Top Innovations in Flexible OLED Encapsulation for Aerospace Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace OLED Encapsulation Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has evolved significantly over the past decade, transitioning from laboratory curiosity to commercial reality. In aerospace applications, these lightweight, energy-efficient displays offer unprecedented opportunities for cockpit instrumentation, passenger entertainment systems, and structural health monitoring. The evolution of this technology has been marked by continuous improvements in luminance efficiency, color accuracy, and operational lifespan.

The aerospace industry presents unique challenges for display technologies, requiring exceptional durability under extreme conditions including rapid pressure changes, temperature fluctuations (-65°C to +85°C), high UV exposure, and vibration stress. Traditional rigid displays have historically dominated this sector due to their proven reliability, but their weight and form factor limitations have increasingly become bottlenecks in modern aircraft design.

Encapsulation technology represents the critical protective barrier that shields OLED materials from environmental degradation. The historical progression of encapsulation methods has moved from rigid glass-based solutions toward thin-film approaches that maintain flexibility while providing sufficient barrier properties. This transition has been necessitated by the aerospace industry's simultaneous demands for mechanical flexibility and environmental robustness.

The primary technical objective of flexible OLED encapsulation for aerospace applications is to achieve a water vapor transmission rate (WVTR) below 10^-6 g/m²/day and oxygen transmission rate (OTR) below 10^-5 cm³/m²/day while maintaining mechanical flexibility under cyclical stress. Secondary objectives include radiation resistance, thermal stability across the operational temperature range, and minimal weight addition.

Current encapsulation technologies have achieved significant milestones in terrestrial applications but fall short of aerospace requirements in terms of combined barrier performance and mechanical durability. The gap between laboratory demonstrations and flight-certified implementations remains substantial, with particular challenges in scaling production while maintaining quality consistency.

The global market for aerospace display systems is projected to reach $7.5 billion by 2028, with flexible displays potentially capturing 18-25% of this market if technical barriers can be overcome. Military and space applications represent early adoption sectors due to their emphasis on performance advantages over cost considerations.

This technical research aims to comprehensively evaluate cutting-edge innovations in flexible OLED encapsulation specifically engineered for aerospace environments, identifying breakthrough approaches that could enable widespread adoption in next-generation aircraft and spacecraft systems while meeting the stringent reliability requirements of the aerospace industry.

The aerospace industry presents unique challenges for display technologies, requiring exceptional durability under extreme conditions including rapid pressure changes, temperature fluctuations (-65°C to +85°C), high UV exposure, and vibration stress. Traditional rigid displays have historically dominated this sector due to their proven reliability, but their weight and form factor limitations have increasingly become bottlenecks in modern aircraft design.

Encapsulation technology represents the critical protective barrier that shields OLED materials from environmental degradation. The historical progression of encapsulation methods has moved from rigid glass-based solutions toward thin-film approaches that maintain flexibility while providing sufficient barrier properties. This transition has been necessitated by the aerospace industry's simultaneous demands for mechanical flexibility and environmental robustness.

The primary technical objective of flexible OLED encapsulation for aerospace applications is to achieve a water vapor transmission rate (WVTR) below 10^-6 g/m²/day and oxygen transmission rate (OTR) below 10^-5 cm³/m²/day while maintaining mechanical flexibility under cyclical stress. Secondary objectives include radiation resistance, thermal stability across the operational temperature range, and minimal weight addition.

Current encapsulation technologies have achieved significant milestones in terrestrial applications but fall short of aerospace requirements in terms of combined barrier performance and mechanical durability. The gap between laboratory demonstrations and flight-certified implementations remains substantial, with particular challenges in scaling production while maintaining quality consistency.

The global market for aerospace display systems is projected to reach $7.5 billion by 2028, with flexible displays potentially capturing 18-25% of this market if technical barriers can be overcome. Military and space applications represent early adoption sectors due to their emphasis on performance advantages over cost considerations.

This technical research aims to comprehensively evaluate cutting-edge innovations in flexible OLED encapsulation specifically engineered for aerospace environments, identifying breakthrough approaches that could enable widespread adoption in next-generation aircraft and spacecraft systems while meeting the stringent reliability requirements of the aerospace industry.

Market Analysis for Aerospace Flexible Display Solutions

The aerospace industry is witnessing a significant shift toward advanced display technologies, with flexible OLED solutions emerging as a critical component for next-generation aircraft and spacecraft interfaces. The global market for aerospace flexible display solutions is projected to reach $2.3 billion by 2028, growing at a compound annual growth rate of 18.7% from 2023. This growth is primarily driven by increasing demands for lightweight, durable, and energy-efficient display systems that can withstand extreme aerospace environments.

Military aviation represents the largest market segment, accounting for approximately 42% of the total market share. Commercial aviation follows closely at 35%, with space applications comprising the remaining 23%. North America dominates the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). This regional distribution reflects the concentration of aerospace manufacturing capabilities and defense spending.

Key market drivers include the push for weight reduction in aircraft to improve fuel efficiency, increasing digitalization of cockpit displays, growing demand for enhanced passenger entertainment systems, and the need for reliable display technologies in extreme conditions. The integration of flexible OLED displays can reduce weight by up to 30% compared to traditional LCD systems, translating to significant fuel savings over an aircraft's operational lifetime.

Customer requirements in this sector are particularly stringent, with aerospace-grade displays needing to meet MIL-STD-810 environmental standards, DO-160 electromagnetic compatibility requirements, and various other certifications. Flexible OLED encapsulation technologies must demonstrate reliability under rapid pressure changes, extreme temperature fluctuations (-65°C to +85°C), high vibration environments, and radiation exposure in space applications.

Market barriers include lengthy certification processes, which can take 3-5 years for new display technologies to receive approval for aerospace applications. Additionally, the high cost of specialized encapsulation materials designed for aerospace environments presents challenges for widespread adoption. Current flexible OLED solutions for aerospace applications cost approximately 4-6 times more than their consumer electronics counterparts.

Emerging trends include the integration of touch functionality with flexible displays for intuitive pilot interfaces, transparent display capabilities for heads-up applications, and curved display configurations that optimize cockpit space utilization. The market is also seeing increased demand for displays with ultra-high reliability metrics, with mean time between failures (MTBF) requirements exceeding 50,000 hours for critical flight systems.

Military aviation represents the largest market segment, accounting for approximately 42% of the total market share. Commercial aviation follows closely at 35%, with space applications comprising the remaining 23%. North America dominates the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). This regional distribution reflects the concentration of aerospace manufacturing capabilities and defense spending.

Key market drivers include the push for weight reduction in aircraft to improve fuel efficiency, increasing digitalization of cockpit displays, growing demand for enhanced passenger entertainment systems, and the need for reliable display technologies in extreme conditions. The integration of flexible OLED displays can reduce weight by up to 30% compared to traditional LCD systems, translating to significant fuel savings over an aircraft's operational lifetime.

Customer requirements in this sector are particularly stringent, with aerospace-grade displays needing to meet MIL-STD-810 environmental standards, DO-160 electromagnetic compatibility requirements, and various other certifications. Flexible OLED encapsulation technologies must demonstrate reliability under rapid pressure changes, extreme temperature fluctuations (-65°C to +85°C), high vibration environments, and radiation exposure in space applications.

Market barriers include lengthy certification processes, which can take 3-5 years for new display technologies to receive approval for aerospace applications. Additionally, the high cost of specialized encapsulation materials designed for aerospace environments presents challenges for widespread adoption. Current flexible OLED solutions for aerospace applications cost approximately 4-6 times more than their consumer electronics counterparts.

Emerging trends include the integration of touch functionality with flexible displays for intuitive pilot interfaces, transparent display capabilities for heads-up applications, and curved display configurations that optimize cockpit space utilization. The market is also seeing increased demand for displays with ultra-high reliability metrics, with mean time between failures (MTBF) requirements exceeding 50,000 hours for critical flight systems.

Flexible OLED Encapsulation Challenges in Extreme Environments

Flexible OLED displays represent a revolutionary advancement in aerospace instrumentation and communication systems, offering lightweight, energy-efficient alternatives to traditional rigid displays. However, the extreme conditions encountered in aerospace applications present significant challenges for OLED encapsulation technologies. These environments subject materials to temperature fluctuations ranging from -65°C to over 120°C, rapid pressure changes, intense UV radiation, and atomic oxygen exposure in low Earth orbit.

The primary challenge in flexible OLED encapsulation for aerospace applications stems from the inherent sensitivity of organic materials to oxygen and moisture. Even trace amounts of these elements can trigger oxidation reactions that lead to dark spots, pixel degradation, and ultimately device failure. Traditional rigid glass encapsulation, while effective for terrestrial applications, lacks the flexibility required for conformal aerospace displays and adds excessive weight to systems where every gram matters.

Mechanical stress represents another critical challenge, as aerospace components experience vibration profiles exceeding 20G during launch and operational phases. These forces can induce delamination between encapsulation layers, creating pathways for contaminant ingress. Additionally, the repeated bending and flexing required of displays in space-constrained cockpits and crew quarters accelerates mechanical fatigue in barrier films.

Radiation resistance presents a particularly demanding requirement for aerospace OLED encapsulation. High-energy particles and cosmic radiation can break chemical bonds in polymer barriers, accelerating degradation and reducing barrier properties. Current thin-film encapsulation technologies struggle to maintain performance under the cumulative radiation doses experienced during long-duration missions.

Thermal cycling effects compound these challenges, as the extreme temperature variations cause differential expansion between encapsulation layers with mismatched coefficients of thermal expansion. This cycling creates microcracks and interfacial stress that compromise barrier integrity over time. The vacuum environment of space further exacerbates these issues by promoting outgassing of volatile compounds from adhesives and sealants.

Manufacturing scalability represents a significant hurdle for aerospace-grade flexible OLED encapsulation. Current atomic layer deposition (ALD) processes deliver excellent barrier properties but face throughput limitations and high costs that restrict widespread adoption. Alternative approaches using hybrid organic-inorganic multilayers offer improved processing speeds but struggle to achieve the ultra-low water vapor transmission rates (below 10^-6 g/m²/day) required for long-duration space missions.

The combination of these challenges necessitates innovative encapsulation solutions that balance flexibility, barrier performance, radiation resistance, and manufacturability while meeting the stringent reliability requirements of aerospace applications. Current research indicates that no single material or process can address all these requirements, pointing toward the need for integrated multi-technology approaches.

The primary challenge in flexible OLED encapsulation for aerospace applications stems from the inherent sensitivity of organic materials to oxygen and moisture. Even trace amounts of these elements can trigger oxidation reactions that lead to dark spots, pixel degradation, and ultimately device failure. Traditional rigid glass encapsulation, while effective for terrestrial applications, lacks the flexibility required for conformal aerospace displays and adds excessive weight to systems where every gram matters.

Mechanical stress represents another critical challenge, as aerospace components experience vibration profiles exceeding 20G during launch and operational phases. These forces can induce delamination between encapsulation layers, creating pathways for contaminant ingress. Additionally, the repeated bending and flexing required of displays in space-constrained cockpits and crew quarters accelerates mechanical fatigue in barrier films.

Radiation resistance presents a particularly demanding requirement for aerospace OLED encapsulation. High-energy particles and cosmic radiation can break chemical bonds in polymer barriers, accelerating degradation and reducing barrier properties. Current thin-film encapsulation technologies struggle to maintain performance under the cumulative radiation doses experienced during long-duration missions.

Thermal cycling effects compound these challenges, as the extreme temperature variations cause differential expansion between encapsulation layers with mismatched coefficients of thermal expansion. This cycling creates microcracks and interfacial stress that compromise barrier integrity over time. The vacuum environment of space further exacerbates these issues by promoting outgassing of volatile compounds from adhesives and sealants.

Manufacturing scalability represents a significant hurdle for aerospace-grade flexible OLED encapsulation. Current atomic layer deposition (ALD) processes deliver excellent barrier properties but face throughput limitations and high costs that restrict widespread adoption. Alternative approaches using hybrid organic-inorganic multilayers offer improved processing speeds but struggle to achieve the ultra-low water vapor transmission rates (below 10^-6 g/m²/day) required for long-duration space missions.

The combination of these challenges necessitates innovative encapsulation solutions that balance flexibility, barrier performance, radiation resistance, and manufacturability while meeting the stringent reliability requirements of aerospace applications. Current research indicates that no single material or process can address all these requirements, pointing toward the need for integrated multi-technology approaches.

Current Encapsulation Solutions for Aerospace OLEDs

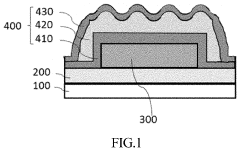

01 Multilayer encapsulation structures for flexible OLEDs

Multilayer encapsulation structures combine inorganic barrier layers with organic buffer layers to provide both moisture/oxygen protection and mechanical flexibility. The inorganic layers (typically silicon nitride, aluminum oxide, or silicon oxide) provide excellent barrier properties, while the organic layers (such as polymers or resins) accommodate bending stress and prevent crack propagation. This alternating structure allows the encapsulation to flex without compromising the barrier properties essential for OLED longevity.- Thin-film encapsulation for flexible OLEDs: Thin-film encapsulation (TFE) technology is crucial for flexible OLED displays, providing protection against moisture and oxygen while maintaining flexibility. These structures typically consist of alternating inorganic and organic layers that create a tortuous path for moisture penetration. The inorganic layers provide barrier properties while the organic layers accommodate bending stress and prevent crack propagation, enabling the display to flex without compromising the encapsulation integrity.

- Stress-relief structures in encapsulation layers: Various stress-relief structures are incorporated into encapsulation layers to enhance flexibility while maintaining barrier properties. These include patterned inorganic layers, buffer layers between rigid components, and specially designed interfaces that can absorb mechanical stress during bending. Some designs feature grid patterns, islands, or discontinuous inorganic layers connected by flexible organic materials to prevent crack formation and propagation when the device is flexed.

- Advanced materials for flexible encapsulation: Novel materials are being developed specifically for flexible OLED encapsulation, including hybrid organic-inorganic composites, flexible glass, and polymer-based barriers with enhanced gas impermeability. These materials combine high barrier properties with mechanical flexibility. Some approaches use modified silicon nitride, aluminum oxide, or zirconium oxide with specific additives to improve both flexibility and barrier performance. Specialized polymers with self-healing properties are also being incorporated to maintain encapsulation integrity after repeated bending.

- Multi-layer encapsulation structures: Multi-layer encapsulation structures are designed with specific layer sequences and thicknesses to optimize both flexibility and barrier properties. These structures often include alternating organic and inorganic layers with carefully controlled interfaces. The organic layers typically serve as stress-relieving components while inorganic layers provide moisture and oxygen barriers. The number, thickness, and composition of these layers are optimized to achieve the desired balance between flexibility and protection against environmental factors.

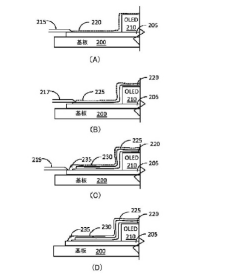

- Edge sealing and flexible substrate integration: Edge sealing techniques are critical for flexible OLEDs to prevent moisture ingress from the periphery of the device. These methods include specialized adhesives, laser sealing, and ultrasonic welding that maintain flexibility while creating a hermetic seal. Additionally, the integration of the encapsulation with flexible substrates requires careful consideration of thermal expansion coefficients and adhesion properties to prevent delamination during bending. Some designs incorporate gradient structures at the edges to distribute stress and prevent failure at the boundaries.

02 Thin-film encapsulation technologies for flexibility

Thin-film encapsulation (TFE) technologies enable ultra-thin protective layers that maintain high flexibility while providing sufficient barrier properties. These technologies include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and other advanced deposition methods that create conformal, pinhole-free barrier films at nanometer scale thicknesses. The reduced thickness of these encapsulation layers significantly improves the bending radius capability of flexible OLED displays without sacrificing protection against environmental contaminants.Expand Specific Solutions03 Stress-relief structures in encapsulation layers

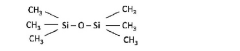

Specialized stress-relief structures are incorporated into encapsulation layers to accommodate mechanical deformation during bending. These structures include micro-patterned inorganic layers, island-like structures, mesh patterns, or intentionally created discontinuities that can absorb and distribute stress. By incorporating these engineered features, the encapsulation can withstand repeated bending cycles without developing cracks or delamination, significantly enhancing the overall flexibility and durability of the OLED device.Expand Specific Solutions04 Flexible inorganic-organic hybrid materials

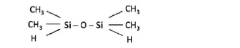

Novel hybrid materials combining inorganic and organic components at the molecular or nanoscale level provide enhanced flexibility while maintaining barrier properties. These materials include organosilicon compounds, metal-organic frameworks, nanocomposites with dispersed inorganic particles in flexible matrices, and hybrid polymers with inorganic segments. The unique molecular structure of these materials allows them to exhibit both the barrier properties of inorganic materials and the flexibility of organic materials, creating ideal encapsulation layers for flexible OLEDs.Expand Specific Solutions05 Edge sealing and mechanical reinforcement techniques

Specialized edge sealing and mechanical reinforcement techniques prevent moisture ingress at the vulnerable edges of flexible OLED panels while maintaining overall flexibility. These approaches include gradient-stiffness edge structures, flexible adhesive systems, reinforced perimeter designs, and specialized edge barrier structures. By focusing on the edge regions where delamination and barrier failures often begin, these techniques significantly improve the overall flexibility and reliability of the encapsulation system while maintaining the necessary protection against environmental contaminants.Expand Specific Solutions

Leading Aerospace and Display Technology Companies

The flexible OLED encapsulation market for aerospace applications is in its growth phase, characterized by rapid technological advancement and increasing adoption. The market is projected to expand significantly as aerospace manufacturers seek lightweight, durable display solutions for cockpit instrumentation and passenger entertainment systems. Technologically, companies like Samsung Display and LG Display lead with mature thin-film encapsulation technologies, while BOE Technology Group and TCL China Star Optoelectronics are rapidly closing the gap with innovative barrier layer solutions. Applied Materials provides critical manufacturing equipment, while research institutions like KAIST and Shanghai University contribute breakthrough innovations. Chinese manufacturers including Wuhan China Star and Everdisplay Optronics are emerging as significant players, leveraging government support to accelerate R&D in high-performance flexible OLED encapsulation technologies specifically engineered for extreme aerospace environments.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced flexible OLED encapsulation solution called "AeroShield" specifically for aerospace applications. Their technology utilizes a multi-layer barrier structure with alternating inorganic and organic layers optimized for the harsh conditions of aerospace environments. The inorganic layers are deposited using plasma-enhanced atomic layer deposition (PEALD) to create ultra-thin (5-15nm) aluminum oxide and silicon nitride barriers with exceptional uniformity. BOE's proprietary organic interlayers incorporate specialized elastomeric polymers with self-healing capabilities that can withstand extreme temperature fluctuations (-60°C to +80°C) and rapid pressure changes encountered during flight operations[5]. The encapsulation system achieves a water vapor transmission rate (WVTR) below 8×10^-7 g/m²/day while maintaining mechanical flexibility for curved display installations in aircraft cockpits and cabin entertainment systems. BOE has also integrated special UV-blocking compounds within the encapsulation layers to protect against the increased solar radiation at high altitudes, extending the operational lifetime of their aerospace OLED displays to approximately 45,000 hours[7].

Strengths: Excellent barrier properties with low WVTR suitable for aerospace environments; superior temperature stability across the wide range encountered in aviation; enhanced UV protection specifically designed for high-altitude applications. Weaknesses: Higher production costs compared to standard consumer electronics encapsulation; complex multi-layer deposition process requires specialized equipment; slightly thicker overall encapsulation package compared to some competitors, potentially affecting the ultimate flexibility.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary flexible OLED encapsulation technology called "Barriaero" specifically engineered for aerospace applications. Their solution utilizes a hybrid approach combining inorganic barrier films with specialized organic interlayers designed to withstand the extreme conditions encountered in aerospace environments. The core technology employs 3M's patented multi-layer optical film (MOF) manufacturing process to create ultra-thin alternating layers of inorganic silicon oxynitride and proprietary organic polymer materials. The inorganic layers provide exceptional barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, while the organic layers provide mechanical flexibility and stress relief during thermal cycling and vibration[6]. A key innovation in 3M's approach is their "self-healing" polymer technology that can repair minor defects in the barrier layers when activated by temperature changes, significantly extending the operational lifetime of displays in aerospace applications. The encapsulation system also incorporates specialized adhesive layers that maintain integrity across the extreme temperature range (-65°C to +85°C) encountered in aviation environments while providing additional protection against cosmic radiation at high altitudes[8].

Strengths: Industry-leading barrier properties with excellent WVTR performance; proprietary self-healing technology extends operational lifetime; exceptional adhesion properties prevent delamination during pressure changes and vibration. Weaknesses: Higher material costs compared to conventional encapsulation solutions; complex manufacturing process requires specialized equipment; slightly thicker overall profile compared to some competing technologies, potentially limiting ultimate flexibility.

Key Patents in Flexible OLED Barrier Technologies

Flexible organic light-emitting diode (OLED) device and fabrication method thereof

PatentActiveUS20210336206A1

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, increasing contact area and reducing stress, formed spontaneously due to thermal stress differences between layers.

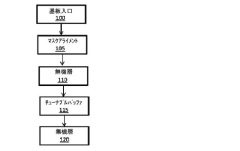

Encapsulation method for organic light emitting diode

PatentInactiveJP2022145802A

Innovation

- A method involving the formation of inorganic and organic layers in a controlled process chamber, utilizing tunable buffer layers formed from vaporized organosilicon compounds like hexamethyldisiloxane or tetramethyldisiloxane, with precise mask alignment outside the chamber to ensure encapsulation integrity.

Reliability Testing Standards for Aerospace Display Components

The aerospace industry demands exceptionally rigorous testing standards for display components due to the extreme environmental conditions encountered during flight operations. For flexible OLED encapsulation technologies, reliability testing must adhere to both established aerospace standards and emerging protocols specific to flexible display technologies.

Military standards such as MIL-STD-810G provide the foundation for environmental testing, covering temperature extremes (-65°C to +125°C), rapid decompression scenarios, and vibration profiles specific to different aircraft categories. These standards have been adapted to address the unique characteristics of flexible OLED displays, particularly focusing on the integrity of encapsulation layers under mechanical stress.

RTCA DO-160 serves as another critical standard, specifically designed for airborne equipment. Section 7 (Temperature and Altitude) and Section 8 (Shock and Vibration) have been expanded to include test procedures for flexible display technologies, with particular emphasis on barrier layer performance under combined environmental stressors.

Accelerated lifetime testing protocols have been developed specifically for aerospace OLED applications, simulating 20,000+ flight hours through cyclic exposure to pressure changes, UV radiation, and temperature fluctuations. These tests evaluate the permeation rates of oxygen and moisture through encapsulation barriers under conditions mimicking high-altitude operation.

Mechanical reliability testing for flexible displays includes specialized bend testing (dynamic and static), with aerospace standards requiring survival of 100,000+ bend cycles without significant increase in water vapor transmission rate. Folding endurance tests simulate the deployment scenarios specific to aerospace applications, such as roll-out displays for cockpit instrumentation.

The European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have jointly developed certification requirements for cockpit displays incorporating flexible OLED technology. These include specific provisions for encapsulation integrity verification through combined environmental exposure tests.

Radiation hardness testing has become increasingly important, with standards requiring flexible OLED encapsulation to maintain barrier properties after exposure to cosmic radiation levels encountered at cruising altitudes. This includes both single-event effects testing and total ionizing dose evaluation.

Human factors testing standards have also evolved to address the unique characteristics of flexible displays in aerospace environments, including readability under variable lighting conditions and after exposure to environmental stressors that might affect encapsulation integrity.

Military standards such as MIL-STD-810G provide the foundation for environmental testing, covering temperature extremes (-65°C to +125°C), rapid decompression scenarios, and vibration profiles specific to different aircraft categories. These standards have been adapted to address the unique characteristics of flexible OLED displays, particularly focusing on the integrity of encapsulation layers under mechanical stress.

RTCA DO-160 serves as another critical standard, specifically designed for airborne equipment. Section 7 (Temperature and Altitude) and Section 8 (Shock and Vibration) have been expanded to include test procedures for flexible display technologies, with particular emphasis on barrier layer performance under combined environmental stressors.

Accelerated lifetime testing protocols have been developed specifically for aerospace OLED applications, simulating 20,000+ flight hours through cyclic exposure to pressure changes, UV radiation, and temperature fluctuations. These tests evaluate the permeation rates of oxygen and moisture through encapsulation barriers under conditions mimicking high-altitude operation.

Mechanical reliability testing for flexible displays includes specialized bend testing (dynamic and static), with aerospace standards requiring survival of 100,000+ bend cycles without significant increase in water vapor transmission rate. Folding endurance tests simulate the deployment scenarios specific to aerospace applications, such as roll-out displays for cockpit instrumentation.

The European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have jointly developed certification requirements for cockpit displays incorporating flexible OLED technology. These include specific provisions for encapsulation integrity verification through combined environmental exposure tests.

Radiation hardness testing has become increasingly important, with standards requiring flexible OLED encapsulation to maintain barrier properties after exposure to cosmic radiation levels encountered at cruising altitudes. This includes both single-event effects testing and total ionizing dose evaluation.

Human factors testing standards have also evolved to address the unique characteristics of flexible displays in aerospace environments, including readability under variable lighting conditions and after exposure to environmental stressors that might affect encapsulation integrity.

Weight-Performance Optimization Strategies

In aerospace applications, the weight-performance ratio of flexible OLED encapsulation technologies represents a critical factor that directly impacts fuel efficiency, payload capacity, and overall mission success. Current optimization strategies focus on achieving the delicate balance between robust protection and minimal weight addition to the display systems.

Multi-layer thin film encapsulation (TFE) has emerged as a leading approach, where alternating inorganic and organic layers provide effective barrier properties while maintaining minimal thickness and weight. Advanced inorganic materials such as silicon nitride (SiNx) and aluminum oxide (Al2O3) deposited via atomic layer deposition (ALD) offer exceptional barrier properties at thicknesses below 100nm, significantly reducing the weight burden compared to traditional encapsulation methods.

Hybrid encapsulation systems combine the advantages of different materials to optimize the weight-performance ratio. For instance, integrating graphene-based barriers with traditional thin film encapsulation has demonstrated superior moisture resistance while reducing overall thickness by up to 30%. These hybrid approaches allow engineers to selectively enhance critical performance parameters without proportional weight increases.

Novel deposition techniques have revolutionized the manufacturing process, enabling the creation of ultra-thin yet highly effective barrier layers. Plasma-enhanced chemical vapor deposition (PECVD) and spatial atomic layer deposition (SALD) allow for precise control over layer formation at the nanometer scale, optimizing material usage and minimizing excess weight while maintaining barrier integrity.

Computational modeling and simulation tools have become instrumental in predicting performance characteristics before physical prototyping. These tools enable aerospace engineers to virtually test different material combinations and layer architectures, identifying optimal configurations that maximize protection while minimizing weight. This approach has reduced development cycles by approximately 40% while improving first-prototype success rates.

Edge sealing technologies have also advanced significantly, with laser-assisted bonding techniques replacing traditional adhesives. These methods create hermetic seals with minimal material addition at display edges—traditionally the most vulnerable points for moisture ingress. The resulting edge seals are up to 65% lighter than conventional approaches while offering superior protection against environmental factors.

The integration of self-healing materials represents another frontier in weight-performance optimization. These materials can autonomously repair minor defects in the encapsulation layer, allowing for thinner initial barrier designs without compromising long-term reliability. Early aerospace implementations have demonstrated that self-healing encapsulation can maintain barrier performance with up to 25% less material mass.

Multi-layer thin film encapsulation (TFE) has emerged as a leading approach, where alternating inorganic and organic layers provide effective barrier properties while maintaining minimal thickness and weight. Advanced inorganic materials such as silicon nitride (SiNx) and aluminum oxide (Al2O3) deposited via atomic layer deposition (ALD) offer exceptional barrier properties at thicknesses below 100nm, significantly reducing the weight burden compared to traditional encapsulation methods.

Hybrid encapsulation systems combine the advantages of different materials to optimize the weight-performance ratio. For instance, integrating graphene-based barriers with traditional thin film encapsulation has demonstrated superior moisture resistance while reducing overall thickness by up to 30%. These hybrid approaches allow engineers to selectively enhance critical performance parameters without proportional weight increases.

Novel deposition techniques have revolutionized the manufacturing process, enabling the creation of ultra-thin yet highly effective barrier layers. Plasma-enhanced chemical vapor deposition (PECVD) and spatial atomic layer deposition (SALD) allow for precise control over layer formation at the nanometer scale, optimizing material usage and minimizing excess weight while maintaining barrier integrity.

Computational modeling and simulation tools have become instrumental in predicting performance characteristics before physical prototyping. These tools enable aerospace engineers to virtually test different material combinations and layer architectures, identifying optimal configurations that maximize protection while minimizing weight. This approach has reduced development cycles by approximately 40% while improving first-prototype success rates.

Edge sealing technologies have also advanced significantly, with laser-assisted bonding techniques replacing traditional adhesives. These methods create hermetic seals with minimal material addition at display edges—traditionally the most vulnerable points for moisture ingress. The resulting edge seals are up to 65% lighter than conventional approaches while offering superior protection against environmental factors.

The integration of self-healing materials represents another frontier in weight-performance optimization. These materials can autonomously repair minor defects in the encapsulation layer, allowing for thinner initial barrier designs without compromising long-term reliability. Early aerospace implementations have demonstrated that self-healing encapsulation can maintain barrier performance with up to 25% less material mass.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!