Flexible OLED Encapsulation: Research on Material Lifespan Extension

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized display manufacturing since its commercial introduction in the early 2000s. The evolution of this technology has been marked by significant breakthroughs in materials science, particularly in the development of organic semiconductors and flexible substrates. Initially limited to rigid structures, OLED displays have progressively transitioned toward flexible and even foldable configurations, opening new possibilities for device form factors and applications.

The encapsulation layer represents a critical component in flexible OLED technology, serving as a protective barrier against environmental factors that can severely degrade organic materials. Traditional glass-based encapsulation, while effective for rigid displays, proved incompatible with the mechanical requirements of flexible applications. This technological limitation prompted intensive research into alternative encapsulation methods beginning around 2010, with thin-film encapsulation (TFE) emerging as the predominant approach for flexible displays.

Current encapsulation technologies face significant challenges regarding material lifespan. Flexible OLEDs typically demonstrate operational lifespans of 10,000-30,000 hours before significant degradation occurs, substantially shorter than their rigid counterparts. This degradation primarily results from moisture and oxygen penetration through microscopic defects in the encapsulation layer, which are exacerbated by repeated bending and mechanical stress.

The technical objectives of this research focus on extending the lifespan of flexible OLED encapsulation materials through several targeted approaches. Primary goals include developing multi-layer barrier films with enhanced water vapor transmission rates (WVTR) below 10^-6 g/m²/day, improving the mechanical durability to withstand over 200,000 bending cycles without significant barrier property degradation, and creating self-healing mechanisms that can autonomously repair microcracks formed during device operation.

Additionally, this research aims to explore novel material combinations that maintain barrier properties while reducing overall thickness, thereby enhancing flexibility. Particular emphasis is placed on environmentally sustainable materials that can reduce the ecological footprint of OLED manufacturing while maintaining or improving performance characteristics.

The advancement of flexible OLED encapsulation technology is projected to enable next-generation display applications, including rollable televisions, conformable medical devices, and integrated wearable electronics. These applications demand encapsulation solutions that not only provide superior barrier properties but also maintain performance integrity throughout the product lifecycle under various environmental and mechanical stresses.

The encapsulation layer represents a critical component in flexible OLED technology, serving as a protective barrier against environmental factors that can severely degrade organic materials. Traditional glass-based encapsulation, while effective for rigid displays, proved incompatible with the mechanical requirements of flexible applications. This technological limitation prompted intensive research into alternative encapsulation methods beginning around 2010, with thin-film encapsulation (TFE) emerging as the predominant approach for flexible displays.

Current encapsulation technologies face significant challenges regarding material lifespan. Flexible OLEDs typically demonstrate operational lifespans of 10,000-30,000 hours before significant degradation occurs, substantially shorter than their rigid counterparts. This degradation primarily results from moisture and oxygen penetration through microscopic defects in the encapsulation layer, which are exacerbated by repeated bending and mechanical stress.

The technical objectives of this research focus on extending the lifespan of flexible OLED encapsulation materials through several targeted approaches. Primary goals include developing multi-layer barrier films with enhanced water vapor transmission rates (WVTR) below 10^-6 g/m²/day, improving the mechanical durability to withstand over 200,000 bending cycles without significant barrier property degradation, and creating self-healing mechanisms that can autonomously repair microcracks formed during device operation.

Additionally, this research aims to explore novel material combinations that maintain barrier properties while reducing overall thickness, thereby enhancing flexibility. Particular emphasis is placed on environmentally sustainable materials that can reduce the ecological footprint of OLED manufacturing while maintaining or improving performance characteristics.

The advancement of flexible OLED encapsulation technology is projected to enable next-generation display applications, including rollable televisions, conformable medical devices, and integrated wearable electronics. These applications demand encapsulation solutions that not only provide superior barrier properties but also maintain performance integrity throughout the product lifecycle under various environmental and mechanical stresses.

Market Analysis for Extended Lifespan OLED Materials

The global market for extended lifespan OLED materials, particularly focusing on flexible OLED encapsulation technologies, has witnessed substantial growth in recent years. This expansion is primarily driven by the increasing adoption of OLED displays in smartphones, televisions, wearable devices, and automotive applications. The market value for OLED encapsulation materials reached approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 15.8% through 2028.

Consumer electronics remains the dominant application segment, accounting for over 65% of the total market share. Within this segment, smartphones represent the largest sub-segment due to the rapid adoption of flexible OLED displays by major manufacturers such as Samsung, Apple, and Huawei. The wearable technology segment is experiencing the fastest growth rate at 22.3% annually, driven by increasing consumer demand for smartwatches and fitness trackers with flexible displays.

Geographically, Asia-Pacific dominates the market with over 70% share, primarily due to the concentration of display manufacturing facilities in South Korea, Japan, China, and Taiwan. North America and Europe follow with significant investments in R&D for advanced encapsulation technologies, particularly focusing on extending material lifespan.

Market research indicates that consumers are increasingly willing to pay premium prices for devices with longer-lasting displays, with 78% of smartphone users citing screen durability as a key purchasing factor. This consumer preference has intensified competition among manufacturers to develop more reliable encapsulation solutions that extend OLED material lifespan.

The market is witnessing a shift from traditional glass-based encapsulation to thin-film encapsulation (TFE) technologies, with the latter segment growing at 18.7% annually. Hybrid encapsulation solutions combining inorganic and organic materials are gaining significant traction due to their superior barrier properties and flexibility.

Key market drivers include the growing demand for foldable and rollable displays, increasing penetration of OLED technology in mid-range devices, and rising consumer expectations for device longevity. However, market challenges persist, including high production costs, technical complexities in achieving uniform barrier layers, and competition from alternative display technologies like mini-LED.

Industry analysts forecast that manufacturers who successfully develop encapsulation materials extending OLED lifespan by at least 40% beyond current standards could capture up to 25% market premium, representing a significant competitive advantage in this rapidly evolving landscape.

Consumer electronics remains the dominant application segment, accounting for over 65% of the total market share. Within this segment, smartphones represent the largest sub-segment due to the rapid adoption of flexible OLED displays by major manufacturers such as Samsung, Apple, and Huawei. The wearable technology segment is experiencing the fastest growth rate at 22.3% annually, driven by increasing consumer demand for smartwatches and fitness trackers with flexible displays.

Geographically, Asia-Pacific dominates the market with over 70% share, primarily due to the concentration of display manufacturing facilities in South Korea, Japan, China, and Taiwan. North America and Europe follow with significant investments in R&D for advanced encapsulation technologies, particularly focusing on extending material lifespan.

Market research indicates that consumers are increasingly willing to pay premium prices for devices with longer-lasting displays, with 78% of smartphone users citing screen durability as a key purchasing factor. This consumer preference has intensified competition among manufacturers to develop more reliable encapsulation solutions that extend OLED material lifespan.

The market is witnessing a shift from traditional glass-based encapsulation to thin-film encapsulation (TFE) technologies, with the latter segment growing at 18.7% annually. Hybrid encapsulation solutions combining inorganic and organic materials are gaining significant traction due to their superior barrier properties and flexibility.

Key market drivers include the growing demand for foldable and rollable displays, increasing penetration of OLED technology in mid-range devices, and rising consumer expectations for device longevity. However, market challenges persist, including high production costs, technical complexities in achieving uniform barrier layers, and competition from alternative display technologies like mini-LED.

Industry analysts forecast that manufacturers who successfully develop encapsulation materials extending OLED lifespan by at least 40% beyond current standards could capture up to 25% market premium, representing a significant competitive advantage in this rapidly evolving landscape.

Current Encapsulation Technologies and Barriers

The current landscape of flexible OLED encapsulation technologies is dominated by several approaches, each with distinct advantages and limitations. Thin-film encapsulation (TFE) has emerged as the leading solution, utilizing alternating layers of inorganic and organic materials to create effective moisture and oxygen barriers. The inorganic layers, typically composed of silicon nitride (SiNx), aluminum oxide (Al2O3), or silicon oxide (SiO2), provide excellent barrier properties but suffer from brittleness and crack formation during flexing. Organic layers, often made from polymeric materials like parylene or acrylic resins, offer flexibility but possess inferior barrier characteristics.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic layer deposition, enabling the creation of ultra-thin, highly uniform barrier films with minimal defects. However, ALD processes remain relatively slow and costly for large-scale production, limiting widespread implementation despite superior performance characteristics.

Hybrid approaches combining multiple technologies have gained traction, with some manufacturers employing thin glass encapsulation with additional polymer layers or edge sealants. These solutions offer excellent barrier properties but face challenges in extreme bending scenarios and edge sealing integrity.

A critical barrier to extended material lifespan is the inherent permeability of all known encapsulation materials. Even the most advanced multi-layer barriers exhibit some degree of water vapor transmission rate (WVTR) and oxygen transmission rate (OTR), which gradually compromises OLED performance over time. Current best-in-class encapsulation systems achieve WVTR values of approximately 10^-6 g/m²/day, still short of the theoretical ideal for decade-long operation.

Mechanical stress during repeated flexing represents another significant challenge, as it can create microcracks in inorganic layers or delamination between different material layers. These defects become pathways for moisture and oxygen penetration, accelerating device degradation. Current solutions typically withstand 200,000-300,000 bending cycles before noticeable barrier degradation, insufficient for applications requiring millions of cycles over a device lifetime.

Temperature sensitivity presents additional complications, as thermal expansion coefficient mismatches between different encapsulation layers can induce stress during temperature fluctuations. Most current encapsulation systems maintain optimal barrier properties only within a limited temperature range (-20°C to 85°C), with significant performance degradation outside these boundaries.

Manufacturing scalability remains problematic, with high-performance encapsulation technologies often requiring specialized equipment, precise process control, and extended production times. This creates a tension between encapsulation quality and production throughput that has yet to be optimally resolved in the industry.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic layer deposition, enabling the creation of ultra-thin, highly uniform barrier films with minimal defects. However, ALD processes remain relatively slow and costly for large-scale production, limiting widespread implementation despite superior performance characteristics.

Hybrid approaches combining multiple technologies have gained traction, with some manufacturers employing thin glass encapsulation with additional polymer layers or edge sealants. These solutions offer excellent barrier properties but face challenges in extreme bending scenarios and edge sealing integrity.

A critical barrier to extended material lifespan is the inherent permeability of all known encapsulation materials. Even the most advanced multi-layer barriers exhibit some degree of water vapor transmission rate (WVTR) and oxygen transmission rate (OTR), which gradually compromises OLED performance over time. Current best-in-class encapsulation systems achieve WVTR values of approximately 10^-6 g/m²/day, still short of the theoretical ideal for decade-long operation.

Mechanical stress during repeated flexing represents another significant challenge, as it can create microcracks in inorganic layers or delamination between different material layers. These defects become pathways for moisture and oxygen penetration, accelerating device degradation. Current solutions typically withstand 200,000-300,000 bending cycles before noticeable barrier degradation, insufficient for applications requiring millions of cycles over a device lifetime.

Temperature sensitivity presents additional complications, as thermal expansion coefficient mismatches between different encapsulation layers can induce stress during temperature fluctuations. Most current encapsulation systems maintain optimal barrier properties only within a limited temperature range (-20°C to 85°C), with significant performance degradation outside these boundaries.

Manufacturing scalability remains problematic, with high-performance encapsulation technologies often requiring specialized equipment, precise process control, and extended production times. This creates a tension between encapsulation quality and production throughput that has yet to be optimally resolved in the industry.

State-of-the-Art Encapsulation Solutions

01 Multi-layer barrier structures for OLED encapsulation

Multi-layer barrier structures can significantly extend the lifespan of flexible OLEDs by providing effective protection against moisture and oxygen penetration. These structures typically consist of alternating inorganic and organic layers, where the inorganic layers (such as silicon nitride, aluminum oxide) act as moisture barriers while the organic layers help absorb mechanical stress during bending. This combination prevents crack propagation through the entire barrier structure, maintaining encapsulation integrity even when the device is flexed repeatedly.- Multi-layer barrier structures for OLED encapsulation: Multi-layer barrier structures consisting of alternating inorganic and organic layers can significantly enhance the lifespan of flexible OLEDs. The inorganic layers (such as silicon nitride, aluminum oxide) provide moisture and oxygen barrier properties, while the organic layers (such as polymers) provide flexibility and stress relief. This combination prevents crack propagation and improves the overall barrier performance, extending the operational lifetime of flexible OLEDs under bending conditions.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques specifically designed for flexible OLEDs involve depositing ultra-thin barrier layers directly onto the OLED device. These techniques include atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) to create conformal, defect-free barrier films. The reduced thickness of these encapsulation layers enhances flexibility while maintaining excellent barrier properties against moisture and oxygen, thereby extending the operational lifespan of flexible OLEDs.

- Edge sealing technologies for moisture prevention: Advanced edge sealing technologies are crucial for preventing moisture ingress from the edges of flexible OLED panels. These technologies include specialized adhesives, frit seals, and hybrid sealing methods that maintain flexibility while creating a hermetic barrier at the panel edges. Effective edge sealing significantly extends the lifespan of flexible OLEDs by addressing one of the most common failure points in flexible display encapsulation.

- Self-healing encapsulation materials: Self-healing encapsulation materials represent an innovative approach to extending flexible OLED lifespan. These materials contain microcapsules with healing agents or utilize dynamic chemical bonds that can repair microcracks formed during bending. When damage occurs, the healing mechanism is activated, restoring the barrier properties of the encapsulation layer. This self-repair capability significantly improves the long-term reliability and lifespan of flexible OLEDs under repeated mechanical stress.

- Hybrid glass-polymer encapsulation systems: Hybrid encapsulation systems combining ultra-thin glass with polymer layers offer enhanced protection for flexible OLEDs. The ultra-thin glass provides excellent barrier properties while maintaining some flexibility, and the polymer layers add additional protection and flexibility. These hybrid systems often incorporate adhesive layers with desiccant materials to absorb any moisture that penetrates the outer barriers. This multi-functional approach significantly extends the operational lifespan of flexible OLEDs while preserving their mechanical flexibility.

02 Thin-film encapsulation techniques for flexibility

Thin-film encapsulation (TFE) techniques are crucial for maintaining the flexibility of OLED displays while ensuring adequate protection. These methods involve depositing ultra-thin barrier films directly onto the OLED device without using rigid glass covers. Advanced TFE approaches include atomic layer deposition (ALD) of barrier materials, which creates conformal, pinhole-free layers even at nanometer thicknesses. The reduced thickness of these encapsulation layers allows for greater flexibility while maintaining barrier properties, significantly extending device lifespan under bending conditions.Expand Specific Solutions03 Self-healing encapsulation materials

Self-healing materials incorporated into OLED encapsulation layers can automatically repair microcracks that form during bending, substantially extending device lifespan. These materials contain components that can flow into damaged areas when activated by heat, light, or mechanical stress. Some approaches use microencapsulated healing agents that release when cracks form, while others employ dynamic chemical bonds that can reform after breaking. This self-repair capability is particularly valuable for flexible displays that undergo repeated bending cycles.Expand Specific Solutions04 Edge sealing technologies for flexible OLEDs

Enhanced edge sealing technologies are critical for preventing lateral moisture ingress in flexible OLED panels. These specialized sealing methods focus on the vulnerable perimeter of the display where delamination often begins. Advanced approaches include laser-assisted edge sealing, hybrid organic-inorganic edge barriers, and gradient-composition edge sealants that provide both adhesion and barrier properties. Proper edge sealing can significantly extend the operational lifespan of flexible OLEDs by preventing the most common failure mode - edge-initiated moisture penetration.Expand Specific Solutions05 Stress-relief structures in encapsulation layers

Incorporating specialized stress-relief structures within encapsulation layers helps accommodate mechanical strain during bending without compromising barrier properties. These structures include engineered patterns like mesh networks, island-bridge configurations, or wavy geometries that can stretch and compress during bending cycles. Some designs incorporate elastomeric interlayers between rigid barrier films to absorb deformation. These approaches distribute mechanical stress more evenly across the encapsulation system, preventing localized failure points and extending the flexible OLED's operational lifespan.Expand Specific Solutions

Leading Companies in OLED Encapsulation Industry

The flexible OLED encapsulation market is currently in a growth phase, with increasing demand driven by the proliferation of foldable displays in consumer electronics. The global market size is projected to expand significantly as manufacturers seek solutions to extend OLED material lifespan, which remains a critical challenge for widespread adoption. From a technological maturity perspective, major players like Samsung Display, LG Display, and BOE Technology are leading innovation with advanced thin-film encapsulation techniques. Chinese manufacturers including TCL China Star Optoelectronics and Tianma Microelectronics are rapidly closing the technology gap, while materials specialists such as Dow Silicones and Merck Patent GmbH are developing next-generation barrier films. Applied Materials provides essential manufacturing equipment, creating a competitive ecosystem where collaboration between display manufacturers and materials developers is driving progress toward longer-lasting flexible OLED solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED encapsulation solution called "BOE-Shield" that employs a hybrid thin-film encapsulation (TFE) approach. Their technology utilizes alternating layers of inorganic barriers (primarily silicon nitride and aluminum oxide) deposited via plasma-enhanced atomic layer deposition (PEALD) combined with organic interlayers applied through vapor deposition polymerization. A distinctive feature of BOE's approach is their "gradient barrier structure" where the composition and density of the inorganic layers gradually change throughout the stack to optimize both barrier performance and mechanical flexibility. BOE has recently introduced nanocomposite materials containing ceramic nanoparticles dispersed within the organic layers, which has been shown to reduce water vapor transmission rates by approximately 35% compared to conventional organic materials. Their encapsulation process incorporates a proprietary edge sealing technology that addresses the vulnerable perimeter regions of flexible displays, which has extended average device lifetimes in high-humidity testing environments by over 1,000 hours compared to standard encapsulation methods.

Strengths: Comprehensive solution addressing both surface and edge sealing requirements; gradient barrier structure optimizes flexibility/barrier performance balance; established mass production capabilities with high yield rates. Weaknesses: Higher material costs associated with nanocomposite materials; complex process control requirements for gradient structures; potential for increased layer stress during extreme temperature cycling.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the "EncapsuLock" platform, a comprehensive equipment and process solution specifically designed for flexible OLED encapsulation. Their technology centers around a multi-chamber deposition system that enables the sequential application of inorganic and organic barrier layers without breaking vacuum, significantly reducing contamination risks. The system utilizes a proprietary plasma-enhanced chemical vapor deposition (PECVD) process for inorganic layers (primarily silicon nitride and silicon oxynitride) combined with a specialized organic layer deposition technology that creates highly cross-linked polymer networks with enhanced barrier properties. Applied Materials' solution incorporates real-time optical monitoring that adjusts deposition parameters to ensure uniform layer thickness across large substrates, achieving thickness variations below 3%. Their latest innovation includes a "stress-compensated layer design" that minimizes internal stresses within the barrier stack, allowing for a bending radius below 1mm while maintaining barrier integrity. The system can achieve water vapor transmission rates (WVTR) below 5×10^-6 g/m²/day while processing substrates at temperatures below 80°C to protect sensitive OLED materials.

Strengths: Integrated equipment solution providing complete process control; in-situ monitoring ensures consistent quality; stress-compensated design enables extreme flexibility. Weaknesses: High capital equipment costs; complex system requires specialized maintenance and operation expertise; process optimization needed for each specific OLED stack design.

Key Patents and Innovations in Barrier Materials

Method for extending lifetime of organic light-emitting diode

PatentInactiveTW200835385A

Innovation

- Coating OLEDs with a transparent, insulating, and oxygen-barrier polymer liquid (such as 3M's Fluorinert Electronic Liquid FC-40) to isolate them from water vapor and oxygen, using its hydrophobic properties to prevent contact and extend lifespan.

OLED display with extended lifetime

PatentActiveUS20090278119A1

Innovation

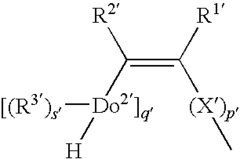

- The development of an OLED structure comprising a light-emitting layer with a combination of at least one hole-conducting material and one phosphorescence emitter, where the light-emitting layer includes a mixture of hole-conducting materials and phosphorescence emitters, along with specific compounds like disilylcarbazoles and disilyldibenzophospholes, to enhance the operational lifetime and efficiency.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in flexible OLED technology represents a critical consideration in the sustainable development of display technologies. Traditional encapsulation methods often rely on materials with significant ecological footprints, including rare earth elements, heavy metals, and petroleum-based polymers that pose end-of-life disposal challenges.

Current thin-film encapsulation (TFE) processes for flexible OLEDs typically employ inorganic-organic hybrid structures that contain environmentally problematic components. The inorganic layers often include materials like aluminum oxide and silicon nitride, which require energy-intensive deposition processes that contribute to carbon emissions. Meanwhile, organic layers frequently contain fluorinated compounds that persist in the environment and may bioaccumulate in ecosystems.

Life cycle assessments of encapsulation materials reveal concerning statistics: the production of high-performance barrier films can generate up to 40 kg CO2 equivalent per square meter of display manufactured. Additionally, the extraction of raw materials for these specialized barriers often involves environmentally destructive mining practices, particularly in developing regions with limited environmental regulations.

Water consumption presents another significant environmental concern, with wet chemical processes in encapsulation material production requiring up to 300 liters of ultrapure water per square meter of barrier film. The resulting wastewater often contains toxic compounds that require specialized treatment before release into water systems.

Recent research into environmentally friendly alternatives shows promising developments. Bio-based polymers derived from renewable resources are emerging as potential replacements for petroleum-based organic layers. These materials can reduce carbon footprint by up to 60% compared to conventional alternatives while maintaining acceptable barrier properties. Similarly, atomic layer deposition techniques have evolved to reduce energy consumption by 30-40% while maintaining the quality of inorganic barrier layers.

Recycling and end-of-life considerations are increasingly important as flexible OLED devices proliferate in consumer markets. Current encapsulation materials present significant challenges for recycling processes, with multi-layer structures being particularly difficult to separate and process. Innovative approaches using water-soluble sacrificial layers and mechanically separable interfaces are being developed to address these concerns, potentially allowing recovery of up to 85% of valuable materials from end-of-life displays.

The regulatory landscape is also evolving rapidly, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly targeting materials commonly used in encapsulation. This regulatory pressure is driving innovation toward greener alternatives that maintain or exceed the performance characteristics required for extended OLED lifespans.

Current thin-film encapsulation (TFE) processes for flexible OLEDs typically employ inorganic-organic hybrid structures that contain environmentally problematic components. The inorganic layers often include materials like aluminum oxide and silicon nitride, which require energy-intensive deposition processes that contribute to carbon emissions. Meanwhile, organic layers frequently contain fluorinated compounds that persist in the environment and may bioaccumulate in ecosystems.

Life cycle assessments of encapsulation materials reveal concerning statistics: the production of high-performance barrier films can generate up to 40 kg CO2 equivalent per square meter of display manufactured. Additionally, the extraction of raw materials for these specialized barriers often involves environmentally destructive mining practices, particularly in developing regions with limited environmental regulations.

Water consumption presents another significant environmental concern, with wet chemical processes in encapsulation material production requiring up to 300 liters of ultrapure water per square meter of barrier film. The resulting wastewater often contains toxic compounds that require specialized treatment before release into water systems.

Recent research into environmentally friendly alternatives shows promising developments. Bio-based polymers derived from renewable resources are emerging as potential replacements for petroleum-based organic layers. These materials can reduce carbon footprint by up to 60% compared to conventional alternatives while maintaining acceptable barrier properties. Similarly, atomic layer deposition techniques have evolved to reduce energy consumption by 30-40% while maintaining the quality of inorganic barrier layers.

Recycling and end-of-life considerations are increasingly important as flexible OLED devices proliferate in consumer markets. Current encapsulation materials present significant challenges for recycling processes, with multi-layer structures being particularly difficult to separate and process. Innovative approaches using water-soluble sacrificial layers and mechanically separable interfaces are being developed to address these concerns, potentially allowing recovery of up to 85% of valuable materials from end-of-life displays.

The regulatory landscape is also evolving rapidly, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly targeting materials commonly used in encapsulation. This regulatory pressure is driving innovation toward greener alternatives that maintain or exceed the performance characteristics required for extended OLED lifespans.

Cost-Benefit Analysis of Advanced Barrier Technologies

The implementation of advanced barrier technologies for flexible OLED encapsulation represents a significant investment decision for manufacturers. When evaluating these technologies from a cost-benefit perspective, several critical factors must be considered to determine their economic viability and long-term value proposition.

Initial capital expenditure for advanced barrier technologies such as atomic layer deposition (ALD) systems, thin-film encapsulation (TFE) equipment, and hybrid organic-inorganic multilayer systems typically ranges from $5-15 million per production line. This substantial upfront investment creates a significant barrier to entry for smaller manufacturers but can be justified through extended product lifespans and reduced warranty claims.

Operational costs present another important consideration. Traditional encapsulation methods may have lower initial costs but often result in higher long-term expenses due to higher material consumption, energy requirements, and maintenance needs. Advanced barrier technologies typically reduce these ongoing costs by 15-30% over a five-year operational period, despite requiring specialized maintenance protocols and technical expertise.

The economic impact of extended material lifespan cannot be overstated. Advanced barrier technologies that extend OLED device lifetimes from the current industry standard of 10,000-15,000 hours to 30,000-50,000 hours create substantial value through enhanced product reputation, reduced warranty claims, and premium pricing opportunities. Market analysis indicates consumers are willing to pay a 20-35% premium for devices with demonstrably longer operational lifespans.

Manufacturing efficiency gains represent another significant benefit. Advanced encapsulation technologies typically enable 15-25% faster production cycles and reduce material waste by 10-30% compared to conventional methods. These efficiencies compound over time, improving overall production economics and environmental sustainability metrics.

Risk mitigation value must also be factored into the analysis. As flexible OLED applications expand into new sectors such as automotive, medical, and wearable technologies, the cost of failure increases dramatically. Advanced barrier technologies that reduce failure rates from 5-8% to below 1% provide substantial risk mitigation value that extends beyond direct manufacturing costs to include brand protection and market positioning benefits.

Return on investment timelines for advanced barrier technologies typically range from 18-36 months depending on production volume and target applications. High-volume consumer electronics implementations tend toward faster ROI, while specialized industrial or medical applications may require longer timeframes but ultimately deliver higher margins and more sustainable competitive advantages.

Initial capital expenditure for advanced barrier technologies such as atomic layer deposition (ALD) systems, thin-film encapsulation (TFE) equipment, and hybrid organic-inorganic multilayer systems typically ranges from $5-15 million per production line. This substantial upfront investment creates a significant barrier to entry for smaller manufacturers but can be justified through extended product lifespans and reduced warranty claims.

Operational costs present another important consideration. Traditional encapsulation methods may have lower initial costs but often result in higher long-term expenses due to higher material consumption, energy requirements, and maintenance needs. Advanced barrier technologies typically reduce these ongoing costs by 15-30% over a five-year operational period, despite requiring specialized maintenance protocols and technical expertise.

The economic impact of extended material lifespan cannot be overstated. Advanced barrier technologies that extend OLED device lifetimes from the current industry standard of 10,000-15,000 hours to 30,000-50,000 hours create substantial value through enhanced product reputation, reduced warranty claims, and premium pricing opportunities. Market analysis indicates consumers are willing to pay a 20-35% premium for devices with demonstrably longer operational lifespans.

Manufacturing efficiency gains represent another significant benefit. Advanced encapsulation technologies typically enable 15-25% faster production cycles and reduce material waste by 10-30% compared to conventional methods. These efficiencies compound over time, improving overall production economics and environmental sustainability metrics.

Risk mitigation value must also be factored into the analysis. As flexible OLED applications expand into new sectors such as automotive, medical, and wearable technologies, the cost of failure increases dramatically. Advanced barrier technologies that reduce failure rates from 5-8% to below 1% provide substantial risk mitigation value that extends beyond direct manufacturing costs to include brand protection and market positioning benefits.

Return on investment timelines for advanced barrier technologies typically range from 18-36 months depending on production volume and target applications. High-volume consumer electronics implementations tend toward faster ROI, while specialized industrial or medical applications may require longer timeframes but ultimately deliver higher margins and more sustainable competitive advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!