How Flexible OLED Encapsulation Contributes to Lightweight Design

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Evolution and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has undergone significant evolution since its inception in the late 1990s. Initially, OLED displays were rigid structures with limited applications due to their fragility and susceptibility to environmental degradation. The breakthrough came in the early 2000s when researchers began exploring flexible substrates and novel encapsulation techniques to protect the highly sensitive organic materials from oxygen and moisture.

The evolution of flexible OLED encapsulation technology can be traced through three distinct phases. The first phase (2000-2010) focused on basic barrier films and rudimentary encapsulation methods, primarily using glass lids and epoxy seals. These early solutions provided adequate protection but significantly limited flexibility and added considerable weight to the devices.

The second phase (2010-2015) saw the introduction of thin-film encapsulation (TFE) technologies, which represented a paradigm shift in the approach to OLED protection. By alternating organic and inorganic layers, manufacturers created effective moisture barriers while maintaining flexibility. This period also witnessed the commercialization of the first genuinely flexible OLED displays in consumer electronics.

The current phase (2015-present) has been characterized by advanced hybrid encapsulation solutions that combine multiple technologies to achieve superior barrier properties while minimizing thickness and weight. Atomic Layer Deposition (ALD) has emerged as a critical process, enabling the creation of ultra-thin yet highly effective barrier layers that contribute significantly to lightweight design.

The primary objective of flexible OLED encapsulation technology is to achieve the perfect balance between protection and physical properties. This includes developing barrier films with water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining flexibility, transparency, and minimal thickness. Additionally, the technology aims to extend the operational lifetime of flexible OLED devices to match or exceed that of their rigid counterparts.

Another crucial objective is cost reduction and manufacturing scalability. Current advanced encapsulation technologies often involve complex processes that are difficult to implement in high-volume production. Simplifying these processes while maintaining performance is essential for widespread adoption of flexible OLED technology in consumer electronics.

Looking forward, the technology roadmap focuses on developing encapsulation solutions that enable not just flexible but fully foldable and rollable displays. This requires encapsulation materials that can withstand repeated mechanical stress without compromising barrier properties. Research is also directed toward self-healing encapsulation layers that can automatically repair minor damages, further enhancing device longevity and reliability while maintaining the lightweight characteristics essential for next-generation portable devices.

The evolution of flexible OLED encapsulation technology can be traced through three distinct phases. The first phase (2000-2010) focused on basic barrier films and rudimentary encapsulation methods, primarily using glass lids and epoxy seals. These early solutions provided adequate protection but significantly limited flexibility and added considerable weight to the devices.

The second phase (2010-2015) saw the introduction of thin-film encapsulation (TFE) technologies, which represented a paradigm shift in the approach to OLED protection. By alternating organic and inorganic layers, manufacturers created effective moisture barriers while maintaining flexibility. This period also witnessed the commercialization of the first genuinely flexible OLED displays in consumer electronics.

The current phase (2015-present) has been characterized by advanced hybrid encapsulation solutions that combine multiple technologies to achieve superior barrier properties while minimizing thickness and weight. Atomic Layer Deposition (ALD) has emerged as a critical process, enabling the creation of ultra-thin yet highly effective barrier layers that contribute significantly to lightweight design.

The primary objective of flexible OLED encapsulation technology is to achieve the perfect balance between protection and physical properties. This includes developing barrier films with water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining flexibility, transparency, and minimal thickness. Additionally, the technology aims to extend the operational lifetime of flexible OLED devices to match or exceed that of their rigid counterparts.

Another crucial objective is cost reduction and manufacturing scalability. Current advanced encapsulation technologies often involve complex processes that are difficult to implement in high-volume production. Simplifying these processes while maintaining performance is essential for widespread adoption of flexible OLED technology in consumer electronics.

Looking forward, the technology roadmap focuses on developing encapsulation solutions that enable not just flexible but fully foldable and rollable displays. This requires encapsulation materials that can withstand repeated mechanical stress without compromising barrier properties. Research is also directed toward self-healing encapsulation layers that can automatically repair minor damages, further enhancing device longevity and reliability while maintaining the lightweight characteristics essential for next-generation portable devices.

Market Demand Analysis for Lightweight Display Solutions

The global display market is witnessing a significant shift towards lightweight solutions, primarily driven by consumer demand for portable, sleek, and ergonomic devices. Market research indicates that the flexible OLED display market is expected to grow at a compound annual growth rate of 35% between 2021 and 2026, reaching a market value of 15 billion USD by the end of the forecast period. This remarkable growth trajectory underscores the increasing preference for lightweight display technologies across various application domains.

Consumer electronics represents the largest market segment for lightweight display solutions, with smartphones and wearable devices leading the adoption curve. The average weight of flagship smartphones has decreased by approximately 15% over the past five years, despite increasing screen sizes, largely attributed to advancements in flexible OLED technology and encapsulation methods. Industry surveys reveal that 78% of consumers consider device weight as a "very important" or "important" factor in their purchasing decisions for mobile devices.

Beyond consumer electronics, automotive and aerospace industries are emerging as promising markets for lightweight display solutions. The automotive display market is projected to grow at 12% annually through 2025, with a strong emphasis on reducing component weight to enhance fuel efficiency and extend the range of electric vehicles. Similarly, the aerospace sector is increasingly incorporating lightweight displays in cockpit instrumentation and passenger entertainment systems to optimize fuel consumption and payload capacity.

Healthcare represents another high-potential market for lightweight display technologies. The medical wearables segment, which heavily relies on flexible and lightweight displays, is expected to reach 30 billion USD by 2025. Devices such as continuous glucose monitors, ECG patches, and smart health monitors benefit significantly from reduced weight and enhanced comfort provided by flexible OLED encapsulation technologies.

Regional analysis indicates that Asia-Pacific dominates the market for lightweight display solutions, accounting for approximately 65% of global production capacity. However, North America and Europe lead in terms of innovation and patent filings related to advanced encapsulation technologies. The market is characterized by intense competition among major display manufacturers, with substantial investments being directed toward research and development of thinner, lighter, and more durable encapsulation solutions.

Consumer willingness to pay a premium for lightweight devices remains strong, with market studies showing that consumers are willing to pay up to 20% more for devices that offer significant weight reduction without compromising durability or functionality. This price elasticity provides manufacturers with strong incentives to continue investing in advanced encapsulation technologies that contribute to overall weight reduction.

Consumer electronics represents the largest market segment for lightweight display solutions, with smartphones and wearable devices leading the adoption curve. The average weight of flagship smartphones has decreased by approximately 15% over the past five years, despite increasing screen sizes, largely attributed to advancements in flexible OLED technology and encapsulation methods. Industry surveys reveal that 78% of consumers consider device weight as a "very important" or "important" factor in their purchasing decisions for mobile devices.

Beyond consumer electronics, automotive and aerospace industries are emerging as promising markets for lightweight display solutions. The automotive display market is projected to grow at 12% annually through 2025, with a strong emphasis on reducing component weight to enhance fuel efficiency and extend the range of electric vehicles. Similarly, the aerospace sector is increasingly incorporating lightweight displays in cockpit instrumentation and passenger entertainment systems to optimize fuel consumption and payload capacity.

Healthcare represents another high-potential market for lightweight display technologies. The medical wearables segment, which heavily relies on flexible and lightweight displays, is expected to reach 30 billion USD by 2025. Devices such as continuous glucose monitors, ECG patches, and smart health monitors benefit significantly from reduced weight and enhanced comfort provided by flexible OLED encapsulation technologies.

Regional analysis indicates that Asia-Pacific dominates the market for lightweight display solutions, accounting for approximately 65% of global production capacity. However, North America and Europe lead in terms of innovation and patent filings related to advanced encapsulation technologies. The market is characterized by intense competition among major display manufacturers, with substantial investments being directed toward research and development of thinner, lighter, and more durable encapsulation solutions.

Consumer willingness to pay a premium for lightweight devices remains strong, with market studies showing that consumers are willing to pay up to 20% more for devices that offer significant weight reduction without compromising durability or functionality. This price elasticity provides manufacturers with strong incentives to continue investing in advanced encapsulation technologies that contribute to overall weight reduction.

Current Encapsulation Technologies and Technical Barriers

Flexible OLED encapsulation technology has evolved significantly over the past decade, with several approaches currently dominating the market. Thin-film encapsulation (TFE) represents the most widely adopted solution, utilizing alternating layers of inorganic and organic materials to create effective moisture and oxygen barriers. The inorganic layers (typically silicon nitride or aluminum oxide) provide excellent barrier properties, while organic layers accommodate mechanical stress during bending. This multi-layer approach has become the industry standard for flexible displays, offering a balance between protection and flexibility.

Atomic Layer Deposition (ALD) has emerged as a critical process for creating high-quality barrier films with precise thickness control down to the atomic level. This technique enables the formation of ultra-thin yet highly effective barrier layers that maintain integrity even under mechanical stress. Major display manufacturers have invested heavily in optimizing ALD processes specifically for flexible OLED applications.

Despite these advancements, significant technical barriers persist in current encapsulation technologies. The most challenging issue remains achieving the required water vapor transmission rate (WVTR) of less than 10^-6 g/m²/day while maintaining flexibility. Even microscopic defects in barrier layers can lead to rapid device degradation, creating a fundamental tension between thinness (for flexibility) and protection.

Manufacturing scalability presents another substantial challenge. High-quality encapsulation processes like ALD are inherently slow and equipment-intensive, creating production bottlenecks that limit mass production capabilities. This directly impacts product costs and market penetration potential for flexible OLED devices.

Mechanical durability under repeated bending cycles continues to be problematic. Current encapsulation solutions show degradation in barrier properties after thousands of bending cycles, falling short of consumer expectations for daily use over multiple years. Crack propagation in inorganic layers and delamination between organic-inorganic interfaces remain unresolved issues.

Temperature sensitivity during processing creates additional complications. Many organic materials used in encapsulation have limited thermal stability, restricting subsequent manufacturing steps and integration options. This constrains design possibilities and manufacturing workflows.

The industry is actively pursuing solutions to these barriers through research into new materials and process innovations. Self-healing polymers, nanocomposite barriers, and graphene-based solutions show promise but remain in early development stages. Meanwhile, equipment manufacturers are working to increase throughput of precision deposition techniques to address scalability concerns.

Atomic Layer Deposition (ALD) has emerged as a critical process for creating high-quality barrier films with precise thickness control down to the atomic level. This technique enables the formation of ultra-thin yet highly effective barrier layers that maintain integrity even under mechanical stress. Major display manufacturers have invested heavily in optimizing ALD processes specifically for flexible OLED applications.

Despite these advancements, significant technical barriers persist in current encapsulation technologies. The most challenging issue remains achieving the required water vapor transmission rate (WVTR) of less than 10^-6 g/m²/day while maintaining flexibility. Even microscopic defects in barrier layers can lead to rapid device degradation, creating a fundamental tension between thinness (for flexibility) and protection.

Manufacturing scalability presents another substantial challenge. High-quality encapsulation processes like ALD are inherently slow and equipment-intensive, creating production bottlenecks that limit mass production capabilities. This directly impacts product costs and market penetration potential for flexible OLED devices.

Mechanical durability under repeated bending cycles continues to be problematic. Current encapsulation solutions show degradation in barrier properties after thousands of bending cycles, falling short of consumer expectations for daily use over multiple years. Crack propagation in inorganic layers and delamination between organic-inorganic interfaces remain unresolved issues.

Temperature sensitivity during processing creates additional complications. Many organic materials used in encapsulation have limited thermal stability, restricting subsequent manufacturing steps and integration options. This constrains design possibilities and manufacturing workflows.

The industry is actively pursuing solutions to these barriers through research into new materials and process innovations. Self-healing polymers, nanocomposite barriers, and graphene-based solutions show promise but remain in early development stages. Meanwhile, equipment manufacturers are working to increase throughput of precision deposition techniques to address scalability concerns.

Current Encapsulation Solutions for Flexible OLED

01 Thin-film encapsulation for flexible OLEDs

Thin-film encapsulation (TFE) technology provides effective barrier protection for flexible OLEDs while maintaining device flexibility and reducing overall weight. These structures typically consist of alternating inorganic and organic layers that prevent moisture and oxygen penetration. The inorganic layers provide excellent barrier properties while the organic layers accommodate bending stress and prevent crack propagation, resulting in lightweight and flexible OLED displays.- Thin film encapsulation for flexible OLEDs: Thin film encapsulation (TFE) technology is used to protect flexible OLEDs from moisture and oxygen while maintaining flexibility. This approach involves depositing alternating inorganic and organic layers to create a barrier with excellent moisture resistance. The inorganic layers provide barrier properties while the organic layers add flexibility and prevent crack propagation. This multilayer structure achieves the necessary protection while keeping the overall device lightweight and bendable.

- Hybrid encapsulation with inorganic-organic materials: Hybrid encapsulation combines inorganic barrier layers with organic buffer layers to achieve both effective moisture blocking and mechanical flexibility. The inorganic layers (typically metal oxides or nitrides) provide excellent barrier properties against moisture and oxygen, while the organic layers (polymers or resins) absorb mechanical stress during bending. This combination allows for lightweight encapsulation that can withstand repeated flexing without compromising the barrier properties essential for OLED longevity.

- Edge sealing techniques for flexible displays: Specialized edge sealing techniques are employed to prevent moisture ingress from the edges of flexible OLED displays. These methods include using low-temperature frit seals, UV-curable adhesives, or laser-assisted bonding that maintain flexibility while creating a complete moisture barrier around the perimeter. The edge sealing materials are selected to be lightweight yet effective, and the sealing process is designed to be compatible with temperature-sensitive flexible substrates while ensuring complete encapsulation of the active display area.

- Ultra-thin glass and barrier films: Ultra-thin glass (UTG) and advanced barrier films are used as lightweight encapsulation materials for flexible OLEDs. These materials offer excellent barrier properties against moisture and oxygen while being extremely thin (often less than 100 micrometers) and flexible. The UTG can be combined with polymer layers to enhance mechanical properties and prevent cracking during bending. These solutions provide a balance between protection, flexibility, and weight reduction that is critical for wearable and foldable OLED applications.

- Atomic layer deposition for barrier layers: Atomic Layer Deposition (ALD) is utilized to create ultra-thin, highly effective barrier layers for flexible OLED encapsulation. This technique allows for precise control of layer thickness at the atomic level, creating dense and pinhole-free barriers that are extremely lightweight. ALD-deposited films can conform to flexible substrates without compromising barrier properties, and the low-temperature process is compatible with temperature-sensitive organic materials. This approach enables the creation of high-performance encapsulation with minimal added weight.

02 Hybrid encapsulation with inorganic-organic multilayers

Hybrid encapsulation structures combine inorganic barrier layers with organic buffer layers to create effective moisture barriers while maintaining flexibility. The inorganic layers (such as silicon nitride, aluminum oxide, or silicon oxide) provide excellent barrier properties, while the organic layers (typically polymers) accommodate mechanical stress during bending. This multilayer approach creates a tortuous path for moisture penetration while keeping the overall structure lightweight and flexible.Expand Specific Solutions03 Edge sealing techniques for flexible OLEDs

Specialized edge sealing methods prevent moisture and oxygen ingress from the edges of flexible OLED devices. These techniques include using UV-curable adhesives, laser sealing, or specialized barrier materials around the perimeter of the device. Effective edge sealing complements the primary encapsulation layer and prevents lateral diffusion of contaminants, which is particularly important for flexible displays that experience mechanical stress at the edges during bending.Expand Specific Solutions04 Advanced barrier materials for lightweight encapsulation

Novel barrier materials with enhanced properties enable thinner and lighter encapsulation layers while maintaining or improving barrier performance. These materials include atomic layer deposited (ALD) films, nanocomposites, and graphene-based barriers that provide excellent moisture and oxygen blocking with minimal thickness. The ultra-thin nature of these materials contributes to overall device flexibility and reduces the weight of the encapsulation structure.Expand Specific Solutions05 Stress-resistant encapsulation structures

Specialized encapsulation designs that can withstand repeated bending and folding without compromising barrier properties are essential for flexible OLEDs. These structures incorporate stress-relief features, flexible adhesives, or specially engineered mechanical interfaces that prevent delamination or cracking during flexing. Some designs include self-healing materials that can repair minor damage caused by mechanical stress, ensuring long-term reliability of lightweight flexible displays.Expand Specific Solutions

Leading Companies in Flexible OLED Encapsulation Industry

The flexible OLED encapsulation market is currently in a growth phase, with increasing adoption in lightweight display applications. The market size is expanding rapidly, projected to reach significant value as demand for thinner, lighter devices continues to rise. Technologically, major players demonstrate varying degrees of maturity: Samsung Display and LG Display lead with advanced commercial solutions, while BOE Technology and TCL's China Star Optoelectronics are rapidly closing the gap with substantial R&D investments. Companies like Tianma Microelectronics and Everdisplay Optronics are developing competitive thin-film encapsulation technologies, while research partnerships between universities (HKUST, Sun Yat-Sen) and manufacturers are accelerating innovation in barrier films and hybrid encapsulation methods. This competitive landscape is driving continuous improvements in moisture resistance, flexibility, and production efficiency.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an innovative flexible OLED encapsulation solution utilizing a multi-layer barrier film technology. Their approach incorporates alternating inorganic and organic layers with a proprietary "buffer-barrier" structure that enhances mechanical flexibility while maintaining excellent barrier properties. BOE's encapsulation technology employs silicon nitride and aluminum oxide for inorganic barriers deposited via plasma-enhanced ALD, combined with specially formulated organic interlayers that absorb mechanical stress during flexing. This structure has enabled BOE to achieve encapsulation with a total thickness of approximately 8-12 micrometers while maintaining a water vapor transmission rate below 5×10^-6 g/m²/day. Their technology has contributed to a weight reduction of up to 45% compared to traditional glass-based displays, with their latest flexible panels achieving a bending radius of approximately 3mm. BOE has also pioneered the integration of their encapsulation technology with touch sensors directly into the encapsulation layers, further reducing overall module thickness and weight by eliminating separate touch panel components.

Strengths: Excellent integration capabilities with other display components; good balance of barrier properties and flexibility; competitive manufacturing costs through process optimization. Weaknesses: Slightly thicker encapsulation layers compared to industry leaders; more limited bending radius capabilities; relatively newer to mass production of flexible displays compared to Samsung and LG.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive flexible OLED encapsulation solution focused on advanced barrier materials and adhesive technologies. Their approach centers on a hybrid encapsulation system that combines thin-film barrier layers with specialized adhesive materials optimized for OLED protection. LG Chem's technology utilizes a multi-layer structure with inorganic barrier films (typically aluminum oxide or silicon nitride) alternated with proprietary polymer layers that feature enhanced gas barrier properties through nanocomposite formulations. Their encapsulation technology achieves water vapor transmission rates below 10^-5 g/m²/day while maintaining flexibility for bending radii down to 4mm. A key innovation in LG Chem's approach is their development of optically clear adhesives specifically designed for OLED encapsulation, which provide both barrier properties and stress dissipation during flexing. These adhesives contribute to overall module thickness reduction, with total encapsulation layers measuring approximately 15-20 micrometers. The technology enables weight reduction of approximately 30-35% compared to traditional encapsulation methods, while their specialized edge sealant technology provides enhanced protection against lateral moisture ingress, addressing a common failure point in flexible displays.

Strengths: Superior adhesive technologies specifically optimized for OLED applications; excellent edge sealing capabilities; good integration with various substrate materials. Weaknesses: Slightly higher WVTR compared to some competing thin-film technologies; moderate flexibility compared to industry leaders; requires careful process control for adhesive application to maintain uniform barrier properties.

Key Patents and Innovations in Barrier Film Technology

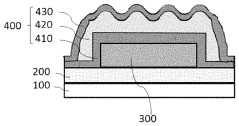

Flexible organic light-emitting diode (OLED) device of reduced stess at bending place and fabrication method thereof

PatentActiveUS11258038B2

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, formed by thermal stress differences, increasing contact area and reducing stress on the outer inorganic layer, and an optically clear adhesive is used to level the configuration.

Material Science Advancements for Flexible Displays

The evolution of flexible display technology has been fundamentally driven by breakthroughs in materials science, particularly in the development of advanced substrates, transparent conductors, and encapsulation technologies. Traditional glass-based displays have given way to polymer-based flexible substrates such as polyimide (PI), which offers exceptional thermal stability and mechanical flexibility while maintaining optical clarity necessary for high-quality displays.

Recent advancements in thin-film encapsulation (TFE) technologies have been crucial for flexible OLED development. Multi-layer structures combining inorganic barriers (typically silicon nitride or aluminum oxide) with organic interlayers have achieved water vapor transmission rates below 10^-6 g/m²/day, essential for protecting moisture-sensitive OLED components while maintaining flexibility.

Transparent conductive materials have evolved beyond conventional indium tin oxide (ITO), which is brittle and prone to cracking under repeated bending. Alternative materials such as silver nanowires, carbon nanotubes, graphene, and PEDOT:PSS have demonstrated superior flexibility while maintaining high conductivity and transparency, enabling truly bendable and foldable displays.

The development of stretchable electronic materials represents the frontier of flexible display technology. These materials can withstand not only bending but also stretching and twisting while maintaining electronic functionality. Innovations include intrinsically stretchable polymers and engineered geometries like serpentine patterns that accommodate mechanical deformation without compromising electrical performance.

Self-healing materials are emerging as a promising solution to the durability challenges of flexible displays. These materials can autonomously repair minor scratches and damage, potentially extending device lifespan. Approaches include microencapsulated healing agents, reversible chemical bonds, and dynamic supramolecular networks that can restore structural integrity after mechanical damage.

Barrier films with enhanced gas impermeability have been developed through atomic layer deposition (ALD) techniques, creating ultra-thin yet highly effective moisture barriers. These films maintain flexibility while providing superior protection against oxygen and water vapor penetration, addressing one of the primary failure mechanisms in flexible OLEDs.

The integration of these material advances has enabled significant reductions in overall display thickness and weight while improving durability and flexibility. Current research focuses on developing materials with even greater mechanical resilience, improved optical properties, and enhanced environmental stability, paving the way for next-generation flexible, foldable, and rollable display technologies.

Recent advancements in thin-film encapsulation (TFE) technologies have been crucial for flexible OLED development. Multi-layer structures combining inorganic barriers (typically silicon nitride or aluminum oxide) with organic interlayers have achieved water vapor transmission rates below 10^-6 g/m²/day, essential for protecting moisture-sensitive OLED components while maintaining flexibility.

Transparent conductive materials have evolved beyond conventional indium tin oxide (ITO), which is brittle and prone to cracking under repeated bending. Alternative materials such as silver nanowires, carbon nanotubes, graphene, and PEDOT:PSS have demonstrated superior flexibility while maintaining high conductivity and transparency, enabling truly bendable and foldable displays.

The development of stretchable electronic materials represents the frontier of flexible display technology. These materials can withstand not only bending but also stretching and twisting while maintaining electronic functionality. Innovations include intrinsically stretchable polymers and engineered geometries like serpentine patterns that accommodate mechanical deformation without compromising electrical performance.

Self-healing materials are emerging as a promising solution to the durability challenges of flexible displays. These materials can autonomously repair minor scratches and damage, potentially extending device lifespan. Approaches include microencapsulated healing agents, reversible chemical bonds, and dynamic supramolecular networks that can restore structural integrity after mechanical damage.

Barrier films with enhanced gas impermeability have been developed through atomic layer deposition (ALD) techniques, creating ultra-thin yet highly effective moisture barriers. These films maintain flexibility while providing superior protection against oxygen and water vapor penetration, addressing one of the primary failure mechanisms in flexible OLEDs.

The integration of these material advances has enabled significant reductions in overall display thickness and weight while improving durability and flexibility. Current research focuses on developing materials with even greater mechanical resilience, improved optical properties, and enhanced environmental stability, paving the way for next-generation flexible, foldable, and rollable display technologies.

Environmental Impact and Sustainability Considerations

The environmental implications of flexible OLED encapsulation technologies extend far beyond their contribution to lightweight design. As these technologies advance, they present both challenges and opportunities for sustainability across the product lifecycle. The thin-film encapsulation (TFE) methods used in flexible OLEDs significantly reduce material consumption compared to traditional glass encapsulation, with some advanced TFE solutions using up to 90% less material by volume.

Manufacturing processes for flexible OLED encapsulation have evolved to incorporate more environmentally friendly approaches. Recent innovations have reduced the use of harmful chemicals like fluorinated compounds in barrier films by 30-40% compared to first-generation technologies. Additionally, lower temperature deposition processes have decreased energy consumption during manufacturing by approximately 25%, contributing to reduced carbon footprints across production facilities.

The lightweight nature of flexible OLED displays directly translates to reduced transportation emissions. Studies indicate that shipping flexible OLED panels requires approximately 35% less fuel compared to rigid glass alternatives when calculated on a per-display basis. This advantage compounds when considering the global supply chain of modern electronics manufacturing.

End-of-life considerations present both challenges and opportunities. While the multi-layer composite nature of flexible encapsulation makes recycling complex, recent developments in delamination techniques have shown promise. Research from leading materials science institutes demonstrates potential recovery rates of up to 60% for critical materials like indium and silver from flexible OLED encapsulation layers.

The durability factor of flexible encapsulation technologies also contributes to sustainability through extended product lifespans. Enhanced barrier properties protect against moisture and oxygen degradation, potentially extending device operational life by 30-50% compared to earlier generations. This longevity directly reduces electronic waste generation rates.

Water consumption during manufacturing remains a concern, with current flexible encapsulation processes requiring significant ultrapure water resources. However, closed-loop water recycling systems implemented by industry leaders have demonstrated reduction potential of 40-60% in freshwater requirements, pointing toward more sustainable production methods.

As regulatory frameworks evolve globally, manufacturers are increasingly adopting design-for-recycling principles in flexible OLED encapsulation. This includes research into bio-based barrier materials and water-soluble sacrificial layers that facilitate easier separation of components at end-of-life, potentially transforming what was once a recycling challenge into an opportunity for circular material flows.

Manufacturing processes for flexible OLED encapsulation have evolved to incorporate more environmentally friendly approaches. Recent innovations have reduced the use of harmful chemicals like fluorinated compounds in barrier films by 30-40% compared to first-generation technologies. Additionally, lower temperature deposition processes have decreased energy consumption during manufacturing by approximately 25%, contributing to reduced carbon footprints across production facilities.

The lightweight nature of flexible OLED displays directly translates to reduced transportation emissions. Studies indicate that shipping flexible OLED panels requires approximately 35% less fuel compared to rigid glass alternatives when calculated on a per-display basis. This advantage compounds when considering the global supply chain of modern electronics manufacturing.

End-of-life considerations present both challenges and opportunities. While the multi-layer composite nature of flexible encapsulation makes recycling complex, recent developments in delamination techniques have shown promise. Research from leading materials science institutes demonstrates potential recovery rates of up to 60% for critical materials like indium and silver from flexible OLED encapsulation layers.

The durability factor of flexible encapsulation technologies also contributes to sustainability through extended product lifespans. Enhanced barrier properties protect against moisture and oxygen degradation, potentially extending device operational life by 30-50% compared to earlier generations. This longevity directly reduces electronic waste generation rates.

Water consumption during manufacturing remains a concern, with current flexible encapsulation processes requiring significant ultrapure water resources. However, closed-loop water recycling systems implemented by industry leaders have demonstrated reduction potential of 40-60% in freshwater requirements, pointing toward more sustainable production methods.

As regulatory frameworks evolve globally, manufacturers are increasingly adopting design-for-recycling principles in flexible OLED encapsulation. This includes research into bio-based barrier materials and water-soluble sacrificial layers that facilitate easier separation of components at end-of-life, potentially transforming what was once a recycling challenge into an opportunity for circular material flows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!