Analysis of Plate Heat Exchanger Efficiency in Cryogenic Applications

Cryogenic PHE Background and Objectives

Plate heat exchangers (PHEs) have been widely used in various industrial applications for decades, but their adoption in cryogenic systems has been a relatively recent development. The cryogenic industry, which deals with extremely low temperatures, typically below -150°C, has traditionally relied on shell-and-tube heat exchangers due to their robustness and reliability in handling extreme conditions. However, the increasing demand for more efficient and compact heat transfer solutions has led to a growing interest in cryogenic PHEs.

The evolution of cryogenic PHE technology can be traced back to the late 1990s when researchers and engineers began exploring ways to adapt conventional PHE designs for low-temperature applications. This endeavor was driven by the need for improved energy efficiency, reduced footprint, and enhanced heat transfer performance in cryogenic processes such as natural gas liquefaction, air separation, and hydrogen production.

Over the past two decades, significant advancements have been made in materials science, manufacturing techniques, and design methodologies, enabling the development of PHEs capable of withstanding the harsh conditions of cryogenic environments. These improvements have addressed key challenges such as thermal stress management, prevention of leakage, and maintenance of structural integrity at extremely low temperatures.

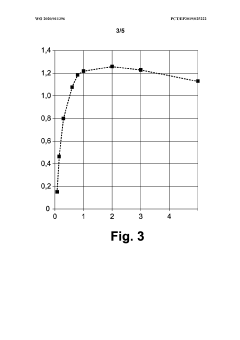

The primary objective of analyzing PHE efficiency in cryogenic applications is to optimize heat transfer performance while ensuring operational reliability and safety. This involves a comprehensive evaluation of various factors, including plate geometry, flow distribution, thermal conductivity of materials, and the overall heat transfer coefficient. By enhancing these aspects, researchers and engineers aim to achieve higher energy efficiency, reduced exergy losses, and improved overall process economics in cryogenic systems.

Another crucial goal is to expand the operating envelope of cryogenic PHEs, enabling their use in an even wider range of low-temperature applications. This includes pushing the boundaries of temperature limits, pressure ratings, and fluid compatibility to meet the evolving needs of industries such as aerospace, superconductivity, and quantum computing, where cryogenic cooling plays a critical role.

Furthermore, the analysis of PHE efficiency in cryogenic applications seeks to address the growing environmental concerns and sustainability requirements in industrial processes. By improving heat recovery and reducing energy consumption, cryogenic PHEs have the potential to significantly lower the carbon footprint of energy-intensive cryogenic operations, aligning with global efforts to combat climate change and promote sustainable industrial practices.

Market Demand Analysis

The market demand for efficient plate heat exchangers in cryogenic applications has been steadily increasing, driven by the growing needs in various industries such as liquefied natural gas (LNG), aerospace, and medical equipment manufacturing. The global cryogenic equipment market, which includes plate heat exchangers, is projected to experience significant growth in the coming years.

The LNG industry, in particular, has been a major driver for the demand of high-efficiency plate heat exchangers in cryogenic applications. As countries worldwide shift towards cleaner energy sources, the demand for LNG has surged, necessitating advanced cryogenic technologies for its production, storage, and transportation. This trend is expected to continue, further boosting the market for cryogenic plate heat exchangers.

In the aerospace sector, the use of cryogenic systems for rocket propulsion and satellite cooling has created a niche market for specialized plate heat exchangers. The increasing number of space missions and satellite launches has contributed to the growing demand for these components, with a focus on lightweight and highly efficient designs.

The medical industry has also emerged as a significant consumer of cryogenic plate heat exchangers, particularly in applications such as MRI machines and cryosurgery equipment. The aging population and increasing prevalence of chronic diseases have led to a rise in diagnostic imaging procedures, driving the demand for more efficient and reliable cryogenic cooling systems.

Furthermore, the industrial gas sector, including air separation plants and hydrogen production facilities, has shown a consistent need for advanced cryogenic heat exchange technologies. The push for hydrogen as a clean energy carrier has created new opportunities for plate heat exchangers in cryogenic applications, especially in large-scale hydrogen liquefaction processes.

The market demand is not only focused on the quantity of plate heat exchangers but also on their quality and efficiency. End-users are increasingly seeking solutions that offer higher thermal efficiency, reduced energy consumption, and improved overall system performance. This has led to a growing emphasis on research and development activities aimed at enhancing the design and materials used in cryogenic plate heat exchangers.

Geographically, the demand for cryogenic plate heat exchangers is particularly strong in regions with significant LNG infrastructure development, such as Asia-Pacific and the Middle East. North America and Europe also represent substantial markets, driven by their advanced healthcare systems and aerospace industries.

Technical Challenges

The analysis of plate heat exchanger efficiency in cryogenic applications presents several significant technical challenges. One of the primary obstacles is the extreme temperature differentials encountered in cryogenic processes, which can lead to thermal stress and material fatigue. The rapid cooling and heating cycles can cause thermal shock, potentially compromising the structural integrity of the heat exchanger components.

Material selection becomes critical in cryogenic environments, as many conventional materials become brittle or lose their mechanical properties at extremely low temperatures. Identifying and implementing materials that maintain their performance characteristics across a wide temperature range, from ambient to cryogenic, is a complex engineering task. This challenge extends to sealing materials and gaskets, which must remain flexible and effective at cryogenic temperatures to prevent leakage.

Heat transfer efficiency is another major concern in cryogenic plate heat exchangers. The formation of frost or ice on the cold surfaces can significantly reduce heat transfer rates and overall system efficiency. Developing effective defrosting mechanisms or designing plate geometries that minimize frost accumulation while maintaining high heat transfer coefficients is a delicate balance that engineers must strike.

Flow distribution and pressure drop management present additional challenges in cryogenic applications. The high viscosity of cryogenic fluids at low temperatures can lead to uneven flow distribution across the plates, reducing overall heat transfer effectiveness. Optimizing plate designs to ensure uniform flow while minimizing pressure drop is crucial for maintaining system efficiency.

Thermal insulation is paramount in cryogenic systems to minimize heat ingress and maintain the desired low temperatures. However, effective insulation often conflicts with the need for compact design in plate heat exchangers. Balancing these competing requirements while ensuring ease of maintenance and accessibility is a significant engineering challenge.

Lastly, the control and monitoring of cryogenic plate heat exchangers pose unique difficulties. Accurate temperature and flow measurement at extremely low temperatures require specialized sensors and instrumentation. Developing robust control systems that can respond quickly to changes in operating conditions while maintaining stable performance is essential for optimal efficiency and safety in cryogenic applications.

Current PHE Solutions

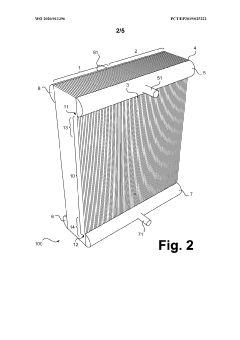

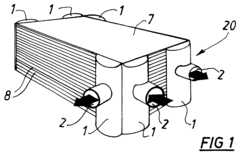

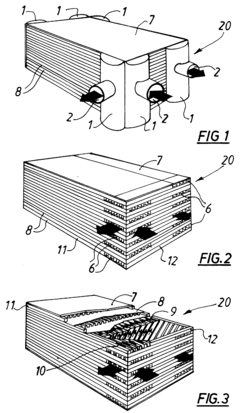

01 Improved plate design for enhanced heat transfer

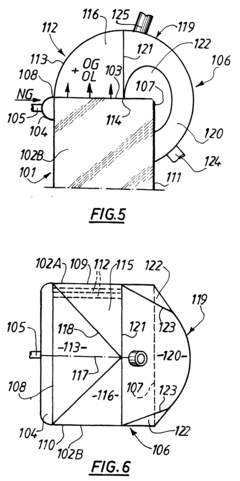

Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids.- Improved plate design for enhanced heat transfer: Innovative plate designs, such as corrugated or chevron patterns, can significantly improve heat transfer efficiency in plate heat exchangers. These designs increase turbulence and surface area, leading to better heat exchange between fluids.

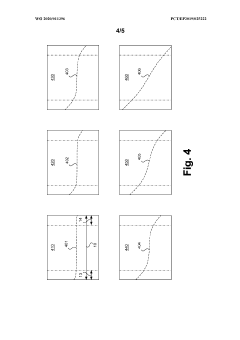

- Optimized flow distribution: Efficient flow distribution systems within plate heat exchangers can enhance overall performance. This includes designing inlet and outlet ports, as well as internal channels, to ensure uniform fluid distribution across the plates, minimizing dead zones and maximizing heat transfer.

- Advanced materials for plate construction: Utilizing high-performance materials in plate construction can improve heat transfer efficiency. Materials with superior thermal conductivity and corrosion resistance can enhance heat exchange rates and extend the lifespan of the exchanger.

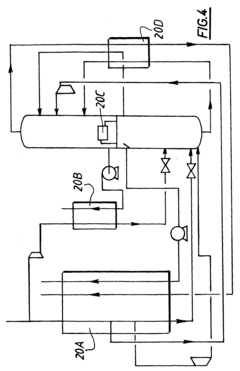

- Intelligent control systems for optimal operation: Implementing smart control systems can optimize plate heat exchanger efficiency by dynamically adjusting flow rates, temperatures, and pressures based on real-time operating conditions and demand. This can lead to improved energy efficiency and performance.

- Modular design for scalability and maintenance: Modular plate heat exchanger designs allow for easy scaling and maintenance, which can contribute to long-term efficiency. These designs enable quick replacement of individual plates or sections, reducing downtime and maintaining optimal performance over time.

02 Optimized flow distribution

Efficient flow distribution systems within plate heat exchangers can enhance overall performance. This includes designing inlet and outlet ports, as well as internal channels, to ensure uniform fluid distribution across the plates, minimizing dead zones and maximizing heat transfer.Expand Specific Solutions03 Advanced materials for plate construction

Utilizing high-performance materials in plate construction can improve heat transfer efficiency. Materials with superior thermal conductivity and corrosion resistance can enhance heat exchange while extending the lifespan of the exchanger.Expand Specific Solutions04 Intelligent control systems for optimal operation

Implementing smart control systems can optimize the performance of plate heat exchangers. These systems can adjust flow rates, temperatures, and other parameters in real-time to maintain peak efficiency under varying operating conditions.Expand Specific Solutions05 Modular design for scalability and maintenance

Modular plate heat exchanger designs allow for easy scaling and maintenance. This approach enables efficient customization for specific applications, simplifies cleaning and replacement of individual components, and can lead to improved overall system efficiency.Expand Specific Solutions

Key Industry Players

The plate heat exchanger efficiency in cryogenic applications market is in a growth phase, driven by increasing demand in industries such as LNG, aerospace, and healthcare. The global market size is projected to expand significantly due to rising energy efficiency requirements and technological advancements. Key players like Air Liquide, Linde, and Danfoss are at the forefront of innovation, developing high-performance cryogenic heat exchangers. These companies, along with emerging players such as Fives Cryo and LG Innotek, are investing in R&D to improve efficiency and reduce costs. The technology is maturing rapidly, with a focus on enhancing heat transfer rates, minimizing pressure drops, and optimizing materials for extreme low-temperature applications.

Air Liquide SA

Danfoss A/S

Core PHE Innovations

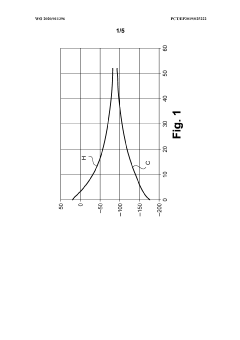

- A method for operating a fin-plate heat exchanger involves alternating between two operating modes to maintain a stable temperature profile, with reduced fluid flow initially to prevent temperature transition and then increasing flow when the temperature change has stabilized, ensuring minimal thermal stress during restarts.

- A plate heat exchanger featuring copper or copper alloy plates with increased separation between corrugations, typically greater than 6 mm, and copper waves, optimized with specific dimensions and configurations to enhance thermal conductivity and reduce the number of plates, while maintaining a leak-tight structure.

Material Advancements

Material advancements play a crucial role in enhancing the efficiency of plate heat exchangers in cryogenic applications. The extreme low-temperature environment poses significant challenges to traditional materials, necessitating the development of innovative solutions to improve heat transfer performance and overall system reliability.

One of the primary focuses in material advancements for cryogenic plate heat exchangers is the development of high-performance alloys. These alloys are designed to maintain their mechanical properties and structural integrity at extremely low temperatures. Nickel-based superalloys, such as Inconel 718 and Hastelloy X, have shown promising results due to their excellent low-temperature strength and resistance to thermal fatigue.

Composite materials have also gained attention in recent years for their potential to enhance heat transfer efficiency in cryogenic applications. Carbon fiber reinforced polymers (CFRP) and metal matrix composites (MMC) offer a combination of high thermal conductivity and low thermal expansion, making them ideal candidates for plate heat exchanger components. These materials can help reduce thermal stress and improve overall system performance.

Surface modification techniques have emerged as another avenue for improving heat transfer efficiency in cryogenic plate heat exchangers. Advanced coatings, such as diamond-like carbon (DLC) and nanostructured surfaces, can significantly enhance heat transfer coefficients by promoting turbulence and reducing fouling. These coatings also provide additional protection against corrosion and wear, extending the lifespan of heat exchanger components.

The development of novel manufacturing processes has enabled the creation of more complex and efficient heat exchanger geometries. Additive manufacturing techniques, such as selective laser melting (SLM) and electron beam melting (EBM), allow for the production of intricate channel designs and optimized flow paths that were previously impossible to achieve with traditional manufacturing methods. These advancements have led to improved heat transfer performance and reduced pressure drop in cryogenic plate heat exchangers.

Nanomaterials have shown great promise in enhancing the thermal properties of heat transfer fluids used in cryogenic applications. The incorporation of nanoparticles, such as carbon nanotubes or graphene, into cryogenic fluids can significantly improve their thermal conductivity and heat transfer characteristics. This approach, known as nanofluids, has the potential to revolutionize the efficiency of plate heat exchangers in low-temperature environments.

As research in material science continues to progress, the development of smart materials for cryogenic heat exchangers is gaining traction. These materials can adapt their properties in response to changes in temperature or pressure, allowing for dynamic optimization of heat transfer performance. Shape memory alloys and piezoelectric materials are being explored for their potential to create self-regulating heat exchanger systems that can maintain optimal efficiency across a wide range of operating conditions.

Safety and Regulations

Safety and regulations play a crucial role in the implementation and operation of plate heat exchangers in cryogenic applications. The extreme low temperatures and potential hazards associated with cryogenic fluids necessitate stringent safety measures and compliance with industry standards.

Cryogenic applications involve working with substances at temperatures below -150°C (-238°F), which can pose significant risks to personnel and equipment. The primary safety concerns include the potential for rapid freezing of tissues upon contact, asphyxiation due to displacement of oxygen, and the risk of explosion or fire when cryogenic fluids come into contact with incompatible materials.

To mitigate these risks, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established comprehensive guidelines for handling cryogenic materials. These regulations cover aspects such as proper insulation, ventilation, personal protective equipment (PPE), and emergency response procedures.

Plate heat exchangers used in cryogenic applications must be designed and manufactured in accordance with specific codes and standards. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, particularly Section VIII, provides guidelines for the construction of pressure vessels, including those used in cryogenic service. Additionally, the European standard EN 13445 offers similar guidance for unfired pressure vessels.

Material selection is a critical aspect of safety in cryogenic plate heat exchangers. Materials must maintain their mechanical properties at extremely low temperatures and resist brittle fracture. Commonly used materials include austenitic stainless steels, aluminum alloys, and nickel alloys. The selection process must consider factors such as thermal expansion, thermal conductivity, and resistance to hydrogen embrittlement.

Operational safety measures for plate heat exchangers in cryogenic applications include regular inspection and maintenance protocols. Non-destructive testing techniques, such as ultrasonic testing and radiography, are employed to detect potential defects or material degradation. Pressure relief devices and rupture disks are essential components to prevent overpressurization and ensure safe operation.

Training and certification of personnel working with cryogenic systems are mandatory requirements in most jurisdictions. Operators must be well-versed in the properties of cryogenic fluids, emergency procedures, and the proper use of safety equipment. Regular safety drills and simulations are conducted to maintain preparedness for potential incidents.

Environmental regulations also impact the design and operation of cryogenic plate heat exchangers. Strict emission control standards and energy efficiency requirements must be met, particularly in industrial applications where large-scale cryogenic processes are involved. This has led to the development of more efficient heat exchanger designs and improved insulation techniques to minimize heat loss and reduce environmental impact.