How Flexible OLED Encapsulation Is Shaping the Wearable Tech Market

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has evolved significantly over the past decade, transforming from a laboratory curiosity to a commercial reality that is revolutionizing display technologies. The journey began in the early 2000s when researchers first demonstrated the potential of flexible organic displays, but significant technical barriers prevented widespread adoption. By 2010, major electronics manufacturers began investing heavily in flexible OLED research, recognizing its potential to enable entirely new product categories.

The evolution of flexible OLED technology has been characterized by continuous improvements in materials science, particularly in the development of flexible substrates and transparent conductive materials that can withstand repeated bending without degradation. A critical milestone was reached around 2013 when the first commercially viable flexible OLED displays appeared in consumer electronics, albeit with limited flexibility and durability.

Encapsulation technology represents the cornerstone challenge in flexible OLED development. Unlike traditional rigid displays, flexible OLEDs are extremely sensitive to oxygen and moisture, which can rapidly degrade organic materials and significantly reduce device lifespan. Early encapsulation methods relied on glass barriers that limited flexibility, creating a fundamental contradiction between flexibility and durability.

The technical objectives for flexible OLED encapsulation focus on achieving a delicate balance between several competing requirements. First, the encapsulation must provide an effective barrier against oxygen and moisture penetration, with water vapor transmission rates (WVTR) below 10^-6 g/m²/day—a challenging benchmark that exceeds the capabilities of most conventional barrier materials by several orders of magnitude.

Second, the encapsulation layer must maintain this barrier performance while undergoing repeated mechanical deformation, including bending, folding, and twisting. This requires materials that combine exceptional barrier properties with mechanical flexibility, a combination rarely found in nature.

Third, the encapsulation solution must be thin enough to preserve the inherent thinness of OLED displays—one of their key advantages over competing technologies. Thick encapsulation layers would negate many of the form factor benefits that make flexible OLEDs attractive for wearable applications.

Finally, any viable encapsulation technology must be compatible with high-volume manufacturing processes to enable cost-effective production at scale. This manufacturing consideration has historically been a significant barrier to commercialization, as laboratory-scale encapsulation techniques often prove impractical for mass production.

The trajectory of flexible OLED encapsulation technology is now moving toward multi-layer thin-film approaches that combine organic and inorganic materials, atomic layer deposition techniques, and novel barrier materials such as graphene and other two-dimensional materials. These emerging solutions aim to simultaneously address the seemingly contradictory requirements of flexibility, barrier performance, and manufacturability.

The evolution of flexible OLED technology has been characterized by continuous improvements in materials science, particularly in the development of flexible substrates and transparent conductive materials that can withstand repeated bending without degradation. A critical milestone was reached around 2013 when the first commercially viable flexible OLED displays appeared in consumer electronics, albeit with limited flexibility and durability.

Encapsulation technology represents the cornerstone challenge in flexible OLED development. Unlike traditional rigid displays, flexible OLEDs are extremely sensitive to oxygen and moisture, which can rapidly degrade organic materials and significantly reduce device lifespan. Early encapsulation methods relied on glass barriers that limited flexibility, creating a fundamental contradiction between flexibility and durability.

The technical objectives for flexible OLED encapsulation focus on achieving a delicate balance between several competing requirements. First, the encapsulation must provide an effective barrier against oxygen and moisture penetration, with water vapor transmission rates (WVTR) below 10^-6 g/m²/day—a challenging benchmark that exceeds the capabilities of most conventional barrier materials by several orders of magnitude.

Second, the encapsulation layer must maintain this barrier performance while undergoing repeated mechanical deformation, including bending, folding, and twisting. This requires materials that combine exceptional barrier properties with mechanical flexibility, a combination rarely found in nature.

Third, the encapsulation solution must be thin enough to preserve the inherent thinness of OLED displays—one of their key advantages over competing technologies. Thick encapsulation layers would negate many of the form factor benefits that make flexible OLEDs attractive for wearable applications.

Finally, any viable encapsulation technology must be compatible with high-volume manufacturing processes to enable cost-effective production at scale. This manufacturing consideration has historically been a significant barrier to commercialization, as laboratory-scale encapsulation techniques often prove impractical for mass production.

The trajectory of flexible OLED encapsulation technology is now moving toward multi-layer thin-film approaches that combine organic and inorganic materials, atomic layer deposition techniques, and novel barrier materials such as graphene and other two-dimensional materials. These emerging solutions aim to simultaneously address the seemingly contradictory requirements of flexibility, barrier performance, and manufacturability.

Wearable Tech Market Demand Analysis for Flexible Displays

The wearable technology market has witnessed exponential growth in recent years, with global revenues reaching $118.2 billion in 2022 and projections indicating a compound annual growth rate of 14.6% through 2030. This remarkable expansion is largely driven by consumer demand for flexible display technologies that enable more comfortable, durable, and aesthetically pleasing wearable devices. Market research indicates that approximately 72% of consumers prioritize comfort and form factor when purchasing wearable technology, highlighting the critical importance of flexible displays in this sector.

Flexible OLED displays have emerged as the preferred technology for premium wearable devices, with smartwatches representing the largest market segment at 43% of total wearable shipments. The fitness and health monitoring segment follows closely at 31%, with both categories showing strong preference for curved and flexible display options. Consumer surveys reveal that 68% of potential buyers consider display quality and flexibility as decisive purchasing factors, particularly in the $300+ price segment.

Regional analysis shows North America leading the market with 37% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region demonstrates the fastest growth trajectory with 17.8% annual expansion, driven by increasing disposable income and rapid technology adoption in China, South Korea, and India. Market penetration of flexible display wearables varies significantly by region, with urban centers showing adoption rates three times higher than rural areas.

Consumer demographic data reveals interesting patterns in the demand landscape. The 25-40 age group represents the largest consumer segment (47%), followed by the 18-24 bracket (28%). These younger demographics show stronger preference for fashion-forward wearable designs that flexible displays enable. Additionally, healthcare applications are driving significant demand among older demographics, with 63% of users over 55 citing health monitoring capabilities as their primary purchase motivation.

Industry forecasts predict that flexible display wearables will continue to capture market share from rigid display alternatives, with market penetration expected to reach 78% by 2027. This transition is accelerated by decreasing production costs, with the price premium for flexible displays dropping from 40% in 2020 to approximately 22% in 2023. As manufacturing scales and yields improve, analysts expect this premium to further decrease to 10-15% by 2025, significantly expanding the addressable market.

The enterprise and industrial wearable segments represent emerging high-growth opportunities, with 29% annual growth projected through 2028. These applications demand particularly robust flexible display solutions capable of withstanding harsh environments while maintaining performance integrity.

Flexible OLED displays have emerged as the preferred technology for premium wearable devices, with smartwatches representing the largest market segment at 43% of total wearable shipments. The fitness and health monitoring segment follows closely at 31%, with both categories showing strong preference for curved and flexible display options. Consumer surveys reveal that 68% of potential buyers consider display quality and flexibility as decisive purchasing factors, particularly in the $300+ price segment.

Regional analysis shows North America leading the market with 37% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region demonstrates the fastest growth trajectory with 17.8% annual expansion, driven by increasing disposable income and rapid technology adoption in China, South Korea, and India. Market penetration of flexible display wearables varies significantly by region, with urban centers showing adoption rates three times higher than rural areas.

Consumer demographic data reveals interesting patterns in the demand landscape. The 25-40 age group represents the largest consumer segment (47%), followed by the 18-24 bracket (28%). These younger demographics show stronger preference for fashion-forward wearable designs that flexible displays enable. Additionally, healthcare applications are driving significant demand among older demographics, with 63% of users over 55 citing health monitoring capabilities as their primary purchase motivation.

Industry forecasts predict that flexible display wearables will continue to capture market share from rigid display alternatives, with market penetration expected to reach 78% by 2027. This transition is accelerated by decreasing production costs, with the price premium for flexible displays dropping from 40% in 2020 to approximately 22% in 2023. As manufacturing scales and yields improve, analysts expect this premium to further decrease to 10-15% by 2025, significantly expanding the addressable market.

The enterprise and industrial wearable segments represent emerging high-growth opportunities, with 29% annual growth projected through 2028. These applications demand particularly robust flexible display solutions capable of withstanding harsh environments while maintaining performance integrity.

Current Encapsulation Technologies and Challenges

Flexible OLED encapsulation technology currently faces significant challenges despite its rapid advancement. The primary encapsulation methods in commercial use include thin-film encapsulation (TFE), hybrid encapsulation, and barrier films. TFE technology, pioneered by Samsung and LG Display, utilizes alternating layers of inorganic (typically silicon nitride or aluminum oxide) and organic materials to create effective moisture and oxygen barriers. This multi-layer approach compensates for the defects in individual layers, providing superior protection for sensitive OLED materials.

Hybrid encapsulation combines TFE with additional protective elements such as glass or metal lids, offering enhanced mechanical stability for semi-flexible applications. Meanwhile, barrier films using multi-layer polymer/inorganic structures are gaining traction for fully flexible displays, with companies like 3M and Vitriflex developing solutions with water vapor transmission rates (WVTR) below 10^-6 g/m²/day.

Despite these advancements, significant technical challenges persist. The foremost issue is achieving consistent ultra-low permeation rates while maintaining flexibility. Current technologies struggle to maintain barrier properties when subjected to repeated bending and folding, particularly at bend radii below 1mm. This limitation directly impacts the durability and lifespan of wearable devices, which typically require thousands of flex cycles without degradation.

Manufacturing scalability presents another major hurdle. High-quality encapsulation layers require precise deposition processes that are difficult to scale economically. Atomic Layer Deposition (ALD), while excellent for creating defect-free barriers, remains slow and expensive for mass production. The industry is actively seeking alternatives that balance performance with manufacturing efficiency.

Material compatibility issues further complicate encapsulation development. The thermal budget constraints of flexible substrates (typically below 100°C) limit the range of applicable deposition techniques and materials. Additionally, the coefficient of thermal expansion mismatch between different encapsulation layers can lead to stress, delamination, and crack formation during temperature fluctuations experienced in both manufacturing and daily use.

Edge sealing represents a particularly vulnerable area in flexible OLED encapsulation. The perimeter of the display, where encapsulation layers terminate, often becomes the primary ingress path for moisture and oxygen. Current edge sealing solutions add bulk and rigidity, contradicting the goal of creating ultra-thin, flexible devices. Companies like Universal Display Corporation and Applied Materials are developing specialized edge sealing technologies, but a definitive solution remains elusive.

These technical challenges are driving significant R&D investment across the industry, with particular focus on novel barrier materials, advanced deposition techniques, and innovative structural designs that can maintain barrier properties under mechanical stress while enabling mass production.

Hybrid encapsulation combines TFE with additional protective elements such as glass or metal lids, offering enhanced mechanical stability for semi-flexible applications. Meanwhile, barrier films using multi-layer polymer/inorganic structures are gaining traction for fully flexible displays, with companies like 3M and Vitriflex developing solutions with water vapor transmission rates (WVTR) below 10^-6 g/m²/day.

Despite these advancements, significant technical challenges persist. The foremost issue is achieving consistent ultra-low permeation rates while maintaining flexibility. Current technologies struggle to maintain barrier properties when subjected to repeated bending and folding, particularly at bend radii below 1mm. This limitation directly impacts the durability and lifespan of wearable devices, which typically require thousands of flex cycles without degradation.

Manufacturing scalability presents another major hurdle. High-quality encapsulation layers require precise deposition processes that are difficult to scale economically. Atomic Layer Deposition (ALD), while excellent for creating defect-free barriers, remains slow and expensive for mass production. The industry is actively seeking alternatives that balance performance with manufacturing efficiency.

Material compatibility issues further complicate encapsulation development. The thermal budget constraints of flexible substrates (typically below 100°C) limit the range of applicable deposition techniques and materials. Additionally, the coefficient of thermal expansion mismatch between different encapsulation layers can lead to stress, delamination, and crack formation during temperature fluctuations experienced in both manufacturing and daily use.

Edge sealing represents a particularly vulnerable area in flexible OLED encapsulation. The perimeter of the display, where encapsulation layers terminate, often becomes the primary ingress path for moisture and oxygen. Current edge sealing solutions add bulk and rigidity, contradicting the goal of creating ultra-thin, flexible devices. Companies like Universal Display Corporation and Applied Materials are developing specialized edge sealing technologies, but a definitive solution remains elusive.

These technical challenges are driving significant R&D investment across the industry, with particular focus on novel barrier materials, advanced deposition techniques, and innovative structural designs that can maintain barrier properties under mechanical stress while enabling mass production.

Current Flexible OLED Barrier Solutions

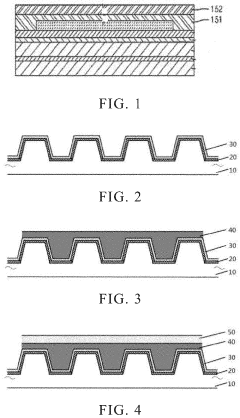

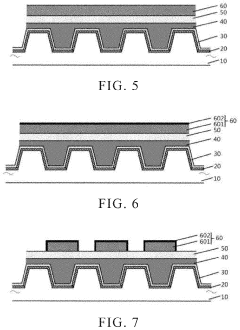

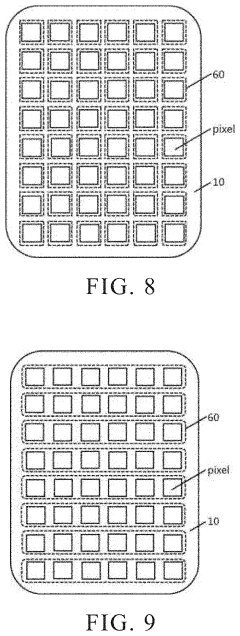

01 Multilayer encapsulation structures for flexible OLEDs

Multilayer encapsulation structures are used to enhance the flexibility of OLED devices while maintaining effective barrier properties against moisture and oxygen. These structures typically consist of alternating inorganic and organic layers, where the inorganic layers provide barrier properties and the organic layers provide flexibility and stress relief. The combination allows the encapsulation to bend without cracking while maintaining protection for the sensitive OLED components.- Multilayer encapsulation structures for flexible OLEDs: Multilayer encapsulation structures consisting of alternating inorganic and organic layers provide effective barrier properties while maintaining flexibility. The inorganic layers (such as silicon nitride, aluminum oxide) provide moisture and oxygen barrier properties, while the organic layers (such as polymers) accommodate mechanical stress during bending. This combination prevents crack propagation through the entire structure, enhancing the overall flexibility and reliability of OLED devices.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques employ ultra-thin barrier layers deposited directly onto the OLED device without rigid cover glass. These techniques utilize atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD) to create conformal barrier films with minimal thickness, significantly improving the bending radius and flexibility of the display while maintaining effective protection against environmental contaminants.

- Stress-relief structures in encapsulation layers: Incorporating specialized stress-relief structures within the encapsulation layers helps accommodate mechanical strain during bending. These structures include micro-patterns, grid patterns, or island structures that can deform without cracking. Some designs feature intentional discontinuities or segmented barrier layers connected by flexible organic materials, allowing the encapsulation to flex while maintaining barrier properties against moisture and oxygen penetration.

- Advanced materials for flexible encapsulation: Novel materials with inherent flexibility are being developed for OLED encapsulation. These include hybrid organic-inorganic materials, flexible glass, specialized polymers with high barrier properties, and nanocomposites. Some approaches utilize materials like parylene, polyimide derivatives, or silicone-based compounds that combine flexibility with excellent barrier properties. These materials can withstand repeated bending cycles while maintaining their protective function.

- Edge sealing techniques for flexible OLEDs: Specialized edge sealing techniques prevent moisture and oxygen ingress from the edges of flexible OLED panels. These methods include flexible edge sealants, extended barrier layers, or edge reinforcement structures that maintain integrity during bending. Some designs incorporate gradient flexibility zones that transition from rigid to flexible areas, preventing delamination and edge-initiated failure modes while allowing the central display area to remain highly flexible.

02 Thin film encapsulation techniques for flexibility

Thin film encapsulation (TFE) techniques are employed to create ultra-thin barrier layers that can flex without compromising their protective properties. These techniques involve depositing thin layers of materials such as silicon nitride, aluminum oxide, or hybrid materials directly onto the OLED device. The reduced thickness of these layers compared to traditional encapsulation methods allows for greater flexibility while maintaining the necessary barrier properties against environmental contaminants.Expand Specific Solutions03 Stress-relieving structures in encapsulation layers

Various stress-relieving structures are incorporated into encapsulation layers to enhance flexibility and prevent cracking during bending. These structures include micro-patterns, grid structures, island-bridge configurations, and engineered interfaces between different materials. By allowing for controlled deformation and stress distribution, these structures enable the encapsulation layer to accommodate bending stresses without failure, thus improving the overall flexibility of the OLED device.Expand Specific Solutions04 Flexible inorganic-organic hybrid materials

Hybrid materials combining inorganic and organic components are developed specifically for flexible OLED encapsulation. These materials offer the barrier properties of inorganic materials while incorporating the flexibility of organic materials. Examples include organosilicon compounds, metal-organic frameworks, and polymer-inorganic nanocomposites. The hybrid nature of these materials allows them to maintain effective barrier properties against moisture and oxygen while accommodating the mechanical stresses associated with flexing.Expand Specific Solutions05 Edge sealing techniques for flexible OLEDs

Specialized edge sealing techniques are developed to maintain encapsulation integrity at the edges of flexible OLED devices, which are particularly vulnerable during bending. These techniques include flexible adhesive systems, reinforced edge structures, and gradient material transitions. By providing robust sealing at the device edges while maintaining flexibility, these approaches prevent moisture and oxygen ingress from the sides of the device, enhancing the overall reliability and lifespan of flexible OLEDs.Expand Specific Solutions

Key Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation market is currently in a growth phase, with the wearable tech sector driving significant demand. The global market is projected to reach substantial value as flexible displays become essential in smartwatches, fitness trackers, and emerging wearable devices. Technologically, Chinese manufacturers like BOE Technology, TCL China Star Optoelectronics, and Wuhan China Star Optoelectronics are rapidly advancing their capabilities, while established players such as Samsung Display, LG Display, and 3M Innovative Properties maintain technological leadership through superior barrier film technologies. The competition is intensifying as companies like Visionox and Guangdong Grenas develop proprietary encapsulation solutions to address the critical challenges of moisture and oxygen protection while maintaining flexibility for next-generation wearable applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an advanced flexible OLED encapsulation solution called "BOE-Shield" specifically designed for wearable applications. This technology utilizes a multi-layer barrier structure consisting of alternating inorganic (primarily SiN and Al2O3) and organic layers deposited through a combination of plasma-enhanced chemical vapor deposition (PECVD) and solution processing. The inorganic layers provide excellent barrier properties against moisture and oxygen, while the organic layers absorb mechanical stress during bending. BOE's innovation lies in their proprietary "nano-composite organic interlayers" that incorporate inorganic nanoparticles within the organic matrix, enhancing both barrier properties and mechanical resilience. Their encapsulation technology achieves a water vapor transmission rate (WVTR) of approximately 10^-6 g/m²/day while maintaining flexibility for over 200,000 bending cycles at a 3mm radius. For wearable applications, BOE has further refined this technology to create an ultra-thin encapsulation (total thickness <8μm) that can conform to curved surfaces while maintaining barrier integrity.

Strengths: Excellent balance between barrier performance and flexibility; proprietary nano-composite interlayers enhancing mechanical durability; good optical transparency (>85%); cost-effective manufacturing process suitable for mass production. Weaknesses: Slightly higher WVTR compared to some competitors; challenges with uniformity in large-area applications; relatively new technology with less field-proven reliability data compared to industry leaders.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a proprietary flexible OLED encapsulation technology called "FlexShield" specifically engineered for wearable applications. This technology employs a hybrid barrier structure combining inorganic layers (primarily SiN and Al2O3) deposited via atomic layer deposition (ALD) with specially formulated organic layers applied through vapor deposition polymerization. The FlexShield technology features a unique "gradient transition layer" between the inorganic and organic components that minimizes interfacial stress and prevents delamination during repeated bending cycles. For wearable devices, TCL has optimized their encapsulation to achieve a water vapor transmission rate below 10^-5 g/m²/day while maintaining flexibility at a bending radius of 2mm for over 150,000 cycles. Their latest innovation incorporates a specialized edge sealing technique using laser-assisted patterning that extends barrier protection to the vulnerable display edges, reducing edge-initiated failures by approximately 60% compared to conventional methods. TCL has also developed a modified version of FlexShield with enhanced UV-blocking properties specifically for outdoor wearable applications.

Strengths: Innovative gradient transition layer technology reducing delamination; excellent edge sealing technique; good balance of barrier properties and flexibility; enhanced UV protection for outdoor applications. Weaknesses: Slightly higher WVTR compared to industry leaders; more complex manufacturing process requiring specialized equipment; moderate yield rates in mass production; limited long-term reliability data in extreme environments.

Critical Patents and Innovations in Encapsulation Technology

Encapsulation structure and encapsulation method for flexible organic light-emitting diode device

PatentActiveUS20230180509A1

Innovation

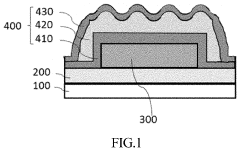

- An encapsulation structure comprising an organic matter protective layer, continuous or discontinuous organic flat layers, and inorganic barrier layers, with the outermost organic layers treated with plasma to form a surface hardened layer, creating an organic barrier layer that enhances moisture and oxygen blocking while allowing stress release.

Flexible organic light-emitting diode (OLED) device and fabrication method thereof

PatentActiveUS20210336206A1

Innovation

- A novel encapsulation layer configuration with a first and second inorganic layer and an organic layer, where the second inorganic layer has a continuous wavy curved configuration, increasing contact area and reducing stress, formed spontaneously due to thermal stress differences between layers.

Environmental Impact and Sustainability Considerations

The environmental footprint of flexible OLED encapsulation technology represents a critical consideration as wearable devices proliferate globally. Traditional encapsulation methods often rely on glass barriers and metal components that present significant end-of-life disposal challenges. In contrast, flexible OLED encapsulation typically employs thin-film barrier technologies that can reduce overall material usage by up to 30% compared to rigid alternatives, potentially decreasing the environmental impact during manufacturing.

However, these advanced barrier films frequently incorporate rare earth elements and specialized polymers that pose extraction and recycling difficulties. The multi-layer thin-film encapsulation (TFE) structures, while enabling flexibility, create complex material composites that current recycling infrastructure struggles to process effectively. Studies indicate that less than 15% of materials from discarded flexible displays are currently recovered through conventional recycling methods.

Energy consumption during manufacturing presents another environmental concern. The atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) processes used for creating high-quality barrier layers require precisely controlled environments and significant energy inputs. Recent innovations have reduced energy requirements by approximately 25%, yet production remains energy-intensive compared to conventional electronics manufacturing.

Water usage represents a substantial environmental factor, with estimates suggesting that producing a single square meter of flexible barrier film requires between 80-120 liters of ultra-pure water. This consumption occurs primarily during cleaning processes and chemical treatments essential for achieving the necessary barrier properties against oxygen and moisture penetration.

Several manufacturers have begun implementing closed-loop water recycling systems and exploring bio-based alternatives for certain barrier components. Companies like Samsung Display and LG Display have announced sustainability initiatives targeting carbon-neutral production facilities by 2030, with specific focus on reducing the environmental impact of their flexible display technologies.

The durability of flexible OLED encapsulation directly influences product lifespan and subsequent environmental impact. Current generation flexible barriers typically maintain effective protection for 3-5 years under normal usage conditions, though this represents significant improvement over earlier iterations. Extended product lifespans through improved encapsulation technology could substantially reduce electronic waste generation in the wearable technology sector.

As the wearable technology market expands at a projected CAGR of 15.9% through 2026, addressing these environmental considerations becomes increasingly urgent. Industry consortiums and research institutions are actively developing more sustainable encapsulation technologies, including biodegradable barrier components and design-for-disassembly approaches that may significantly improve the environmental profile of next-generation wearable devices.

However, these advanced barrier films frequently incorporate rare earth elements and specialized polymers that pose extraction and recycling difficulties. The multi-layer thin-film encapsulation (TFE) structures, while enabling flexibility, create complex material composites that current recycling infrastructure struggles to process effectively. Studies indicate that less than 15% of materials from discarded flexible displays are currently recovered through conventional recycling methods.

Energy consumption during manufacturing presents another environmental concern. The atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) processes used for creating high-quality barrier layers require precisely controlled environments and significant energy inputs. Recent innovations have reduced energy requirements by approximately 25%, yet production remains energy-intensive compared to conventional electronics manufacturing.

Water usage represents a substantial environmental factor, with estimates suggesting that producing a single square meter of flexible barrier film requires between 80-120 liters of ultra-pure water. This consumption occurs primarily during cleaning processes and chemical treatments essential for achieving the necessary barrier properties against oxygen and moisture penetration.

Several manufacturers have begun implementing closed-loop water recycling systems and exploring bio-based alternatives for certain barrier components. Companies like Samsung Display and LG Display have announced sustainability initiatives targeting carbon-neutral production facilities by 2030, with specific focus on reducing the environmental impact of their flexible display technologies.

The durability of flexible OLED encapsulation directly influences product lifespan and subsequent environmental impact. Current generation flexible barriers typically maintain effective protection for 3-5 years under normal usage conditions, though this represents significant improvement over earlier iterations. Extended product lifespans through improved encapsulation technology could substantially reduce electronic waste generation in the wearable technology sector.

As the wearable technology market expands at a projected CAGR of 15.9% through 2026, addressing these environmental considerations becomes increasingly urgent. Industry consortiums and research institutions are actively developing more sustainable encapsulation technologies, including biodegradable barrier components and design-for-disassembly approaches that may significantly improve the environmental profile of next-generation wearable devices.

Manufacturing Scalability and Cost Analysis

The scalability of flexible OLED encapsulation manufacturing represents a critical factor in the widespread adoption of wearable technology. Current production methods face significant challenges in transitioning from small-batch manufacturing to mass production scales. The thin-film encapsulation (TFE) process, essential for protecting flexible OLEDs from moisture and oxygen degradation, requires precision deposition equipment operating in ultra-clean environments, creating substantial capital expenditure barriers for manufacturers entering this space.

Production yield rates remain a persistent challenge, with industry averages hovering between 60-70% for flexible OLED encapsulation, compared to 85-90% for conventional rigid displays. This yield gap directly impacts unit economics and creates pricing pressure that limits market penetration in mid-range wearable segments. The complex multi-layer barrier structures necessary for effective encapsulation demand specialized equipment that currently lacks standardization across the industry.

Cost analysis reveals that encapsulation represents approximately 15-20% of total flexible OLED manufacturing expenses, with materials accounting for 40% of this cost component. Inorganic barrier layers utilizing atomic layer deposition (ALD) technology remain particularly expensive due to slow deposition rates and specialized precursor materials. Alternative approaches using hybrid organic-inorganic structures show promise for cost reduction but currently sacrifice some performance metrics.

Regional manufacturing capabilities demonstrate significant concentration, with South Korean and Chinese manufacturers controlling approximately 85% of production capacity. This geographic concentration creates supply chain vulnerabilities for Western wearable technology companies and influences pricing dynamics across global markets. Emerging production facilities in Vietnam and India may help diversify manufacturing bases by 2025-2026.

Equipment amortization represents another significant cost factor, with specialized encapsulation tools requiring 3-5 year depreciation schedules that must be factored into unit economics. Industry leaders have begun implementing automated inspection systems that improve yield rates by identifying defects earlier in the production process, potentially reducing costs by 8-12% according to recent industry analyses.

For wearable technology manufacturers, these scalability and cost factors directly influence product design decisions, with many companies optimizing form factors specifically to maximize yield rates from current encapsulation technologies rather than pursuing more ambitious but less manufacturable designs. This manufacturing-driven design approach may limit innovation until encapsulation processes achieve greater maturity and cost efficiency.

Production yield rates remain a persistent challenge, with industry averages hovering between 60-70% for flexible OLED encapsulation, compared to 85-90% for conventional rigid displays. This yield gap directly impacts unit economics and creates pricing pressure that limits market penetration in mid-range wearable segments. The complex multi-layer barrier structures necessary for effective encapsulation demand specialized equipment that currently lacks standardization across the industry.

Cost analysis reveals that encapsulation represents approximately 15-20% of total flexible OLED manufacturing expenses, with materials accounting for 40% of this cost component. Inorganic barrier layers utilizing atomic layer deposition (ALD) technology remain particularly expensive due to slow deposition rates and specialized precursor materials. Alternative approaches using hybrid organic-inorganic structures show promise for cost reduction but currently sacrifice some performance metrics.

Regional manufacturing capabilities demonstrate significant concentration, with South Korean and Chinese manufacturers controlling approximately 85% of production capacity. This geographic concentration creates supply chain vulnerabilities for Western wearable technology companies and influences pricing dynamics across global markets. Emerging production facilities in Vietnam and India may help diversify manufacturing bases by 2025-2026.

Equipment amortization represents another significant cost factor, with specialized encapsulation tools requiring 3-5 year depreciation schedules that must be factored into unit economics. Industry leaders have begun implementing automated inspection systems that improve yield rates by identifying defects earlier in the production process, potentially reducing costs by 8-12% according to recent industry analyses.

For wearable technology manufacturers, these scalability and cost factors directly influence product design decisions, with many companies optimizing form factors specifically to maximize yield rates from current encapsulation technologies rather than pursuing more ambitious but less manufacturable designs. This manufacturing-driven design approach may limit innovation until encapsulation processes achieve greater maturity and cost efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!