Applications of Microfluidic Chips in Fuel Cell Research

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Chips in Fuel Cell Research: Background and Objectives

Microfluidic technology has emerged as a revolutionary approach in various scientific fields since its inception in the early 1990s. The integration of microfluidic chips with fuel cell research represents a significant technological convergence that has gained momentum over the past decade. Microfluidic devices, characterized by their ability to manipulate fluids at the microscale level, offer unprecedented control over reaction conditions, making them ideal platforms for fuel cell development and optimization.

The evolution of microfluidic technology in fuel cell research has progressed from simple channel designs to sophisticated integrated systems capable of mimicking complex fuel cell environments. This progression has been driven by advances in microfabrication techniques, materials science, and a deeper understanding of fluid dynamics at the microscale. The miniaturization capabilities of microfluidics align perfectly with the trend toward more compact and efficient fuel cell systems.

Current technological trajectories indicate a growing emphasis on developing microfluidic platforms that can address key challenges in fuel cell technology, including catalyst optimization, membrane performance enhancement, and real-time monitoring of electrochemical reactions. The integration of advanced sensing capabilities within microfluidic fuel cell systems represents a particularly promising direction for future development.

The primary technical objectives of applying microfluidic chips in fuel cell research encompass several dimensions. First, these platforms aim to provide high-throughput screening capabilities for catalyst materials and electrolyte compositions, significantly accelerating the discovery and optimization process. Second, microfluidic systems seek to enable precise control over mass transport phenomena, which is crucial for understanding and improving fuel cell performance. Third, these technologies target the development of in-situ characterization methods that can provide real-time insights into reaction kinetics and degradation mechanisms.

Additionally, microfluidic fuel cell research aims to bridge the gap between laboratory-scale experiments and practical applications by providing scalable and reproducible testing environments. The ability to precisely replicate operating conditions and systematically vary parameters offers unprecedented opportunities for fundamental studies and applied research alike.

Looking forward, the field is moving toward more integrated approaches that combine microfluidic fuel cell testing with advanced computational modeling and artificial intelligence for data analysis. This synergy promises to accelerate the development cycle of next-generation fuel cell technologies by enabling more efficient exploration of the vast design space and more accurate prediction of performance characteristics under various operating conditions.

The evolution of microfluidic technology in fuel cell research has progressed from simple channel designs to sophisticated integrated systems capable of mimicking complex fuel cell environments. This progression has been driven by advances in microfabrication techniques, materials science, and a deeper understanding of fluid dynamics at the microscale. The miniaturization capabilities of microfluidics align perfectly with the trend toward more compact and efficient fuel cell systems.

Current technological trajectories indicate a growing emphasis on developing microfluidic platforms that can address key challenges in fuel cell technology, including catalyst optimization, membrane performance enhancement, and real-time monitoring of electrochemical reactions. The integration of advanced sensing capabilities within microfluidic fuel cell systems represents a particularly promising direction for future development.

The primary technical objectives of applying microfluidic chips in fuel cell research encompass several dimensions. First, these platforms aim to provide high-throughput screening capabilities for catalyst materials and electrolyte compositions, significantly accelerating the discovery and optimization process. Second, microfluidic systems seek to enable precise control over mass transport phenomena, which is crucial for understanding and improving fuel cell performance. Third, these technologies target the development of in-situ characterization methods that can provide real-time insights into reaction kinetics and degradation mechanisms.

Additionally, microfluidic fuel cell research aims to bridge the gap between laboratory-scale experiments and practical applications by providing scalable and reproducible testing environments. The ability to precisely replicate operating conditions and systematically vary parameters offers unprecedented opportunities for fundamental studies and applied research alike.

Looking forward, the field is moving toward more integrated approaches that combine microfluidic fuel cell testing with advanced computational modeling and artificial intelligence for data analysis. This synergy promises to accelerate the development cycle of next-generation fuel cell technologies by enabling more efficient exploration of the vast design space and more accurate prediction of performance characteristics under various operating conditions.

Market Analysis for Microfluidic-Enhanced Fuel Cell Technologies

The global market for microfluidic-enhanced fuel cell technologies is experiencing significant growth, driven by increasing demand for clean energy solutions and advancements in miniaturization technologies. Current market valuations indicate that the microfluidic fuel cell segment reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate of 14.8% through 2030. This growth trajectory is substantially higher than the broader fuel cell market, which is growing at around 9.7% annually.

The automotive sector represents the largest application market for microfluidic fuel cell technologies, accounting for roughly 42% of total market share. This dominance stems from automotive manufacturers' increasing investments in hydrogen fuel cell vehicles as part of their zero-emission strategies. Toyota, Hyundai, and Honda have all incorporated microfluidic elements in their latest fuel cell stack designs to enhance performance and reduce costs.

Portable electronics constitutes the fastest-growing segment, with an estimated growth rate of 18.3% annually. The miniaturization capabilities of microfluidic systems make them particularly suitable for small-scale power applications in consumer electronics, medical devices, and military equipment. Market research indicates that consumers are willing to pay premium prices for devices with longer battery life, creating a favorable environment for microfluidic fuel cell adoption.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 25%. However, the Asia-Pacific region is expected to overtake North America by 2026, driven primarily by substantial government investments in hydrogen infrastructure in Japan, South Korea, and China. The European market is also accelerating rapidly due to stringent carbon emission regulations and substantial green hydrogen initiatives.

Key market barriers include high manufacturing costs, with microfluidic fuel cell components currently costing 2.3 times more than conventional fuel cell components on a per-watt basis. Additionally, durability concerns and integration challenges with existing systems remain significant obstacles to widespread adoption. Market surveys indicate that potential industrial adopters cite cost (67%) and reliability (58%) as their primary concerns regarding microfluidic fuel cell implementation.

Despite these challenges, the market outlook remains highly positive. Decreasing production costs through economies of scale and manufacturing innovations are expected to reduce the price premium to 1.4 times conventional systems by 2027. Furthermore, the unique advantages of microfluidic systems in terms of efficiency, reduced catalyst loading, and improved water management are increasingly recognized as critical differentiators in next-generation fuel cell designs.

The automotive sector represents the largest application market for microfluidic fuel cell technologies, accounting for roughly 42% of total market share. This dominance stems from automotive manufacturers' increasing investments in hydrogen fuel cell vehicles as part of their zero-emission strategies. Toyota, Hyundai, and Honda have all incorporated microfluidic elements in their latest fuel cell stack designs to enhance performance and reduce costs.

Portable electronics constitutes the fastest-growing segment, with an estimated growth rate of 18.3% annually. The miniaturization capabilities of microfluidic systems make them particularly suitable for small-scale power applications in consumer electronics, medical devices, and military equipment. Market research indicates that consumers are willing to pay premium prices for devices with longer battery life, creating a favorable environment for microfluidic fuel cell adoption.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 25%. However, the Asia-Pacific region is expected to overtake North America by 2026, driven primarily by substantial government investments in hydrogen infrastructure in Japan, South Korea, and China. The European market is also accelerating rapidly due to stringent carbon emission regulations and substantial green hydrogen initiatives.

Key market barriers include high manufacturing costs, with microfluidic fuel cell components currently costing 2.3 times more than conventional fuel cell components on a per-watt basis. Additionally, durability concerns and integration challenges with existing systems remain significant obstacles to widespread adoption. Market surveys indicate that potential industrial adopters cite cost (67%) and reliability (58%) as their primary concerns regarding microfluidic fuel cell implementation.

Despite these challenges, the market outlook remains highly positive. Decreasing production costs through economies of scale and manufacturing innovations are expected to reduce the price premium to 1.4 times conventional systems by 2027. Furthermore, the unique advantages of microfluidic systems in terms of efficiency, reduced catalyst loading, and improved water management are increasingly recognized as critical differentiators in next-generation fuel cell designs.

Current Challenges in Microfluidic Applications for Fuel Cells

Despite significant advancements in microfluidic technology for fuel cell applications, several critical challenges continue to impede widespread implementation and commercialization. One of the primary obstacles remains the fabrication complexity of integrated microfluidic fuel cell systems. Current manufacturing processes often require specialized equipment and clean room facilities, resulting in high production costs that limit scalability for mass production.

Material compatibility presents another significant challenge, particularly when dealing with corrosive fuels and oxidants. Many polymer-based microfluidic platforms suffer from degradation when exposed to harsh chemical environments, while alternative materials like glass or silicon may be too brittle or expensive for practical applications. The development of cost-effective, chemically resistant materials that maintain their integrity over extended operational periods remains an ongoing research focus.

Flow control and distribution within microfluidic channels constitutes a persistent technical hurdle. Achieving uniform reactant distribution across the active area of fuel cells is critical for performance optimization, yet difficult to maintain under varying operational conditions. Pressure drops, channel clogging, and two-phase flow instabilities can lead to significant performance degradation and reduced system reliability.

Heat management represents another formidable challenge in microfluidic fuel cell systems. The confined spaces within microchannels can lead to localized hotspots and thermal gradients that negatively impact catalytic activity and membrane performance. Effective thermal management strategies must be developed without significantly increasing system complexity or size.

Interface issues between the microfluidic components and other fuel cell elements (electrodes, membranes, current collectors) continue to present integration challenges. Creating reliable, low-resistance connections while maintaining fluidic integrity requires innovative approaches to system design and assembly.

Long-term durability and reliability remain significant concerns for practical applications. Microfluidic fuel cell systems must demonstrate consistent performance over thousands of hours under varying operational conditions. Current systems often show performance degradation due to catalyst poisoning, membrane fouling, and mechanical failures at interfaces.

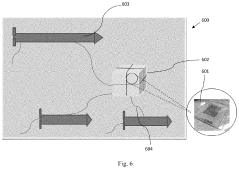

Scaling microfluidic fuel cell technology from laboratory demonstrations to commercially viable products presents additional challenges. While microfluidic approaches excel at small scales, achieving power outputs suitable for practical applications often requires effective strategies for parallelization or scale-up that maintain the benefits of microfluidic operation while delivering useful power levels.

Finally, standardization across the field remains limited, with researchers employing diverse materials, designs, and testing protocols that complicate direct performance comparisons and technology assessment. Establishing industry standards for microfluidic fuel cell testing and characterization would accelerate development and commercialization efforts.

Material compatibility presents another significant challenge, particularly when dealing with corrosive fuels and oxidants. Many polymer-based microfluidic platforms suffer from degradation when exposed to harsh chemical environments, while alternative materials like glass or silicon may be too brittle or expensive for practical applications. The development of cost-effective, chemically resistant materials that maintain their integrity over extended operational periods remains an ongoing research focus.

Flow control and distribution within microfluidic channels constitutes a persistent technical hurdle. Achieving uniform reactant distribution across the active area of fuel cells is critical for performance optimization, yet difficult to maintain under varying operational conditions. Pressure drops, channel clogging, and two-phase flow instabilities can lead to significant performance degradation and reduced system reliability.

Heat management represents another formidable challenge in microfluidic fuel cell systems. The confined spaces within microchannels can lead to localized hotspots and thermal gradients that negatively impact catalytic activity and membrane performance. Effective thermal management strategies must be developed without significantly increasing system complexity or size.

Interface issues between the microfluidic components and other fuel cell elements (electrodes, membranes, current collectors) continue to present integration challenges. Creating reliable, low-resistance connections while maintaining fluidic integrity requires innovative approaches to system design and assembly.

Long-term durability and reliability remain significant concerns for practical applications. Microfluidic fuel cell systems must demonstrate consistent performance over thousands of hours under varying operational conditions. Current systems often show performance degradation due to catalyst poisoning, membrane fouling, and mechanical failures at interfaces.

Scaling microfluidic fuel cell technology from laboratory demonstrations to commercially viable products presents additional challenges. While microfluidic approaches excel at small scales, achieving power outputs suitable for practical applications often requires effective strategies for parallelization or scale-up that maintain the benefits of microfluidic operation while delivering useful power levels.

Finally, standardization across the field remains limited, with researchers employing diverse materials, designs, and testing protocols that complicate direct performance comparisons and technology assessment. Establishing industry standards for microfluidic fuel cell testing and characterization would accelerate development and commercialization efforts.

Current Microfluidic Approaches for Fuel Cell Optimization

01 Fabrication techniques for microfluidic chips

Various fabrication methods are employed to create microfluidic chips with precise channel geometries and surface properties. These techniques include soft lithography, hot embossing, injection molding, and 3D printing. The choice of fabrication method depends on the desired application, material properties, and production scale. Advanced fabrication techniques enable the creation of complex microstructures with high precision, which is crucial for applications requiring precise fluid control.- Fabrication methods for microfluidic chips: Various techniques are employed in the fabrication of microfluidic chips, including photolithography, soft lithography, and 3D printing. These methods allow for precise control over channel dimensions and geometries. Materials commonly used include polymers like PDMS, glass, and silicon. Advanced fabrication techniques enable the creation of complex microstructures with high resolution and reproducibility, which is essential for applications requiring precise fluid control.

- Integration of sensing and detection systems: Microfluidic chips can be integrated with various sensing and detection systems to enable real-time monitoring and analysis. These systems may include optical sensors, electrochemical detectors, and spectroscopic tools. The integration allows for enhanced sensitivity and specificity in detecting analytes, making these chips valuable for diagnostic applications. Such integrated systems can detect biomarkers, pathogens, or chemical compounds at very low concentrations.

- Applications in biological and medical research: Microfluidic chips have extensive applications in biological and medical research, including cell culture, drug screening, and disease modeling. These platforms enable precise control over cellular microenvironments and can mimic physiological conditions. They are particularly valuable for studying cell behavior, drug responses, and disease mechanisms at the microscale level. The ability to work with small sample volumes makes them ideal for rare cell analysis and personalized medicine approaches.

- Flow control and manipulation techniques: Advanced techniques for controlling and manipulating fluid flow within microfluidic chips are essential for their functionality. These include passive methods like capillary forces and active methods such as pressure-driven flow, electrokinetic flow, and acoustic manipulation. Precise flow control enables operations like mixing, separation, and concentration of samples. Innovations in valve systems, pumps, and channel designs allow for complex fluid handling protocols to be automated within these miniaturized platforms.

- Novel designs for specific applications: Specialized microfluidic chip designs are being developed for specific applications across various fields. These include droplet-based microfluidics for digital PCR, gradient generators for chemotaxis studies, and organ-on-chip platforms for toxicology testing. Novel designs incorporate features like mixing chambers, reaction zones, and separation channels tailored to specific analytical needs. The customization of chip architecture enables optimization for particular assays, improving efficiency and performance in targeted applications.

02 Integration of sensing and detection systems

Microfluidic chips can be integrated with various sensing and detection systems to enable real-time monitoring and analysis. These systems include optical sensors, electrochemical detectors, and spectroscopic instruments that can detect and quantify analytes within the microfluidic channels. The integration of these sensing technologies enhances the functionality of microfluidic chips, allowing for automated and high-throughput analysis in applications such as diagnostics, environmental monitoring, and drug discovery.Expand Specific Solutions03 Microfluidic chip designs for biological applications

Specialized microfluidic chip designs have been developed for various biological applications, including cell culture, DNA analysis, protein separation, and organ-on-a-chip systems. These designs incorporate features such as cell trapping structures, gradient generators, and mixing chambers to mimic physiological conditions and enable complex biological studies. The miniaturized format of these chips allows for reduced reagent consumption, faster reaction times, and the ability to perform multiple analyses in parallel.Expand Specific Solutions04 Flow control and manipulation in microfluidic systems

Various mechanisms are employed to control and manipulate fluid flow within microfluidic chips, including valves, pumps, and mixers. These components enable precise control over fluid movement, mixing, and separation, which is essential for complex analytical procedures. Advanced flow control techniques include electrokinetic methods, acoustic manipulation, and magnetic actuation, which provide non-contact and programmable control over fluid and particle movement within the microchannels.Expand Specific Solutions05 Materials and surface modifications for microfluidic chips

The choice of materials and surface modifications significantly impacts the performance of microfluidic chips. Common materials include glass, silicon, and various polymers such as PDMS, PMMA, and COC. Surface modifications can alter properties such as hydrophobicity, charge, and biocompatibility, which are crucial for specific applications. These modifications can prevent non-specific adsorption, control cell adhesion, or enable specific molecular interactions, enhancing the functionality and reliability of microfluidic devices.Expand Specific Solutions

Leading Organizations in Microfluidic Fuel Cell Development

Microfluidic chips in fuel cell research represent an emerging field at the intersection of nanotechnology and energy, currently in the early growth phase. The market is expanding rapidly, projected to reach significant scale as clean energy demands increase. Technologically, academic institutions like Chongqing University, Yale University, and Tsinghua Shenzhen International Graduate School are driving fundamental research, while companies including General Motors, Sony Group, and Sekisui Chemical are advancing commercial applications. Research centers such as Karlsruher Institut für Technologie and Commissariat à l'énergie atomique are bridging the gap between theoretical work and practical implementation. The technology shows promising maturity in lab settings but requires further development for widespread commercial deployment, with key players focusing on improving efficiency, durability, and cost-effectiveness of microfluidic-based fuel cell systems.

National University of Singapore

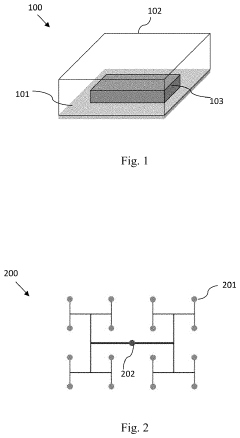

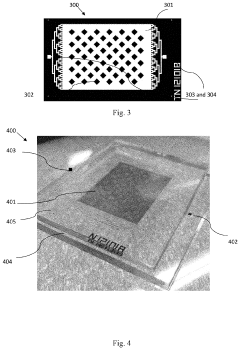

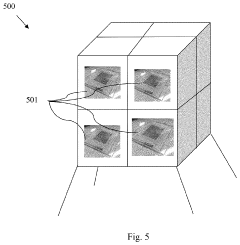

Technical Solution: The National University of Singapore (NUS) has established cutting-edge microfluidic platforms specifically designed for fuel cell research and development. Their technology features multi-layer microfluidic devices with precisely controlled flow distribution networks that enable detailed studies of reactant transport and electrochemical kinetics in fuel cell environments. NUS researchers have developed transparent microfluidic fuel cells that incorporate nanoporous electrodes and ion-exchange membranes, allowing for direct visualization of electrochemical processes at the microscale. Their microfluidic chips integrate advanced sensing elements including micro-reference electrodes and temperature sensors for comprehensive characterization of local reaction environments. NUS has pioneered microfluidic devices with variable channel geometries that can simulate different flow field designs, enabling rapid optimization of fuel cell architectures without fabricating full-scale prototypes. Their technology also features specialized microreactors for studying catalyst performance and degradation mechanisms under precisely controlled conditions, with capabilities for in-situ spectroscopic analysis of reaction intermediates and products.

Strengths: Strong interdisciplinary approach combining materials science, electrochemistry, and microfluidics; excellent international research collaborations. Weaknesses: May face challenges in translating academic research to industrial applications; potential resource limitations compared to larger industrial research programs.

General Motors LLC

Technical Solution: General Motors has developed advanced microfluidic chip platforms specifically designed for fuel cell research and optimization. Their technology integrates multiple microchannels with precise flow control systems to simulate and test various aspects of fuel cell operation in miniaturized environments. GM's microfluidic chips feature integrated sensors that enable real-time monitoring of reaction kinetics, mass transport phenomena, and electrochemical processes within polymer electrolyte membrane (PEM) fuel cells. The company has pioneered "lab-on-a-chip" solutions that allow for rapid screening of catalyst materials and membrane electrode assembly (MEA) configurations under various operating conditions. Their microfluidic platforms incorporate temperature control systems that can simulate the thermal gradients experienced in full-scale automotive fuel cells, providing valuable data for optimizing thermal management strategies in their commercial fuel cell vehicles.

Strengths: Direct application to automotive fuel cell development with immediate commercial relevance; extensive integration with vehicle systems expertise. Weaknesses: Research may be primarily focused on automotive applications rather than broader fuel cell applications; proprietary technology with limited academic publication.

Key Patents and Innovations in Microfluidic Fuel Cell Integration

Microfluidic microbacterial fuel cell chips and related optimization methods

PatentActiveUS20210104767A1

Innovation

- Microfluidic microbacterial fuel cell chips with elastomeric structures and H-architecture minimize electrode-bacteria distance, enhancing power capture efficiency by using benthic bacteria to generate electrical power, and arraying these chips into a three-dimensional power cube for increased output.

A microfluidic chip and its applications

PatentActiveZA202401129A

Innovation

- Integration of multiple functions (droplet generation, mixing, amplification, magnetic separation, and SERS detection) into a single microfluidic chip for high-precision miRNA detection.

- High-throughput Surface-Enhanced Raman Scattering (SERS) detection capability combined with magnetic separation for enhanced sensitivity and specificity in miRNA detection.

- Successful application in detecting dual-target miRNA markers (miR-21 and miR-155) in IPF patients with high repeatability and accuracy.

Materials Science Advancements for Microfluidic Fuel Cell Components

Recent advancements in materials science have significantly propelled the development of microfluidic fuel cell technology. The integration of novel materials has addressed critical challenges related to durability, efficiency, and cost-effectiveness of microfluidic fuel cell components. These innovations are transforming the landscape of portable and small-scale power generation systems.

Polymer-based materials have emerged as frontrunners in microfluidic channel fabrication, with polydimethylsiloxane (PDMS) demonstrating exceptional properties including optical transparency, gas permeability, and biocompatibility. However, PDMS faces limitations in fuel cell applications due to its susceptibility to swelling when exposed to certain fuels. This has prompted research into alternative polymers such as perfluorinated compounds and thermoplastics that offer superior chemical resistance while maintaining the flexibility required for microfluidic applications.

Electrode materials have undergone substantial evolution, moving beyond traditional carbon-based substrates to incorporate nanomaterials that dramatically enhance catalytic activity and power density. Carbon nanotubes, graphene, and metal nanoparticles have been strategically integrated to create composite electrodes with unprecedented surface area-to-volume ratios. These nanostructured electrodes facilitate more efficient electrochemical reactions while reducing precious metal catalyst loading, addressing a significant cost barrier in fuel cell commercialization.

Membrane materials have similarly benefited from materials science breakthroughs. Novel proton exchange membranes (PEMs) with enhanced conductivity and reduced thickness have been developed specifically for microfluidic architectures. These include modified Nafion formulations and composite membranes incorporating inorganic nanoparticles that maintain high proton conductivity while operating under the unique flow conditions present in microfluidic systems.

Catalyst layer optimization represents another critical area of materials advancement. Researchers have developed precise deposition techniques for creating ultrathin catalyst layers with controlled porosity and composition. Platinum-alloy catalysts and non-precious metal alternatives have demonstrated promising performance in microfluidic environments, potentially reducing dependence on scarce and expensive platinum group metals.

Sealing and bonding technologies have also progressed significantly, with new adhesives and surface treatment methods enabling hermetic sealing between disparate materials while withstanding the chemical and thermal stresses inherent in fuel cell operation. These advances have improved device reliability and extended operational lifetimes, critical factors for commercial viability.

The convergence of additive manufacturing with advanced materials science has opened new possibilities for complex microfluidic fuel cell architectures that were previously unattainable. 3D printing of specialized polymers, ceramics, and even metal components allows for rapid prototyping and customization of microfluidic fuel cell designs, accelerating the innovation cycle and enabling application-specific optimization.

Polymer-based materials have emerged as frontrunners in microfluidic channel fabrication, with polydimethylsiloxane (PDMS) demonstrating exceptional properties including optical transparency, gas permeability, and biocompatibility. However, PDMS faces limitations in fuel cell applications due to its susceptibility to swelling when exposed to certain fuels. This has prompted research into alternative polymers such as perfluorinated compounds and thermoplastics that offer superior chemical resistance while maintaining the flexibility required for microfluidic applications.

Electrode materials have undergone substantial evolution, moving beyond traditional carbon-based substrates to incorporate nanomaterials that dramatically enhance catalytic activity and power density. Carbon nanotubes, graphene, and metal nanoparticles have been strategically integrated to create composite electrodes with unprecedented surface area-to-volume ratios. These nanostructured electrodes facilitate more efficient electrochemical reactions while reducing precious metal catalyst loading, addressing a significant cost barrier in fuel cell commercialization.

Membrane materials have similarly benefited from materials science breakthroughs. Novel proton exchange membranes (PEMs) with enhanced conductivity and reduced thickness have been developed specifically for microfluidic architectures. These include modified Nafion formulations and composite membranes incorporating inorganic nanoparticles that maintain high proton conductivity while operating under the unique flow conditions present in microfluidic systems.

Catalyst layer optimization represents another critical area of materials advancement. Researchers have developed precise deposition techniques for creating ultrathin catalyst layers with controlled porosity and composition. Platinum-alloy catalysts and non-precious metal alternatives have demonstrated promising performance in microfluidic environments, potentially reducing dependence on scarce and expensive platinum group metals.

Sealing and bonding technologies have also progressed significantly, with new adhesives and surface treatment methods enabling hermetic sealing between disparate materials while withstanding the chemical and thermal stresses inherent in fuel cell operation. These advances have improved device reliability and extended operational lifetimes, critical factors for commercial viability.

The convergence of additive manufacturing with advanced materials science has opened new possibilities for complex microfluidic fuel cell architectures that were previously unattainable. 3D printing of specialized polymers, ceramics, and even metal components allows for rapid prototyping and customization of microfluidic fuel cell designs, accelerating the innovation cycle and enabling application-specific optimization.

Scaling and Commercialization Challenges for Microfluidic Fuel Cells

Despite the promising potential of microfluidic fuel cells, significant challenges remain in scaling these technologies from laboratory prototypes to commercially viable products. The miniaturization that makes microfluidic systems advantageous for research also presents unique obstacles when attempting to increase production volume and market penetration. Current manufacturing processes for microfluidic chips, primarily based on soft lithography techniques using polydimethylsiloxane (PDMS), are well-suited for laboratory-scale production but lack the efficiency required for mass manufacturing.

Material selection represents another critical challenge. While PDMS offers excellent properties for prototyping, including optical transparency and ease of fabrication, it suffers from limitations in durability, chemical compatibility, and long-term stability that hinder commercial applications. Alternative materials such as thermoplastics or glass may offer better performance characteristics but require different and often more complex manufacturing approaches.

The integration of microfluidic fuel cells with existing energy infrastructure presents additional hurdles. Current energy systems are designed for conventional power sources, and the adaptation necessary to incorporate microfluidic fuel cell technology requires significant investment in infrastructure development and standardization. This creates a chicken-and-egg problem where market adoption is hindered by lack of infrastructure, while infrastructure development is limited by uncertain market demand.

Economic factors further complicate commercialization efforts. The current cost structure of microfluidic fuel cell production remains prohibitively high compared to established energy technologies. Initial capital investment for manufacturing facilities, coupled with relatively low production volumes, results in high unit costs that make market entry challenging. Additionally, the specialized expertise required for design, fabrication, and operation of these systems creates workforce development challenges.

Regulatory frameworks and standards for microfluidic fuel cells remain underdeveloped, creating uncertainty for potential manufacturers and investors. Safety certifications, performance standards, and environmental impact assessments need to be established to facilitate market acceptance and ensure consistent quality across the industry.

Despite these challenges, several pathways could accelerate commercialization. Strategic partnerships between academic institutions, startups, and established energy companies could leverage complementary expertise and resources. Modular design approaches may allow for incremental scaling and adaptation to various application contexts. Additionally, targeting niche markets with specific needs that align with the unique advantages of microfluidic fuel cells—such as portable electronics or specialized industrial applications—could provide initial commercial footholds before broader market penetration.

Material selection represents another critical challenge. While PDMS offers excellent properties for prototyping, including optical transparency and ease of fabrication, it suffers from limitations in durability, chemical compatibility, and long-term stability that hinder commercial applications. Alternative materials such as thermoplastics or glass may offer better performance characteristics but require different and often more complex manufacturing approaches.

The integration of microfluidic fuel cells with existing energy infrastructure presents additional hurdles. Current energy systems are designed for conventional power sources, and the adaptation necessary to incorporate microfluidic fuel cell technology requires significant investment in infrastructure development and standardization. This creates a chicken-and-egg problem where market adoption is hindered by lack of infrastructure, while infrastructure development is limited by uncertain market demand.

Economic factors further complicate commercialization efforts. The current cost structure of microfluidic fuel cell production remains prohibitively high compared to established energy technologies. Initial capital investment for manufacturing facilities, coupled with relatively low production volumes, results in high unit costs that make market entry challenging. Additionally, the specialized expertise required for design, fabrication, and operation of these systems creates workforce development challenges.

Regulatory frameworks and standards for microfluidic fuel cells remain underdeveloped, creating uncertainty for potential manufacturers and investors. Safety certifications, performance standards, and environmental impact assessments need to be established to facilitate market acceptance and ensure consistent quality across the industry.

Despite these challenges, several pathways could accelerate commercialization. Strategic partnerships between academic institutions, startups, and established energy companies could leverage complementary expertise and resources. Modular design approaches may allow for incremental scaling and adaptation to various application contexts. Additionally, targeting niche markets with specific needs that align with the unique advantages of microfluidic fuel cells—such as portable electronics or specialized industrial applications—could provide initial commercial footholds before broader market penetration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!