What Are the Mechanical Performance Benefits of Flexible OLED Encapsulation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible OLED Encapsulation Evolution and Objectives

Flexible OLED (Organic Light Emitting Diode) technology has evolved significantly over the past two decades, transforming from rigid laboratory prototypes to commercially viable flexible displays. The evolution began in the early 2000s when researchers first demonstrated the possibility of creating OLEDs on flexible substrates, primarily using plastic materials instead of traditional glass.

The initial encapsulation methods for these displays relied heavily on glass barriers with limited flexibility, severely restricting the mechanical performance of the overall device. By 2010, thin-film encapsulation (TFE) technologies emerged as a promising alternative, allowing for significantly improved flexibility while maintaining adequate protection against moisture and oxygen penetration.

A critical milestone occurred around 2015 when multi-layer barrier films combining organic and inorganic layers demonstrated superior mechanical properties while maintaining effective barrier performance. This hybrid approach addressed the fundamental challenge of creating encapsulation that could withstand repeated bending and folding without compromising the sensitive OLED materials beneath.

The primary objective of flexible OLED encapsulation development has been to achieve a delicate balance between mechanical flexibility and barrier properties. Specifically, the encapsulation must prevent water vapor transmission rates below 10^-6 g/m²/day and oxygen transmission rates below 10^-5 cc/m²/day while withstanding bending radii of less than 1mm without degradation.

Recent advancements have focused on developing encapsulation technologies that can endure dynamic folding operations exceeding 200,000 cycles without significant performance deterioration. This represents a substantial improvement from early flexible displays that could only withstand a few thousand bending cycles before failure.

Another key objective has been reducing the thickness of encapsulation layers while maintaining or improving barrier properties. Current state-of-the-art encapsulation systems have achieved thicknesses below 10 micrometers, contributing significantly to the overall flexibility of OLED devices while providing adequate protection.

The evolution trajectory points toward encapsulation systems that can support not just bending but also stretching capabilities, opening possibilities for conformable and even stretchable display applications. Research is increasingly focused on self-healing encapsulation materials that can automatically repair microcracks formed during mechanical deformation, potentially extending device lifetime dramatically.

As we look toward future developments, the ultimate objective remains creating encapsulation solutions that offer perfect transparency, impermeability to harmful elements, unlimited mechanical flexibility, and cost-effective manufacturing processes suitable for mass production.

The initial encapsulation methods for these displays relied heavily on glass barriers with limited flexibility, severely restricting the mechanical performance of the overall device. By 2010, thin-film encapsulation (TFE) technologies emerged as a promising alternative, allowing for significantly improved flexibility while maintaining adequate protection against moisture and oxygen penetration.

A critical milestone occurred around 2015 when multi-layer barrier films combining organic and inorganic layers demonstrated superior mechanical properties while maintaining effective barrier performance. This hybrid approach addressed the fundamental challenge of creating encapsulation that could withstand repeated bending and folding without compromising the sensitive OLED materials beneath.

The primary objective of flexible OLED encapsulation development has been to achieve a delicate balance between mechanical flexibility and barrier properties. Specifically, the encapsulation must prevent water vapor transmission rates below 10^-6 g/m²/day and oxygen transmission rates below 10^-5 cc/m²/day while withstanding bending radii of less than 1mm without degradation.

Recent advancements have focused on developing encapsulation technologies that can endure dynamic folding operations exceeding 200,000 cycles without significant performance deterioration. This represents a substantial improvement from early flexible displays that could only withstand a few thousand bending cycles before failure.

Another key objective has been reducing the thickness of encapsulation layers while maintaining or improving barrier properties. Current state-of-the-art encapsulation systems have achieved thicknesses below 10 micrometers, contributing significantly to the overall flexibility of OLED devices while providing adequate protection.

The evolution trajectory points toward encapsulation systems that can support not just bending but also stretching capabilities, opening possibilities for conformable and even stretchable display applications. Research is increasingly focused on self-healing encapsulation materials that can automatically repair microcracks formed during mechanical deformation, potentially extending device lifetime dramatically.

As we look toward future developments, the ultimate objective remains creating encapsulation solutions that offer perfect transparency, impermeability to harmful elements, unlimited mechanical flexibility, and cost-effective manufacturing processes suitable for mass production.

Market Demand Analysis for Flexible Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for innovative form factors in electronic devices. Market research indicates that the global flexible display market is projected to reach $15.5 billion by 2026, growing at a CAGR of 28% from 2021. This substantial growth reflects the shifting consumer preferences toward devices that offer enhanced portability, durability, and novel user experiences.

Smartphone manufacturers represent the primary demand drivers for flexible OLED technology, accounting for approximately 67% of the current market share. Major players like Samsung, Apple, and Huawei have increasingly incorporated flexible displays into their flagship products, signaling strong industry confidence in this technology. The foldable smartphone segment alone has seen a 300% year-over-year growth between 2020 and 2021, despite premium pricing models.

Beyond smartphones, diversification into other product categories is expanding market opportunities. Wearable devices constitute the second-largest application segment, with smartwatches and fitness trackers incorporating curved displays to improve ergonomics and user comfort. The automotive industry has also begun integrating flexible displays into dashboard systems and entertainment consoles, with projections suggesting this segment will grow at 35% annually through 2025.

Consumer research reveals that device durability ranks among the top three purchasing considerations for premium smartphones. This directly correlates with the mechanical performance benefits of flexible OLED encapsulation, as consumers increasingly expect devices to withstand daily wear and accidental impacts. Market surveys indicate 78% of consumers would pay a premium for devices with enhanced durability and flexible form factors.

Regional analysis shows Asia-Pacific dominating the flexible display market with 58% share, followed by North America at 24% and Europe at 15%. China and South Korea lead manufacturing capacity, while North American and European markets drive premium device adoption. Emerging markets are expected to contribute significantly to future growth as manufacturing costs decrease and technology becomes more accessible.

Supply chain analysis reveals increasing investments in flexible display manufacturing infrastructure, with capital expenditures exceeding $10 billion in 2021 alone. This indicates strong industry confidence in long-term market demand. However, material constraints, particularly for specialized encapsulation materials, remain a potential bottleneck that could impact market growth rates if not addressed through continued research and development efforts.

Smartphone manufacturers represent the primary demand drivers for flexible OLED technology, accounting for approximately 67% of the current market share. Major players like Samsung, Apple, and Huawei have increasingly incorporated flexible displays into their flagship products, signaling strong industry confidence in this technology. The foldable smartphone segment alone has seen a 300% year-over-year growth between 2020 and 2021, despite premium pricing models.

Beyond smartphones, diversification into other product categories is expanding market opportunities. Wearable devices constitute the second-largest application segment, with smartwatches and fitness trackers incorporating curved displays to improve ergonomics and user comfort. The automotive industry has also begun integrating flexible displays into dashboard systems and entertainment consoles, with projections suggesting this segment will grow at 35% annually through 2025.

Consumer research reveals that device durability ranks among the top three purchasing considerations for premium smartphones. This directly correlates with the mechanical performance benefits of flexible OLED encapsulation, as consumers increasingly expect devices to withstand daily wear and accidental impacts. Market surveys indicate 78% of consumers would pay a premium for devices with enhanced durability and flexible form factors.

Regional analysis shows Asia-Pacific dominating the flexible display market with 58% share, followed by North America at 24% and Europe at 15%. China and South Korea lead manufacturing capacity, while North American and European markets drive premium device adoption. Emerging markets are expected to contribute significantly to future growth as manufacturing costs decrease and technology becomes more accessible.

Supply chain analysis reveals increasing investments in flexible display manufacturing infrastructure, with capital expenditures exceeding $10 billion in 2021 alone. This indicates strong industry confidence in long-term market demand. However, material constraints, particularly for specialized encapsulation materials, remain a potential bottleneck that could impact market growth rates if not addressed through continued research and development efforts.

Current Mechanical Performance Challenges in OLED Encapsulation

The encapsulation of flexible OLED displays presents significant mechanical performance challenges that must be addressed to ensure device reliability and longevity. Traditional rigid glass encapsulation methods, while effective for barrier properties, are fundamentally incompatible with the flexibility requirements of next-generation displays. This incompatibility creates a critical technical bottleneck in the advancement of flexible display technology.

The primary mechanical challenge lies in maintaining barrier integrity during repeated bending and folding operations. Current thin-film encapsulation (TFE) structures often develop microcracks when subjected to mechanical stress, creating pathways for moisture and oxygen penetration. Testing has shown that after 100,000 bending cycles at a 5mm radius, conventional barrier films can experience up to a 100-fold increase in water vapor transmission rate (WVTR), severely compromising OLED lifetime.

Interfacial adhesion between different encapsulation layers represents another significant challenge. The multi-layer structure of modern TFE systems—typically alternating organic and inorganic materials—is prone to delamination under mechanical stress. This occurs due to the mismatch in elastic moduli between rigid inorganic layers (often 70-200 GPa) and more compliant organic layers (2-5 GPa), creating high interfacial shear stresses during bending.

Stress concentration at the edges of the encapsulation layers is particularly problematic. Research has demonstrated that edge effects can amplify local stress by factors of 3-5 times compared to the nominal stress in central regions, leading to premature failure. This phenomenon is especially pronounced in devices with complex form factors or sharp bending radii below 3mm.

Temperature cycling exacerbates mechanical challenges due to coefficient of thermal expansion (CTE) mismatches between encapsulation materials. During operational temperature fluctuations (typically -20°C to 85°C), differential expansion creates additional internal stresses that compound with mechanical bending stresses, accelerating failure mechanisms.

Current manufacturing processes introduce their own set of challenges. Vacuum deposition of inorganic barrier layers often creates pinhole defects that serve as failure initiation points under mechanical stress. Solution-processed organic layers may have thickness variations that lead to non-uniform mechanical properties across the display area.

The industry faces a fundamental materials science dilemma: materials with excellent barrier properties (such as SiOx and Al2O3) tend to be brittle with fracture strains below 2%, while materials with good mechanical flexibility often have insufficient barrier performance. This inverse relationship between barrier quality and mechanical robustness represents perhaps the most significant challenge in the field.

The primary mechanical challenge lies in maintaining barrier integrity during repeated bending and folding operations. Current thin-film encapsulation (TFE) structures often develop microcracks when subjected to mechanical stress, creating pathways for moisture and oxygen penetration. Testing has shown that after 100,000 bending cycles at a 5mm radius, conventional barrier films can experience up to a 100-fold increase in water vapor transmission rate (WVTR), severely compromising OLED lifetime.

Interfacial adhesion between different encapsulation layers represents another significant challenge. The multi-layer structure of modern TFE systems—typically alternating organic and inorganic materials—is prone to delamination under mechanical stress. This occurs due to the mismatch in elastic moduli between rigid inorganic layers (often 70-200 GPa) and more compliant organic layers (2-5 GPa), creating high interfacial shear stresses during bending.

Stress concentration at the edges of the encapsulation layers is particularly problematic. Research has demonstrated that edge effects can amplify local stress by factors of 3-5 times compared to the nominal stress in central regions, leading to premature failure. This phenomenon is especially pronounced in devices with complex form factors or sharp bending radii below 3mm.

Temperature cycling exacerbates mechanical challenges due to coefficient of thermal expansion (CTE) mismatches between encapsulation materials. During operational temperature fluctuations (typically -20°C to 85°C), differential expansion creates additional internal stresses that compound with mechanical bending stresses, accelerating failure mechanisms.

Current manufacturing processes introduce their own set of challenges. Vacuum deposition of inorganic barrier layers often creates pinhole defects that serve as failure initiation points under mechanical stress. Solution-processed organic layers may have thickness variations that lead to non-uniform mechanical properties across the display area.

The industry faces a fundamental materials science dilemma: materials with excellent barrier properties (such as SiOx and Al2O3) tend to be brittle with fracture strains below 2%, while materials with good mechanical flexibility often have insufficient barrier performance. This inverse relationship between barrier quality and mechanical robustness represents perhaps the most significant challenge in the field.

Current Mechanical Enhancement Approaches for OLED Encapsulation

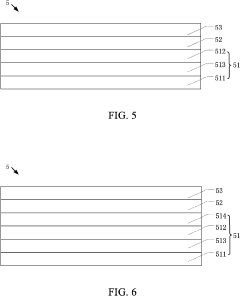

01 Multi-layer encapsulation structures for mechanical flexibility

Multi-layer encapsulation structures can enhance the mechanical performance of flexible OLEDs. These structures typically consist of alternating inorganic and organic layers, where the inorganic layers provide barrier properties against moisture and oxygen, while the organic layers provide flexibility and stress relief. This combination allows the encapsulation to bend without cracking, maintaining barrier performance during flexing operations. The thickness and material properties of each layer can be optimized to achieve the desired balance between barrier performance and mechanical flexibility.- Multi-layer encapsulation structures for improved mechanical flexibility: Multi-layer encapsulation structures can enhance the mechanical flexibility of OLED devices. These structures typically consist of alternating inorganic and organic layers, where the inorganic layers provide barrier properties against moisture and oxygen, while the organic layers improve flexibility and absorb mechanical stress. This combination allows the encapsulation to bend without cracking, which is crucial for flexible OLED applications. The thickness and material composition of each layer can be optimized to achieve the desired balance between barrier performance and mechanical flexibility.

- Stress-relief mechanisms in encapsulation layers: Various stress-relief mechanisms can be incorporated into OLED encapsulation layers to improve mechanical performance during bending. These include the use of stress-buffering layers, stress-relaxation patterns, and specially designed interfaces between different materials. Some approaches involve creating microstructures or patterns within the encapsulation layers that can absorb or distribute mechanical stress. These mechanisms help prevent crack formation and propagation when the device is subjected to repeated bending or folding, thereby extending the operational lifetime of flexible OLED displays.

- Advanced barrier materials for flexible encapsulation: Advanced materials with superior barrier properties and mechanical flexibility are being developed for OLED encapsulation. These include modified inorganic films with enhanced ductility, hybrid organic-inorganic composites, and novel polymeric materials with improved barrier characteristics. Some materials incorporate nanoparticles or specialized additives to enhance both barrier performance and mechanical properties. The selection of materials with appropriate elastic modulus and elongation properties is critical for maintaining encapsulation integrity during bending while still providing effective protection against environmental factors.

- Thin-film encapsulation techniques for flexibility: Thin-film encapsulation (TFE) techniques are particularly suitable for flexible OLED applications due to their inherent thinness and conformability. These techniques include atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based processes that can create ultra-thin barrier layers. The reduced thickness of these encapsulation layers minimizes bending stress and improves flexibility. Various deposition parameters and post-treatment processes can be optimized to enhance the mechanical durability of these thin films while maintaining their barrier properties against moisture and oxygen.

- Testing and evaluation methods for mechanical performance: Specialized testing and evaluation methods have been developed to assess the mechanical performance of flexible OLED encapsulation. These include cyclic bending tests, tensile and compression tests, and environmental stress testing under various conditions. Advanced analytical techniques such as in-situ microscopy, stress-strain measurements, and accelerated lifetime testing help identify failure modes and optimize encapsulation designs. Computational modeling and simulation approaches are also used to predict mechanical behavior and identify potential weak points in the encapsulation structure before physical prototyping.

02 Thin film encapsulation with stress-relieving properties

Thin film encapsulation (TFE) technologies incorporate stress-relieving mechanisms to improve mechanical performance during bending. These can include specially designed buffer layers, stress-absorbing materials, or engineered interfaces that prevent crack propagation. Some approaches use elastomeric materials or polymers with high elongation properties to absorb mechanical stress during flexing. The thin film nature of these encapsulation systems allows for better flexibility compared to traditional rigid encapsulation methods while maintaining effective barrier properties against environmental contaminants.Expand Specific Solutions03 Hybrid encapsulation with inorganic-organic materials

Hybrid encapsulation systems combine the advantages of inorganic barrier materials (excellent moisture and oxygen blocking) with organic materials (flexibility and impact resistance). These systems often feature inorganic layers deposited by atomic layer deposition (ALD) or chemical vapor deposition (CVD) combined with organic layers applied via solution processes. The hybrid approach creates encapsulation structures that can withstand repeated bending cycles while maintaining barrier performance. Some designs incorporate nanocomposite materials that provide both barrier properties and mechanical flexibility in a single layer.Expand Specific Solutions04 Mechanical reinforcement structures for encapsulation

Various mechanical reinforcement structures can be incorporated into OLED encapsulation to improve durability during flexing. These include fiber-reinforced polymer layers, mesh structures, or specially designed geometric patterns that distribute stress more evenly. Some approaches use additional support layers or frames that protect the encapsulation barrier while allowing for controlled bending. These reinforcement structures are designed to prevent catastrophic failure of the encapsulation barrier during mechanical stress events while maintaining the overall flexibility of the device.Expand Specific Solutions05 Edge sealing and interface engineering for flexible encapsulation

Edge sealing techniques and interface engineering are critical for maintaining mechanical performance in flexible OLED encapsulation. These approaches focus on the vulnerable areas where different materials meet, which are often the first to fail during bending. Advanced edge sealing methods use gradient materials, specialized adhesives, or thermal bonding techniques to create strong but flexible seals. Interface engineering between different encapsulation layers can include chemical treatments, adhesion promoters, or nanostructured surfaces that improve layer-to-layer adhesion while allowing for some movement during flexing operations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Flexible Encapsulation

The flexible OLED encapsulation market is currently in a growth phase, with significant technological advancements driving expansion. The global market size is projected to increase substantially as flexible displays become mainstream in consumer electronics. From a technical maturity perspective, industry leaders like Samsung Display, LG Display, and BOE Technology have achieved commercial-scale production capabilities, while companies such as Tianma Microelectronics and TCL CSOT are rapidly advancing their technologies. The mechanical performance benefits of flexible OLED encapsulation include enhanced durability against bending stress, improved impact resistance, reduced weight, and better form factor versatility. These advantages are critical as manufacturers like Visionox and Everdisplay Optronics pursue thinner, lighter, and more resilient display solutions for next-generation foldable and rollable devices.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED encapsulation solution utilizing a multi-layer barrier film technology. Their approach incorporates alternating layers of inorganic barrier films (primarily aluminum oxide and silicon nitride) deposited via atomic layer deposition (ALD) and organic planarization layers applied through vapor deposition processes. This structure creates a tortuous path for moisture and oxygen molecules, significantly extending the diffusion path length. BOE's encapsulation technology achieves water vapor transmission rates below 10^-5 g/m²/day while maintaining mechanical flexibility that allows for bending radii as small as 3mm. Their process includes a proprietary stress-relief mechanism in the organic layers that incorporates elastomeric polymers with high elongation properties (>150%) to absorb mechanical stress during flexing operations. BOE has also developed specialized edge sealing techniques to prevent lateral ingress of contaminants, which is often a critical failure point in flexible displays.

Strengths: Excellent combination of barrier properties and mechanical flexibility; compatible with various manufacturing processes including roll-to-roll production; good uniformity across large display areas. Weaknesses: Slightly higher thickness compared to some competing technologies; requires precise control of layer interfaces to prevent delamination; potential for barrier property degradation after repeated extreme bending cycles.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed an innovative flexible OLED encapsulation technology that utilizes a multi-layer composite structure optimized for both barrier performance and mechanical flexibility. Their approach employs alternating layers of inorganic barriers (primarily silicon nitride and aluminum oxide) deposited through plasma-enhanced chemical vapor deposition (PECVD) and specially formulated organic layers with high elasticity. The inorganic layers provide excellent barrier properties with water vapor transmission rates approaching 10^-6 g/m²/day, while the organic layers serve as stress-relieving buffers during bending operations. TCL's encapsulation technology incorporates a gradient-density structure in the organic layers, with higher crosslinking density near the interfaces with inorganic layers and lower density in the middle, creating an optimal stress distribution during flexing. Their process also includes a specialized edge sealing technique using laser-assisted patterning to prevent lateral moisture ingress while maintaining flexibility at the display edges, which are often subject to the highest mechanical stress during bending.

Strengths: Excellent balance between barrier properties and mechanical flexibility; optimized stress distribution during bending operations; good compatibility with existing manufacturing infrastructure. Weaknesses: Slightly higher thickness compared to some competing technologies; requires precise control of organic layer formulation; potential for interface delamination under extreme temperature cycling conditions.

Key Patents and Innovations in Flexible Barrier Technologies

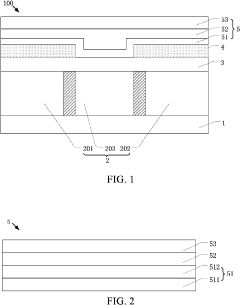

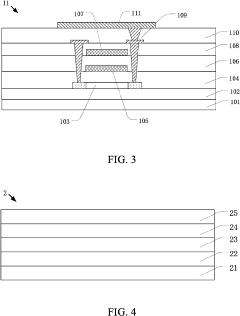

Flexible display panel

PatentActiveUS20230157078A1

Innovation

- A flexible display panel structure comprising an array substrate, organic light-emitting layer, cathode layer, optical coupling output layer, and thin film encapsulation layer, where the optical coupling output layer is positioned only over red and green pixel units, and the thin film encapsulation layer includes a multi-layered inorganic and organic barrier system to enhance light efficiency and reduce power consumption.

Durability Testing Methodologies for Flexible OLED Devices

Testing the durability of flexible OLED devices requires specialized methodologies that differ significantly from those used for rigid displays. These methodologies must account for the unique mechanical stresses experienced by flexible displays during normal operation and potential misuse scenarios. The primary testing approaches can be categorized into static and dynamic mechanical tests, environmental stress tests, and combined stress evaluations.

Static mechanical tests typically involve bend radius testing, where displays are subjected to specific curvature radii to determine the minimum bend radius before failure. This includes both tensile and compressive bending modes, as materials behave differently under each condition. Folding endurance tests complement these by evaluating how many fold cycles a display can withstand at various angles before showing degradation in optical or electrical performance.

Dynamic mechanical testing introduces time-variable stresses to simulate real-world usage. Cyclic bend testing, where displays undergo repeated bending and unbending at controlled speeds and angles, provides critical data on fatigue resistance. Impact and drop testing methodologies have been adapted specifically for flexible displays, with specialized fixtures that account for the different energy absorption characteristics of flexible substrates compared to rigid ones.

Environmental stress testing evaluates durability under varying temperature and humidity conditions. Temperature cycling tests (typically from -40°C to 85°C) assess how thermal expansion and contraction affect the integrity of encapsulation layers and interfaces. High-humidity storage tests (85% relative humidity at 85°C) are particularly important for evaluating barrier properties of encapsulation systems against moisture ingress.

Combined stress testing represents the most comprehensive evaluation approach, where mechanical stresses are applied simultaneously with environmental factors. For example, bend testing conducted at extreme temperatures or high humidity provides insights into how environmental conditions might accelerate mechanical failure mechanisms in flexible displays.

Accelerated aging protocols have been developed to compress years of normal usage into weeks of testing. These protocols typically involve higher stress levels than normal operation but must be carefully calibrated to ensure failure modes remain representative of real-world degradation mechanisms rather than introducing artificial failure pathways.

Standardization efforts by organizations such as ASTM International and IEC are ongoing to establish uniform testing methodologies specific to flexible displays. These emerging standards aim to provide consistent evaluation frameworks that enable meaningful comparisons between different encapsulation technologies and flexible OLED implementations.

Static mechanical tests typically involve bend radius testing, where displays are subjected to specific curvature radii to determine the minimum bend radius before failure. This includes both tensile and compressive bending modes, as materials behave differently under each condition. Folding endurance tests complement these by evaluating how many fold cycles a display can withstand at various angles before showing degradation in optical or electrical performance.

Dynamic mechanical testing introduces time-variable stresses to simulate real-world usage. Cyclic bend testing, where displays undergo repeated bending and unbending at controlled speeds and angles, provides critical data on fatigue resistance. Impact and drop testing methodologies have been adapted specifically for flexible displays, with specialized fixtures that account for the different energy absorption characteristics of flexible substrates compared to rigid ones.

Environmental stress testing evaluates durability under varying temperature and humidity conditions. Temperature cycling tests (typically from -40°C to 85°C) assess how thermal expansion and contraction affect the integrity of encapsulation layers and interfaces. High-humidity storage tests (85% relative humidity at 85°C) are particularly important for evaluating barrier properties of encapsulation systems against moisture ingress.

Combined stress testing represents the most comprehensive evaluation approach, where mechanical stresses are applied simultaneously with environmental factors. For example, bend testing conducted at extreme temperatures or high humidity provides insights into how environmental conditions might accelerate mechanical failure mechanisms in flexible displays.

Accelerated aging protocols have been developed to compress years of normal usage into weeks of testing. These protocols typically involve higher stress levels than normal operation but must be carefully calibrated to ensure failure modes remain representative of real-world degradation mechanisms rather than introducing artificial failure pathways.

Standardization efforts by organizations such as ASTM International and IEC are ongoing to establish uniform testing methodologies specific to flexible displays. These emerging standards aim to provide consistent evaluation frameworks that enable meaningful comparisons between different encapsulation technologies and flexible OLED implementations.

Environmental Impact and Sustainability of Encapsulation Materials

The environmental impact of flexible OLED encapsulation materials represents a critical consideration in the sustainable development of next-generation display technologies. Traditional encapsulation methods often rely on glass barriers and metal cans, which present significant environmental challenges due to their energy-intensive production processes and limited recyclability. In contrast, flexible encapsulation technologies offer potential environmental advantages through reduced material usage and enhanced product longevity.

Thin-film encapsulation (TFE) systems, particularly those utilizing organic-inorganic hybrid structures, demonstrate promising sustainability profiles. These systems typically require less raw material input compared to rigid encapsulation alternatives, potentially reducing the overall carbon footprint of OLED manufacturing. Additionally, the reduced weight of flexible encapsulation contributes to lower transportation-related emissions throughout the product lifecycle.

The durability of advanced flexible encapsulation directly impacts product lifespan, which constitutes a key sustainability metric. By extending the operational lifetime of OLED devices through superior moisture and oxygen barrier properties, these encapsulation technologies effectively reduce electronic waste generation. This aspect becomes increasingly important as consumer electronics turnover rates continue to accelerate globally.

Material selection for flexible encapsulation presents both challenges and opportunities from an environmental perspective. While some high-performance barrier films incorporate fluorinated compounds with significant environmental persistence, research into bio-based alternatives shows promise. Recent developments in cellulose-derived barrier materials and biodegradable polymers could potentially address end-of-life concerns while maintaining adequate barrier performance.

Manufacturing processes for flexible encapsulation technologies vary considerably in their environmental impact. Atomic layer deposition (ALD) methods, while offering excellent barrier properties, typically require high vacuum conditions and energy-intensive operations. Conversely, solution-processed encapsulation approaches may utilize lower-energy deposition techniques but often involve organic solvents that require careful management to prevent environmental contamination.

Regulatory frameworks increasingly influence encapsulation material selection, with restrictions on hazardous substances driving innovation toward more environmentally benign alternatives. The European Union's RoHS and REACH regulations, in particular, have accelerated the development of halogen-free barrier materials and reduced reliance on heavy metal catalysts in encapsulation systems.

Life cycle assessment (LCA) studies comparing rigid and flexible encapsulation technologies generally indicate that flexible systems offer environmental advantages, particularly when considering end-of-life scenarios. The potential for roll-to-roll manufacturing of flexible encapsulation further enhances sustainability through process efficiency and reduced material waste, though these benefits must be balanced against the current challenges in recycling multi-layer barrier films.

Thin-film encapsulation (TFE) systems, particularly those utilizing organic-inorganic hybrid structures, demonstrate promising sustainability profiles. These systems typically require less raw material input compared to rigid encapsulation alternatives, potentially reducing the overall carbon footprint of OLED manufacturing. Additionally, the reduced weight of flexible encapsulation contributes to lower transportation-related emissions throughout the product lifecycle.

The durability of advanced flexible encapsulation directly impacts product lifespan, which constitutes a key sustainability metric. By extending the operational lifetime of OLED devices through superior moisture and oxygen barrier properties, these encapsulation technologies effectively reduce electronic waste generation. This aspect becomes increasingly important as consumer electronics turnover rates continue to accelerate globally.

Material selection for flexible encapsulation presents both challenges and opportunities from an environmental perspective. While some high-performance barrier films incorporate fluorinated compounds with significant environmental persistence, research into bio-based alternatives shows promise. Recent developments in cellulose-derived barrier materials and biodegradable polymers could potentially address end-of-life concerns while maintaining adequate barrier performance.

Manufacturing processes for flexible encapsulation technologies vary considerably in their environmental impact. Atomic layer deposition (ALD) methods, while offering excellent barrier properties, typically require high vacuum conditions and energy-intensive operations. Conversely, solution-processed encapsulation approaches may utilize lower-energy deposition techniques but often involve organic solvents that require careful management to prevent environmental contamination.

Regulatory frameworks increasingly influence encapsulation material selection, with restrictions on hazardous substances driving innovation toward more environmentally benign alternatives. The European Union's RoHS and REACH regulations, in particular, have accelerated the development of halogen-free barrier materials and reduced reliance on heavy metal catalysts in encapsulation systems.

Life cycle assessment (LCA) studies comparing rigid and flexible encapsulation technologies generally indicate that flexible systems offer environmental advantages, particularly when considering end-of-life scenarios. The potential for roll-to-roll manufacturing of flexible encapsulation further enhances sustainability through process efficiency and reduced material waste, though these benefits must be balanced against the current challenges in recycling multi-layer barrier films.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!