Flexible OLED Encapsulation: Analysis of Barrier Properties

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Technology Background and Objectives

Flexible OLED (Organic Light-Emitting Diode) technology has revolutionized the display industry over the past decade, enabling the development of bendable, foldable, and rollable displays that were once confined to science fiction. The evolution of this technology can be traced back to the early 2000s when researchers first demonstrated the potential of organic materials for creating flexible light-emitting devices. Since then, the field has witnessed remarkable advancements in materials science, manufacturing processes, and device architectures.

The critical challenge in flexible OLED technology lies in protecting the highly sensitive organic materials from environmental factors, particularly oxygen and moisture, which can rapidly degrade device performance and lifetime. This protection requirement has driven the development of encapsulation technologies as a cornerstone of flexible OLED innovation. Traditional rigid glass encapsulation, while effective for conventional displays, is incompatible with the mechanical flexibility demanded by next-generation devices.

The technical evolution trajectory shows a clear shift from early single-layer barrier films toward sophisticated multi-layer architectures and hybrid organic-inorganic systems. These advanced encapsulation solutions aim to achieve the stringent water vapor transmission rate (WVTR) requirements of less than 10^-6 g/m²/day while maintaining mechanical flexibility under repeated bending and folding operations.

Current technological objectives in flexible OLED encapsulation focus on several key areas: enhancing barrier properties against oxygen and moisture permeation, improving mechanical durability under dynamic stress conditions, developing cost-effective manufacturing processes suitable for mass production, and ensuring compatibility with increasingly complex device architectures such as foldable and rollable displays.

The field is witnessing convergence between thin-film deposition technologies, including atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based approaches. Each offers distinct advantages in terms of barrier performance, process temperature, throughput, and cost considerations. The ultimate goal is to develop encapsulation solutions that provide perfect protection while imposing minimal constraints on device flexibility and optical performance.

Looking forward, the technology is expected to evolve toward ultra-thin barrier films with self-healing capabilities, environmentally friendly materials, and integration with other functional components such as touch sensors and color filters. These advancements will be crucial for enabling the next generation of flexible, foldable, and stretchable display technologies that promise to transform consumer electronics, healthcare devices, and automotive displays.

The critical challenge in flexible OLED technology lies in protecting the highly sensitive organic materials from environmental factors, particularly oxygen and moisture, which can rapidly degrade device performance and lifetime. This protection requirement has driven the development of encapsulation technologies as a cornerstone of flexible OLED innovation. Traditional rigid glass encapsulation, while effective for conventional displays, is incompatible with the mechanical flexibility demanded by next-generation devices.

The technical evolution trajectory shows a clear shift from early single-layer barrier films toward sophisticated multi-layer architectures and hybrid organic-inorganic systems. These advanced encapsulation solutions aim to achieve the stringent water vapor transmission rate (WVTR) requirements of less than 10^-6 g/m²/day while maintaining mechanical flexibility under repeated bending and folding operations.

Current technological objectives in flexible OLED encapsulation focus on several key areas: enhancing barrier properties against oxygen and moisture permeation, improving mechanical durability under dynamic stress conditions, developing cost-effective manufacturing processes suitable for mass production, and ensuring compatibility with increasingly complex device architectures such as foldable and rollable displays.

The field is witnessing convergence between thin-film deposition technologies, including atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based approaches. Each offers distinct advantages in terms of barrier performance, process temperature, throughput, and cost considerations. The ultimate goal is to develop encapsulation solutions that provide perfect protection while imposing minimal constraints on device flexibility and optical performance.

Looking forward, the technology is expected to evolve toward ultra-thin barrier films with self-healing capabilities, environmentally friendly materials, and integration with other functional components such as touch sensors and color filters. These advancements will be crucial for enabling the next generation of flexible, foldable, and stretchable display technologies that promise to transform consumer electronics, healthcare devices, and automotive displays.

Market Demand Analysis for Flexible OLED Displays

The flexible OLED display market has witnessed exponential growth over the past decade, driven primarily by consumer electronics applications. Market research indicates that the global flexible OLED display market reached approximately $18.6 billion in 2022 and is projected to grow at a CAGR of 27.3% through 2028, potentially reaching $78.3 billion by the end of the forecast period. This remarkable growth trajectory underscores the significant market demand for this technology.

Smartphone manufacturers represent the largest consumer segment, accounting for nearly 65% of flexible OLED display consumption. Major players like Samsung, Apple, and Huawei have increasingly incorporated flexible OLED displays into their flagship devices, with Samsung alone shipping over 300 million flexible OLED panels in 2022. The premium smartphone segment has particularly embraced this technology, with curved edges and foldable designs becoming key differentiators in the high-end market.

Beyond smartphones, wearable devices constitute the second-largest application segment, with smartwatches and fitness trackers driving demand for small-sized flexible displays. The automotive industry has also begun integrating flexible OLED technology into dashboard displays and entertainment systems, with luxury vehicle manufacturers leading adoption. Market analysts predict this segment will grow at 35% annually through 2027.

Regional analysis reveals Asia-Pacific dominates both production and consumption, with South Korea, China, and Japan collectively accounting for 78% of global manufacturing capacity. North America and Europe follow as significant consumption markets, primarily driven by premium consumer electronics adoption.

Consumer preference surveys indicate increasing demand for devices with larger screen-to-body ratios, enhanced durability, and novel form factors. The ability of flexible OLEDs to enable foldable and rollable devices aligns perfectly with these consumer preferences. Market research shows consumers are willing to pay a 15-20% premium for devices featuring flexible displays compared to conventional alternatives.

However, barrier properties remain a critical concern for market expansion. Industry reports highlight that inadequate encapsulation leading to moisture and oxygen penetration remains the primary cause of flexible OLED failure in commercial devices. Manufacturers report that improving barrier properties could potentially extend device lifespans by 30-40%, significantly enhancing consumer satisfaction and reducing warranty claims.

Smartphone manufacturers represent the largest consumer segment, accounting for nearly 65% of flexible OLED display consumption. Major players like Samsung, Apple, and Huawei have increasingly incorporated flexible OLED displays into their flagship devices, with Samsung alone shipping over 300 million flexible OLED panels in 2022. The premium smartphone segment has particularly embraced this technology, with curved edges and foldable designs becoming key differentiators in the high-end market.

Beyond smartphones, wearable devices constitute the second-largest application segment, with smartwatches and fitness trackers driving demand for small-sized flexible displays. The automotive industry has also begun integrating flexible OLED technology into dashboard displays and entertainment systems, with luxury vehicle manufacturers leading adoption. Market analysts predict this segment will grow at 35% annually through 2027.

Regional analysis reveals Asia-Pacific dominates both production and consumption, with South Korea, China, and Japan collectively accounting for 78% of global manufacturing capacity. North America and Europe follow as significant consumption markets, primarily driven by premium consumer electronics adoption.

Consumer preference surveys indicate increasing demand for devices with larger screen-to-body ratios, enhanced durability, and novel form factors. The ability of flexible OLEDs to enable foldable and rollable devices aligns perfectly with these consumer preferences. Market research shows consumers are willing to pay a 15-20% premium for devices featuring flexible displays compared to conventional alternatives.

However, barrier properties remain a critical concern for market expansion. Industry reports highlight that inadequate encapsulation leading to moisture and oxygen penetration remains the primary cause of flexible OLED failure in commercial devices. Manufacturers report that improving barrier properties could potentially extend device lifespans by 30-40%, significantly enhancing consumer satisfaction and reducing warranty claims.

Current Barrier Technology Status and Challenges

The current state of flexible OLED encapsulation technology faces significant challenges despite substantial progress in recent years. Traditional glass-based encapsulation methods, while effective for rigid displays, are fundamentally incompatible with flexible applications due to their inherent brittleness and inability to withstand repeated bending cycles. This technological gap has driven intensive research into alternative barrier solutions specifically designed for flexible OLEDs.

Water vapor transmission rate (WVTR) requirements for flexible OLED encapsulation remain extremely demanding, with industry standards requiring levels below 10^-6 g/m²/day. Oxygen transmission rates must similarly be maintained below 10^-3 cm³/m²/day to ensure adequate device lifetimes. These stringent requirements significantly exceed the capabilities of conventional plastic substrates by several orders of magnitude, creating a fundamental materials science challenge.

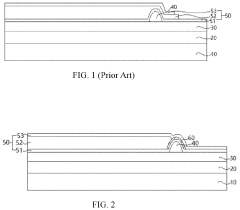

Current thin-film encapsulation (TFE) technologies predominantly utilize alternating layers of inorganic and organic materials. The inorganic layers (typically AlOx, SiNx, or SiOx) provide excellent barrier properties but are prone to defects and cracking under mechanical stress. Organic layers (often based on polyacrylates or parylene derivatives) offer flexibility but possess inferior barrier characteristics. This hybrid approach attempts to combine the advantages of both material classes while mitigating their respective limitations.

Atomic Layer Deposition (ALD) has emerged as a promising technique for creating high-quality inorganic barrier layers with precise thickness control down to the atomic level. However, ALD processes face significant challenges in manufacturing scalability, with deposition rates typically too slow for high-volume production environments. Additionally, the high temperatures often required for optimal ALD film formation can damage temperature-sensitive OLED materials and substrates.

Geographical distribution of barrier technology development shows concentration in East Asia, particularly South Korea and Japan, where major display manufacturers have established significant intellectual property portfolios. Research institutions in Europe and North America have contributed fundamental innovations, but commercial implementation remains primarily centered in Asia's established display manufacturing ecosystem.

The mechanical durability of barrier films under repeated bending, folding, and rolling conditions represents perhaps the most significant unresolved challenge. Current solutions typically demonstrate significant degradation in barrier properties after mechanical stress cycles, with crack propagation in inorganic layers being the primary failure mechanism. This limitation directly impacts device lifetime in real-world usage scenarios where displays undergo frequent flexing.

Edge sealing technology presents another critical challenge, as the perimeter of flexible displays remains particularly vulnerable to moisture and oxygen ingress. Traditional edge sealing methods developed for rigid displays are not directly transferable to flexible form factors, necessitating novel approaches that maintain barrier integrity while accommodating mechanical movement.

Water vapor transmission rate (WVTR) requirements for flexible OLED encapsulation remain extremely demanding, with industry standards requiring levels below 10^-6 g/m²/day. Oxygen transmission rates must similarly be maintained below 10^-3 cm³/m²/day to ensure adequate device lifetimes. These stringent requirements significantly exceed the capabilities of conventional plastic substrates by several orders of magnitude, creating a fundamental materials science challenge.

Current thin-film encapsulation (TFE) technologies predominantly utilize alternating layers of inorganic and organic materials. The inorganic layers (typically AlOx, SiNx, or SiOx) provide excellent barrier properties but are prone to defects and cracking under mechanical stress. Organic layers (often based on polyacrylates or parylene derivatives) offer flexibility but possess inferior barrier characteristics. This hybrid approach attempts to combine the advantages of both material classes while mitigating their respective limitations.

Atomic Layer Deposition (ALD) has emerged as a promising technique for creating high-quality inorganic barrier layers with precise thickness control down to the atomic level. However, ALD processes face significant challenges in manufacturing scalability, with deposition rates typically too slow for high-volume production environments. Additionally, the high temperatures often required for optimal ALD film formation can damage temperature-sensitive OLED materials and substrates.

Geographical distribution of barrier technology development shows concentration in East Asia, particularly South Korea and Japan, where major display manufacturers have established significant intellectual property portfolios. Research institutions in Europe and North America have contributed fundamental innovations, but commercial implementation remains primarily centered in Asia's established display manufacturing ecosystem.

The mechanical durability of barrier films under repeated bending, folding, and rolling conditions represents perhaps the most significant unresolved challenge. Current solutions typically demonstrate significant degradation in barrier properties after mechanical stress cycles, with crack propagation in inorganic layers being the primary failure mechanism. This limitation directly impacts device lifetime in real-world usage scenarios where displays undergo frequent flexing.

Edge sealing technology presents another critical challenge, as the perimeter of flexible displays remains particularly vulnerable to moisture and oxygen ingress. Traditional edge sealing methods developed for rigid displays are not directly transferable to flexible form factors, necessitating novel approaches that maintain barrier integrity while accommodating mechanical movement.

Current Barrier Layer Solutions and Implementation

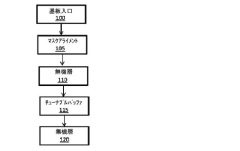

01 Multi-layer barrier structures for OLED encapsulation

Multi-layer barrier structures are used to protect flexible OLEDs from moisture and oxygen penetration. These structures typically consist of alternating inorganic and organic layers that provide effective barrier properties while maintaining flexibility. The inorganic layers (such as metal oxides) provide the primary barrier function, while the organic layers help to decouple defects and provide stress relief during bending. This combination enhances the overall barrier performance and extends the lifetime of flexible OLED devices.- Multi-layer barrier structures for OLED encapsulation: Multi-layer barrier structures are used in flexible OLED encapsulation to provide enhanced protection against moisture and oxygen penetration. These structures typically consist of alternating organic and inorganic layers that create a tortuous path for water and oxygen molecules. The inorganic layers provide barrier properties while the organic layers decouple defects between the inorganic layers and add flexibility. This approach significantly improves the barrier properties while maintaining the flexibility required for bendable displays.

- Thin-film encapsulation technologies: Thin-film encapsulation (TFE) technologies are critical for flexible OLED devices as they eliminate the need for rigid glass encapsulation. These technologies involve depositing ultra-thin barrier films directly onto the OLED device using methods such as atomic layer deposition (ALD) or chemical vapor deposition (CVD). TFE provides excellent barrier properties against moisture and oxygen while maintaining the flexibility of the device. The thinness of these films also contributes to the overall thinness and lightweight nature of flexible OLED displays.

- Advanced materials for barrier layers: Various advanced materials are employed in flexible OLED encapsulation barriers to achieve superior protection. These include silicon nitride, aluminum oxide, and hybrid organic-inorganic materials. These materials offer excellent barrier properties against moisture and oxygen while maintaining flexibility. Some formulations incorporate nanoparticles or specialized polymers to enhance barrier performance. The selection of materials is crucial for achieving the balance between barrier effectiveness and mechanical flexibility required for bendable OLED devices.

- Edge sealing techniques for flexible OLEDs: Edge sealing is a critical aspect of flexible OLED encapsulation as the edges are particularly vulnerable to moisture and oxygen ingress. Various techniques have been developed to create effective edge seals for flexible displays, including specialized adhesives, laser sealing methods, and hybrid sealing approaches. These techniques ensure that the entire perimeter of the OLED device is protected while maintaining flexibility. Effective edge sealing significantly extends the lifetime of flexible OLED devices by preventing lateral diffusion of harmful elements.

- Flexibility and mechanical durability enhancements: Enhancing the mechanical durability of barrier layers is essential for flexible OLED applications. Various approaches are used to improve the flexibility and durability of encapsulation barriers, including stress-relief structures, specialized buffer layers, and engineered interfaces between layers. These enhancements allow the barrier to withstand repeated bending and folding without compromising barrier properties. Some technologies incorporate self-healing materials or stretchable components to further improve the mechanical resilience of the encapsulation system.

02 Thin-film encapsulation techniques for flexible displays

Thin-film encapsulation (TFE) techniques are employed to create ultra-thin barrier layers directly on the OLED device, eliminating the need for rigid glass encapsulation. These techniques include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and other vacuum deposition methods that enable the formation of high-quality barrier films with minimal defects. TFE allows for the production of flexible, lightweight OLED displays while maintaining excellent barrier properties against moisture and oxygen ingress.Expand Specific Solutions03 Hybrid organic-inorganic barrier materials

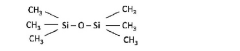

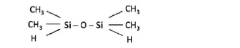

Hybrid organic-inorganic materials combine the advantages of both material types to create effective encapsulation barriers for flexible OLEDs. These materials often incorporate siloxane-based compounds, metal oxide nanoparticles, or other hybrid structures that provide excellent barrier properties while maintaining flexibility. The organic components contribute to flexibility and crack resistance, while the inorganic components enhance the barrier performance against moisture and oxygen permeation, resulting in improved device lifetime and reliability.Expand Specific Solutions04 Edge sealing and mechanical protection for flexible OLEDs

Edge sealing techniques and mechanical protection layers are critical for preventing lateral diffusion of moisture and oxygen into flexible OLED devices. These approaches include specialized edge sealants, barrier adhesives, and protective films that extend beyond the active display area. Additional mechanical protection layers may be incorporated to prevent damage during bending and folding operations, ensuring that the barrier properties remain intact throughout the device lifetime even under mechanical stress.Expand Specific Solutions05 Self-healing barrier technologies

Self-healing barrier technologies incorporate materials that can repair minor defects or damage in the encapsulation layer of flexible OLEDs. These materials often contain reactive components that can fill microcracks or defects when activated by environmental factors or external stimuli. Some approaches use liquid or gel-like materials that flow into damaged areas, while others employ chemical reactions triggered by moisture or oxygen exposure. Self-healing barriers significantly improve the long-term reliability and lifetime of flexible OLED devices by maintaining barrier integrity even after mechanical deformation.Expand Specific Solutions

Key Industry Players in Flexible OLED Encapsulation

The flexible OLED encapsulation market is currently in a growth phase, with increasing demand driven by the proliferation of foldable displays in consumer electronics. The global market size is projected to reach significant value as major players invest heavily in barrier technology development. From a technical maturity perspective, the industry is advancing rapidly with companies like Samsung Display, BOE Technology, and TCL's China Star Optoelectronics leading innovation in thin-film encapsulation solutions. These companies are developing multi-layer barrier films that effectively prevent moisture and oxygen penetration while maintaining flexibility. Universal Display Corporation and Applied Materials are contributing critical materials and equipment technologies, while emerging players like Tianma Microelectronics and Visionox are gaining market share through specialized barrier solutions for different OLED applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a multi-layer thin-film encapsulation (TFE) technology for flexible OLED displays that combines inorganic and organic layers. Their approach utilizes alternating layers of inorganic materials (primarily silicon nitride and aluminum oxide) deposited via plasma-enhanced chemical vapor deposition (PECVD) and organic materials applied through inkjet printing. This creates a tortuous path structure that effectively blocks moisture and oxygen penetration. BOE's latest barrier technology achieves a water vapor transmission rate (WVTR) of less than 10^-6 g/m²/day, which exceeds industry standards for OLED longevity. They've also implemented a proprietary edge sealing technology to address the vulnerable perimeter areas of flexible displays, using laser-assisted patterning to create seamless barrier integration at the edges.

Strengths: BOE's multi-layer approach provides excellent barrier properties while maintaining flexibility. Their high-volume manufacturing capability allows for cost-effective production. Weaknesses: The complex multi-layer structure requires precise process control, and the technology still faces challenges with mechanical durability during repeated folding operations, potentially creating micro-cracks in barrier layers.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has pioneered an advanced thin-film encapsulation (TFE) technology for flexible OLEDs featuring a hybrid structure of inorganic and organic layers. Their proprietary approach uses atomic layer deposition (ALD) to create ultra-thin, highly uniform inorganic barrier layers (primarily Al2O3) combined with specialized polymer materials for the organic layers. This technology achieves a water vapor transmission rate (WVTR) below 10^-7 g/m²/day, representing industry-leading barrier performance. Samsung has also developed a unique "buffer layer" technology that absorbs mechanical stress during bending, preventing barrier layer damage. Their encapsulation process incorporates in-situ plasma treatment between layer depositions to enhance adhesion and barrier properties. For ultra-flexible applications, Samsung employs a stress-relief mechanism within the barrier structure that allows for a bending radius down to 1.4mm while maintaining barrier integrity.

Strengths: Samsung's ALD-based technology provides superior barrier uniformity and exceptional moisture resistance. Their integrated stress management approach enables reliable performance in highly flexible applications. Weaknesses: The ALD process has relatively slow deposition rates compared to other methods, potentially limiting throughput in mass production. The complex multi-layer structure also increases manufacturing costs compared to simpler barrier solutions.

Critical Patents and Research on Barrier Properties

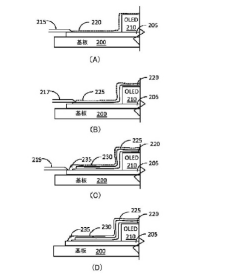

Encapsulation method for organic light emitting diode

PatentInactiveJP2022145802A

Innovation

- A method involving the formation of inorganic and organic layers in a controlled process chamber, utilizing tunable buffer layers formed from vaporized organosilicon compounds like hexamethyldisiloxane or tetramethyldisiloxane, with precise mask alignment outside the chamber to ensure encapsulation integrity.

OLED display device

PatentActiveUS20200099007A1

Innovation

- The OLED display device incorporates a flexible substrate with a thin-film transistor layer, an OLED light emitting layer, a barrier layer, and an encapsulation layer comprising a first and second inorganic layer, along with a protection layer made of monocrystalline silicon, which completely covers the barrier layer to prevent organic ink overflow and separate the organic layer from the barrier layer, thereby preventing external moisture and oxygen ingress.

Material Science Advancements for Enhanced Barrier Properties

Recent advancements in material science have significantly contributed to overcoming the critical challenges in flexible OLED encapsulation. The development of multi-layer thin film encapsulation (TFE) structures has emerged as a breakthrough, combining inorganic and organic materials to achieve superior barrier properties while maintaining flexibility. These hybrid structures typically alternate between inorganic layers (such as Al2O3, SiO2, or SiNx) that provide excellent barrier properties and organic layers that accommodate mechanical stress during bending.

Atomic Layer Deposition (ALD) technology has revolutionized the fabrication of ultra-thin inorganic barrier layers with exceptional uniformity and minimal defects. This process enables the deposition of films with thickness control at the atomic level, resulting in highly effective moisture and oxygen barriers even at thicknesses below 10nm. The precision of ALD has allowed for unprecedented water vapor transmission rates (WVTR) below 10^-6 g/m²/day, which meets the stringent requirements for OLED protection.

Novel nanocomposite materials represent another significant advancement, incorporating nanoparticles such as graphene, clay, or metal oxides into polymer matrices. These nanocomposites create tortuous paths for water and oxygen molecules, substantially extending diffusion pathways and reducing permeation rates. For instance, graphene oxide-reinforced polymers have demonstrated up to 95% improvement in barrier properties compared to conventional materials while maintaining excellent mechanical flexibility.

Self-healing materials constitute a promising frontier in encapsulation technology. These innovative materials contain microcapsules with healing agents that are released upon crack formation, automatically repairing barrier defects before they compromise device integrity. Preliminary studies show that self-healing encapsulation can extend OLED lifetime by up to 60% under mechanical stress conditions compared to conventional barriers.

Surface modification techniques have also advanced significantly, with plasma treatments and chemical functionalization methods enhancing adhesion between different barrier layers. These improvements address delamination issues that commonly occur during repeated bending cycles. Modified surfaces with controlled hydrophobicity further contribute to moisture resistance, with contact angles exceeding 110° demonstrating superior water repellency.

Transparent metal oxide semiconductors with high electron mobility and optical transparency have been engineered specifically for flexible barrier applications. Materials such as IGZO (Indium Gallium Zinc Oxide) not only contribute to barrier properties but also enable integration of thin-film transistors directly into the encapsulation structure, potentially simplifying device architecture while enhancing protection against environmental factors.

Atomic Layer Deposition (ALD) technology has revolutionized the fabrication of ultra-thin inorganic barrier layers with exceptional uniformity and minimal defects. This process enables the deposition of films with thickness control at the atomic level, resulting in highly effective moisture and oxygen barriers even at thicknesses below 10nm. The precision of ALD has allowed for unprecedented water vapor transmission rates (WVTR) below 10^-6 g/m²/day, which meets the stringent requirements for OLED protection.

Novel nanocomposite materials represent another significant advancement, incorporating nanoparticles such as graphene, clay, or metal oxides into polymer matrices. These nanocomposites create tortuous paths for water and oxygen molecules, substantially extending diffusion pathways and reducing permeation rates. For instance, graphene oxide-reinforced polymers have demonstrated up to 95% improvement in barrier properties compared to conventional materials while maintaining excellent mechanical flexibility.

Self-healing materials constitute a promising frontier in encapsulation technology. These innovative materials contain microcapsules with healing agents that are released upon crack formation, automatically repairing barrier defects before they compromise device integrity. Preliminary studies show that self-healing encapsulation can extend OLED lifetime by up to 60% under mechanical stress conditions compared to conventional barriers.

Surface modification techniques have also advanced significantly, with plasma treatments and chemical functionalization methods enhancing adhesion between different barrier layers. These improvements address delamination issues that commonly occur during repeated bending cycles. Modified surfaces with controlled hydrophobicity further contribute to moisture resistance, with contact angles exceeding 110° demonstrating superior water repellency.

Transparent metal oxide semiconductors with high electron mobility and optical transparency have been engineered specifically for flexible barrier applications. Materials such as IGZO (Indium Gallium Zinc Oxide) not only contribute to barrier properties but also enable integration of thin-film transistors directly into the encapsulation structure, potentially simplifying device architecture while enhancing protection against environmental factors.

Environmental Impact and Sustainability Considerations

The environmental footprint of flexible OLED encapsulation technologies represents a critical consideration as these displays gain market prominence. Traditional encapsulation methods often rely on materials with significant environmental concerns, including perfluorinated compounds and heavy metals that pose disposal challenges and potential ecological hazards. The manufacturing processes for barrier films typically demand substantial energy consumption and generate considerable waste, particularly when utilizing inorganic materials that require high-temperature vacuum deposition techniques.

Water usage in production represents another significant environmental concern, with thin-film deposition processes often requiring ultra-pure water resources. As global water scarcity intensifies, the sustainability of these manufacturing approaches faces increasing scrutiny from regulatory bodies and environmentally conscious consumers alike.

Recent advancements in bio-based and biodegradable barrier materials offer promising alternatives to conventional petroleum-derived polymers. Research into cellulose nanofiber composites and other plant-derived materials demonstrates potential for creating effective moisture barriers with substantially reduced environmental impact. These innovations align with circular economy principles, potentially enabling end-of-life recovery and material reuse that conventional multi-layer barriers cannot achieve.

Life cycle assessment (LCA) studies reveal that the environmental impact of flexible OLED encapsulation extends beyond manufacturing to include transportation efficiency, operational energy consumption, and end-of-life management. The lightweight nature of flexible displays contributes to reduced transportation emissions compared to rigid alternatives, while their potential for improved energy efficiency during operation may offset initial production impacts over the product lifecycle.

Regulatory frameworks worldwide increasingly mandate extended producer responsibility for electronic components, creating urgent incentives for developing encapsulation technologies with improved recyclability profiles. Current multi-layer barrier structures present significant recycling challenges due to the difficulty in separating diverse material components, often resulting in downcycling rather than true material recovery.

Industry leaders are responding with green chemistry initiatives focused on developing halogen-free barrier materials and solvent-free deposition processes. These approaches aim to minimize hazardous waste generation while maintaining the exceptional barrier properties required for OLED protection. The integration of atomic layer deposition techniques at lower temperatures represents another promising direction, potentially reducing energy requirements while enabling the use of more environmentally benign substrate materials.

Water usage in production represents another significant environmental concern, with thin-film deposition processes often requiring ultra-pure water resources. As global water scarcity intensifies, the sustainability of these manufacturing approaches faces increasing scrutiny from regulatory bodies and environmentally conscious consumers alike.

Recent advancements in bio-based and biodegradable barrier materials offer promising alternatives to conventional petroleum-derived polymers. Research into cellulose nanofiber composites and other plant-derived materials demonstrates potential for creating effective moisture barriers with substantially reduced environmental impact. These innovations align with circular economy principles, potentially enabling end-of-life recovery and material reuse that conventional multi-layer barriers cannot achieve.

Life cycle assessment (LCA) studies reveal that the environmental impact of flexible OLED encapsulation extends beyond manufacturing to include transportation efficiency, operational energy consumption, and end-of-life management. The lightweight nature of flexible displays contributes to reduced transportation emissions compared to rigid alternatives, while their potential for improved energy efficiency during operation may offset initial production impacts over the product lifecycle.

Regulatory frameworks worldwide increasingly mandate extended producer responsibility for electronic components, creating urgent incentives for developing encapsulation technologies with improved recyclability profiles. Current multi-layer barrier structures present significant recycling challenges due to the difficulty in separating diverse material components, often resulting in downcycling rather than true material recovery.

Industry leaders are responding with green chemistry initiatives focused on developing halogen-free barrier materials and solvent-free deposition processes. These approaches aim to minimize hazardous waste generation while maintaining the exceptional barrier properties required for OLED protection. The integration of atomic layer deposition techniques at lower temperatures represents another promising direction, potentially reducing energy requirements while enabling the use of more environmentally benign substrate materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!