Standards Governing Flexible OLED Encapsulation Quality Assurance

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized display manufacturing over the past decade, enabling the creation of bendable, foldable, and rollable displays that have transformed consumer electronics. The evolution of this technology began in the early 2000s with rudimentary flexible displays, progressing significantly around 2013 when Samsung and LG introduced the first commercially viable flexible OLED panels.

The critical challenge in flexible OLED development has consistently been encapsulation - the protective barrier that shields the highly sensitive organic materials from oxygen and moisture. Traditional rigid glass encapsulation used in conventional OLEDs cannot accommodate the mechanical stress of flexing, necessitating innovative approaches to maintain display integrity while enabling flexibility.

Encapsulation technology has evolved from early thin-film approaches to current multi-layer barrier solutions that combine inorganic and organic materials. This progression has been driven by the need to achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining mechanical flexibility - a demanding technical requirement that continues to challenge manufacturers.

The primary objective of flexible OLED encapsulation quality assurance standards is to establish uniform testing methodologies and acceptance criteria that ensure long-term reliability under various environmental conditions and mechanical stresses. These standards must address the unique challenges of flexible displays, including repeated bending cycles, temperature fluctuations, and exposure to varying humidity levels.

Current technological trends point toward thinner barrier layers with enhanced performance, advanced atomic layer deposition (ALD) techniques, and hybrid organic-inorganic structures that optimize both barrier properties and mechanical flexibility. The industry is moving toward standardized testing protocols that can accurately predict display lifetime under real-world usage conditions.

The development of these standards requires collaboration between display manufacturers, materials scientists, testing equipment providers, and standards organizations. Major industry players have established proprietary testing methodologies, but there remains a need for universally accepted standards that can facilitate quality comparison across different manufacturers and technologies.

Looking forward, the technical objectives for flexible OLED encapsulation standards include: establishing reliable accelerated aging tests that correlate with real-world performance, developing non-destructive testing methods suitable for production environments, creating standardized bend-testing protocols that simulate actual device usage patterns, and defining minimum performance requirements for different application categories from smartphones to wearable devices.

The critical challenge in flexible OLED development has consistently been encapsulation - the protective barrier that shields the highly sensitive organic materials from oxygen and moisture. Traditional rigid glass encapsulation used in conventional OLEDs cannot accommodate the mechanical stress of flexing, necessitating innovative approaches to maintain display integrity while enabling flexibility.

Encapsulation technology has evolved from early thin-film approaches to current multi-layer barrier solutions that combine inorganic and organic materials. This progression has been driven by the need to achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day while maintaining mechanical flexibility - a demanding technical requirement that continues to challenge manufacturers.

The primary objective of flexible OLED encapsulation quality assurance standards is to establish uniform testing methodologies and acceptance criteria that ensure long-term reliability under various environmental conditions and mechanical stresses. These standards must address the unique challenges of flexible displays, including repeated bending cycles, temperature fluctuations, and exposure to varying humidity levels.

Current technological trends point toward thinner barrier layers with enhanced performance, advanced atomic layer deposition (ALD) techniques, and hybrid organic-inorganic structures that optimize both barrier properties and mechanical flexibility. The industry is moving toward standardized testing protocols that can accurately predict display lifetime under real-world usage conditions.

The development of these standards requires collaboration between display manufacturers, materials scientists, testing equipment providers, and standards organizations. Major industry players have established proprietary testing methodologies, but there remains a need for universally accepted standards that can facilitate quality comparison across different manufacturers and technologies.

Looking forward, the technical objectives for flexible OLED encapsulation standards include: establishing reliable accelerated aging tests that correlate with real-world performance, developing non-destructive testing methods suitable for production environments, creating standardized bend-testing protocols that simulate actual device usage patterns, and defining minimum performance requirements for different application categories from smartphones to wearable devices.

Market Demand Analysis for High-Quality Flexible OLED Displays

The flexible OLED display market has experienced remarkable growth in recent years, driven by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible OLED market reached approximately $18.2 billion in 2022 and is projected to grow at a CAGR of 27.3% through 2028, potentially exceeding $76 billion by the end of the forecast period.

Consumer electronics manufacturers are increasingly adopting flexible OLED technology to differentiate their products in a highly competitive market. Smartphones represent the largest application segment, accounting for over 65% of flexible OLED demand, followed by smartwatches and other wearable devices at roughly 18%. The automotive sector is emerging as a promising growth area, with premium vehicle manufacturers incorporating curved OLED displays in dashboard and entertainment systems.

Market surveys reveal that consumers are willing to pay premium prices for devices featuring flexible displays, with durability and visual quality being the primary concerns. This highlights the critical importance of encapsulation quality assurance standards, as inadequate encapsulation directly impacts both these factors. Approximately 87% of consumers cited display longevity as "very important" or "extremely important" in their purchasing decisions for premium devices.

Regional analysis shows Asia-Pacific dominating the flexible OLED market, with South Korea and China leading in both production capacity and technological innovation. North America and Europe follow as significant markets driven by high consumer purchasing power and early technology adoption trends.

The supply chain for high-quality flexible OLEDs remains constrained by technical challenges in mass production, particularly in achieving consistent encapsulation quality at scale. This has created a market dynamic where demand consistently outpaces supply for the highest quality flexible displays, allowing manufacturers with superior encapsulation technology to command price premiums of 15-30% compared to standard offerings.

Industry forecasts suggest that as encapsulation technologies mature and standardization increases, production yields will improve, potentially reducing the current supply constraints. However, this will likely be offset by expanding applications in new device categories such as rollable displays, transparent displays, and larger-format flexible panels, maintaining strong market growth through the next decade.

Consumer electronics manufacturers are increasingly adopting flexible OLED technology to differentiate their products in a highly competitive market. Smartphones represent the largest application segment, accounting for over 65% of flexible OLED demand, followed by smartwatches and other wearable devices at roughly 18%. The automotive sector is emerging as a promising growth area, with premium vehicle manufacturers incorporating curved OLED displays in dashboard and entertainment systems.

Market surveys reveal that consumers are willing to pay premium prices for devices featuring flexible displays, with durability and visual quality being the primary concerns. This highlights the critical importance of encapsulation quality assurance standards, as inadequate encapsulation directly impacts both these factors. Approximately 87% of consumers cited display longevity as "very important" or "extremely important" in their purchasing decisions for premium devices.

Regional analysis shows Asia-Pacific dominating the flexible OLED market, with South Korea and China leading in both production capacity and technological innovation. North America and Europe follow as significant markets driven by high consumer purchasing power and early technology adoption trends.

The supply chain for high-quality flexible OLEDs remains constrained by technical challenges in mass production, particularly in achieving consistent encapsulation quality at scale. This has created a market dynamic where demand consistently outpaces supply for the highest quality flexible displays, allowing manufacturers with superior encapsulation technology to command price premiums of 15-30% compared to standard offerings.

Industry forecasts suggest that as encapsulation technologies mature and standardization increases, production yields will improve, potentially reducing the current supply constraints. However, this will likely be offset by expanding applications in new device categories such as rollable displays, transparent displays, and larger-format flexible panels, maintaining strong market growth through the next decade.

Current Standards and Technical Challenges in OLED Encapsulation

The current landscape of flexible OLED encapsulation quality assurance is characterized by a fragmented standardization framework. While rigid OLED technologies have established standards through organizations like the International Electrotechnical Commission (IEC) and Society for Information Display (SID), flexible OLED encapsulation faces unique challenges that existing standards inadequately address. This creates significant obstacles for manufacturers seeking to ensure consistent quality across production lines.

Primary technical standards currently governing this field include IEC 62341 series for OLED displays, which provides basic parameters for performance evaluation but lacks specific provisions for flexible applications. ASTM E96 for water vapor transmission rate (WVTR) measurement offers some guidance, though it was not specifically designed for the ultra-low permeation requirements of flexible OLEDs. The JEDEC JESD22-A101 environmental test method provides humidity testing protocols that manufacturers have adapted for encapsulation evaluation.

The technical challenges in standardization stem from the extreme sensitivity of OLED materials to moisture and oxygen. Flexible OLEDs require barrier films with WVTR values below 10^-6 g/m²/day, which exceeds the measurement capabilities of conventional testing equipment. This creates a fundamental metrology challenge: how to standardize what cannot be consistently measured with current technology.

Another significant obstacle is the diversity of encapsulation approaches, including thin-film encapsulation (TFE), hybrid inorganic-organic multilayers, and atomic layer deposition (ALD) techniques. Each method presents different failure modes and requires specialized testing protocols, complicating the development of universal standards. The mechanical stress unique to flexible displays further compounds this challenge, as encapsulation must maintain integrity during repeated bending cycles.

Industry consortia like the Flexible Display Center and Korea Display Industry Association have attempted to establish working groups for standardization, but consensus remains elusive. The absence of standardized accelerated aging tests specifically calibrated for flexible OLED encapsulation represents a critical gap, as manufacturers currently rely on proprietary methods that yield inconsistent results across the industry.

The lack of harmonized standards has led to market fragmentation, with major manufacturers like Samsung, LG Display, and BOE developing proprietary specifications. This creates barriers to entry for smaller players and impedes supply chain optimization. Additionally, the absence of standardized quality metrics complicates warranty terms and consumer protection frameworks for products incorporating flexible OLED technology.

Primary technical standards currently governing this field include IEC 62341 series for OLED displays, which provides basic parameters for performance evaluation but lacks specific provisions for flexible applications. ASTM E96 for water vapor transmission rate (WVTR) measurement offers some guidance, though it was not specifically designed for the ultra-low permeation requirements of flexible OLEDs. The JEDEC JESD22-A101 environmental test method provides humidity testing protocols that manufacturers have adapted for encapsulation evaluation.

The technical challenges in standardization stem from the extreme sensitivity of OLED materials to moisture and oxygen. Flexible OLEDs require barrier films with WVTR values below 10^-6 g/m²/day, which exceeds the measurement capabilities of conventional testing equipment. This creates a fundamental metrology challenge: how to standardize what cannot be consistently measured with current technology.

Another significant obstacle is the diversity of encapsulation approaches, including thin-film encapsulation (TFE), hybrid inorganic-organic multilayers, and atomic layer deposition (ALD) techniques. Each method presents different failure modes and requires specialized testing protocols, complicating the development of universal standards. The mechanical stress unique to flexible displays further compounds this challenge, as encapsulation must maintain integrity during repeated bending cycles.

Industry consortia like the Flexible Display Center and Korea Display Industry Association have attempted to establish working groups for standardization, but consensus remains elusive. The absence of standardized accelerated aging tests specifically calibrated for flexible OLED encapsulation represents a critical gap, as manufacturers currently rely on proprietary methods that yield inconsistent results across the industry.

The lack of harmonized standards has led to market fragmentation, with major manufacturers like Samsung, LG Display, and BOE developing proprietary specifications. This creates barriers to entry for smaller players and impedes supply chain optimization. Additionally, the absence of standardized quality metrics complicates warranty terms and consumer protection frameworks for products incorporating flexible OLED technology.

Current Quality Assurance Methodologies for Flexible OLED

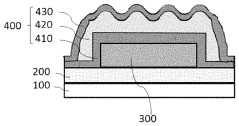

01 Thin film encapsulation techniques for flexible OLEDs

Thin film encapsulation (TFE) is a critical technology for flexible OLEDs that provides protection against moisture and oxygen while maintaining device flexibility. These techniques involve depositing alternating inorganic and organic layers to create effective barrier films. Quality assurance methods for TFE include monitoring layer thickness uniformity, interface quality, and overall barrier performance. Advanced deposition techniques such as atomic layer deposition (ALD) are employed to ensure high-quality encapsulation layers with minimal defects.- Thin film encapsulation techniques for flexible OLEDs: Thin film encapsulation (TFE) is a critical technology for flexible OLEDs that provides protection against moisture and oxygen while maintaining flexibility. These techniques involve depositing alternating inorganic and organic layers to create a barrier with high flexibility and low permeability. Quality assurance methods for TFE include monitoring layer thickness uniformity, adhesion between layers, and overall barrier performance to ensure long-term device reliability.

- Inspection and testing methods for encapsulation defects: Various inspection and testing methods are employed to detect defects in flexible OLED encapsulation layers. These include optical inspection techniques, electrical testing, and specialized imaging methods that can identify pinholes, cracks, or delamination in the barrier layers. Advanced quality assurance systems may incorporate machine vision, infrared thermography, or acoustic microscopy to detect defects that could compromise the moisture barrier properties of the encapsulation.

- Multi-layer barrier structures with enhanced protection: Multi-layer barrier structures provide enhanced protection for flexible OLEDs by combining different materials with complementary properties. These structures typically include inorganic layers for moisture resistance and organic layers for flexibility and stress relief. Quality assurance focuses on verifying the integrity of each layer and the interfaces between them, ensuring that the composite structure maintains its barrier properties even when subjected to bending and other mechanical stresses.

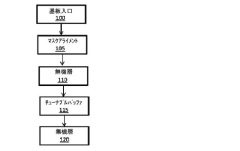

- In-line monitoring and process control for encapsulation: In-line monitoring and process control systems are implemented during the manufacturing of flexible OLED encapsulation to ensure consistent quality. These systems monitor critical parameters such as deposition rates, layer thickness, temperature, and pressure in real-time. Advanced quality assurance approaches incorporate statistical process control, automated inspection, and feedback loops to adjust process parameters when deviations are detected, minimizing defects and ensuring uniform encapsulation quality.

- Environmental stress testing for encapsulation durability: Environmental stress testing is essential for evaluating the long-term durability of flexible OLED encapsulation. These tests subject encapsulated devices to accelerated aging conditions including high temperature, high humidity, thermal cycling, and mechanical stress. Quality assurance protocols include measuring water vapor transmission rates, monitoring device performance degradation over time, and analyzing failure modes to improve encapsulation designs and manufacturing processes for enhanced reliability.

02 Inspection and testing methods for encapsulation defects

Various inspection and testing methodologies are employed to ensure the quality of flexible OLED encapsulation. These include optical inspection systems, electrical testing, and specialized imaging techniques to detect defects such as pinholes, cracks, and delamination. Automated vision systems can identify microscopic defects that might compromise barrier properties. Calcium tests and water vapor transmission rate measurements are used to evaluate the effectiveness of the encapsulation barrier. These quality assurance methods help maintain consistent production standards and improve device reliability.Expand Specific Solutions03 Multi-layer barrier structures for moisture protection

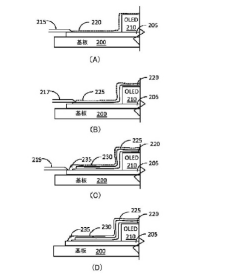

Multi-layer barrier structures are designed to provide superior moisture protection for flexible OLEDs. These structures typically consist of alternating inorganic and organic layers that effectively block moisture penetration pathways. The inorganic layers (such as silicon nitride, aluminum oxide) provide the primary barrier properties, while organic layers help decouple defects between inorganic layers and provide stress relief during bending. Quality assurance focuses on evaluating the integrity of each layer and the overall barrier performance under various environmental conditions and mechanical stress.Expand Specific Solutions04 Edge sealing and terminal protection techniques

Edge sealing and terminal protection are crucial aspects of flexible OLED encapsulation quality assurance. These techniques prevent lateral moisture ingress at device edges and protect electrical connection points. Special sealant materials and structures are employed to reinforce vulnerable areas. Quality assurance methods include testing the adhesion strength of edge seals, evaluating their barrier properties, and assessing their durability under mechanical stress. Proper edge sealing significantly extends device lifetime by preventing moisture penetration from the periphery of the display.Expand Specific Solutions05 Stress management and mechanical durability testing

Ensuring mechanical durability of encapsulation layers is essential for flexible OLEDs. Quality assurance protocols include bend testing, folding endurance evaluation, and stress distribution analysis to identify potential failure points. Specialized materials and structures are developed to accommodate mechanical stress without compromising barrier properties. Testing methods simulate real-world usage conditions, including repeated bending, temperature cycling, and impact resistance. Advanced imaging techniques monitor the formation of microcracks and delamination under stress to improve encapsulation designs and manufacturing processes.Expand Specific Solutions

Major Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation quality assurance standards landscape is currently in a growth phase, with the market expanding rapidly as OLED technology transitions from emerging to mainstream status. Key players including BOE Technology, LG Display, and TCL China Star Optoelectronics are driving technical innovation in this field. Chinese manufacturers like Visionox and Everdisplay Optronics are gaining market share, while established players such as LG Chem focus on advanced encapsulation materials. The technology is approaching maturity in certain applications but still evolving for flexible implementations, with companies like Applied Materials developing specialized equipment for quality control. Standardization efforts remain fragmented across regions, creating opportunities for companies that can establish industry-wide benchmarks.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED encapsulation solution utilizing atomic layer deposition (ALD) technology for creating ultra-thin barrier films. Their process employs alternating layers of Al2O3 and organic polymer materials to achieve a total encapsulation thickness below 10μm while maintaining excellent barrier properties. BOE's encapsulation technology incorporates a specialized edge sealing method that addresses the vulnerable perimeter areas of flexible displays. Their quality assurance system includes high-precision optical inspection that can detect defects down to 0.5μm, electrical calcium tests that quantify barrier performance with sensitivity to detect WVTR rates as low as 10^-7 g/m²/day, and mechanical durability testing that simulates up to 300,000 folding cycles at various bending radii (1R-5R)[5]. BOE has also implemented an AI-powered defect detection system that continuously improves through machine learning algorithms, reducing false positives by over 40% compared to conventional optical inspection methods[7].

Strengths: Ultra-thin encapsulation layers that maximize flexibility; advanced edge sealing technology that addresses a common failure point; automated AI-powered quality inspection system with high accuracy. Weaknesses: Higher initial capital investment for ALD equipment; slower deposition rates compared to some alternative methods; challenges in scaling to larger display sizes while maintaining uniform barrier properties.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered hybrid encapsulation technology for flexible OLEDs that combines the advantages of both face seal and edge seal approaches. Their solution utilizes a proprietary barrier film composed of alternating inorganic/organic layers with specialized adhesive materials that maintain barrier properties even under mechanical stress. The company's encapsulation system achieves water vapor transmission rates (WVTR) below 10^-6 g/m²/day through their patented multi-layer deposition process[2]. LG Chem's quality assurance protocol includes calcium tests for barrier performance verification, infrared spectroscopy for chemical composition analysis, and specialized mechanical testing that simulates repeated bending cycles (up to 200,000 cycles at various radii). Their encapsulation materials undergo rigorous environmental testing including temperature cycling (-40°C to 85°C), high humidity exposure (85°C/85% RH), and UV stability testing to ensure long-term reliability in diverse operating conditions[4].

Strengths: Excellent barrier properties maintained even after repeated mechanical deformation; proprietary adhesive technology that preserves barrier integrity at edges; comprehensive testing methodology that exceeds industry standards. Weaknesses: Higher material costs compared to conventional encapsulation; complex manufacturing process requiring specialized equipment; limited transparency in some formulations which can affect display brightness.

Key Patents and Technical Literature on Encapsulation Standards

Flexible organic light-emitting diode (OLED) device of reduced stess at bending place and fabrication method thereof

PatentActiveUS11258038B2

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, formed by thermal stress differences, increasing contact area and reducing stress on the outer inorganic layer, and an optically clear adhesive is used to level the configuration.

Encapsulation method for organic light emitting diode

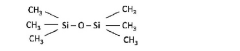

PatentInactiveJP2022145802A

Innovation

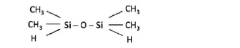

- A method involving the formation of inorganic and organic layers in a controlled process chamber, utilizing tunable buffer layers formed from vaporized organosilicon compounds like hexamethyldisiloxane or tetramethyldisiloxane, with precise mask alignment outside the chamber to ensure encapsulation integrity.

Regulatory Framework and Compliance Requirements

The regulatory landscape for flexible OLED encapsulation quality assurance is governed by a complex framework of international, regional, and industry-specific standards. The International Electrotechnical Commission (IEC) has established several standards specifically addressing OLED technology, including IEC 62341 series which covers organic light-emitting diode displays. These standards provide baseline requirements for reliability testing, environmental performance, and quality control methodologies applicable to encapsulation processes.

In the United States, the Underwriters Laboratories (UL) certification is crucial for market entry, with UL 8752 specifically addressing organic light-emitting diode panels. This standard encompasses encapsulation integrity testing as a critical component of overall device safety assessment. Meanwhile, the European Union enforces compliance with the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, which impact material selection for encapsulation technologies.

The Japanese Industrial Standards Committee (JISC) has developed JIS C 7021, which outlines testing methods for OLED displays including encapsulation performance metrics. Similarly, Korea's technology standards agency (KATS) has implemented KS C 7021 with specific provisions for flexible display encapsulation requirements. These standards are particularly significant given that South Korea houses major flexible OLED manufacturers.

Industry consortia like the Society for Information Display (SID) and the International Display Measurement Committee (IDMC) have published technical specifications that, while not legally binding, serve as de facto standards for encapsulation quality metrics. These include water vapor transmission rate (WVTR) thresholds and accelerated aging test protocols specifically designed for flexible display technologies.

Compliance verification typically involves third-party testing laboratories accredited by organizations such as the International Laboratory Accreditation Cooperation (ILAC). These facilities conduct standardized tests including calcium tests for moisture permeation, optical transmission degradation measurements, and mechanical durability assessments under various environmental conditions.

Emerging regulatory trends indicate a move toward more stringent requirements for encapsulation longevity, with expected service life standards increasing from 10,000 hours to 30,000+ hours for premium applications. Additionally, sustainability regulations are beginning to impact encapsulation technologies, with several jurisdictions implementing extended producer responsibility (EPR) schemes that consider end-of-life recyclability of display components including barrier films and encapsulation materials.

Military and aerospace applications of flexible OLED technology face additional compliance requirements outlined in MIL-STD-810H, which specifies environmental engineering considerations including extreme temperature cycling and humidity resistance that directly impact encapsulation performance specifications.

In the United States, the Underwriters Laboratories (UL) certification is crucial for market entry, with UL 8752 specifically addressing organic light-emitting diode panels. This standard encompasses encapsulation integrity testing as a critical component of overall device safety assessment. Meanwhile, the European Union enforces compliance with the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, which impact material selection for encapsulation technologies.

The Japanese Industrial Standards Committee (JISC) has developed JIS C 7021, which outlines testing methods for OLED displays including encapsulation performance metrics. Similarly, Korea's technology standards agency (KATS) has implemented KS C 7021 with specific provisions for flexible display encapsulation requirements. These standards are particularly significant given that South Korea houses major flexible OLED manufacturers.

Industry consortia like the Society for Information Display (SID) and the International Display Measurement Committee (IDMC) have published technical specifications that, while not legally binding, serve as de facto standards for encapsulation quality metrics. These include water vapor transmission rate (WVTR) thresholds and accelerated aging test protocols specifically designed for flexible display technologies.

Compliance verification typically involves third-party testing laboratories accredited by organizations such as the International Laboratory Accreditation Cooperation (ILAC). These facilities conduct standardized tests including calcium tests for moisture permeation, optical transmission degradation measurements, and mechanical durability assessments under various environmental conditions.

Emerging regulatory trends indicate a move toward more stringent requirements for encapsulation longevity, with expected service life standards increasing from 10,000 hours to 30,000+ hours for premium applications. Additionally, sustainability regulations are beginning to impact encapsulation technologies, with several jurisdictions implementing extended producer responsibility (EPR) schemes that consider end-of-life recyclability of display components including barrier films and encapsulation materials.

Military and aerospace applications of flexible OLED technology face additional compliance requirements outlined in MIL-STD-810H, which specifies environmental engineering considerations including extreme temperature cycling and humidity resistance that directly impact encapsulation performance specifications.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible OLED encapsulation processes represents a critical consideration in the development and implementation of quality assurance standards. Traditional encapsulation methods often involve energy-intensive processes and environmentally harmful materials, including heavy metals and volatile organic compounds (VOCs). As the industry scales production of flexible OLED displays, the cumulative environmental footprint becomes increasingly significant, necessitating comprehensive sustainability frameworks within quality assurance protocols.

Material selection for encapsulation layers presents both challenges and opportunities for environmental stewardship. Advanced thin-film encapsulation (TFE) technologies utilizing inorganic-organic hybrid structures can reduce material consumption compared to conventional glass-based encapsulation. However, these materials often contain rare earth elements and specialized chemicals that present end-of-life recycling challenges. Quality assurance standards must therefore incorporate lifecycle assessment metrics to evaluate encapsulation solutions beyond mere performance parameters.

Energy consumption during the encapsulation process contributes substantially to the carbon footprint of flexible OLED manufacturing. Vacuum deposition techniques commonly employed for barrier layers require significant energy inputs, while plasma-enhanced chemical vapor deposition (PECVD) processes utilize greenhouse gases with high global warming potential. Emerging standards are beginning to address these concerns by establishing maximum energy consumption thresholds and mandating energy efficiency improvements in encapsulation equipment.

Waste management considerations are increasingly integrated into encapsulation quality assurance frameworks. The industry is witnessing a shift toward standards that require manufacturers to implement closed-loop systems for chemical recovery and recycling of process materials. Particularly noteworthy are requirements for the reduction of perfluorinated compounds (PFCs) and other persistent pollutants commonly used in barrier layer deposition processes.

Circular economy principles are gradually being incorporated into flexible OLED encapsulation standards. These include design-for-disassembly requirements that facilitate the separation of encapsulation layers from other display components at end-of-life. Additionally, emerging standards are beginning to specify minimum recyclable content percentages and maximum allowable environmental impact scores for encapsulation materials and processes.

Water usage represents another environmental dimension addressed in evolving encapsulation standards. The semiconductor-like processes used in advanced barrier layer deposition can consume substantial quantities of ultra-pure water. Progressive quality assurance frameworks now include water footprint assessments and mandate water recycling systems within manufacturing facilities to minimize this impact.

Material selection for encapsulation layers presents both challenges and opportunities for environmental stewardship. Advanced thin-film encapsulation (TFE) technologies utilizing inorganic-organic hybrid structures can reduce material consumption compared to conventional glass-based encapsulation. However, these materials often contain rare earth elements and specialized chemicals that present end-of-life recycling challenges. Quality assurance standards must therefore incorporate lifecycle assessment metrics to evaluate encapsulation solutions beyond mere performance parameters.

Energy consumption during the encapsulation process contributes substantially to the carbon footprint of flexible OLED manufacturing. Vacuum deposition techniques commonly employed for barrier layers require significant energy inputs, while plasma-enhanced chemical vapor deposition (PECVD) processes utilize greenhouse gases with high global warming potential. Emerging standards are beginning to address these concerns by establishing maximum energy consumption thresholds and mandating energy efficiency improvements in encapsulation equipment.

Waste management considerations are increasingly integrated into encapsulation quality assurance frameworks. The industry is witnessing a shift toward standards that require manufacturers to implement closed-loop systems for chemical recovery and recycling of process materials. Particularly noteworthy are requirements for the reduction of perfluorinated compounds (PFCs) and other persistent pollutants commonly used in barrier layer deposition processes.

Circular economy principles are gradually being incorporated into flexible OLED encapsulation standards. These include design-for-disassembly requirements that facilitate the separation of encapsulation layers from other display components at end-of-life. Additionally, emerging standards are beginning to specify minimum recyclable content percentages and maximum allowable environmental impact scores for encapsulation materials and processes.

Water usage represents another environmental dimension addressed in evolving encapsulation standards. The semiconductor-like processes used in advanced barrier layer deposition can consume substantial quantities of ultra-pure water. Progressive quality assurance frameworks now include water footprint assessments and mandate water recycling systems within manufacturing facilities to minimize this impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!