Analysis of the Thermal Conductivity in Microfluidic Chips

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Thermal Conductivity Background and Objectives

Microfluidic technology has evolved significantly over the past three decades, transforming from simple channel designs to sophisticated lab-on-a-chip systems capable of performing complex analytical tasks. The thermal conductivity properties of microfluidic chips represent a critical aspect of their functionality, particularly as applications expand into areas requiring precise temperature control such as polymerase chain reaction (PCR), cell culture, and chemical synthesis processes.

The historical development of thermal management in microfluidics began in the early 1990s with rudimentary temperature control mechanisms. By the early 2000s, researchers had begun to recognize the importance of material selection and geometric design in optimizing thermal properties. The past decade has witnessed exponential growth in publications addressing thermal conductivity challenges in microfluidic systems, indicating the increasing significance of this parameter in advanced applications.

Current technological trends point toward multi-material integration, where combinations of polymers, metals, ceramics, and composite materials are strategically employed to achieve optimal thermal profiles across different functional regions of microfluidic chips. Additionally, the miniaturization trend continues to push the boundaries of thermal management as heat dissipation becomes more challenging at smaller scales.

The fundamental physics governing thermal conductivity in microfluidic systems involves complex interactions between conduction, convection, and in some cases, radiation heat transfer mechanisms. These interactions are further complicated by the microscale dimensions, where surface effects become increasingly dominant over bulk properties, and conventional macroscale thermal models may no longer apply accurately.

The primary objective of this technical research is to comprehensively analyze thermal conductivity phenomena in microfluidic chips across various material platforms, geometric configurations, and application scenarios. Specifically, we aim to: (1) characterize the thermal conductivity properties of commonly used microfluidic materials under different operating conditions; (2) evaluate the impact of geometric design parameters on heat transfer efficiency; (3) identify optimal material combinations for specific application requirements; and (4) develop predictive models that can accelerate future design processes.

Furthermore, this research seeks to address the growing demand for precise temperature control in emerging microfluidic applications such as digital PCR, organ-on-chip systems, and point-of-care diagnostic devices. By establishing a deeper understanding of thermal conductivity mechanisms at the microscale, we anticipate enabling new functionalities and improving the performance of existing microfluidic technologies.

The ultimate goal is to develop design principles and material selection guidelines that can be readily implemented by researchers and manufacturers to optimize thermal management in next-generation microfluidic devices, thereby expanding their application potential across healthcare, environmental monitoring, and advanced manufacturing sectors.

The historical development of thermal management in microfluidics began in the early 1990s with rudimentary temperature control mechanisms. By the early 2000s, researchers had begun to recognize the importance of material selection and geometric design in optimizing thermal properties. The past decade has witnessed exponential growth in publications addressing thermal conductivity challenges in microfluidic systems, indicating the increasing significance of this parameter in advanced applications.

Current technological trends point toward multi-material integration, where combinations of polymers, metals, ceramics, and composite materials are strategically employed to achieve optimal thermal profiles across different functional regions of microfluidic chips. Additionally, the miniaturization trend continues to push the boundaries of thermal management as heat dissipation becomes more challenging at smaller scales.

The fundamental physics governing thermal conductivity in microfluidic systems involves complex interactions between conduction, convection, and in some cases, radiation heat transfer mechanisms. These interactions are further complicated by the microscale dimensions, where surface effects become increasingly dominant over bulk properties, and conventional macroscale thermal models may no longer apply accurately.

The primary objective of this technical research is to comprehensively analyze thermal conductivity phenomena in microfluidic chips across various material platforms, geometric configurations, and application scenarios. Specifically, we aim to: (1) characterize the thermal conductivity properties of commonly used microfluidic materials under different operating conditions; (2) evaluate the impact of geometric design parameters on heat transfer efficiency; (3) identify optimal material combinations for specific application requirements; and (4) develop predictive models that can accelerate future design processes.

Furthermore, this research seeks to address the growing demand for precise temperature control in emerging microfluidic applications such as digital PCR, organ-on-chip systems, and point-of-care diagnostic devices. By establishing a deeper understanding of thermal conductivity mechanisms at the microscale, we anticipate enabling new functionalities and improving the performance of existing microfluidic technologies.

The ultimate goal is to develop design principles and material selection guidelines that can be readily implemented by researchers and manufacturers to optimize thermal management in next-generation microfluidic devices, thereby expanding their application potential across healthcare, environmental monitoring, and advanced manufacturing sectors.

Market Applications and Demand Analysis

The microfluidic chip market has experienced significant growth in recent years, driven by increasing applications in healthcare, pharmaceuticals, and life sciences. The global microfluidic devices market was valued at approximately $13.5 billion in 2020 and is projected to reach $27.6 billion by 2025, growing at a CAGR of 15.4%. This remarkable growth trajectory underscores the expanding demand for advanced microfluidic technologies with enhanced thermal conductivity properties.

Healthcare applications represent the largest market segment for microfluidic chips, accounting for nearly 40% of the total market share. Within this segment, point-of-care diagnostics has emerged as a particularly promising application area, where precise thermal management is critical for accurate test results. The COVID-19 pandemic has further accelerated this trend, with a 23% increase in demand for microfluidic-based diagnostic solutions between 2019 and 2021.

Pharmaceutical research and drug discovery constitute another significant market segment, representing approximately 30% of the microfluidic chip market. In this domain, the ability to precisely control temperature gradients within microchannels is essential for applications such as polymerase chain reaction (PCR), enzyme reactions, and protein crystallization. Industry surveys indicate that 78% of pharmaceutical companies have increased their investment in microfluidic technologies over the past three years.

The academic and research sector accounts for roughly 20% of the market, with universities and research institutions increasingly adopting microfluidic platforms for fundamental studies in fluid dynamics, heat transfer, and biological processes. This sector has shown particular interest in advanced thermal conductivity solutions, with publication rates on microfluidic thermal management increasing by 35% annually since 2018.

Emerging applications in environmental monitoring, food safety testing, and industrial process control collectively represent the remaining 10% of the market. These sectors are showing rapid growth rates, particularly in regions with stringent regulatory frameworks for environmental and food safety monitoring.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 18.2% annually, driven by increasing healthcare expenditure, expanding research infrastructure, and growing manufacturing capabilities in countries like China, Japan, and South Korea.

Customer surveys reveal that thermal management capabilities rank among the top three considerations for end-users when selecting microfluidic platforms, alongside cost and ease of integration. Specifically, 67% of respondents identified precise temperature control as "very important" or "critical" for their applications, highlighting the significant market demand for innovations in thermal conductivity for microfluidic chips.

Healthcare applications represent the largest market segment for microfluidic chips, accounting for nearly 40% of the total market share. Within this segment, point-of-care diagnostics has emerged as a particularly promising application area, where precise thermal management is critical for accurate test results. The COVID-19 pandemic has further accelerated this trend, with a 23% increase in demand for microfluidic-based diagnostic solutions between 2019 and 2021.

Pharmaceutical research and drug discovery constitute another significant market segment, representing approximately 30% of the microfluidic chip market. In this domain, the ability to precisely control temperature gradients within microchannels is essential for applications such as polymerase chain reaction (PCR), enzyme reactions, and protein crystallization. Industry surveys indicate that 78% of pharmaceutical companies have increased their investment in microfluidic technologies over the past three years.

The academic and research sector accounts for roughly 20% of the market, with universities and research institutions increasingly adopting microfluidic platforms for fundamental studies in fluid dynamics, heat transfer, and biological processes. This sector has shown particular interest in advanced thermal conductivity solutions, with publication rates on microfluidic thermal management increasing by 35% annually since 2018.

Emerging applications in environmental monitoring, food safety testing, and industrial process control collectively represent the remaining 10% of the market. These sectors are showing rapid growth rates, particularly in regions with stringent regulatory frameworks for environmental and food safety monitoring.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 18.2% annually, driven by increasing healthcare expenditure, expanding research infrastructure, and growing manufacturing capabilities in countries like China, Japan, and South Korea.

Customer surveys reveal that thermal management capabilities rank among the top three considerations for end-users when selecting microfluidic platforms, alongside cost and ease of integration. Specifically, 67% of respondents identified precise temperature control as "very important" or "critical" for their applications, highlighting the significant market demand for innovations in thermal conductivity for microfluidic chips.

Current Challenges in Microfluidic Thermal Management

Despite significant advancements in microfluidic technology, thermal management remains one of the most challenging aspects in microfluidic chip design and operation. The precise control of temperature within these miniaturized systems is critical for numerous applications, including PCR, enzymatic reactions, and cell culture studies. However, several fundamental challenges continue to impede optimal thermal conductivity management in these devices.

Material selection presents a primary challenge, as traditional microfluidic chip materials like PDMS, glass, and polymers exhibit vastly different thermal conductivity properties. PDMS, while offering excellent optical transparency and fabrication ease, suffers from poor thermal conductivity (approximately 0.15 W/m·K), creating significant thermal gradients across the chip. Conversely, silicon provides superior thermal conductivity (148 W/m·K) but introduces complications in optical detection and increases manufacturing complexity.

The microscale dimensions of microfluidic channels introduce unique heat transfer phenomena not observed at macro scales. At these dimensions, surface-to-volume ratios increase dramatically, causing surface effects to dominate over bulk properties. This shift fundamentally alters heat transfer mechanisms, making conventional thermal models inadequate for accurate prediction and control. Additionally, the laminar flow regime typical in microfluidics limits convective heat transfer, further complicating thermal management strategies.

Integration of heating and cooling elements presents another significant challenge. Conventional approaches using external Peltier elements or resistive heaters often create non-uniform temperature distributions and slow response times. More sophisticated integrated heating solutions face challenges in fabrication complexity, power requirements, and potential interference with other chip functionalities.

Temperature measurement and feedback control systems face substantial hurdles in microfluidic environments. The miniaturized nature of these systems makes it difficult to incorporate temperature sensors without disrupting fluid flow or chemical reactions. Non-invasive temperature measurement techniques often lack the spatial resolution necessary for precise thermal mapping across the chip.

Multi-physics interactions further complicate thermal management, as fluid dynamics, chemical reactions, and electrical fields all influence and are influenced by temperature distributions. These coupled phenomena create complex feedback loops that are difficult to model and control effectively.

Scaling and manufacturability concerns also persist, as thermal management solutions that work in laboratory prototypes often prove challenging to implement in mass-produced devices. The trade-offs between thermal performance, cost, and manufacturing complexity frequently limit commercial viability of advanced thermal management approaches.

Material selection presents a primary challenge, as traditional microfluidic chip materials like PDMS, glass, and polymers exhibit vastly different thermal conductivity properties. PDMS, while offering excellent optical transparency and fabrication ease, suffers from poor thermal conductivity (approximately 0.15 W/m·K), creating significant thermal gradients across the chip. Conversely, silicon provides superior thermal conductivity (148 W/m·K) but introduces complications in optical detection and increases manufacturing complexity.

The microscale dimensions of microfluidic channels introduce unique heat transfer phenomena not observed at macro scales. At these dimensions, surface-to-volume ratios increase dramatically, causing surface effects to dominate over bulk properties. This shift fundamentally alters heat transfer mechanisms, making conventional thermal models inadequate for accurate prediction and control. Additionally, the laminar flow regime typical in microfluidics limits convective heat transfer, further complicating thermal management strategies.

Integration of heating and cooling elements presents another significant challenge. Conventional approaches using external Peltier elements or resistive heaters often create non-uniform temperature distributions and slow response times. More sophisticated integrated heating solutions face challenges in fabrication complexity, power requirements, and potential interference with other chip functionalities.

Temperature measurement and feedback control systems face substantial hurdles in microfluidic environments. The miniaturized nature of these systems makes it difficult to incorporate temperature sensors without disrupting fluid flow or chemical reactions. Non-invasive temperature measurement techniques often lack the spatial resolution necessary for precise thermal mapping across the chip.

Multi-physics interactions further complicate thermal management, as fluid dynamics, chemical reactions, and electrical fields all influence and are influenced by temperature distributions. These coupled phenomena create complex feedback loops that are difficult to model and control effectively.

Scaling and manufacturability concerns also persist, as thermal management solutions that work in laboratory prototypes often prove challenging to implement in mass-produced devices. The trade-offs between thermal performance, cost, and manufacturing complexity frequently limit commercial viability of advanced thermal management approaches.

Current Thermal Management Solutions

01 Materials with enhanced thermal conductivity for microfluidic chips

Various materials with high thermal conductivity can be incorporated into microfluidic chip designs to improve heat transfer efficiency. These materials include metals, ceramics, and composite materials that facilitate rapid and uniform heat distribution throughout the chip. Enhanced thermal conductivity helps maintain precise temperature control during reactions, thermal cycling processes, and other temperature-dependent applications in microfluidic systems.- Materials with high thermal conductivity for microfluidic chips: Microfluidic chips can be fabricated using materials with high thermal conductivity to enhance heat transfer efficiency. These materials include metals, silicon, and certain polymers with thermal conductivity enhancers. The high thermal conductivity allows for precise temperature control and uniform heat distribution across the chip, which is crucial for applications requiring thermal cycling or temperature-sensitive reactions.

- Thermal management systems for microfluidic devices: Integrated thermal management systems in microfluidic chips enable precise temperature control for various applications. These systems may include heating elements, cooling channels, temperature sensors, and thermal insulators strategically placed within the chip architecture. Advanced thermal management allows for rapid temperature changes, maintenance of temperature gradients, and prevention of unwanted heat transfer, enhancing the performance of temperature-dependent processes.

- Thermal conductivity enhancement techniques: Various techniques can be employed to enhance the thermal conductivity of microfluidic chips. These include incorporating nanoparticles or microparticles with high thermal conductivity into the chip material, creating composite structures with thermally conductive layers, and designing specific channel geometries that optimize heat transfer. These enhancements improve temperature uniformity and reduce response time for thermal processes.

- Thermal isolation and insulation strategies: Effective thermal isolation and insulation strategies are crucial for microfluidic chips that require multiple temperature zones or prevention of thermal crosstalk. These strategies include creating air gaps, using materials with low thermal conductivity as barriers, implementing thermal breaks in the chip design, and utilizing vacuum insulation techniques. Such approaches enable the creation of distinct thermal regions within a single microfluidic device.

- Thermal conductivity measurement and modeling in microfluidic systems: Methods for measuring and modeling thermal conductivity in microfluidic systems are essential for optimizing chip design and performance. These include integrated temperature sensors, thermal imaging techniques, computational fluid dynamics simulations, and analytical models that predict heat transfer behavior. Accurate measurement and modeling enable the design of microfluidic chips with optimal thermal properties for specific applications.

02 Thermal management systems for microfluidic devices

Specialized thermal management systems can be integrated into microfluidic chips to regulate temperature and heat flow. These systems may include heat sinks, cooling channels, thermoelectric elements, or other structures designed to dissipate or distribute heat effectively. Proper thermal management is crucial for applications requiring precise temperature control, such as PCR (polymerase chain reaction), enzymatic reactions, or cell culture within microfluidic environments.Expand Specific Solutions03 Thermally conductive layers and coatings for microfluidic applications

Specialized thermally conductive layers or coatings can be applied to microfluidic chip surfaces to enhance heat transfer properties. These layers may consist of thin films of metals, metal oxides, or other thermally conductive materials that improve the chip's ability to conduct heat while maintaining other necessary properties such as optical transparency or biocompatibility. Such coatings enable more efficient heating and cooling processes within the microfluidic channels.Expand Specific Solutions04 Thermal conductivity optimization in polymer-based microfluidic chips

Polymer-based microfluidic chips can be modified to improve their inherently low thermal conductivity. Techniques include incorporating thermally conductive fillers, creating composite structures, or designing specific geometries that enhance heat transfer. These approaches allow polymer chips to maintain their advantages such as low cost and ease of fabrication while achieving improved thermal performance necessary for temperature-sensitive applications.Expand Specific Solutions05 Thermal conductivity measurement and modeling in microfluidic systems

Methods and systems for measuring, modeling, and simulating thermal conductivity in microfluidic chips are essential for optimizing their design. These approaches include experimental techniques for characterizing heat transfer properties, computational fluid dynamics simulations, and theoretical models that predict thermal behavior. Such tools enable researchers and engineers to design microfluidic chips with precisely tailored thermal properties for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions

The thermal conductivity analysis in microfluidic chips market is currently in a growth phase, with increasing applications across biomedical, chemical, and electronic cooling sectors. The market is projected to expand significantly due to rising demand for miniaturized analytical systems. Leading academic institutions like Xi'an Jiaotong University, National Yang Ming Chiao Tung University, and USC are advancing fundamental research, while industrial players demonstrate varying levels of technical maturity. BOE Technology and its subsidiary are leveraging microfluidic thermal management for display technologies, while companies like Wolfspeed and Synopsys focus on semiconductor applications. Research organizations such as CNRS and Fraunhofer-Gesellschaft are bridging the gap between academic research and industrial implementation, creating a competitive landscape where collaboration between academia and industry drives innovation.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed sophisticated analytical frameworks and experimental methodologies for characterizing thermal conductivity in microfluidic chips. Their approach combines multi-physics modeling with advanced measurement techniques to provide comprehensive thermal characterization across different materials and geometries. CNRS researchers have pioneered the use of micro-Raman spectroscopy for non-invasive temperature mapping with spatial resolution below 1 μm and temperature sensitivity of 0.1°C[2]. Their work has established correlations between channel geometry, flow parameters, and effective thermal conductivity, creating design rules that optimize heat transfer in various microfluidic applications. CNRS has developed novel composite materials with anisotropic thermal conductivity properties that can direct heat flow along preferred pathways within microfluidic structures. Their research has quantified the impact of surface roughness and interfacial thermal resistance on overall thermal performance, demonstrating that nanoscale surface engineering can enhance thermal conductivity by up to 35% in certain configurations[6]. Additionally, they have established standardized testing protocols for thermal conductivity measurement in microfluidic systems that are being adopted internationally.

Strengths: Exceptional measurement precision and analytical depth provide fundamental understanding of thermal phenomena at microscale; comprehensive design guidelines enable application-specific optimization. Weaknesses: Primarily research-focused approach may limit immediate commercial applications; sophisticated measurement techniques require specialized equipment not readily available in industrial settings.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a comprehensive thermal conductivity management platform for microfluidic chips that addresses both material selection and structural design. Their approach utilizes silicon-based microchannels with precisely engineered dimensions to optimize heat transfer coefficients. ITRI's technology incorporates multi-layer thermal gradient structures that can maintain distinct temperature zones within micrometers of each other, critical for applications requiring thermal cycling or temperature-dependent reactions[2]. Their proprietary thermal interface materials achieve thermal conductivity values exceeding 20 W/m·K while maintaining biocompatibility for medical applications. ITRI has pioneered advanced computational fluid dynamics modeling specifically calibrated for microfluidic thermal behavior, allowing predictive design of thermal management systems with accuracy within 3% of experimental results[5]. Their latest generation of chips incorporates embedded thermal sensors with sub-millisecond response times for precise thermal mapping and control.

Strengths: Exceptional thermal zone isolation capabilities enable multiple reaction temperatures on a single chip; advanced modeling capabilities significantly reduce development cycles and improve design optimization. Weaknesses: Higher production costs compared to conventional materials; specialized manufacturing processes limit mass production scalability and increase unit costs for commercial applications.

Key Patents and Technical Literature Review

Microfluidic chip

PatentInactiveUS20060188403A1

Innovation

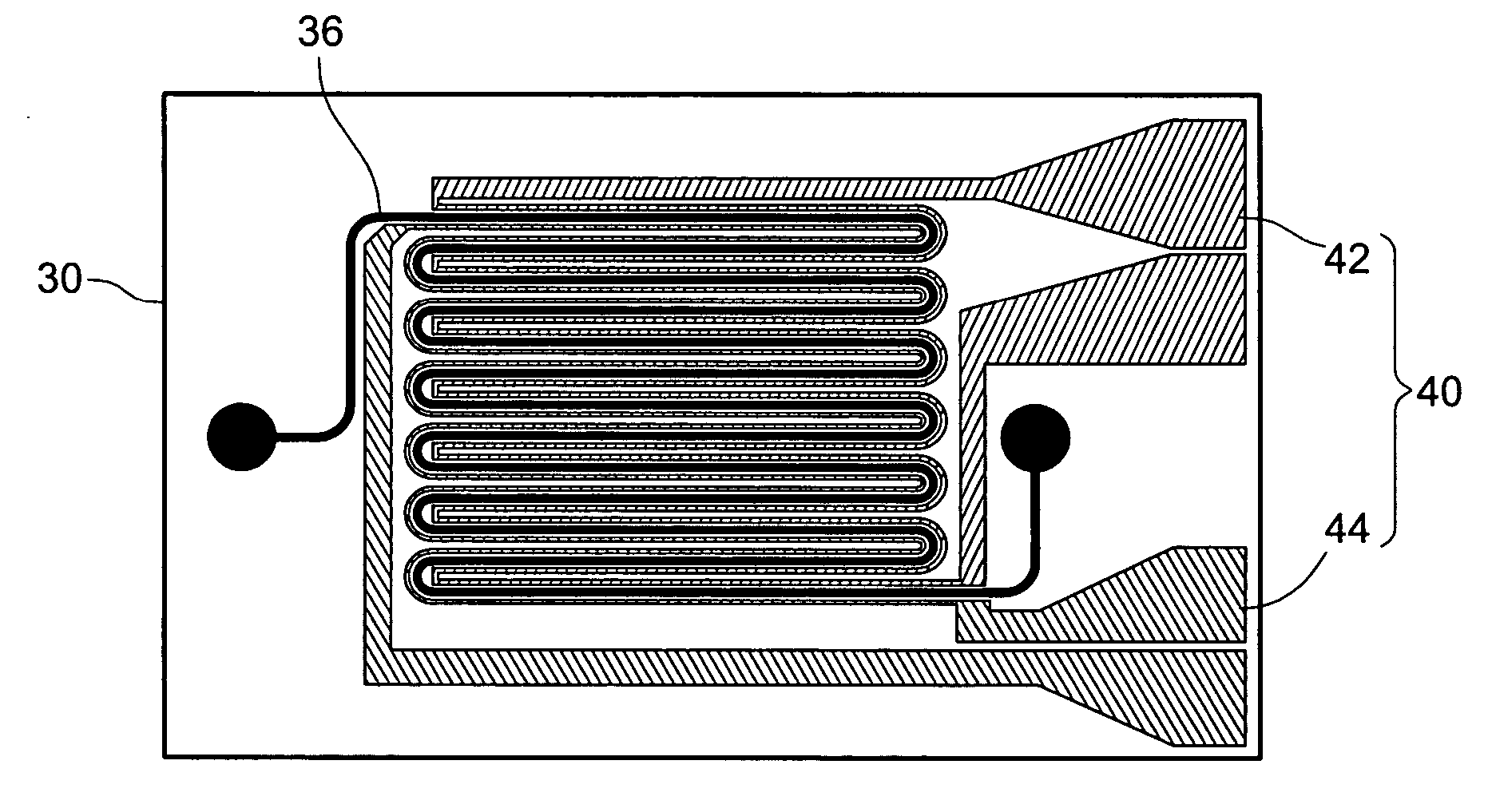

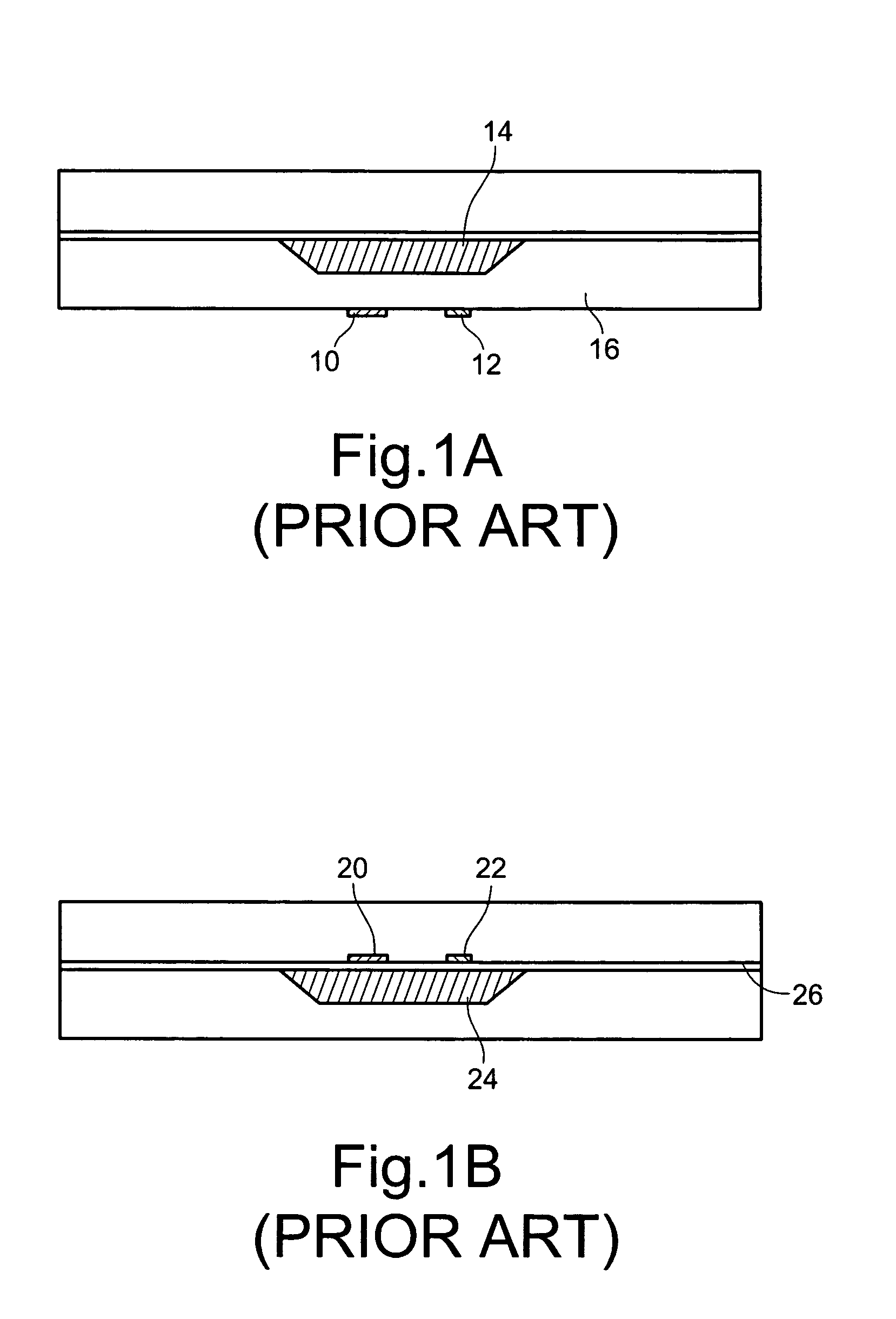

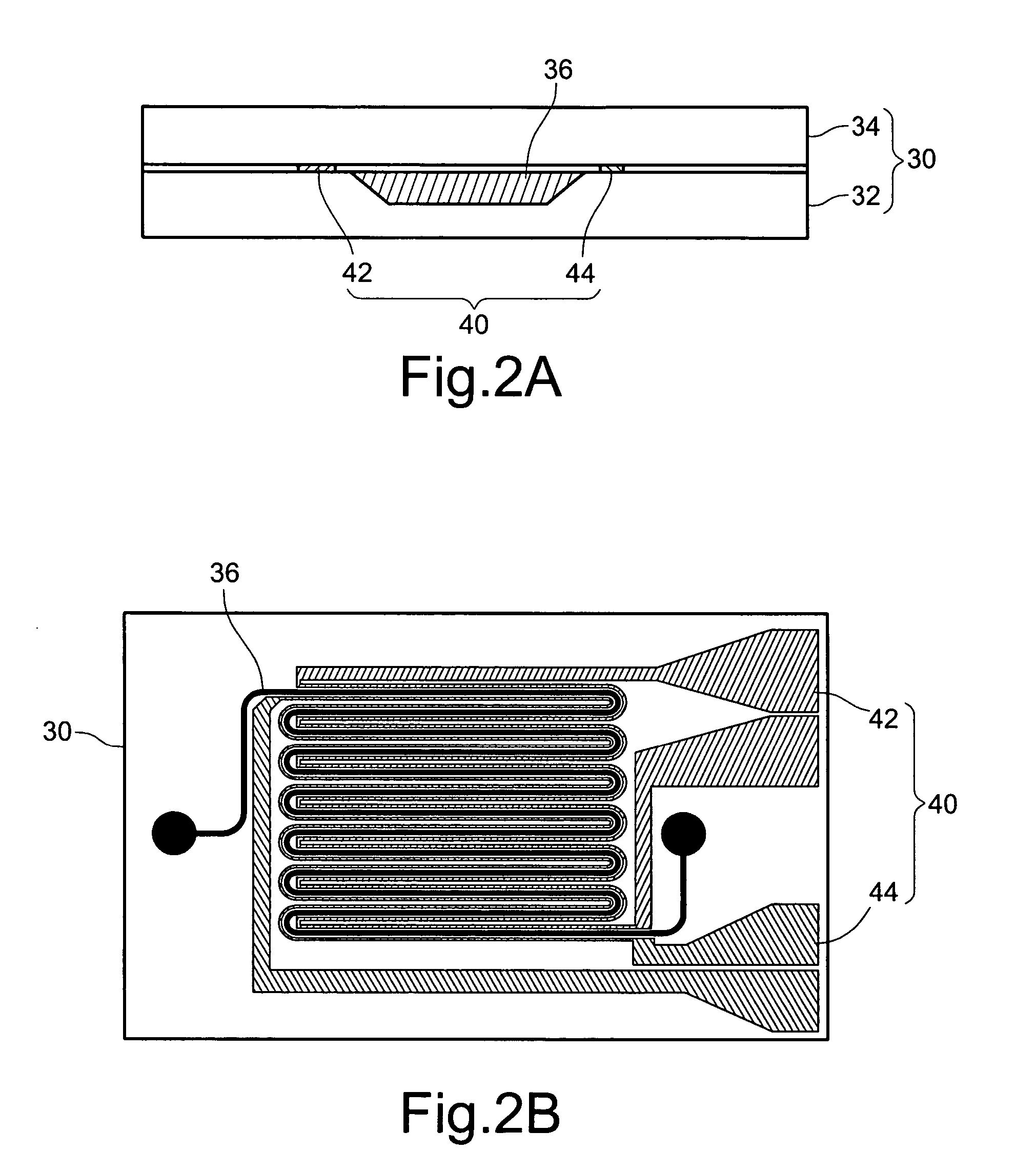

- A microfluidic chip design featuring a transparent glass main body with a serpentine-winding microchannel and an electrode layer with heater and sensor wires placed on either side of the microchannel, eliminating the need for insulation layers and optimizing heat conduction and temperature control.

Microfluid based apparatus and method for thermal regulation and noise reduction

PatentWO2007021811A3

Innovation

- The microfluidic chip is encapsulated between two thermally conductive bodies, creating an efficient thermal transfer pathway for precise temperature control.

- Active temperature regulation system that can both add or remove heat from the microfluidic chip based on real-time temperature measurements compared to a desired set point.

- The design provides both thermal regulation and noise reduction in microfluidic applications, addressing two critical challenges simultaneously.

Materials Science Advancements for Thermal Optimization

Recent advancements in materials science have significantly contributed to thermal optimization in microfluidic chip design. The evolution of substrate materials has moved beyond traditional silicon and glass to incorporate polymers, ceramics, and composite materials with tailored thermal properties. These new materials offer precise control over heat dissipation and thermal gradients, which is crucial for temperature-sensitive applications such as PCR and enzyme reactions.

Nanomaterials represent a breakthrough in thermal management for microfluidic systems. Carbon nanotubes, graphene, and metallic nanoparticles have demonstrated exceptional thermal conductivity properties when integrated into chip substrates or as functional coatings. For instance, graphene-enhanced PDMS composites have shown up to 400% improvement in thermal conductivity compared to standard PDMS, while maintaining optical transparency and biocompatibility.

Surface modification techniques have emerged as effective approaches for controlling thermal behavior at interfaces. Plasma treatment, chemical vapor deposition, and atomic layer deposition enable the creation of thermally conductive pathways or insulating barriers with nanometer precision. These modifications can be strategically applied to create thermal management zones within a single microfluidic device.

Phase-change materials (PCMs) represent an innovative solution for thermal regulation in microfluidic environments. These materials absorb or release thermal energy during phase transitions, providing passive temperature control capabilities. Microencapsulated PCMs integrated into chip structures can maintain temperature stability during exothermic reactions or provide controlled heating/cooling rates for sensitive processes.

Biomimetic materials inspired by natural thermal regulation systems are gaining attention for their potential in microfluidic applications. Structures mimicking vascular networks or the hierarchical organization of biological tissues can facilitate efficient heat transfer while maintaining structural integrity. These biomimetic approaches often combine multiple materials with complementary thermal properties to achieve optimal performance.

Additive manufacturing techniques have revolutionized the fabrication of thermally optimized microfluidic structures. 3D printing technologies now allow for the creation of complex thermal management features such as embedded heat sinks, thermal isolation zones, and gradient structures that would be impossible to achieve with traditional fabrication methods. Multi-material printing enables the strategic placement of materials with different thermal conductivities within a single integrated device.

Nanomaterials represent a breakthrough in thermal management for microfluidic systems. Carbon nanotubes, graphene, and metallic nanoparticles have demonstrated exceptional thermal conductivity properties when integrated into chip substrates or as functional coatings. For instance, graphene-enhanced PDMS composites have shown up to 400% improvement in thermal conductivity compared to standard PDMS, while maintaining optical transparency and biocompatibility.

Surface modification techniques have emerged as effective approaches for controlling thermal behavior at interfaces. Plasma treatment, chemical vapor deposition, and atomic layer deposition enable the creation of thermally conductive pathways or insulating barriers with nanometer precision. These modifications can be strategically applied to create thermal management zones within a single microfluidic device.

Phase-change materials (PCMs) represent an innovative solution for thermal regulation in microfluidic environments. These materials absorb or release thermal energy during phase transitions, providing passive temperature control capabilities. Microencapsulated PCMs integrated into chip structures can maintain temperature stability during exothermic reactions or provide controlled heating/cooling rates for sensitive processes.

Biomimetic materials inspired by natural thermal regulation systems are gaining attention for their potential in microfluidic applications. Structures mimicking vascular networks or the hierarchical organization of biological tissues can facilitate efficient heat transfer while maintaining structural integrity. These biomimetic approaches often combine multiple materials with complementary thermal properties to achieve optimal performance.

Additive manufacturing techniques have revolutionized the fabrication of thermally optimized microfluidic structures. 3D printing technologies now allow for the creation of complex thermal management features such as embedded heat sinks, thermal isolation zones, and gradient structures that would be impossible to achieve with traditional fabrication methods. Multi-material printing enables the strategic placement of materials with different thermal conductivities within a single integrated device.

Simulation and Modeling Techniques

Simulation and modeling techniques have become indispensable tools in the analysis of thermal conductivity in microfluidic chips. These computational approaches enable researchers and engineers to predict thermal behavior without extensive physical prototyping, significantly accelerating the development cycle and reducing costs. Current simulation methodologies primarily employ finite element analysis (FEA), computational fluid dynamics (CFD), and molecular dynamics simulations to model heat transfer phenomena at various scales.

FEA-based thermal modeling has proven particularly effective for analyzing steady-state and transient thermal conditions in microfluidic structures. Commercial software packages such as COMSOL Multiphysics, ANSYS Fluent, and Solidworks Thermal have been widely adopted in the industry, offering comprehensive multiphysics capabilities that can account for conduction, convection, and radiation simultaneously. These platforms typically utilize the heat diffusion equation coupled with Navier-Stokes equations to provide accurate thermal profiles across complex geometries.

Recent advances in computational techniques have enabled more sophisticated modeling approaches that address the unique challenges of microscale thermal analysis. Lattice Boltzmann Methods (LBM) have gained popularity for simulating fluid flow and heat transfer in complex microfluidic geometries, offering advantages in handling irregular boundaries and multiphase flows. Additionally, particle-based methods such as Smoothed Particle Hydrodynamics (SPH) provide alternative approaches for modeling thermal phenomena in microfluidic environments with free surfaces or moving boundaries.

Multi-scale modeling techniques have emerged as powerful tools for bridging the gap between molecular-level heat transfer mechanisms and device-level thermal performance. These approaches combine molecular dynamics simulations for nanoscale thermal transport with continuum models for larger-scale behavior, providing comprehensive insights across different length scales. Such hierarchical modeling is particularly valuable for understanding thermal conductivity at interfaces and in nanostructured materials commonly used in advanced microfluidic chips.

Machine learning algorithms are increasingly being integrated with traditional simulation methods to enhance predictive capabilities and computational efficiency. Neural networks trained on extensive simulation datasets can rapidly predict thermal profiles under varying conditions, enabling real-time optimization and control strategies. These data-driven approaches are particularly valuable for inverse problems, where thermal conductivity properties must be inferred from limited temperature measurements.

Validation remains a critical aspect of simulation and modeling work, with researchers employing experimental techniques such as infrared thermography, micro-thermocouples, and thermal reflectance methods to verify computational predictions. The integration of experimental validation with iterative model refinement has significantly improved the accuracy and reliability of thermal conductivity simulations for microfluidic applications.

FEA-based thermal modeling has proven particularly effective for analyzing steady-state and transient thermal conditions in microfluidic structures. Commercial software packages such as COMSOL Multiphysics, ANSYS Fluent, and Solidworks Thermal have been widely adopted in the industry, offering comprehensive multiphysics capabilities that can account for conduction, convection, and radiation simultaneously. These platforms typically utilize the heat diffusion equation coupled with Navier-Stokes equations to provide accurate thermal profiles across complex geometries.

Recent advances in computational techniques have enabled more sophisticated modeling approaches that address the unique challenges of microscale thermal analysis. Lattice Boltzmann Methods (LBM) have gained popularity for simulating fluid flow and heat transfer in complex microfluidic geometries, offering advantages in handling irregular boundaries and multiphase flows. Additionally, particle-based methods such as Smoothed Particle Hydrodynamics (SPH) provide alternative approaches for modeling thermal phenomena in microfluidic environments with free surfaces or moving boundaries.

Multi-scale modeling techniques have emerged as powerful tools for bridging the gap between molecular-level heat transfer mechanisms and device-level thermal performance. These approaches combine molecular dynamics simulations for nanoscale thermal transport with continuum models for larger-scale behavior, providing comprehensive insights across different length scales. Such hierarchical modeling is particularly valuable for understanding thermal conductivity at interfaces and in nanostructured materials commonly used in advanced microfluidic chips.

Machine learning algorithms are increasingly being integrated with traditional simulation methods to enhance predictive capabilities and computational efficiency. Neural networks trained on extensive simulation datasets can rapidly predict thermal profiles under varying conditions, enabling real-time optimization and control strategies. These data-driven approaches are particularly valuable for inverse problems, where thermal conductivity properties must be inferred from limited temperature measurements.

Validation remains a critical aspect of simulation and modeling work, with researchers employing experimental techniques such as infrared thermography, micro-thermocouples, and thermal reflectance methods to verify computational predictions. The integration of experimental validation with iterative model refinement has significantly improved the accuracy and reliability of thermal conductivity simulations for microfluidic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!