Exploring the Semiconductor Applications of Microfluidic Chips

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Semiconductor Microfluidics Background and Objectives

Microfluidic technology has evolved significantly since its inception in the 1950s, initially emerging from inkjet printing applications. The field gained substantial momentum in the 1990s with the development of lab-on-a-chip systems, which demonstrated the potential for miniaturizing complex laboratory processes. Over the past two decades, microfluidic technology has expanded beyond biomedical applications into various industries, with semiconductor manufacturing representing one of the most promising frontier applications.

The convergence of microfluidics and semiconductor technology addresses critical challenges in modern chip fabrication processes. As semiconductor devices continue to shrink according to Moore's Law, traditional manufacturing methods face increasing limitations in precision fluid handling, thermal management, and process control. Microfluidic systems offer unprecedented control over small volumes of liquids at the microscale, enabling more precise etching, cleaning, and chemical delivery processes essential for advanced semiconductor manufacturing.

Current semiconductor fabrication requires ultra-pure chemicals and precise fluid control to achieve the nanometer-scale features in modern integrated circuits. Microfluidic platforms can potentially revolutionize these processes by enabling precise manipulation of reagents, reducing chemical consumption, enhancing process uniformity, and facilitating novel approaches to lithography and etching. The integration of microfluidic systems into semiconductor manufacturing workflows represents a paradigm shift in how critical fluid-based processes are conducted.

The primary technical objectives of this research include developing microfluidic platforms specifically optimized for semiconductor applications, with particular focus on chemical delivery systems that can achieve sub-nanometer precision. We aim to explore novel materials compatible with both microfluidic operations and semiconductor clean room environments, while designing systems that can be seamlessly integrated into existing semiconductor manufacturing equipment with minimal disruption to established workflows.

Additionally, this research seeks to establish new methodologies for quality control and process monitoring using microfluidic sensors that can provide real-time feedback during semiconductor fabrication steps. The development of specialized microfluidic chips capable of withstanding harsh chemical environments common in semiconductor processing represents another critical objective, requiring innovations in materials science and manufacturing techniques.

The long-term vision encompasses creating a new generation of semiconductor manufacturing tools that leverage microfluidic principles to enable the production of increasingly complex and miniaturized electronic components. This includes exploring how microfluidic technology might facilitate the transition to new semiconductor materials beyond silicon, such as compound semiconductors and emerging 2D materials, which present unique processing challenges that conventional methods struggle to address.

The convergence of microfluidics and semiconductor technology addresses critical challenges in modern chip fabrication processes. As semiconductor devices continue to shrink according to Moore's Law, traditional manufacturing methods face increasing limitations in precision fluid handling, thermal management, and process control. Microfluidic systems offer unprecedented control over small volumes of liquids at the microscale, enabling more precise etching, cleaning, and chemical delivery processes essential for advanced semiconductor manufacturing.

Current semiconductor fabrication requires ultra-pure chemicals and precise fluid control to achieve the nanometer-scale features in modern integrated circuits. Microfluidic platforms can potentially revolutionize these processes by enabling precise manipulation of reagents, reducing chemical consumption, enhancing process uniformity, and facilitating novel approaches to lithography and etching. The integration of microfluidic systems into semiconductor manufacturing workflows represents a paradigm shift in how critical fluid-based processes are conducted.

The primary technical objectives of this research include developing microfluidic platforms specifically optimized for semiconductor applications, with particular focus on chemical delivery systems that can achieve sub-nanometer precision. We aim to explore novel materials compatible with both microfluidic operations and semiconductor clean room environments, while designing systems that can be seamlessly integrated into existing semiconductor manufacturing equipment with minimal disruption to established workflows.

Additionally, this research seeks to establish new methodologies for quality control and process monitoring using microfluidic sensors that can provide real-time feedback during semiconductor fabrication steps. The development of specialized microfluidic chips capable of withstanding harsh chemical environments common in semiconductor processing represents another critical objective, requiring innovations in materials science and manufacturing techniques.

The long-term vision encompasses creating a new generation of semiconductor manufacturing tools that leverage microfluidic principles to enable the production of increasingly complex and miniaturized electronic components. This includes exploring how microfluidic technology might facilitate the transition to new semiconductor materials beyond silicon, such as compound semiconductors and emerging 2D materials, which present unique processing challenges that conventional methods struggle to address.

Market Analysis for Microfluidic Semiconductor Applications

The microfluidic chip market for semiconductor applications is experiencing robust growth, driven by increasing demand for miniaturized analytical systems and advanced manufacturing processes. Current market valuations place the global microfluidic chip sector at approximately 16 billion USD in 2023, with semiconductor applications representing about 22% of this market. Industry analysts project a compound annual growth rate (CAGR) of 18.7% for microfluidic semiconductor applications through 2030, significantly outpacing the broader semiconductor industry's growth rate of 7-9%.

Key market drivers include the semiconductor industry's push toward smaller node sizes, which requires increasingly precise fluid handling capabilities for processes such as photolithography, etching, and cleaning. The demand for high-precision chemical delivery systems in semiconductor manufacturing has created a specialized microfluidic segment valued at 1.8 billion USD, growing at 21% annually.

Regional analysis reveals Asia-Pacific dominates the market with 47% share, led by Taiwan, South Korea, and increasingly China. North America follows at 31%, with Europe accounting for 18% of the market. The remaining 4% is distributed across other regions. This distribution closely mirrors the geographic concentration of advanced semiconductor fabrication facilities.

By application segment, photolithography-related microfluidic systems represent the largest market share at 38%, followed by precise chemical delivery systems (27%), cooling solutions (19%), and testing/quality control applications (16%). The fastest-growing segment is precision cooling solutions, expanding at 24% annually due to increasing thermal management challenges in advanced semiconductor nodes.

End-user segmentation shows integrated device manufacturers (IDMs) account for 43% of market demand, foundries represent 37%, and equipment manufacturers constitute 20%. The foundry segment is experiencing the most rapid growth as contract manufacturing continues to expand in the semiconductor industry.

Market challenges include high initial investment costs, with specialized microfluidic systems for semiconductor applications typically costing 3-5 times more than general-purpose alternatives. Technical barriers to entry remain significant, as manufacturing microfluidic chips for semiconductor applications requires cleanroom facilities rated at ISO Class 3 or better, representing substantial capital expenditure.

Emerging opportunities include the development of microfluidic solutions for advanced packaging technologies, particularly for heterogeneous integration and chiplet-based designs. Additionally, the growing adoption of silicon photonics is creating demand for specialized microfluidic systems capable of handling optical materials and processes, potentially opening a new market segment valued at 600 million USD by 2028.

Key market drivers include the semiconductor industry's push toward smaller node sizes, which requires increasingly precise fluid handling capabilities for processes such as photolithography, etching, and cleaning. The demand for high-precision chemical delivery systems in semiconductor manufacturing has created a specialized microfluidic segment valued at 1.8 billion USD, growing at 21% annually.

Regional analysis reveals Asia-Pacific dominates the market with 47% share, led by Taiwan, South Korea, and increasingly China. North America follows at 31%, with Europe accounting for 18% of the market. The remaining 4% is distributed across other regions. This distribution closely mirrors the geographic concentration of advanced semiconductor fabrication facilities.

By application segment, photolithography-related microfluidic systems represent the largest market share at 38%, followed by precise chemical delivery systems (27%), cooling solutions (19%), and testing/quality control applications (16%). The fastest-growing segment is precision cooling solutions, expanding at 24% annually due to increasing thermal management challenges in advanced semiconductor nodes.

End-user segmentation shows integrated device manufacturers (IDMs) account for 43% of market demand, foundries represent 37%, and equipment manufacturers constitute 20%. The foundry segment is experiencing the most rapid growth as contract manufacturing continues to expand in the semiconductor industry.

Market challenges include high initial investment costs, with specialized microfluidic systems for semiconductor applications typically costing 3-5 times more than general-purpose alternatives. Technical barriers to entry remain significant, as manufacturing microfluidic chips for semiconductor applications requires cleanroom facilities rated at ISO Class 3 or better, representing substantial capital expenditure.

Emerging opportunities include the development of microfluidic solutions for advanced packaging technologies, particularly for heterogeneous integration and chiplet-based designs. Additionally, the growing adoption of silicon photonics is creating demand for specialized microfluidic systems capable of handling optical materials and processes, potentially opening a new market segment valued at 600 million USD by 2028.

Current Challenges in Semiconductor Microfluidic Integration

Despite the promising potential of microfluidic chips in semiconductor applications, several significant challenges impede their widespread integration. The miniaturization requirements of modern semiconductor processes demand microfluidic channels at sub-micron scales, which introduces fabrication difficulties using conventional methods. Current photolithography and etching techniques struggle to consistently produce high-aspect-ratio microchannels with the precision required for semiconductor manufacturing environments.

Material compatibility presents another substantial hurdle. Semiconductor processes often involve harsh chemicals and extreme temperatures that can degrade traditional microfluidic materials like PDMS (polydimethylsiloxane). While glass and silicon offer better chemical resistance, they lack the flexibility and optical properties advantageous in many microfluidic applications, creating a difficult trade-off between functionality and durability.

Integration with existing semiconductor manufacturing workflows remains problematic. The semiconductor industry relies on standardized processes and equipment, whereas microfluidic fabrication often requires specialized techniques that don't align with established semiconductor manufacturing lines. This misalignment creates significant barriers to adoption and increases implementation costs.

Thermal management issues also plague microfluidic-semiconductor integration. Semiconductor processes generate substantial heat, which can cause thermal expansion in microfluidic components, potentially leading to deformation, leakage, or complete device failure. Developing materials and designs that maintain structural integrity under these thermal stresses remains challenging.

Scaling production from laboratory prototypes to high-volume manufacturing introduces additional complexities. Current microfluidic chip fabrication methods are often labor-intensive and difficult to automate at the scale required by the semiconductor industry. The lack of standardized design rules and manufacturing protocols further complicates mass production efforts.

Interfacing between electronic components and fluidic elements presents persistent challenges. Creating reliable, leak-proof connections between these fundamentally different systems requires novel approaches to packaging and interconnection. Current solutions often suffer from reliability issues, particularly under the mechanical and thermal stresses common in semiconductor applications.

Contamination control represents a critical concern, as semiconductor manufacturing demands extraordinarily clean environments. Microfluidic systems must prevent particle generation and cross-contamination while maintaining the ultra-pure conditions necessary for semiconductor processing. Achieving this level of cleanliness in dynamic fluid systems requires significant engineering innovations beyond current capabilities.

Material compatibility presents another substantial hurdle. Semiconductor processes often involve harsh chemicals and extreme temperatures that can degrade traditional microfluidic materials like PDMS (polydimethylsiloxane). While glass and silicon offer better chemical resistance, they lack the flexibility and optical properties advantageous in many microfluidic applications, creating a difficult trade-off between functionality and durability.

Integration with existing semiconductor manufacturing workflows remains problematic. The semiconductor industry relies on standardized processes and equipment, whereas microfluidic fabrication often requires specialized techniques that don't align with established semiconductor manufacturing lines. This misalignment creates significant barriers to adoption and increases implementation costs.

Thermal management issues also plague microfluidic-semiconductor integration. Semiconductor processes generate substantial heat, which can cause thermal expansion in microfluidic components, potentially leading to deformation, leakage, or complete device failure. Developing materials and designs that maintain structural integrity under these thermal stresses remains challenging.

Scaling production from laboratory prototypes to high-volume manufacturing introduces additional complexities. Current microfluidic chip fabrication methods are often labor-intensive and difficult to automate at the scale required by the semiconductor industry. The lack of standardized design rules and manufacturing protocols further complicates mass production efforts.

Interfacing between electronic components and fluidic elements presents persistent challenges. Creating reliable, leak-proof connections between these fundamentally different systems requires novel approaches to packaging and interconnection. Current solutions often suffer from reliability issues, particularly under the mechanical and thermal stresses common in semiconductor applications.

Contamination control represents a critical concern, as semiconductor manufacturing demands extraordinarily clean environments. Microfluidic systems must prevent particle generation and cross-contamination while maintaining the ultra-pure conditions necessary for semiconductor processing. Achieving this level of cleanliness in dynamic fluid systems requires significant engineering innovations beyond current capabilities.

Current Microfluidic Solutions for Semiconductor Processing

01 Fabrication techniques for microfluidic chips

Various fabrication methods are employed to create microfluidic chips with precise channel geometries and surface properties. These techniques include soft lithography, injection molding, hot embossing, and 3D printing. The choice of fabrication method depends on the desired features, material properties, and production scale. Advanced manufacturing approaches enable the creation of complex microstructures with high resolution and reproducibility, which are essential for applications requiring precise fluid control.- Fabrication techniques for microfluidic chips: Various fabrication methods are employed to create microfluidic chips with precise channel geometries and surface properties. These techniques include soft lithography, injection molding, hot embossing, and 3D printing. The choice of fabrication method depends on the desired features, material properties, and production scale. Advanced manufacturing approaches enable the creation of complex microstructures with high resolution and reproducibility, which are essential for applications requiring precise fluid control.

- Integration of sensing and detection systems: Microfluidic chips can be integrated with various sensing and detection systems to enable real-time monitoring and analysis of samples. These systems include optical sensors, electrochemical detectors, and spectroscopic instruments that can be miniaturized and incorporated directly into the chip architecture. The integration of these detection systems allows for enhanced sensitivity, specificity, and throughput in applications such as diagnostics, environmental monitoring, and chemical analysis.

- Microfluidic chip designs for biological applications: Specialized microfluidic chip designs have been developed for various biological applications, including cell culture, DNA analysis, protein separation, and organ-on-a-chip systems. These designs incorporate features such as cell trapping structures, gradient generators, and perfusion systems to mimic physiological conditions. The ability to precisely control the microenvironment makes these chips valuable tools for drug screening, personalized medicine, and fundamental biological research.

- Flow control and manipulation in microfluidic systems: Advanced techniques for controlling and manipulating fluid flow within microfluidic chips include the use of valves, pumps, mixers, and droplet generators. These components enable precise control over sample volumes, flow rates, and mixing ratios. Passive and active flow control mechanisms can be implemented depending on the application requirements. The ability to precisely manipulate fluids at the microscale is crucial for applications requiring accurate dosing, sequential operations, or parallel processing.

- Materials and surface modifications for microfluidic chips: The selection of materials and surface modifications plays a critical role in the performance of microfluidic chips. Common materials include glass, silicon, polymers (PDMS, PMMA), and paper, each offering different properties in terms of optical transparency, chemical resistance, and biocompatibility. Surface modifications can alter wettability, prevent non-specific adsorption, or introduce functional groups for biomolecule immobilization. These considerations are essential for optimizing chip performance in specific applications and ensuring compatibility with the samples being analyzed.

02 Integration of sensing and detection systems

Microfluidic chips can be integrated with various sensing and detection systems to enable real-time monitoring and analysis of samples. These systems include optical sensors, electrochemical detectors, and spectroscopic instruments that can detect biological markers, chemical compounds, or physical parameters. The integration of these detection systems with microfluidic platforms enhances the analytical capabilities and enables applications in diagnostics, environmental monitoring, and drug discovery.Expand Specific Solutions03 Microfluidic chip designs for biological applications

Specialized microfluidic chip designs have been developed for various biological applications, including cell culture, DNA analysis, protein separation, and organ-on-a-chip systems. These designs incorporate features such as cell trapping structures, gradient generators, and perfusion systems to mimic physiological conditions. The ability to precisely control the microenvironment makes these chips valuable tools for studying cellular behavior, drug responses, and disease mechanisms at the microscale level.Expand Specific Solutions04 Flow control and manipulation in microfluidic systems

Effective flow control and manipulation are critical aspects of microfluidic chip operation. Various mechanisms have been developed to control fluid flow, including valves, pumps, mixers, and droplet generators. These components enable precise manipulation of small fluid volumes, allowing for operations such as sample preparation, reagent mixing, and separation. Advanced flow control systems can be integrated into microfluidic chips to automate complex protocols and improve reproducibility.Expand Specific Solutions05 Materials and surface modifications for microfluidic chips

The choice of materials and surface modifications significantly impacts the performance of microfluidic chips. Common materials include glass, polymers (PDMS, PMMA), and silicon, each offering different properties in terms of optical transparency, chemical resistance, and fabrication ease. Surface modifications can alter wettability, prevent non-specific adsorption, or introduce functional groups for biomolecule immobilization. These material considerations are crucial for optimizing chip performance for specific applications and ensuring compatibility with biological samples.Expand Specific Solutions

Leading Companies in Semiconductor Microfluidics

The semiconductor applications of microfluidic chips market is in a growth phase, with increasing adoption across various industries. The global market size is expanding rapidly, driven by demand for miniaturized, efficient semiconductor processing solutions. Technologically, the field is advancing from early-stage development toward commercial maturity, with key players demonstrating varying levels of expertise. IBM and Samsung lead with established research capabilities and extensive patent portfolios, while Sony and BOE Technology are leveraging their display technology expertise for innovative applications. Specialized companies like Rheonix and Pattern Bioscience are developing niche microfluidic solutions for semiconductor manufacturing. Academic institutions including Duke University and Technical University of Denmark are contributing fundamental research, while Infineon and Lansion Biotechnology are commercializing integrated microfluidic-semiconductor systems for next-generation devices.

International Business Machines Corp.

Technical Solution: IBM has pioneered semiconductor applications of microfluidic chips through their "lab-on-a-chip" technology. Their approach integrates microfluidic channels directly with semiconductor processing to create hybrid systems capable of both electronic and fluidic functions. IBM's technology utilizes silicon-based fabrication techniques to create microchannels with precise dimensions (typically 10-100 micrometers) that can be integrated with transistors and sensors on the same substrate. This integration enables real-time analysis and control of fluid samples while leveraging semiconductor manufacturing precision. IBM has developed specialized cooling systems for high-performance computing using microfluidic channels embedded directly within semiconductor packages, allowing coolant to flow in close proximity to heat-generating components, significantly improving thermal management in advanced processors[1][3]. Their patented technology also includes microfluidic structures for precise reagent delivery in semiconductor manufacturing processes, reducing chemical consumption and improving uniformity in etching and cleaning operations.

Strengths: IBM's approach leverages existing semiconductor fabrication infrastructure, allowing for high-volume production and precise integration of electronic and fluidic components. Their cooling solutions address critical thermal management challenges in advanced computing systems. Weaknesses: The complexity of integrating fluidic and electronic systems increases manufacturing costs and may introduce reliability concerns due to potential fluid leakage near sensitive electronic components.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: IMEC has developed cutting-edge semiconductor applications of microfluidic technology through their silicon-based lab-on-chip platforms. Their approach integrates microfluidic structures directly with CMOS technology, creating highly functional systems for biological and chemical analysis. IMEC's platform features microchannels with dimensions as small as 5 micrometers, fabricated using advanced semiconductor processing techniques including deep reactive ion etching (DRIE). The organization has pioneered silicon nanopore technology integrated with microfluidic channels for single-molecule detection and DNA sequencing applications, achieving detection sensitivities orders of magnitude better than conventional methods[5]. IMEC has also developed specialized microfluidic chips for semiconductor process monitoring, where microchannels sample and analyze chemicals used in semiconductor manufacturing in real-time. Their technology includes integrated sensor arrays within microfluidic channels that can detect multiple analytes simultaneously, enabling comprehensive process control. Additionally, IMEC has created microfluidic cooling solutions specifically designed for 3D-stacked integrated circuits, where cooling channels are integrated between silicon layers to address thermal challenges in vertically integrated semiconductor devices[6].

Strengths: IMEC's solutions leverage advanced semiconductor fabrication techniques to achieve extremely precise microfluidic structures with high reproducibility. Their integrated approach combines sensing, processing, and fluidic functions on a single chip. Weaknesses: The highly specialized nature of their technology requires sophisticated manufacturing capabilities, limiting widespread adoption and increasing production costs compared to simpler microfluidic approaches.

Key Patents and Innovations in Semiconductor Microfluidics

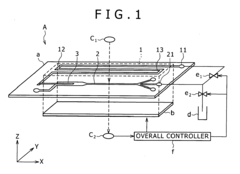

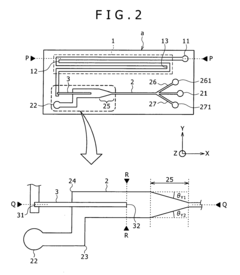

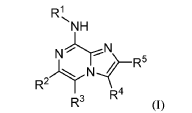

Microparticle analysis device, microfluidic chip for microparticle analysis, and microparticle analysis method

PatentInactiveEP2191895A1

Innovation

- A microparticle analysis device with a micro-fluidic chip that uses a magnetic field to separate magnetic and non-magnetic microparticles, where the magnetic microparticles are held in the region and the non-magnetic microparticles are sent to a microfluidic channel for analysis, allowing for efficient sorting and detection using optical, electrical, or magnetic characteristics.

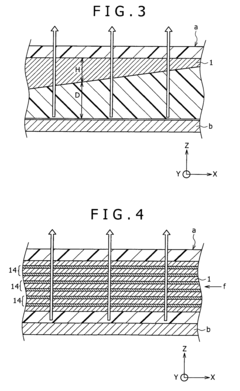

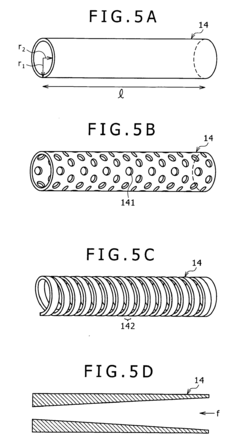

Microfluidic chips and uses thereof

PatentWO2017096414A1

Innovation

- A microfluidic chip with a high aspect ratio channel design that allows immiscible or partially immiscible liquid and gas streams to flow in contact, facilitating the transfer of chemical entities through a contact zone and outlet, with optional multiple inlets and a collection chamber for efficient phase separation.

Materials Science Advancements for Microfluidic Semiconductors

Recent advancements in materials science have significantly propelled the development of microfluidic semiconductor applications. Traditional silicon-based materials, while effective for many semiconductor applications, present limitations when integrated with microfluidic systems, particularly regarding biocompatibility, optical transparency, and chemical resistance. The emergence of novel polymeric materials such as polydimethylsiloxane (PDMS), cyclic olefin copolymer (COC), and perfluoropolyethers (PFPEs) has revolutionized the field by offering enhanced flexibility, transparency, and compatibility with biological samples.

Hybrid material systems combining inorganic semiconductors with organic polymers have emerged as particularly promising platforms. These systems leverage the electrical properties of semiconductors while benefiting from the adaptability of polymeric materials. For instance, graphene-polymer composites demonstrate exceptional electrical conductivity while maintaining the flexibility required for microfluidic applications, enabling the development of highly sensitive biosensors integrated within microfluidic channels.

Surface modification techniques have evolved substantially, allowing precise control over the interface between microfluidic channels and semiconductor components. Techniques such as plasma treatment, chemical vapor deposition, and layer-by-layer assembly enable tailored surface properties, including hydrophilicity, charge density, and biomolecule immobilization capacity. These advancements facilitate more efficient electron transfer and signal transduction in semiconductor-based sensing applications.

Nanomaterials integration represents another frontier in microfluidic semiconductor development. Quantum dots, carbon nanotubes, and metallic nanoparticles incorporated into microfluidic platforms provide enhanced detection capabilities through their unique optical and electrical properties. For example, semiconductor quantum dots embedded in microfluidic channels offer multiplexed detection capabilities with exceptional sensitivity for biomarker analysis in minimal sample volumes.

3D printing technologies have revolutionized the fabrication of complex microfluidic semiconductor devices. Multi-material printing capabilities now allow the simultaneous deposition of conductive, semiconductive, and insulating materials within a single manufacturing process. This advancement has dramatically reduced production time and costs while enabling previously unattainable geometries and functionalities, such as embedded electrodes and integrated sensing elements.

Self-healing materials represent an emerging trend with significant implications for microfluidic semiconductor longevity. These materials can autonomously repair microcracks and damage that typically occur during operation, substantially extending device lifespan. Preliminary research demonstrates that incorporating self-healing polymers into microfluidic semiconductor packaging can increase operational durability by up to 300% under standard testing conditions.

Hybrid material systems combining inorganic semiconductors with organic polymers have emerged as particularly promising platforms. These systems leverage the electrical properties of semiconductors while benefiting from the adaptability of polymeric materials. For instance, graphene-polymer composites demonstrate exceptional electrical conductivity while maintaining the flexibility required for microfluidic applications, enabling the development of highly sensitive biosensors integrated within microfluidic channels.

Surface modification techniques have evolved substantially, allowing precise control over the interface between microfluidic channels and semiconductor components. Techniques such as plasma treatment, chemical vapor deposition, and layer-by-layer assembly enable tailored surface properties, including hydrophilicity, charge density, and biomolecule immobilization capacity. These advancements facilitate more efficient electron transfer and signal transduction in semiconductor-based sensing applications.

Nanomaterials integration represents another frontier in microfluidic semiconductor development. Quantum dots, carbon nanotubes, and metallic nanoparticles incorporated into microfluidic platforms provide enhanced detection capabilities through their unique optical and electrical properties. For example, semiconductor quantum dots embedded in microfluidic channels offer multiplexed detection capabilities with exceptional sensitivity for biomarker analysis in minimal sample volumes.

3D printing technologies have revolutionized the fabrication of complex microfluidic semiconductor devices. Multi-material printing capabilities now allow the simultaneous deposition of conductive, semiconductive, and insulating materials within a single manufacturing process. This advancement has dramatically reduced production time and costs while enabling previously unattainable geometries and functionalities, such as embedded electrodes and integrated sensing elements.

Self-healing materials represent an emerging trend with significant implications for microfluidic semiconductor longevity. These materials can autonomously repair microcracks and damage that typically occur during operation, substantially extending device lifespan. Preliminary research demonstrates that incorporating self-healing polymers into microfluidic semiconductor packaging can increase operational durability by up to 300% under standard testing conditions.

Environmental Impact and Sustainability Considerations

The integration of microfluidic technology with semiconductor manufacturing presents significant environmental and sustainability implications that warrant careful consideration. Traditional semiconductor fabrication processes are notorious for their substantial environmental footprint, consuming large quantities of ultra-pure water, chemicals, and energy. Microfluidic chip applications offer promising pathways to reduce these impacts through miniaturization and process optimization.

Microfluidic systems enable precise control over chemical reactions at microscale levels, potentially reducing chemical waste by up to 90% compared to conventional semiconductor manufacturing methods. This dramatic reduction in hazardous chemical usage not only decreases environmental contamination risks but also minimizes worker exposure to dangerous substances. Furthermore, the reduced reagent volumes translate directly to lower transportation emissions and storage requirements throughout the supply chain.

Water conservation represents another critical sustainability advantage. Semiconductor manufacturing typically requires 2,000-5,000 gallons of ultra-pure water per wafer. Microfluidic-based processes can potentially reduce water consumption by 30-60% through closed-loop systems and enhanced efficiency in cleaning and rinsing operations. This water reduction is particularly significant given that many semiconductor manufacturing facilities operate in water-stressed regions.

Energy efficiency improvements constitute a third major environmental benefit. Microfluidic chip applications enable more precise temperature control and faster heat transfer due to high surface-area-to-volume ratios, potentially reducing energy consumption by 25-40% in certain processes. Additionally, the smaller footprint of microfluidic systems reduces clean room requirements, further decreasing the energy-intensive HVAC demands typical of semiconductor fabrication facilities.

Life cycle assessment studies indicate that microfluidic-based semiconductor manufacturing could reduce the overall carbon footprint by 15-35% compared to conventional methods. However, challenges remain regarding the end-of-life management of microfluidic devices themselves, particularly those incorporating multiple materials that complicate recycling efforts. Research into biodegradable polymers and design-for-disassembly approaches is ongoing to address these concerns.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing practices, with particular focus on chemical use reduction, water conservation, and energy efficiency. Companies adopting microfluidic technologies for semiconductor applications may gain competitive advantages through compliance with emerging environmental regulations while simultaneously reducing operational costs associated with resource consumption and waste management.

Microfluidic systems enable precise control over chemical reactions at microscale levels, potentially reducing chemical waste by up to 90% compared to conventional semiconductor manufacturing methods. This dramatic reduction in hazardous chemical usage not only decreases environmental contamination risks but also minimizes worker exposure to dangerous substances. Furthermore, the reduced reagent volumes translate directly to lower transportation emissions and storage requirements throughout the supply chain.

Water conservation represents another critical sustainability advantage. Semiconductor manufacturing typically requires 2,000-5,000 gallons of ultra-pure water per wafer. Microfluidic-based processes can potentially reduce water consumption by 30-60% through closed-loop systems and enhanced efficiency in cleaning and rinsing operations. This water reduction is particularly significant given that many semiconductor manufacturing facilities operate in water-stressed regions.

Energy efficiency improvements constitute a third major environmental benefit. Microfluidic chip applications enable more precise temperature control and faster heat transfer due to high surface-area-to-volume ratios, potentially reducing energy consumption by 25-40% in certain processes. Additionally, the smaller footprint of microfluidic systems reduces clean room requirements, further decreasing the energy-intensive HVAC demands typical of semiconductor fabrication facilities.

Life cycle assessment studies indicate that microfluidic-based semiconductor manufacturing could reduce the overall carbon footprint by 15-35% compared to conventional methods. However, challenges remain regarding the end-of-life management of microfluidic devices themselves, particularly those incorporating multiple materials that complicate recycling efforts. Research into biodegradable polymers and design-for-disassembly approaches is ongoing to address these concerns.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing practices, with particular focus on chemical use reduction, water conservation, and energy efficiency. Companies adopting microfluidic technologies for semiconductor applications may gain competitive advantages through compliance with emerging environmental regulations while simultaneously reducing operational costs associated with resource consumption and waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!