise deposition of nanometer-scale layers. Current production methods face yield challenges when scaled to automotive-grade quality requirements, with defect rates significantly higher than those acceptable for instrument clusters and central information displays.

Cost considerations further complicate implementation, with current encapsulation technologies adding approximately 15-20% to overall display manufacturing costs. This premium becomes particularly problematic for mid-range vehicle segments where price sensitivity is higher but durability requirements remain stringent.

Comparative Analysis of Encapsulation Solutions

01 Thin-film encapsulation for flexible OLEDs

Thin-film encapsulation (TFE) technology is crucial for flexible OLED displays, providing protection against moisture and oxygen while maintaining flexibility. These structures typically consist of alternating inorganic and organic layers that create a tortuous path for moisture penetration while allowing the display to bend without cracking. The inorganic layers provide barrier properties while the organic layers absorb mechanical stress during bending, resulting in a flexible yet protective encapsulation structure.- Multilayer encapsulation structures for flexible OLEDs: Multilayer encapsulation structures combine inorganic barrier layers with organic buffer layers to achieve both flexibility and effective moisture/oxygen barrier properties. The inorganic layers (such as silicon nitride, aluminum oxide, or silicon oxide) provide excellent barrier properties, while the organic layers (such as polymers) accommodate bending stress and prevent crack propagation. This alternating structure allows the encapsulation to maintain integrity during flexing while protecting the sensitive OLED components from environmental degradation.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques deposit ultra-thin barrier layers directly onto the OLED device, eliminating the need for rigid glass encapsulation. These techniques include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and other vacuum deposition methods that create conformal, pinhole-free barriers with minimal thickness. The reduced thickness of these encapsulation layers significantly improves the overall flexibility of the OLED device while maintaining sufficient protection against moisture and oxygen penetration.

- Stress-relief structures in encapsulation layers: Specialized stress-relief structures are incorporated into encapsulation layers to accommodate mechanical stress during bending. These structures include micro-patterns, mesh designs, island structures, or engineered discontinuities that can deform without cracking. By strategically distributing stress throughout the encapsulation layer, these designs prevent catastrophic failure during flexing while maintaining barrier properties. Some approaches also incorporate elastomeric materials or specially designed geometric patterns that can stretch and compress during bending cycles.

- Self-healing encapsulation materials: Self-healing materials are incorporated into flexible OLED encapsulation to repair microcracks that form during bending. These materials contain components that can flow into damaged areas when activated by heat, light, or mechanical stress, restoring the barrier properties of the encapsulation layer. Some approaches use microencapsulated healing agents that release when cracks form, while others employ polymers with dynamic bonds that can reform after breaking. This self-healing capability extends the lifetime of flexible OLEDs by maintaining encapsulation integrity through multiple bending cycles.

- Edge sealing techniques for flexible encapsulation: Enhanced edge sealing techniques prevent moisture and oxygen ingress at the vulnerable perimeter of flexible OLED devices. These methods include specialized adhesive formulations, laser sealing processes, and multi-barrier edge structures that maintain flexibility while providing robust environmental protection. Some approaches incorporate hydrophobic materials or additional barrier layers specifically at the edges where delamination typically begins. Advanced edge sealing designs also accommodate the differential movement between layers during bending to prevent separation and maintain the integrity of the encapsulation system.

02 Flexible barrier materials and compositions

Advanced barrier materials are essential for flexible OLED encapsulation, including specialized polymers, hybrid organic-inorganic composites, and nanocomposites. These materials combine high barrier properties against moisture and oxygen with mechanical flexibility. Some approaches incorporate nanoparticles or specialized additives into polymer matrices to enhance both barrier performance and flexibility. The composition of these materials is carefully engineered to maintain integrity during repeated bending cycles while providing sufficient protection for the sensitive OLED components.Expand Specific Solutions03 Multi-layer encapsulation structures

Multi-layer encapsulation architectures are designed specifically for flexible OLEDs, featuring strategically arranged layers with different functions. These structures typically include moisture barrier layers, stress-relief layers, and adhesion-promoting layers. The arrangement and thickness of each layer are optimized to distribute mechanical stress during bending while maintaining an effective barrier against environmental contaminants. Some designs incorporate gradient structures or functional interlayers that enhance the overall flexibility and reliability of the encapsulation.Expand Specific Solutions04 Edge sealing techniques for flexible displays

Edge sealing is critical for flexible OLED encapsulation as the display edges are particularly vulnerable to moisture ingress during bending. Advanced edge sealing techniques include specialized adhesives, laser sealing methods, and multi-component edge structures that maintain flexibility while providing robust protection. These methods focus on creating a continuous barrier at the interface between different encapsulation layers and around the perimeter of the display, preventing delamination and crack formation during repeated flexing of the device.Expand Specific Solutions05 Deposition methods for flexible encapsulation

Specialized deposition techniques are employed to create flexible encapsulation layers that maintain their protective properties during bending. These include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based processes optimized for flexible substrates. The deposition parameters are carefully controlled to ensure uniform coverage, strong adhesion between layers, and minimal residual stress. Some approaches incorporate low-temperature processes that prevent thermal damage to flexible substrates while still achieving high-quality barrier films with excellent flexibility.Expand Specific Solutions

Leading Automotive Display and OLED Manufacturers

The flexible OLED encapsulation market for automotive displays is currently in a growth phase, with increasing adoption driven by demand for curved, lightweight displays in premium vehicles. The market size is expanding rapidly, projected to reach significant value as automotive manufacturers integrate more advanced display technologies. Technologically, companies like Samsung Display, LG Display, and BOE Technology Group are leading innovation with mature thin-film encapsulation solutions, while Chinese players including Tianma Microelectronics, Visionox, and TCL CSOT are rapidly advancing their capabilities. AUDI AG and other automotive OEMs are pushing requirements for higher durability and reliability in harsh automotive environments, creating competitive pressure for display manufacturers to develop specialized encapsulation technologies that can withstand temperature fluctuations and extended lifecycle demands.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced "Auto-Flex" encapsulation solution specifically for automotive flexible OLED displays. Their technology employs a hybrid encapsulation approach combining thin-film encapsulation (TFE) with face sealing techniques. The TFE structure consists of alternating layers of Al2O3 and organic polymer deposited via atomic layer deposition and plasma-enhanced CVD processes. For automotive applications, BOE has incorporated additional barrier enhancement layers and specialized edge sealing technology to withstand the harsh environmental conditions in vehicles. Their encapsulation system achieves a water vapor transmission rate (WVTR) of approximately 10^-6 g/m²/day while maintaining mechanical flexibility for curved dashboard implementations. BOE's solution also includes proprietary stress-relief structures at the interface between rigid and flexible regions to prevent delamination during thermal cycling.

Strengths: Robust performance under automotive temperature cycling conditions; good barrier properties with competitive WVTR values; established mass production capabilities with high yield rates. Weaknesses: Slightly higher thickness compared to competitors; potential for optical degradation at extreme humidity conditions; higher production costs for automotive-grade specifications.

Hefei Visionox Technology Co., Ltd.

Technical Solution: Visionox has developed a "V-Shield" encapsulation technology for automotive flexible OLED displays. Their approach utilizes a multi-layer structure combining inorganic barrier layers (primarily SiNx and Al2O3) with organic buffer layers in an alternating configuration. For automotive applications, Visionox has enhanced their standard encapsulation with additional passivation layers and specialized adhesives that maintain integrity under the extreme temperature cycling required for automotive qualification. Their technology incorporates a proprietary "Stress-Balanced TFE" approach that distributes mechanical stress evenly throughout the encapsulation layers during flexing, preventing crack formation and propagation. Visionox's solution achieves a water vapor transmission rate below 8×10^-6 g/m²/day while maintaining flexibility for curved automotive display implementations. Their encapsulation also features enhanced UV protection layers to prevent degradation of organic materials from prolonged sunlight exposure in vehicle environments.

Strengths: Good balance of barrier properties and mechanical flexibility; specialized stress distribution technology prevents cracking during repeated flexing; competitive manufacturing costs. Weaknesses: Slightly higher WVTR compared to industry leaders; limited track record in automotive applications; potential for optical degradation under extreme temperature conditions.

Key Patents and Innovations in OLED Encapsulation

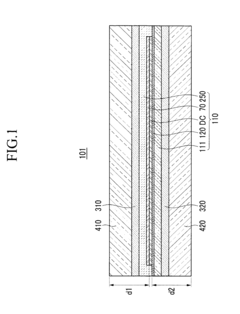

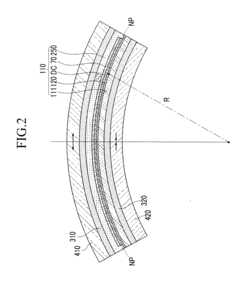

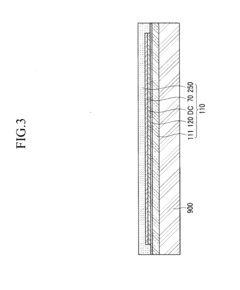

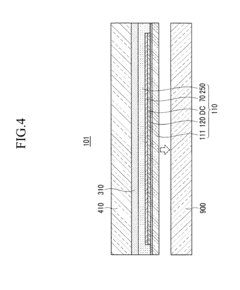

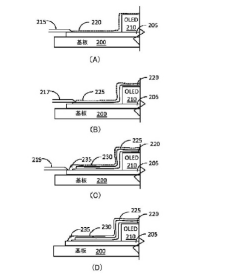

Organic light emitting diode display and method of manufacturing the same

PatentActiveEP2259321B1

Innovation

- The OLED display features a flexible substrate with a driving circuit unit directly formed on it, encapsulating thin films covering the organic light emission element and circuit unit, and protection films on either side of the substrate, allowing for enhanced mechanical stability and increased bending degree without damaging the TFTs.

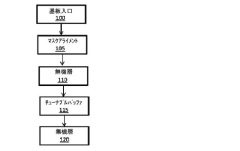

Encapsulation method for organic light emitting diode

PatentInactiveJP2022145802A

Innovation

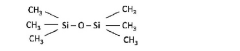

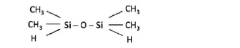

- A method involving the formation of inorganic and organic layers in a controlled process chamber, utilizing tunable buffer layers formed from vaporized organosilicon compounds like hexamethyldisiloxane or tetramethyldisiloxane, with precise mask alignment outside the chamber to ensure encapsulation integrity.

Environmental Impact and Sustainability Factors

The environmental impact of flexible OLED encapsulation technologies in automotive displays represents a critical consideration as the industry moves toward more sustainable manufacturing practices. Traditional encapsulation methods often rely on glass barriers and metal cans, which involve energy-intensive production processes and contain materials that are difficult to recycle. In contrast, thin-film encapsulation (TFE) technologies used in flexible OLEDs offer potential environmental advantages through reduced material usage and lower energy consumption during manufacturing.

Life cycle assessments of flexible OLED encapsulation reveal significant differences in carbon footprint compared to conventional technologies. The production of multi-layer barrier films typically generates 15-20% less carbon emissions than rigid glass encapsulation systems when evaluated across the entire manufacturing process. Additionally, the reduced weight of flexible displays contributes to vehicle fuel efficiency, with estimates suggesting that each 10kg reduction in vehicle weight can decrease fuel consumption by approximately 0.4 liters per 100 kilometers driven.

Material selection for encapsulation layers presents both challenges and opportunities for sustainability. While high-performance barrier films often incorporate synthetic polymers and inorganic materials, recent innovations have focused on bio-based alternatives and recyclable barrier components. For instance, cellulose-derived barrier films have demonstrated promising oxygen and moisture barrier properties while offering improved end-of-life recyclability compared to conventional petroleum-based polymers.

Waste management considerations are particularly relevant for automotive displays, which must meet stringent durability requirements while addressing end-of-life concerns. Flexible OLED encapsulation technologies generally produce less waste during manufacturing due to more efficient material deposition processes. However, the complex multi-layer structure of these barriers can complicate recycling efforts, necessitating specialized separation techniques to recover valuable materials.

Energy efficiency during operation represents another environmental dimension of flexible OLED encapsulation. The lightweight nature of flexible displays contributes to reduced power consumption in automotive applications, with flexible OLEDs typically requiring 10-15% less energy than comparable rigid displays. This operational efficiency translates to lower lifetime environmental impact, particularly important given the extended service life expected of automotive components.

Regulatory frameworks increasingly influence encapsulation technology selection, with policies like the European Union's End-of-Life Vehicle Directive mandating specific recycling rates and restricting hazardous materials. Manufacturers adopting flexible OLED encapsulation must navigate these requirements while balancing performance demands, driving innovation toward more environmentally compatible barrier solutions that maintain the necessary protection against oxygen and moisture ingress.

Life cycle assessments of flexible OLED encapsulation reveal significant differences in carbon footprint compared to conventional technologies. The production of multi-layer barrier films typically generates 15-20% less carbon emissions than rigid glass encapsulation systems when evaluated across the entire manufacturing process. Additionally, the reduced weight of flexible displays contributes to vehicle fuel efficiency, with estimates suggesting that each 10kg reduction in vehicle weight can decrease fuel consumption by approximately 0.4 liters per 100 kilometers driven.

Material selection for encapsulation layers presents both challenges and opportunities for sustainability. While high-performance barrier films often incorporate synthetic polymers and inorganic materials, recent innovations have focused on bio-based alternatives and recyclable barrier components. For instance, cellulose-derived barrier films have demonstrated promising oxygen and moisture barrier properties while offering improved end-of-life recyclability compared to conventional petroleum-based polymers.

Waste management considerations are particularly relevant for automotive displays, which must meet stringent durability requirements while addressing end-of-life concerns. Flexible OLED encapsulation technologies generally produce less waste during manufacturing due to more efficient material deposition processes. However, the complex multi-layer structure of these barriers can complicate recycling efforts, necessitating specialized separation techniques to recover valuable materials.

Energy efficiency during operation represents another environmental dimension of flexible OLED encapsulation. The lightweight nature of flexible displays contributes to reduced power consumption in automotive applications, with flexible OLEDs typically requiring 10-15% less energy than comparable rigid displays. This operational efficiency translates to lower lifetime environmental impact, particularly important given the extended service life expected of automotive components.

Regulatory frameworks increasingly influence encapsulation technology selection, with policies like the European Union's End-of-Life Vehicle Directive mandating specific recycling rates and restricting hazardous materials. Manufacturers adopting flexible OLED encapsulation must navigate these requirements while balancing performance demands, driving innovation toward more environmentally compatible barrier solutions that maintain the necessary protection against oxygen and moisture ingress.

Durability Testing Standards for Automotive Applications

Automotive displays incorporating flexible OLED technology must meet stringent durability requirements that far exceed those of consumer electronics. The automotive industry has established comprehensive testing standards specifically designed to evaluate the resilience of display components under extreme conditions typical in vehicle environments. These standards are critical for ensuring that flexible OLED encapsulation systems can maintain their protective functions throughout the vehicle's operational lifetime.

The Society of Automotive Engineers (SAE) has developed several key standards, including SAE J1455 and SAE J575, which outline environmental testing procedures for electronic equipment in heavy-duty vehicles. These standards specify temperature cycling tests ranging from -40°C to +85°C, humidity exposure tests at 95% relative humidity, and vibration testing at frequencies mimicking real-world driving conditions.

The International Electrotechnical Commission (IEC) contributes additional relevant standards, particularly IEC 60068, which defines environmental testing procedures for electronic components. For automotive displays, the IEC 60068-2-14 (temperature cycling), IEC 60068-2-30 (damp heat cycling), and IEC 60068-2-64 (vibration testing) are especially pertinent to evaluating flexible OLED encapsulation durability.

Automotive-specific standards from ISO, such as ISO 16750, provide comprehensive testing protocols for electrical and electronic equipment in road vehicles. The standard includes mechanical, electrical, thermal, and chemical stress tests that directly impact encapsulation performance. Of particular importance is ISO 16750-4, which addresses environmental conditions and testing for electrical and electronic equipment.

USCAR (United States Council for Automotive Research) has developed the USCAR-2 specification, which outlines performance requirements for automotive-grade electronic components, including displays. This standard mandates 1,000 hours of high-temperature operating life testing and 1,000 temperature cycles, significantly more rigorous than consumer electronics requirements.

The Automotive Electronics Council's AEC-Q100 qualification defines stress test qualifications for integrated circuits in automotive applications. While primarily focused on semiconductors, these standards influence testing protocols for display systems incorporating driver ICs and control electronics that interface with flexible OLED panels.

For flexible OLED encapsulation specifically, ASTM F1249 (water vapor transmission rate) and ASTM F1927 (oxygen transmission rate) provide standardized methods to evaluate barrier performance, which is critical for preventing moisture and oxygen ingress that can degrade OLED materials. These tests must be conducted under automotive-relevant conditions to accurately predict field performance.

The Society of Automotive Engineers (SAE) has developed several key standards, including SAE J1455 and SAE J575, which outline environmental testing procedures for electronic equipment in heavy-duty vehicles. These standards specify temperature cycling tests ranging from -40°C to +85°C, humidity exposure tests at 95% relative humidity, and vibration testing at frequencies mimicking real-world driving conditions.

The International Electrotechnical Commission (IEC) contributes additional relevant standards, particularly IEC 60068, which defines environmental testing procedures for electronic components. For automotive displays, the IEC 60068-2-14 (temperature cycling), IEC 60068-2-30 (damp heat cycling), and IEC 60068-2-64 (vibration testing) are especially pertinent to evaluating flexible OLED encapsulation durability.

Automotive-specific standards from ISO, such as ISO 16750, provide comprehensive testing protocols for electrical and electronic equipment in road vehicles. The standard includes mechanical, electrical, thermal, and chemical stress tests that directly impact encapsulation performance. Of particular importance is ISO 16750-4, which addresses environmental conditions and testing for electrical and electronic equipment.

USCAR (United States Council for Automotive Research) has developed the USCAR-2 specification, which outlines performance requirements for automotive-grade electronic components, including displays. This standard mandates 1,000 hours of high-temperature operating life testing and 1,000 temperature cycles, significantly more rigorous than consumer electronics requirements.

The Automotive Electronics Council's AEC-Q100 qualification defines stress test qualifications for integrated circuits in automotive applications. While primarily focused on semiconductors, these standards influence testing protocols for display systems incorporating driver ICs and control electronics that interface with flexible OLED panels.

For flexible OLED encapsulation specifically, ASTM F1249 (water vapor transmission rate) and ASTM F1927 (oxygen transmission rate) provide standardized methods to evaluate barrier performance, which is critical for preventing moisture and oxygen ingress that can degrade OLED materials. These tests must be conducted under automotive-relevant conditions to accurately predict field performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!