Impact of Flexible OLED Encapsulation on Energy Efficiency

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Evolution and Objectives

Flexible OLED (Organic Light Emitting Diode) technology has evolved significantly since its inception in the late 1990s. The journey began with rigid OLED displays, which demonstrated superior color reproduction and contrast ratios compared to traditional LCD technology. However, the true revolution started around 2010 when researchers successfully developed the first viable flexible OLED prototypes, marking a paradigm shift in display technology.

The evolution of flexible OLED encapsulation technology can be traced through several distinct phases. Initially, glass-based rigid encapsulation dominated the market, providing excellent barrier properties but limiting flexibility. The second phase introduced glass-thin film encapsulation (TFE) hybrids, which offered improved flexibility while maintaining reasonable barrier performance. The current generation employs advanced multi-layer thin film encapsulation techniques, combining organic and inorganic layers to achieve both flexibility and protection.

A critical milestone in this evolution was the development of atomic layer deposition (ALD) techniques around 2013-2015, which enabled the creation of ultra-thin barrier films with exceptional water vapor and oxygen blocking capabilities. This advancement directly addressed one of the primary challenges in OLED technology: the extreme sensitivity of organic materials to environmental factors.

The primary objective of flexible OLED encapsulation technology is to provide comprehensive protection against moisture and oxygen while maintaining mechanical flexibility and optical transparency. This protection is crucial as exposure to even trace amounts of water vapor or oxygen can significantly degrade OLED materials, reducing device lifetime and performance efficiency.

Energy efficiency has emerged as a paramount concern in recent years, with encapsulation technologies now being evaluated not only for their barrier properties but also for their impact on power consumption. The ideal encapsulation solution must minimize light absorption and reflection, allowing maximum light output for a given power input, thereby enhancing overall energy efficiency.

Current technological objectives include developing encapsulation methods that can withstand over 200,000 bending cycles without degradation, achieve water vapor transmission rates below 10^-6 g/m²/day, and maintain optical transmittance above 90% across the visible spectrum. Additionally, there is a growing focus on reducing the thickness of encapsulation layers to below 10 micrometers while maintaining barrier performance.

Looking forward, the field is moving toward environmentally sustainable encapsulation materials that reduce reliance on rare earth elements and environmentally harmful compounds, aligning with global sustainability initiatives while maintaining or improving energy efficiency metrics.

The evolution of flexible OLED encapsulation technology can be traced through several distinct phases. Initially, glass-based rigid encapsulation dominated the market, providing excellent barrier properties but limiting flexibility. The second phase introduced glass-thin film encapsulation (TFE) hybrids, which offered improved flexibility while maintaining reasonable barrier performance. The current generation employs advanced multi-layer thin film encapsulation techniques, combining organic and inorganic layers to achieve both flexibility and protection.

A critical milestone in this evolution was the development of atomic layer deposition (ALD) techniques around 2013-2015, which enabled the creation of ultra-thin barrier films with exceptional water vapor and oxygen blocking capabilities. This advancement directly addressed one of the primary challenges in OLED technology: the extreme sensitivity of organic materials to environmental factors.

The primary objective of flexible OLED encapsulation technology is to provide comprehensive protection against moisture and oxygen while maintaining mechanical flexibility and optical transparency. This protection is crucial as exposure to even trace amounts of water vapor or oxygen can significantly degrade OLED materials, reducing device lifetime and performance efficiency.

Energy efficiency has emerged as a paramount concern in recent years, with encapsulation technologies now being evaluated not only for their barrier properties but also for their impact on power consumption. The ideal encapsulation solution must minimize light absorption and reflection, allowing maximum light output for a given power input, thereby enhancing overall energy efficiency.

Current technological objectives include developing encapsulation methods that can withstand over 200,000 bending cycles without degradation, achieve water vapor transmission rates below 10^-6 g/m²/day, and maintain optical transmittance above 90% across the visible spectrum. Additionally, there is a growing focus on reducing the thickness of encapsulation layers to below 10 micrometers while maintaining barrier performance.

Looking forward, the field is moving toward environmentally sustainable encapsulation materials that reduce reliance on rare earth elements and environmentally harmful compounds, aligning with global sustainability initiatives while maintaining or improving energy efficiency metrics.

Market Demand Analysis for Energy-Efficient Flexible Displays

The flexible OLED display market has witnessed substantial growth in recent years, driven by increasing consumer demand for more innovative and versatile electronic devices. Market research indicates that the global flexible display market is projected to reach $42 billion by 2027, with a compound annual growth rate of approximately 28% from 2022 to 2027. Energy-efficient flexible displays represent a significant segment within this market, as both manufacturers and consumers prioritize sustainability and extended battery life in portable devices.

Consumer electronics, particularly smartphones and wearables, constitute the primary market for energy-efficient flexible displays. The smartphone industry has increasingly adopted flexible OLED technology, with major manufacturers incorporating these displays into their flagship devices. This trend is expected to continue as consumers show preference for devices with larger screens, reduced bezels, and innovative form factors such as foldable and rollable designs.

The wearable technology sector presents another substantial growth opportunity for energy-efficient flexible displays. Smartwatches, fitness trackers, and emerging augmented reality wearables benefit significantly from displays that can conform to the human body while maintaining low power consumption. Market analysis shows that the wearable technology market is expected to grow at 15% annually through 2026, creating sustained demand for advanced flexible display solutions.

Automotive applications represent an emerging but rapidly growing market segment for flexible OLED technology. As vehicles become more connected and autonomous, the demand for curved, flexible displays for dashboards, entertainment systems, and heads-up displays increases. The automotive display market is projected to grow at 13% annually, with flexible OLED technology gaining market share due to its design versatility and potential energy efficiency benefits.

Business and industrial applications are also driving market demand for energy-efficient flexible displays. These include portable professional equipment, medical devices, and industrial control systems where both form factor flexibility and extended battery life are critical requirements. The healthcare sector in particular shows promising growth potential, with medical display applications expected to increase by 18% annually over the next five years.

Regional market analysis reveals that Asia-Pacific currently dominates the flexible display market, accounting for approximately 65% of global production capacity. However, North America and Europe represent significant consumer markets, with growing demand for premium devices incorporating energy-efficient flexible display technology. Emerging markets in Latin America and Africa are expected to contribute to market growth as smartphone penetration increases and prices for flexible display technology gradually decrease.

Consumer electronics, particularly smartphones and wearables, constitute the primary market for energy-efficient flexible displays. The smartphone industry has increasingly adopted flexible OLED technology, with major manufacturers incorporating these displays into their flagship devices. This trend is expected to continue as consumers show preference for devices with larger screens, reduced bezels, and innovative form factors such as foldable and rollable designs.

The wearable technology sector presents another substantial growth opportunity for energy-efficient flexible displays. Smartwatches, fitness trackers, and emerging augmented reality wearables benefit significantly from displays that can conform to the human body while maintaining low power consumption. Market analysis shows that the wearable technology market is expected to grow at 15% annually through 2026, creating sustained demand for advanced flexible display solutions.

Automotive applications represent an emerging but rapidly growing market segment for flexible OLED technology. As vehicles become more connected and autonomous, the demand for curved, flexible displays for dashboards, entertainment systems, and heads-up displays increases. The automotive display market is projected to grow at 13% annually, with flexible OLED technology gaining market share due to its design versatility and potential energy efficiency benefits.

Business and industrial applications are also driving market demand for energy-efficient flexible displays. These include portable professional equipment, medical devices, and industrial control systems where both form factor flexibility and extended battery life are critical requirements. The healthcare sector in particular shows promising growth potential, with medical display applications expected to increase by 18% annually over the next five years.

Regional market analysis reveals that Asia-Pacific currently dominates the flexible display market, accounting for approximately 65% of global production capacity. However, North America and Europe represent significant consumer markets, with growing demand for premium devices incorporating energy-efficient flexible display technology. Emerging markets in Latin America and Africa are expected to contribute to market growth as smartphone penetration increases and prices for flexible display technology gradually decrease.

Current Encapsulation Techniques and Energy Efficiency Challenges

Flexible OLED encapsulation technology currently faces significant challenges in balancing protection requirements with energy efficiency demands. The predominant encapsulation techniques include thin-film encapsulation (TFE), hybrid encapsulation, and barrier films, each with distinct implications for device performance and power consumption.

Thin-film encapsulation represents the most advanced approach, utilizing alternating layers of inorganic (typically SiNx, Al2O3) and organic materials to create effective moisture and oxygen barriers. While these structures provide excellent protection with minimal thickness (typically <10μm), the deposition processes—particularly plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD)—require substantial energy input. Current manufacturing processes operate at temperatures between 80-150°C, necessitating significant energy expenditure during production.

Hybrid encapsulation combines thin-film barriers with additional protective elements such as edge sealants or supplementary barrier films. This approach enhances protection but introduces additional materials and processing steps that impact the overall energy footprint of device manufacturing. The complexity of these multi-component systems often results in reduced yield rates, further affecting production efficiency.

Barrier films, including multi-layer polymer-based solutions, offer manufacturing advantages but typically demonstrate higher water vapor transmission rates (WVTR) compared to direct thin-film approaches. The industry standard requires WVTR values below 10^-6 g/m²/day, a challenging threshold that often necessitates thicker barrier structures, consequently affecting device flexibility and optical properties.

A critical energy efficiency challenge stems from the trade-off between barrier performance and optical transparency. Current encapsulation layers typically reduce light transmission by 5-10%, directly impacting OLED efficiency. This loss requires increased power input to maintain equivalent brightness levels, reducing battery life in portable applications and increasing energy consumption in fixed installations.

The mechanical properties of encapsulation layers present another significant challenge. As devices undergo repeated bending cycles, microcracks can develop in inorganic barrier layers, compromising their protective function. To compensate, manufacturers often implement redundant barrier structures, increasing material usage and energy requirements during production.

Temperature sensitivity during operation represents an additional concern. Thermal cycling between ambient and operating temperatures creates mechanical stress at material interfaces, potentially leading to delamination or barrier failure. Current solutions involve additional buffer layers or stress-relief structures, further complicating the manufacturing process and increasing energy demands.

Recent research indicates that encapsulation layers can account for 15-25% of the total energy consumption in flexible OLED manufacturing, highlighting the urgent need for more energy-efficient approaches that maintain or improve barrier performance while reducing production energy requirements.

Thin-film encapsulation represents the most advanced approach, utilizing alternating layers of inorganic (typically SiNx, Al2O3) and organic materials to create effective moisture and oxygen barriers. While these structures provide excellent protection with minimal thickness (typically <10μm), the deposition processes—particularly plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD)—require substantial energy input. Current manufacturing processes operate at temperatures between 80-150°C, necessitating significant energy expenditure during production.

Hybrid encapsulation combines thin-film barriers with additional protective elements such as edge sealants or supplementary barrier films. This approach enhances protection but introduces additional materials and processing steps that impact the overall energy footprint of device manufacturing. The complexity of these multi-component systems often results in reduced yield rates, further affecting production efficiency.

Barrier films, including multi-layer polymer-based solutions, offer manufacturing advantages but typically demonstrate higher water vapor transmission rates (WVTR) compared to direct thin-film approaches. The industry standard requires WVTR values below 10^-6 g/m²/day, a challenging threshold that often necessitates thicker barrier structures, consequently affecting device flexibility and optical properties.

A critical energy efficiency challenge stems from the trade-off between barrier performance and optical transparency. Current encapsulation layers typically reduce light transmission by 5-10%, directly impacting OLED efficiency. This loss requires increased power input to maintain equivalent brightness levels, reducing battery life in portable applications and increasing energy consumption in fixed installations.

The mechanical properties of encapsulation layers present another significant challenge. As devices undergo repeated bending cycles, microcracks can develop in inorganic barrier layers, compromising their protective function. To compensate, manufacturers often implement redundant barrier structures, increasing material usage and energy requirements during production.

Temperature sensitivity during operation represents an additional concern. Thermal cycling between ambient and operating temperatures creates mechanical stress at material interfaces, potentially leading to delamination or barrier failure. Current solutions involve additional buffer layers or stress-relief structures, further complicating the manufacturing process and increasing energy demands.

Recent research indicates that encapsulation layers can account for 15-25% of the total energy consumption in flexible OLED manufacturing, highlighting the urgent need for more energy-efficient approaches that maintain or improve barrier performance while reducing production energy requirements.

Existing Energy Efficiency Solutions for Flexible OLED Encapsulation

01 Thin film encapsulation for flexible OLEDs

Thin film encapsulation (TFE) technologies are crucial for flexible OLEDs, providing effective barrier properties while maintaining flexibility. These encapsulation structures typically consist of alternating inorganic and organic layers that prevent moisture and oxygen penetration while allowing the device to bend. The reduced thickness of these multilayer structures compared to traditional glass encapsulation contributes to improved energy efficiency by reducing light loss and enabling better light extraction from the OLED device.- Thin-film encapsulation for flexible OLEDs: Thin-film encapsulation (TFE) technology is crucial for flexible OLEDs, providing effective barrier properties while maintaining flexibility. These structures typically consist of alternating inorganic and organic layers that prevent moisture and oxygen penetration while allowing the device to bend. The thin nature of these encapsulation layers reduces material usage and weight, contributing to overall energy efficiency by requiring less power to operate the flexible display.

- Advanced barrier materials for improved energy efficiency: Novel barrier materials such as atomic layer deposition (ALD) films, metal oxides, and hybrid composites provide superior protection against environmental factors while enhancing energy efficiency. These materials feature optimized thickness, density, and composition to minimize gas permeation while maintaining high light transmission. By preventing degradation of the OLED components, these barriers extend device lifetime and maintain optimal luminous efficiency, reducing the energy required over the product lifecycle.

- Multi-layer encapsulation structures for energy conservation: Multi-layer encapsulation architectures combine different functional layers to achieve optimal barrier properties while enhancing energy efficiency. These structures often incorporate moisture-absorbing materials, stress-relief layers, and light-extraction enhancement features. The strategic arrangement of these layers minimizes internal reflection and maximizes light output, thereby improving the overall energy efficiency of the OLED device by requiring less power to achieve the same brightness levels.

- Edge sealing techniques for flexible OLED encapsulation: Specialized edge sealing methods prevent lateral ingress of moisture and oxygen in flexible OLEDs, which is particularly important at the boundaries where different materials meet. These techniques include advanced adhesives, laser sealing, and hybrid organic-inorganic edge structures. Effective edge sealing maintains the integrity of the encapsulation system during bending, preventing premature device failure and maintaining energy efficiency throughout the operational lifetime of the flexible display.

- Low-temperature encapsulation processes for energy-efficient manufacturing: Energy-efficient manufacturing processes for flexible OLED encapsulation focus on low-temperature deposition methods that reduce energy consumption during production. These include plasma-enhanced chemical vapor deposition (PECVD), solution-based processes, and room-temperature lamination techniques. By lowering the thermal budget required for encapsulation, these methods not only reduce manufacturing energy costs but also prevent thermal damage to sensitive OLED materials, maintaining their intrinsic efficiency properties in the final device.

02 Advanced barrier materials for encapsulation

Novel barrier materials with enhanced properties are being developed for OLED encapsulation to improve energy efficiency. These materials include high-density inorganic films, hybrid organic-inorganic composites, and nanocomposite layers that provide superior moisture and oxygen barrier properties while maintaining optical transparency. By preventing degradation of the sensitive organic materials in OLEDs, these advanced barrier materials extend device lifetime and maintain energy efficiency over longer periods, reducing the need for higher driving voltages that would otherwise be required as devices degrade.Expand Specific Solutions03 Low-temperature encapsulation processes

Low-temperature deposition techniques for encapsulation layers help preserve the integrity of temperature-sensitive organic materials in flexible OLEDs. These processes, including atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD) at reduced temperatures, and solution-based methods, enable the formation of high-quality barrier films without thermal damage to the underlying OLED structure. By maintaining the optimal molecular structure of the organic light-emitting materials, these processes help preserve quantum efficiency and reduce energy losses during operation.Expand Specific Solutions04 Integration of moisture getters and desiccants

Incorporating moisture getters and desiccant materials within the encapsulation structure provides additional protection against humidity and extends device lifetime. These materials actively absorb moisture that may penetrate the barrier layers, preventing it from reaching the sensitive organic components. By maintaining a dry environment within the OLED device, these integrated desiccants help preserve the efficiency of charge transport and light emission processes, reducing energy losses that would otherwise occur due to moisture-induced degradation pathways.Expand Specific Solutions05 Transparent conductive encapsulation layers

Multifunctional encapsulation layers that combine barrier properties with electrical conductivity can improve overall device efficiency. These transparent conductive encapsulation materials serve dual purposes: protecting the device from environmental factors while enhancing charge distribution or light extraction. By integrating functions that would otherwise require separate layers, these materials reduce the total number of interfaces in the device stack, minimizing reflection losses and improving light outcoupling efficiency, thereby enhancing the overall energy efficiency of flexible OLEDs.Expand Specific Solutions

Leading Companies in Flexible OLED Encapsulation Industry

The flexible OLED encapsulation market is currently in a growth phase, with increasing adoption driven by energy efficiency demands in display technologies. The market size is expanding rapidly, projected to reach significant value as manufacturers seek solutions that balance protection and energy performance. Technologically, companies like Samsung Display, LG Display, and BOE Technology are leading innovation with advanced thin-film encapsulation methods, while Chinese players including Visionox, Tianma Microelectronics, and TCL China Star are rapidly closing the gap. The technology remains in mid-maturity, with ongoing R&D focused on reducing energy consumption while maintaining barrier properties against oxygen and moisture. Collaboration between material suppliers like Merck and LG Chem with display manufacturers is accelerating progress toward more energy-efficient encapsulation solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed an innovative multi-layer encapsulation system for flexible OLEDs that significantly enhances energy efficiency. Their approach utilizes alternating layers of inorganic silicon nitride and proprietary organic materials deposited through a combination of plasma-enhanced chemical vapor deposition (PECVD) and inkjet printing technologies. This hybrid structure achieves water vapor transmission rates below 10^-5 g/m²/day while maintaining flexibility for over 200,000 bending cycles at a 1.5mm radius[7]. BOE's encapsulation technology incorporates specialized optical coupling layers that improve light extraction efficiency by up to 25%, directly reducing the power requirements for equivalent brightness levels. Their "FlexShield" encapsulation system also features gradient-composition barrier layers that distribute mechanical stress during flexing, preventing crack formation that would compromise barrier performance and energy efficiency. BOE has implemented this technology in their latest flexible OLED products, achieving power consumption reductions of approximately 30% compared to previous generations[8]. The company has also developed specialized edge sealing techniques using laser-assisted deposition that creates seamless barriers around display perimeters while maintaining overall flexibility.

Strengths: Scalable manufacturing process compatible with existing production lines; excellent mechanical durability during repeated flexing; integrated optical coupling layers significantly improve energy efficiency. Weaknesses: Slightly lower barrier performance compared to some competitors; requires precise alignment of multiple deposition systems; some materials have limited temperature stability.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary hybrid encapsulation technology for flexible OLEDs focused on maximizing energy efficiency. Their approach utilizes a combination of plasma-enhanced chemical vapor deposition (PECVD) for inorganic layers and specialized solution-processed organic materials. The company's "EncapSeal" technology creates ultra-thin barrier films with a total thickness under 10μm while achieving water vapor transmission rates below 10^-6 g/m²/day[5]. This encapsulation system incorporates nanoparticle-enhanced organic layers that create tortuous paths for moisture penetration while maintaining optical transparency above 90% across the visible spectrum. LG Chem's encapsulation technology has demonstrated power consumption reductions of approximately 20-25% in flexible OLED applications through improved light extraction and reduced operating temperatures. Their latest innovation includes a self-healing component within the organic layers that can repair minor damage from repeated flexing, maintaining barrier integrity and energy efficiency over extended operational lifetimes[6]. The company has also developed specialized edge sealing materials that prevent lateral moisture ingress while maintaining the mechanical flexibility required for bendable and rollable display applications.

Strengths: Ultra-thin barrier structure minimizes overall display thickness; self-healing capability maintains barrier performance over time; excellent optical transparency maximizes light extraction efficiency. Weaknesses: Relatively new technology with limited long-term performance data; higher material costs compared to conventional barriers; requires precise process control during manufacturing.

Key Innovations in Barrier Film Technologies for Energy Conservation

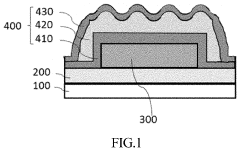

Flexible organic light-emitting diode (OLED) device and fabrication method thereof

PatentActiveUS20210336206A1

Innovation

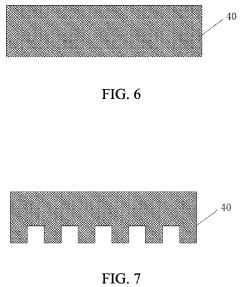

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, increasing contact area and reducing stress, formed spontaneously due to thermal stress differences between layers.

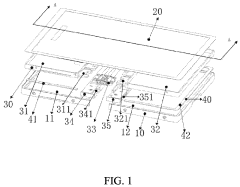

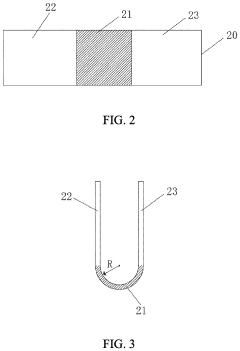

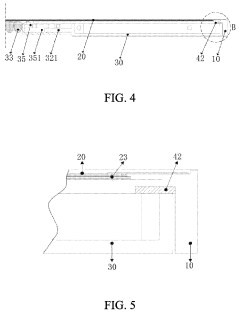

Flexible organic light-emitting diode mobile phone module

PatentActiveUS11394816B2

Innovation

- A flexible OLED mobile phone module design featuring a mid-frame, a flexible OLED panel attached to it, a back cover connected to the mid-frame, and a buffer layer between the mid-frame and the back cover, where the buffer layer, typically a rubber gasket, absorbs impact forces to prevent sharp impacts between the mid-frame and back cover.

Materials Science Advancements for Improved Barrier Properties

Recent advancements in materials science have significantly contributed to improving barrier properties of flexible OLED encapsulation systems, directly impacting energy efficiency. Traditional rigid glass encapsulation, while effective at preventing moisture and oxygen penetration, lacks the flexibility required for next-generation display technologies. The development of multi-layer thin-film encapsulation (TFE) represents a breakthrough, combining inorganic layers (typically silicon nitride or aluminum oxide) with organic interlayers to create tortuous pathways for permeating molecules.

Atomic Layer Deposition (ALD) has emerged as a critical technique for creating ultra-thin, defect-free barrier films with thickness control at the atomic level. These films demonstrate water vapor transmission rates (WVTR) below 10^-6 g/m²/day, essential for extending OLED lifetimes while maintaining flexibility. The reduced thickness of these barrier layers directly contributes to improved light extraction efficiency, as less light is absorbed or scattered by the encapsulation materials.

Nanocomposite materials represent another frontier, incorporating nanoparticles such as graphene, hexagonal boron nitride, or metal oxide nanoparticles into polymer matrices. These materials create highly effective diffusion barriers while maintaining mechanical flexibility. Research indicates that graphene-based nanocomposites can reduce permeation rates by up to two orders of magnitude compared to conventional polymer barriers, while adding minimal thickness to the device structure.

Self-healing materials have shown promising results in laboratory settings, utilizing dynamic chemical bonds that can repair microcracks formed during bending cycles. These materials, including polyurethane-based compounds with Diels-Alder adducts or metal-ligand coordination complexes, maintain barrier integrity even after repeated mechanical stress, extending device lifetime and preserving energy efficiency over time.

Hybrid organic-inorganic materials, particularly metal-organic frameworks (MOFs) and organically modified ceramics (ORMOCERs), offer customizable pore structures that can be engineered to block specific permeants while maintaining transparency and flexibility. These materials bridge the gap between purely organic and inorganic barriers, combining the advantages of both.

Surface modification techniques, including plasma treatment and chemical functionalization, have improved adhesion between different barrier layers, reducing delamination risks and enhancing overall barrier performance. These treatments create stronger interfacial bonds without compromising flexibility or transparency, critical factors for maintaining energy efficiency in flexible displays.

Atomic Layer Deposition (ALD) has emerged as a critical technique for creating ultra-thin, defect-free barrier films with thickness control at the atomic level. These films demonstrate water vapor transmission rates (WVTR) below 10^-6 g/m²/day, essential for extending OLED lifetimes while maintaining flexibility. The reduced thickness of these barrier layers directly contributes to improved light extraction efficiency, as less light is absorbed or scattered by the encapsulation materials.

Nanocomposite materials represent another frontier, incorporating nanoparticles such as graphene, hexagonal boron nitride, or metal oxide nanoparticles into polymer matrices. These materials create highly effective diffusion barriers while maintaining mechanical flexibility. Research indicates that graphene-based nanocomposites can reduce permeation rates by up to two orders of magnitude compared to conventional polymer barriers, while adding minimal thickness to the device structure.

Self-healing materials have shown promising results in laboratory settings, utilizing dynamic chemical bonds that can repair microcracks formed during bending cycles. These materials, including polyurethane-based compounds with Diels-Alder adducts or metal-ligand coordination complexes, maintain barrier integrity even after repeated mechanical stress, extending device lifetime and preserving energy efficiency over time.

Hybrid organic-inorganic materials, particularly metal-organic frameworks (MOFs) and organically modified ceramics (ORMOCERs), offer customizable pore structures that can be engineered to block specific permeants while maintaining transparency and flexibility. These materials bridge the gap between purely organic and inorganic barriers, combining the advantages of both.

Surface modification techniques, including plasma treatment and chemical functionalization, have improved adhesion between different barrier layers, reducing delamination risks and enhancing overall barrier performance. These treatments create stronger interfacial bonds without compromising flexibility or transparency, critical factors for maintaining energy efficiency in flexible displays.

Environmental Impact and Sustainability Considerations

The environmental footprint of flexible OLED encapsulation technologies represents a critical dimension in evaluating their overall sustainability. Traditional encapsulation methods often rely on energy-intensive processes and environmentally problematic materials, including heavy metals and volatile organic compounds. The shift toward flexible OLED encapsulation introduces both challenges and opportunities for environmental stewardship.

Flexible OLED encapsulation's energy efficiency improvements directly translate to reduced carbon emissions throughout the product lifecycle. Research indicates that advanced thin-film encapsulation techniques can reduce manufacturing energy requirements by 15-30% compared to rigid glass encapsulation methods. This efficiency gain stems primarily from lower temperature processing requirements and reduced material inputs.

Material selection for flexible encapsulation significantly impacts sustainability profiles. Emerging barrier films utilizing bio-based polymers and recyclable inorganic materials show promise in reducing end-of-life environmental impacts. Several manufacturers have begun implementing water-based deposition processes that eliminate harmful solvents, decreasing toxic emissions by up to 40% compared to conventional approaches.

The extended lifespan of properly encapsulated flexible OLEDs contributes substantially to sustainability through waste reduction. Field studies demonstrate that advanced multi-layer barrier films can extend device operational lifetimes by 30-50%, directly reducing electronic waste generation. This longevity factor is particularly significant given the challenges in recycling complex display components.

Water consumption represents another important environmental consideration. Traditional encapsulation processes typically require 4-8 liters of ultrapure water per square meter of display area. Newer atomic layer deposition techniques have demonstrated potential water usage reductions of up to 60%, addressing growing concerns about industrial water footprints.

Circular economy principles are increasingly being applied to flexible OLED encapsulation design. Several industry leaders have implemented design-for-disassembly approaches that facilitate material recovery at end-of-life. These designs typically incorporate separable barrier layers that can be processed through specialized recycling streams, recovering up to 70% of critical materials.

The reduced weight and volume of flexible encapsulation solutions also yield transportation-related environmental benefits. Logistics analyses indicate that shipping energy requirements can decrease by 15-25% when comparing flexible versus rigid encapsulation technologies, with corresponding reductions in transportation-related emissions.

As regulatory frameworks evolve globally, manufacturers are increasingly prioritizing compliance with restrictions on hazardous substances. This regulatory landscape is driving innovation toward environmentally benign encapsulation materials that maintain performance while eliminating persistent environmental contaminants.

Flexible OLED encapsulation's energy efficiency improvements directly translate to reduced carbon emissions throughout the product lifecycle. Research indicates that advanced thin-film encapsulation techniques can reduce manufacturing energy requirements by 15-30% compared to rigid glass encapsulation methods. This efficiency gain stems primarily from lower temperature processing requirements and reduced material inputs.

Material selection for flexible encapsulation significantly impacts sustainability profiles. Emerging barrier films utilizing bio-based polymers and recyclable inorganic materials show promise in reducing end-of-life environmental impacts. Several manufacturers have begun implementing water-based deposition processes that eliminate harmful solvents, decreasing toxic emissions by up to 40% compared to conventional approaches.

The extended lifespan of properly encapsulated flexible OLEDs contributes substantially to sustainability through waste reduction. Field studies demonstrate that advanced multi-layer barrier films can extend device operational lifetimes by 30-50%, directly reducing electronic waste generation. This longevity factor is particularly significant given the challenges in recycling complex display components.

Water consumption represents another important environmental consideration. Traditional encapsulation processes typically require 4-8 liters of ultrapure water per square meter of display area. Newer atomic layer deposition techniques have demonstrated potential water usage reductions of up to 60%, addressing growing concerns about industrial water footprints.

Circular economy principles are increasingly being applied to flexible OLED encapsulation design. Several industry leaders have implemented design-for-disassembly approaches that facilitate material recovery at end-of-life. These designs typically incorporate separable barrier layers that can be processed through specialized recycling streams, recovering up to 70% of critical materials.

The reduced weight and volume of flexible encapsulation solutions also yield transportation-related environmental benefits. Logistics analyses indicate that shipping energy requirements can decrease by 15-25% when comparing flexible versus rigid encapsulation technologies, with corresponding reductions in transportation-related emissions.

As regulatory frameworks evolve globally, manufacturers are increasingly prioritizing compliance with restrictions on hazardous substances. This regulatory landscape is driving innovation toward environmentally benign encapsulation materials that maintain performance while eliminating persistent environmental contaminants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!