Role of Microfluidic Chips in Improving Food Quality Testing

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Technology Evolution and Objectives

Microfluidic technology has evolved significantly over the past three decades, transforming from a theoretical concept to a practical tool with diverse applications. The journey began in the 1990s with pioneering work on miniaturized total analysis systems (μTAS), which laid the foundation for what we now recognize as microfluidic technology. Early developments focused primarily on proof-of-concept demonstrations in laboratory settings, with limited practical applications beyond research environments.

The early 2000s marked a significant transition as microfluidic technology began to demonstrate practical utility in analytical chemistry and biomedical diagnostics. This period saw the emergence of polydimethylsiloxane (PDMS) as a preferred material for chip fabrication, enabling more rapid prototyping and experimentation. The technology's ability to manipulate fluids at the microscale opened new possibilities for precise sample handling and analysis.

By the 2010s, microfluidic technology had expanded beyond academic research into commercial applications, with food safety emerging as a promising field. The increasing global concern over foodborne illnesses and contaminants created a demand for faster, more accurate testing methods that could be deployed throughout the food supply chain. This market pull accelerated the development of specialized microfluidic platforms designed specifically for food quality assessment.

Current microfluidic technology for food quality testing leverages several key advantages: minimal sample and reagent consumption, rapid analysis times, potential for automation, and the ability to integrate multiple analytical steps onto a single chip. These characteristics address critical limitations of traditional food testing methods, which often require extensive sample preparation, specialized laboratory equipment, and significant time to generate results.

The primary objective of microfluidic technology in food quality testing is to enable rapid, sensitive, and specific detection of contaminants, pathogens, and quality indicators throughout the food supply chain. This includes the development of portable, user-friendly devices that can be operated by personnel with minimal training, allowing for on-site testing at production facilities, distribution centers, and retail locations.

Secondary objectives include reducing the cost per test, minimizing environmental impact through reduced chemical usage, and creating systems capable of multiplexed analysis to detect multiple contaminants simultaneously. There is also a growing focus on developing interconnected systems that can transmit results to centralized databases, enabling real-time monitoring and trend analysis across the food supply chain.

Looking forward, the technology aims to achieve greater integration with other emerging technologies such as artificial intelligence for automated result interpretation, nanomaterials for enhanced sensitivity, and wireless connectivity for seamless data management. The ultimate goal is to establish microfluidic-based testing as a standard component of comprehensive food safety management systems, contributing to improved public health outcomes and reduced economic losses from contaminated food products.

The early 2000s marked a significant transition as microfluidic technology began to demonstrate practical utility in analytical chemistry and biomedical diagnostics. This period saw the emergence of polydimethylsiloxane (PDMS) as a preferred material for chip fabrication, enabling more rapid prototyping and experimentation. The technology's ability to manipulate fluids at the microscale opened new possibilities for precise sample handling and analysis.

By the 2010s, microfluidic technology had expanded beyond academic research into commercial applications, with food safety emerging as a promising field. The increasing global concern over foodborne illnesses and contaminants created a demand for faster, more accurate testing methods that could be deployed throughout the food supply chain. This market pull accelerated the development of specialized microfluidic platforms designed specifically for food quality assessment.

Current microfluidic technology for food quality testing leverages several key advantages: minimal sample and reagent consumption, rapid analysis times, potential for automation, and the ability to integrate multiple analytical steps onto a single chip. These characteristics address critical limitations of traditional food testing methods, which often require extensive sample preparation, specialized laboratory equipment, and significant time to generate results.

The primary objective of microfluidic technology in food quality testing is to enable rapid, sensitive, and specific detection of contaminants, pathogens, and quality indicators throughout the food supply chain. This includes the development of portable, user-friendly devices that can be operated by personnel with minimal training, allowing for on-site testing at production facilities, distribution centers, and retail locations.

Secondary objectives include reducing the cost per test, minimizing environmental impact through reduced chemical usage, and creating systems capable of multiplexed analysis to detect multiple contaminants simultaneously. There is also a growing focus on developing interconnected systems that can transmit results to centralized databases, enabling real-time monitoring and trend analysis across the food supply chain.

Looking forward, the technology aims to achieve greater integration with other emerging technologies such as artificial intelligence for automated result interpretation, nanomaterials for enhanced sensitivity, and wireless connectivity for seamless data management. The ultimate goal is to establish microfluidic-based testing as a standard component of comprehensive food safety management systems, contributing to improved public health outcomes and reduced economic losses from contaminated food products.

Food Safety Testing Market Analysis

The global food safety testing market has been experiencing robust growth, valued at approximately $19.7 billion in 2022 and projected to reach $32.5 billion by 2027, growing at a CAGR of 10.6%. This growth is primarily driven by increasing consumer awareness about food safety, stringent regulatory standards, and the rising incidence of foodborne illnesses worldwide. According to the World Health Organization, an estimated 600 million people fall ill after consuming contaminated food annually, highlighting the critical importance of effective testing mechanisms.

The market is segmented by testing type, with pathogen testing holding the largest share (42%), followed by GMO testing (18%), pesticide residue testing (15%), and others including allergen testing and chemical contaminant analysis. Regionally, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%), with the latter showing the fastest growth rate due to increasing food exports and regulatory developments.

Technological advancements are reshaping the landscape of food safety testing, with rapid testing methods gaining significant traction. Traditional culture-based methods are gradually being supplemented or replaced by molecular diagnostic techniques, immunoassays, and biosensor technologies. The integration of microfluidic chips represents a particularly promising development, offering advantages in terms of speed, sensitivity, and cost-effectiveness.

The competitive landscape features both established players and innovative startups. Major companies including Eurofins Scientific, Bureau Veritas, SGS SA, and Intertek Group collectively hold approximately 40% market share. These companies are increasingly investing in R&D to develop advanced testing solutions incorporating microfluidic technology. Meanwhile, specialized technology providers like Illumina, bioMérieux, and Thermo Fisher Scientific are focusing on developing next-generation testing platforms.

Key market drivers include the globalization of food supply chains, increasing regulatory pressure, and growing consumer demand for transparency. The implementation of regulations such as the Food Safety Modernization Act (FSMA) in the US and similar frameworks in other regions has significantly boosted demand for comprehensive testing solutions. Additionally, the COVID-19 pandemic has heightened awareness about hygiene and safety in food processing, further accelerating market growth.

Challenges facing the market include the high cost of advanced testing equipment, technical expertise requirements, and the need for standardization across different regions. However, these challenges also present opportunities for innovation, particularly in developing more accessible, user-friendly testing solutions that can be deployed across various points in the food supply chain.

The market is segmented by testing type, with pathogen testing holding the largest share (42%), followed by GMO testing (18%), pesticide residue testing (15%), and others including allergen testing and chemical contaminant analysis. Regionally, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%), with the latter showing the fastest growth rate due to increasing food exports and regulatory developments.

Technological advancements are reshaping the landscape of food safety testing, with rapid testing methods gaining significant traction. Traditional culture-based methods are gradually being supplemented or replaced by molecular diagnostic techniques, immunoassays, and biosensor technologies. The integration of microfluidic chips represents a particularly promising development, offering advantages in terms of speed, sensitivity, and cost-effectiveness.

The competitive landscape features both established players and innovative startups. Major companies including Eurofins Scientific, Bureau Veritas, SGS SA, and Intertek Group collectively hold approximately 40% market share. These companies are increasingly investing in R&D to develop advanced testing solutions incorporating microfluidic technology. Meanwhile, specialized technology providers like Illumina, bioMérieux, and Thermo Fisher Scientific are focusing on developing next-generation testing platforms.

Key market drivers include the globalization of food supply chains, increasing regulatory pressure, and growing consumer demand for transparency. The implementation of regulations such as the Food Safety Modernization Act (FSMA) in the US and similar frameworks in other regions has significantly boosted demand for comprehensive testing solutions. Additionally, the COVID-19 pandemic has heightened awareness about hygiene and safety in food processing, further accelerating market growth.

Challenges facing the market include the high cost of advanced testing equipment, technical expertise requirements, and the need for standardization across different regions. However, these challenges also present opportunities for innovation, particularly in developing more accessible, user-friendly testing solutions that can be deployed across various points in the food supply chain.

Current Microfluidic Applications in Food Quality Assessment

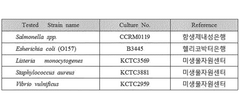

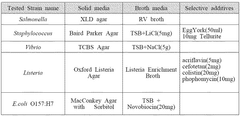

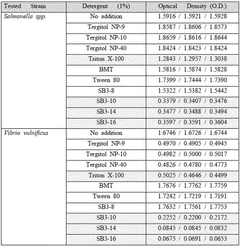

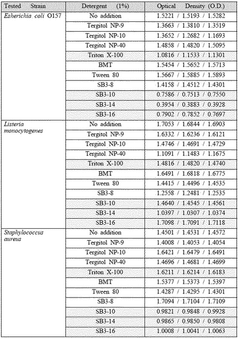

Microfluidic technology has rapidly evolved to become a cornerstone in modern food quality assessment systems. Currently, these miniaturized laboratories are deployed across various segments of the food industry, from raw material inspection to finished product evaluation. The integration of microfluidic platforms with sensing technologies has enabled rapid detection of foodborne pathogens including Salmonella, E. coli, and Listeria monocytogenes, with detection times reduced from traditional 24-72 hours to under 2 hours in some advanced systems.

Paper-based microfluidic devices (μPADs) represent one of the most cost-effective implementations in the field, utilizing capillary action to transport samples through hydrophilic channels. These devices have gained significant traction in resource-limited settings due to their affordability and minimal instrumentation requirements, allowing for on-site detection of adulterants and contaminants in various food products.

Droplet-based microfluidics has emerged as another prominent application, where discrete droplets serve as microreactors for analytical processes. This approach enables high-throughput screening of multiple samples simultaneously, significantly increasing testing efficiency. Commercial systems now routinely process thousands of droplets per second, each functioning as an independent reaction vessel for quality parameters assessment.

Digital microfluidic (DMF) platforms utilize electrowetting principles to manipulate discrete droplets on an array of electrodes. These systems have demonstrated particular utility in complex food matrix analysis, where traditional methods struggle with interference issues. Recent implementations have achieved detection limits in the parts-per-billion range for pesticide residues in fruits and vegetables, meeting stringent regulatory requirements.

Organ-on-a-chip technologies, though primarily developed for biomedical applications, have been adapted for food toxicity testing. These systems simulate human physiological responses to food components, providing more relevant data than traditional cell culture or animal testing. Several research institutions have developed gut-on-a-chip models specifically designed to evaluate the bioavailability and potential toxicity of food additives and contaminants.

Integrated microfluidic systems combining sample preparation, amplification, and detection functions have revolutionized molecular testing in food safety. These "sample-to-answer" platforms reduce human intervention, minimizing contamination risks while improving reproducibility. Commercial systems now offer fully automated nucleic acid-based detection of pathogens from complex food matrices within 30-60 minutes, compared to conventional PCR methods requiring specialized laboratory facilities and trained personnel.

The integration of smartphone-based detection with microfluidic chips has democratized food testing capabilities, allowing consumers and small-scale producers to perform quality assessments previously restricted to specialized laboratories. These systems typically utilize colorimetric or fluorescence-based detection methods coupled with image analysis algorithms to provide quantitative results through user-friendly mobile applications.

Paper-based microfluidic devices (μPADs) represent one of the most cost-effective implementations in the field, utilizing capillary action to transport samples through hydrophilic channels. These devices have gained significant traction in resource-limited settings due to their affordability and minimal instrumentation requirements, allowing for on-site detection of adulterants and contaminants in various food products.

Droplet-based microfluidics has emerged as another prominent application, where discrete droplets serve as microreactors for analytical processes. This approach enables high-throughput screening of multiple samples simultaneously, significantly increasing testing efficiency. Commercial systems now routinely process thousands of droplets per second, each functioning as an independent reaction vessel for quality parameters assessment.

Digital microfluidic (DMF) platforms utilize electrowetting principles to manipulate discrete droplets on an array of electrodes. These systems have demonstrated particular utility in complex food matrix analysis, where traditional methods struggle with interference issues. Recent implementations have achieved detection limits in the parts-per-billion range for pesticide residues in fruits and vegetables, meeting stringent regulatory requirements.

Organ-on-a-chip technologies, though primarily developed for biomedical applications, have been adapted for food toxicity testing. These systems simulate human physiological responses to food components, providing more relevant data than traditional cell culture or animal testing. Several research institutions have developed gut-on-a-chip models specifically designed to evaluate the bioavailability and potential toxicity of food additives and contaminants.

Integrated microfluidic systems combining sample preparation, amplification, and detection functions have revolutionized molecular testing in food safety. These "sample-to-answer" platforms reduce human intervention, minimizing contamination risks while improving reproducibility. Commercial systems now offer fully automated nucleic acid-based detection of pathogens from complex food matrices within 30-60 minutes, compared to conventional PCR methods requiring specialized laboratory facilities and trained personnel.

The integration of smartphone-based detection with microfluidic chips has democratized food testing capabilities, allowing consumers and small-scale producers to perform quality assessments previously restricted to specialized laboratories. These systems typically utilize colorimetric or fluorescence-based detection methods coupled with image analysis algorithms to provide quantitative results through user-friendly mobile applications.

Existing Microfluidic Solutions for Food Quality Testing

01 Microfluidic detection systems for food contaminants

Microfluidic chips designed specifically for detecting contaminants in food samples, including pathogens, toxins, and chemical residues. These systems utilize various detection methods such as optical, electrochemical, or fluorescence-based techniques to identify harmful substances in food products. The chips enable rapid and sensitive detection, allowing for on-site testing and reducing the time required for food safety assessment compared to traditional laboratory methods.- Microfluidic detection systems for food contaminants: Microfluidic chips can be designed with integrated detection systems to identify various contaminants in food samples. These systems utilize sensors that can detect pathogens, toxins, and chemical residues in food products. The detection methods often incorporate electrochemical, optical, or fluorescence-based sensing technologies that provide rapid and sensitive analysis of food samples, enabling real-time monitoring of food quality and safety parameters.

- Lab-on-a-chip devices for food quality analysis: Lab-on-a-chip devices integrate multiple laboratory functions on a single microfluidic platform for comprehensive food quality testing. These miniaturized systems can perform sample preparation, separation, and analysis in a single device, reducing the need for complex laboratory equipment. The technology enables rapid screening of food samples for various quality parameters including nutritional content, freshness indicators, and adulterants, making it suitable for both field and laboratory applications.

- Biosensor integration in microfluidic platforms: Microfluidic chips can be integrated with biosensors to enhance the specificity and sensitivity of food quality testing. These biosensors utilize biological recognition elements such as enzymes, antibodies, or nucleic acids to detect specific compounds or microorganisms in food samples. The combination of biosensors with microfluidic technology allows for multiplexed detection of multiple analytes simultaneously, providing comprehensive assessment of food quality and safety in a single test.

- Automated sample processing in microfluidic systems: Microfluidic chips can be designed with automated sample processing capabilities for efficient food quality testing. These systems incorporate features for sample preparation, including filtration, concentration, and extraction of target analytes from complex food matrices. Automated fluid handling within the microchannels ensures precise control over sample volumes and reaction conditions, improving the reproducibility and reliability of food quality tests while minimizing human intervention and potential contamination.

- Portable microfluidic devices for on-site food testing: Portable microfluidic devices enable on-site testing of food quality parameters without the need for sophisticated laboratory facilities. These compact systems are designed for field use throughout the food supply chain, from production to retail. The devices often incorporate simplified user interfaces, battery operation, and wireless connectivity for data transmission. This portability allows for rapid decision-making regarding food quality and safety at critical control points, reducing the time and cost associated with traditional laboratory testing methods.

02 Lab-on-a-chip devices for food quality analysis

Integrated microfluidic platforms that combine multiple analytical functions on a single chip for comprehensive food quality assessment. These lab-on-a-chip devices incorporate sample preparation, separation, and detection capabilities to analyze various quality parameters of food products. The miniaturized systems enable portable testing solutions for field use, allowing food producers and regulatory agencies to perform quality control tests with minimal equipment and expertise requirements.Expand Specific Solutions03 Sensor integration in microfluidic platforms for food freshness monitoring

Microfluidic chips equipped with specialized sensors for monitoring food freshness parameters such as pH, gas composition, microbial growth, and metabolite levels. These integrated sensing platforms can detect early signs of food spoilage through chemical and biological markers. The technology enables continuous monitoring of food products throughout the supply chain, providing real-time data on product freshness and helping to reduce food waste through timely intervention.Expand Specific Solutions04 Automated microfluidic systems for food composition analysis

Automated microfluidic platforms designed for analyzing the nutritional composition and authenticity of food products. These systems can quantify proteins, fats, carbohydrates, vitamins, and other nutrients in food samples with high precision. The automation of sample handling, reagent mixing, and data analysis reduces human error and increases throughput. These technologies are particularly valuable for detecting food fraud, verifying product claims, and ensuring compliance with labeling regulations.Expand Specific Solutions05 Portable microfluidic devices for on-site food testing

Compact and portable microfluidic devices specifically designed for on-site testing of food quality and safety parameters. These devices are engineered to be user-friendly, requiring minimal training and equipment to operate in field conditions. They often incorporate smartphone integration for data analysis and sharing, enabling rapid decision-making at various points in the food supply chain. The portability aspect allows for testing to occur at farms, processing facilities, distribution centers, and retail locations.Expand Specific Solutions

Leading Companies in Food Testing Microfluidics

The microfluidic chip market for food quality testing is currently in a growth phase, with increasing adoption driven by demands for faster, more accurate food safety analysis. The global market is expanding rapidly, estimated to reach significant value as food safety concerns intensify worldwide. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Lansion Biotechnology and Pattern Bioscience are advancing rapid detection technologies, while academic institutions like Tsinghua University, Cornell, and Jiangsu University contribute fundamental research. Established corporations such as Haier Smart Home and Riken are exploring integration opportunities. Green City Agricultural Testing and Boao Biology Group focus specifically on food safety applications, indicating the technology's commercial viability despite remaining challenges in standardization and cost-effectiveness.

Pattern Bioscience, Inc.

Technical Solution: Pattern Bioscience has developed advanced microfluidic chip technology for rapid food quality testing that integrates multiple detection methods on a single platform. Their system employs digital microfluidics to manipulate discrete droplets containing food samples across an array of biosensors, enabling simultaneous detection of multiple pathogens and contaminants. The technology utilizes impedance-based detection combined with molecular recognition elements to identify bacterial contamination in food samples within 2-4 hours, compared to traditional methods requiring 24-72 hours. Their proprietary microfluidic chips incorporate antimicrobial resistance (AMR) testing capabilities, allowing for comprehensive food safety analysis that can detect both the presence of pathogens and their potential resistance to common treatments, providing critical information for food safety management systems.

Strengths: Significantly faster detection times compared to conventional methods; multiplexed testing capabilities allowing simultaneous screening for multiple contaminants; reduced reagent consumption due to microfluidic architecture. Weaknesses: Higher initial implementation costs compared to traditional testing methods; requires specialized training for operation; sensitivity may be affected by complex food matrices.

Life Technologies Corp.

Technical Solution: Life Technologies has pioneered a comprehensive microfluidic platform specifically designed for food quality testing applications. Their system integrates sample preparation, nucleic acid amplification, and multi-analyte detection on a single microfluidic chip. The technology employs digital PCR capabilities within microfluidic channels to achieve detection limits as low as 1-5 CFU/mL for common foodborne pathogens such as E. coli, Salmonella, and Listeria. Their chips feature integrated heating elements and temperature sensors for precise thermal control during amplification processes, enhancing detection accuracy. The platform incorporates fluorescence-based detection systems with multiple wavelength capabilities, allowing for multiplexed identification of different contaminants simultaneously. Additionally, their proprietary surface chemistry reduces biofouling and sample carryover, addressing common challenges in food sample analysis where proteins and fats can interfere with detection systems.

Strengths: Exceptional sensitivity with industry-leading detection limits; comprehensive sample-to-result workflow integration reducing handling steps; robust performance across diverse food matrices including dairy, meat, and produce. Weaknesses: Higher cost per test compared to bulk traditional methods; requires dedicated instrumentation platform; limited shelf-life of reagent-loaded microfluidic chips.

Key Innovations in Microfluidic Food Testing Technologies

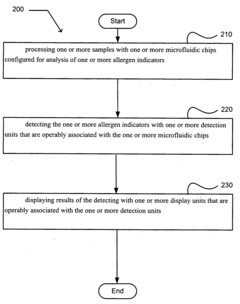

Microfluidic chips for allergen detection

PatentInactiveUS20080181821A1

Innovation

- The use of microfluidic chips configured with accepting units, analysis units, and detection units that can process and detect allergen indicators through various methods such as nucleic acid hybridization, immunological methods, and chromatography, along with reagent delivery and centrifugation units, enables efficient sample processing and detection.

Microfluidic paper chip for detecting micro-organism, method for preparing the same and method for detecting micro-organism using the same

PatentWO2019124904A1

Innovation

- A microfluidic paper chip with sequentially stacked hydrophilic paper layers containing a lytic reagent composition and a chromogenic reagent, allowing for easy and quick detection of microorganisms through color development, using a chromogenic substrate that reacts with specific enzymes, and includes an oxidation layer to enhance detection speed.

Regulatory Standards for Food Testing Technologies

The global food safety regulatory landscape has evolved significantly in response to technological advancements in testing methodologies. For microfluidic chip technology in food quality testing, compliance with established regulatory standards is paramount for market acceptance and implementation. The FDA in the United States has developed specific guidelines under the Food Safety Modernization Act (FSMA) that outline validation requirements for rapid detection methods, including those utilizing microfluidic platforms. These standards emphasize sensitivity, specificity, and reproducibility benchmarks that must be met before commercial deployment.

The European Food Safety Authority (EFSA) has established complementary frameworks through Regulation (EC) No 2073/2005 on microbiological criteria for foodstuffs, which was updated in 2019 to incorporate considerations for novel testing technologies. These regulations specify performance criteria rather than prescribing specific methodologies, allowing innovation while maintaining rigorous safety standards. Microfluidic technologies must demonstrate equivalence to reference methods through collaborative studies and validation protocols.

In Asia, China's National Food Safety Standard GB 4789 series and Japan's Food Sanitation Law enforcement regulations have been updated between 2016-2021 to accommodate rapid detection technologies. These frameworks increasingly recognize the value of microfluidic approaches while maintaining stringent verification requirements. The Chinese market, in particular, has seen accelerated adoption of new standards for contaminant detection that specifically reference microfluidic capabilities.

International harmonization efforts through organizations like Codex Alimentarius and ISO have resulted in standards such as ISO 16140 for method validation and ISO 22174 for nucleic acid-based detection systems. These standards provide crucial benchmarks for microfluidic chip developers seeking multinational approval. The ISO/TC 34 committee has been particularly active in developing technical specifications for emerging food testing technologies.

Regulatory compliance pathways typically require extensive validation studies comparing microfluidic methods against established reference techniques. This process includes multi-laboratory collaborative studies, robustness testing across diverse food matrices, and statistical analysis of detection limits and false positive/negative rates. For microfluidic chip manufacturers, navigating these requirements represents a significant investment but is essential for commercial viability.

Recent regulatory trends indicate movement toward risk-based approaches that may accelerate approval processes for technologies demonstrating exceptional reliability. The FDA's 2022 "New Era of Smarter Food Safety" blueprint specifically highlights the potential for microfluidic and other rapid testing technologies to enhance food safety monitoring systems, suggesting a supportive regulatory environment for continued innovation in this space.

The European Food Safety Authority (EFSA) has established complementary frameworks through Regulation (EC) No 2073/2005 on microbiological criteria for foodstuffs, which was updated in 2019 to incorporate considerations for novel testing technologies. These regulations specify performance criteria rather than prescribing specific methodologies, allowing innovation while maintaining rigorous safety standards. Microfluidic technologies must demonstrate equivalence to reference methods through collaborative studies and validation protocols.

In Asia, China's National Food Safety Standard GB 4789 series and Japan's Food Sanitation Law enforcement regulations have been updated between 2016-2021 to accommodate rapid detection technologies. These frameworks increasingly recognize the value of microfluidic approaches while maintaining stringent verification requirements. The Chinese market, in particular, has seen accelerated adoption of new standards for contaminant detection that specifically reference microfluidic capabilities.

International harmonization efforts through organizations like Codex Alimentarius and ISO have resulted in standards such as ISO 16140 for method validation and ISO 22174 for nucleic acid-based detection systems. These standards provide crucial benchmarks for microfluidic chip developers seeking multinational approval. The ISO/TC 34 committee has been particularly active in developing technical specifications for emerging food testing technologies.

Regulatory compliance pathways typically require extensive validation studies comparing microfluidic methods against established reference techniques. This process includes multi-laboratory collaborative studies, robustness testing across diverse food matrices, and statistical analysis of detection limits and false positive/negative rates. For microfluidic chip manufacturers, navigating these requirements represents a significant investment but is essential for commercial viability.

Recent regulatory trends indicate movement toward risk-based approaches that may accelerate approval processes for technologies demonstrating exceptional reliability. The FDA's 2022 "New Era of Smarter Food Safety" blueprint specifically highlights the potential for microfluidic and other rapid testing technologies to enhance food safety monitoring systems, suggesting a supportive regulatory environment for continued innovation in this space.

Cost-Benefit Analysis of Microfluidic Implementation

Implementing microfluidic technology for food quality testing requires careful evaluation of both financial investments and potential returns. Initial capital expenditure for microfluidic systems ranges from $50,000 to $200,000, depending on complexity, automation level, and analytical capabilities. This includes costs for chip fabrication equipment, detection systems, and supporting infrastructure. Additionally, organizations must consider recurring expenses for specialized materials, reagents, and maintenance, estimated at $10,000-30,000 annually.

Personnel training represents another significant investment, requiring specialized knowledge in microfluidics operation and data interpretation. Training programs typically cost $5,000-15,000 per technical staff member, with ongoing professional development necessary as technology evolves.

Against these expenses, microfluidic implementation offers substantial benefits. Testing time reduction from days to hours or minutes translates to approximately 70-90% decrease in analysis duration. This efficiency allows for higher testing throughput and faster product release cycles, directly impacting revenue generation.

Sample consumption efficiency presents another economic advantage, with microfluidic systems requiring only microliters compared to milliliters in conventional testing. This represents a 95-99% reduction in reagent usage, significantly lowering per-test costs over time. For large-scale operations processing thousands of samples monthly, annual savings can exceed $50,000 in consumables alone.

Quality control improvements deliver perhaps the most substantial economic benefit. Early contaminant detection prevents costly product recalls, which average $10 million per incident in the food industry according to FDA data. By identifying quality issues before distribution, companies avoid not only direct recall expenses but also brand damage and potential legal liabilities.

Return on investment calculations indicate most food producers can expect to recoup microfluidic implementation costs within 18-36 months, depending on testing volume. Organizations processing over 5,000 samples annually typically achieve faster payback periods. The technology becomes increasingly cost-effective as testing requirements grow, making it particularly valuable for larger operations or those facing stringent regulatory compliance demands.

Long-term economic analysis suggests microfluidic technology adoption creates competitive advantages through improved product consistency, reduced time-to-market, and enhanced food safety assurance. These factors contribute to brand premium potential and market differentiation that extend beyond direct operational savings.

Personnel training represents another significant investment, requiring specialized knowledge in microfluidics operation and data interpretation. Training programs typically cost $5,000-15,000 per technical staff member, with ongoing professional development necessary as technology evolves.

Against these expenses, microfluidic implementation offers substantial benefits. Testing time reduction from days to hours or minutes translates to approximately 70-90% decrease in analysis duration. This efficiency allows for higher testing throughput and faster product release cycles, directly impacting revenue generation.

Sample consumption efficiency presents another economic advantage, with microfluidic systems requiring only microliters compared to milliliters in conventional testing. This represents a 95-99% reduction in reagent usage, significantly lowering per-test costs over time. For large-scale operations processing thousands of samples monthly, annual savings can exceed $50,000 in consumables alone.

Quality control improvements deliver perhaps the most substantial economic benefit. Early contaminant detection prevents costly product recalls, which average $10 million per incident in the food industry according to FDA data. By identifying quality issues before distribution, companies avoid not only direct recall expenses but also brand damage and potential legal liabilities.

Return on investment calculations indicate most food producers can expect to recoup microfluidic implementation costs within 18-36 months, depending on testing volume. Organizations processing over 5,000 samples annually typically achieve faster payback periods. The technology becomes increasingly cost-effective as testing requirements grow, making it particularly valuable for larger operations or those facing stringent regulatory compliance demands.

Long-term economic analysis suggests microfluidic technology adoption creates competitive advantages through improved product consistency, reduced time-to-market, and enhanced food safety assurance. These factors contribute to brand premium potential and market differentiation that extend beyond direct operational savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!