The Impact of Microfluidic Chips on Chemical Reaction Kinetics

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Technology Evolution and Objectives

Microfluidic technology has evolved significantly since its inception in the early 1990s, transforming from simple channel-based systems to sophisticated integrated platforms capable of performing complex chemical operations. The initial development phase focused primarily on fabrication techniques, with polydimethylsiloxane (PDMS) emerging as a dominant material due to its optical transparency, gas permeability, and ease of prototyping. This period established the foundational capabilities for fluid manipulation at the microscale.

The second evolutionary phase, spanning approximately 2000-2010, witnessed the integration of additional functionalities such as valves, pumps, and mixers, enabling more precise control over fluid dynamics. During this period, researchers began exploring the potential of microfluidic systems for enhancing chemical reaction kinetics, recognizing the advantages offered by high surface-to-volume ratios, efficient heat transfer, and precise control over reaction parameters.

From 2010 onwards, microfluidic technology entered a phase of application-specific development, with particular emphasis on chemical synthesis, analytical chemistry, and biological applications. The miniaturization of reaction environments facilitated unprecedented control over reaction conditions, allowing researchers to achieve reaction kinetics unattainable in conventional batch reactors. This period also saw the emergence of droplet-based microfluidics, which enabled compartmentalization of reactions and high-throughput experimentation.

Recent advancements have focused on integrating microfluidic chips with advanced detection systems, computational modeling, and automation technologies. The development of "lab-on-a-chip" devices has demonstrated the potential for complete chemical workflows to be executed within a single integrated platform, significantly reducing analysis time and reagent consumption while enhancing reaction efficiency and selectivity.

The current technological trajectory aims to address several key objectives in the context of chemical reaction kinetics. Primary among these is the development of standardized platforms that can reliably reproduce reaction conditions across different laboratories, addressing the challenge of reproducibility in chemical research. Additionally, there is significant interest in scaling microfluidic technologies to accommodate industrial production volumes while maintaining the kinetic advantages observed at the microscale.

Another critical objective is the integration of real-time monitoring capabilities to enable in situ analysis of reaction progress and kinetics. This includes the development of embedded sensors and spectroscopic techniques compatible with microfluidic environments. Furthermore, researchers are pursuing the creation of predictive models that can accurately simulate reaction behavior in microfluidic environments, facilitating rational design of reaction conditions and chip architectures for specific chemical transformations.

The ultimate goal of this technological evolution is to establish microfluidic platforms as standard tools for chemical reaction development, optimization, and execution, fundamentally changing how chemists approach reaction kinetics and process development across academic and industrial settings.

The second evolutionary phase, spanning approximately 2000-2010, witnessed the integration of additional functionalities such as valves, pumps, and mixers, enabling more precise control over fluid dynamics. During this period, researchers began exploring the potential of microfluidic systems for enhancing chemical reaction kinetics, recognizing the advantages offered by high surface-to-volume ratios, efficient heat transfer, and precise control over reaction parameters.

From 2010 onwards, microfluidic technology entered a phase of application-specific development, with particular emphasis on chemical synthesis, analytical chemistry, and biological applications. The miniaturization of reaction environments facilitated unprecedented control over reaction conditions, allowing researchers to achieve reaction kinetics unattainable in conventional batch reactors. This period also saw the emergence of droplet-based microfluidics, which enabled compartmentalization of reactions and high-throughput experimentation.

Recent advancements have focused on integrating microfluidic chips with advanced detection systems, computational modeling, and automation technologies. The development of "lab-on-a-chip" devices has demonstrated the potential for complete chemical workflows to be executed within a single integrated platform, significantly reducing analysis time and reagent consumption while enhancing reaction efficiency and selectivity.

The current technological trajectory aims to address several key objectives in the context of chemical reaction kinetics. Primary among these is the development of standardized platforms that can reliably reproduce reaction conditions across different laboratories, addressing the challenge of reproducibility in chemical research. Additionally, there is significant interest in scaling microfluidic technologies to accommodate industrial production volumes while maintaining the kinetic advantages observed at the microscale.

Another critical objective is the integration of real-time monitoring capabilities to enable in situ analysis of reaction progress and kinetics. This includes the development of embedded sensors and spectroscopic techniques compatible with microfluidic environments. Furthermore, researchers are pursuing the creation of predictive models that can accurately simulate reaction behavior in microfluidic environments, facilitating rational design of reaction conditions and chip architectures for specific chemical transformations.

The ultimate goal of this technological evolution is to establish microfluidic platforms as standard tools for chemical reaction development, optimization, and execution, fundamentally changing how chemists approach reaction kinetics and process development across academic and industrial settings.

Market Analysis for Microfluidic-Enhanced Chemical Processes

The microfluidic chip market for chemical applications has experienced significant growth, with a global valuation reaching $4.5 billion in 2022 and projected to exceed $12 billion by 2030, representing a compound annual growth rate of approximately 13%. This robust expansion is primarily driven by increasing demand across pharmaceutical, analytical chemistry, and materials science sectors where precise reaction control is paramount.

Pharmaceutical companies constitute the largest market segment, accounting for nearly 40% of current microfluidic applications in chemical processes. These organizations are increasingly adopting microfluidic technologies to accelerate drug discovery processes, optimize formulation development, and enhance high-throughput screening capabilities. The ability to perform reactions with minimal reagent consumption while maintaining precise control over reaction parameters has proven particularly valuable in an industry where development costs continue to rise.

Academic and research institutions represent another significant market segment, contributing approximately 25% of the current demand. These entities primarily utilize microfluidic platforms for fundamental research in reaction kinetics, catalysis optimization, and novel synthetic methodologies. The detailed reaction insights provided by microfluidic systems have enabled breakthroughs in understanding complex chemical transformations that were previously difficult to monitor in real-time.

Chemical manufacturing companies are emerging as the fastest-growing segment, with adoption rates increasing by 18% annually. These organizations are implementing microfluidic technologies to develop continuous flow processes, optimize catalyst performance, and explore green chemistry applications. The enhanced reaction efficiency and reduced environmental impact align with growing sustainability initiatives across the chemical industry.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, with China and India making substantial investments in microfluidic research infrastructure and manufacturing capabilities. This regional shift reflects broader trends in chemical manufacturing relocation and expanding research capabilities in emerging economies.

Market barriers include high initial investment costs for microfluidic systems, technical expertise requirements for implementation, and challenges in scaling from laboratory demonstrations to industrial production. Despite these obstacles, the market continues to expand as vendors develop more user-friendly systems and demonstrate compelling return-on-investment cases through enhanced reaction yields, reduced waste generation, and accelerated development timelines.

Customer demand increasingly focuses on integrated systems that combine reaction optimization, in-line analysis, and automated control capabilities. This trend is driving partnerships between microfluidic device manufacturers, analytical instrument companies, and software developers to create comprehensive solutions that address end-to-end chemical process development needs.

Pharmaceutical companies constitute the largest market segment, accounting for nearly 40% of current microfluidic applications in chemical processes. These organizations are increasingly adopting microfluidic technologies to accelerate drug discovery processes, optimize formulation development, and enhance high-throughput screening capabilities. The ability to perform reactions with minimal reagent consumption while maintaining precise control over reaction parameters has proven particularly valuable in an industry where development costs continue to rise.

Academic and research institutions represent another significant market segment, contributing approximately 25% of the current demand. These entities primarily utilize microfluidic platforms for fundamental research in reaction kinetics, catalysis optimization, and novel synthetic methodologies. The detailed reaction insights provided by microfluidic systems have enabled breakthroughs in understanding complex chemical transformations that were previously difficult to monitor in real-time.

Chemical manufacturing companies are emerging as the fastest-growing segment, with adoption rates increasing by 18% annually. These organizations are implementing microfluidic technologies to develop continuous flow processes, optimize catalyst performance, and explore green chemistry applications. The enhanced reaction efficiency and reduced environmental impact align with growing sustainability initiatives across the chemical industry.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, with China and India making substantial investments in microfluidic research infrastructure and manufacturing capabilities. This regional shift reflects broader trends in chemical manufacturing relocation and expanding research capabilities in emerging economies.

Market barriers include high initial investment costs for microfluidic systems, technical expertise requirements for implementation, and challenges in scaling from laboratory demonstrations to industrial production. Despite these obstacles, the market continues to expand as vendors develop more user-friendly systems and demonstrate compelling return-on-investment cases through enhanced reaction yields, reduced waste generation, and accelerated development timelines.

Customer demand increasingly focuses on integrated systems that combine reaction optimization, in-line analysis, and automated control capabilities. This trend is driving partnerships between microfluidic device manufacturers, analytical instrument companies, and software developers to create comprehensive solutions that address end-to-end chemical process development needs.

Current Microfluidic Chip Capabilities and Limitations

Microfluidic chips have revolutionized chemical reaction studies by enabling precise control over reaction conditions at microscale levels. Current capabilities include exceptional thermal management, with temperature gradients as precise as 0.1°C across reaction chambers, allowing for unprecedented control over reaction kinetics. These chips can handle reaction volumes in the nanoliter to picoliter range, dramatically reducing reagent consumption by up to 1000-fold compared to conventional methods.

The integration of multiple reaction steps on a single chip represents another significant advancement. Modern microfluidic platforms can incorporate mixing chambers, reaction zones, separation channels, and detection areas in devices smaller than a credit card. This integration enables complex multi-step reactions to be performed with minimal human intervention, reducing both experimental time and potential for contamination.

Real-time monitoring capabilities have also evolved substantially, with integrated sensors capable of measuring pH, temperature, pressure, and concentration changes during reactions. Advanced optical detection methods, including fluorescence spectroscopy and Raman spectroscopy, can be directly integrated into chip designs, providing immediate feedback on reaction progress and product formation.

Despite these impressive capabilities, microfluidic technology faces several limitations. Material compatibility remains a significant challenge, as many chemical reactions involve solvents that can degrade common chip materials like PDMS (polydimethylsiloxane). While glass and silicon alternatives offer better chemical resistance, they come with higher manufacturing costs and reduced design flexibility.

Scaling issues present another major limitation. While microfluidic chips excel at small-scale reactions and analysis, translating these advantages to industrial production volumes remains problematic. The "scaling out" approach (using multiple parallel chips) rather than "scaling up" introduces complexity in system control and uniformity maintenance across multiple devices.

Surface effects become increasingly dominant at the microscale, sometimes leading to unpredictable reaction behavior. The high surface-to-volume ratio in microchannels can cause significant adsorption of reagents onto channel walls, altering effective concentrations and potentially catalyzing unwanted side reactions.

Clogging and fouling represent persistent operational challenges, particularly for reactions involving precipitates or biological materials. Even microscopic particles can obstruct the narrow channels typical in microfluidic devices, leading to pressure buildup and potential system failure.

Standardization across the field remains limited, with researchers often developing custom chips for specific applications. This lack of standardization hampers reproducibility between laboratories and slows the broader adoption of microfluidic technology in chemical research and industrial applications.

The integration of multiple reaction steps on a single chip represents another significant advancement. Modern microfluidic platforms can incorporate mixing chambers, reaction zones, separation channels, and detection areas in devices smaller than a credit card. This integration enables complex multi-step reactions to be performed with minimal human intervention, reducing both experimental time and potential for contamination.

Real-time monitoring capabilities have also evolved substantially, with integrated sensors capable of measuring pH, temperature, pressure, and concentration changes during reactions. Advanced optical detection methods, including fluorescence spectroscopy and Raman spectroscopy, can be directly integrated into chip designs, providing immediate feedback on reaction progress and product formation.

Despite these impressive capabilities, microfluidic technology faces several limitations. Material compatibility remains a significant challenge, as many chemical reactions involve solvents that can degrade common chip materials like PDMS (polydimethylsiloxane). While glass and silicon alternatives offer better chemical resistance, they come with higher manufacturing costs and reduced design flexibility.

Scaling issues present another major limitation. While microfluidic chips excel at small-scale reactions and analysis, translating these advantages to industrial production volumes remains problematic. The "scaling out" approach (using multiple parallel chips) rather than "scaling up" introduces complexity in system control and uniformity maintenance across multiple devices.

Surface effects become increasingly dominant at the microscale, sometimes leading to unpredictable reaction behavior. The high surface-to-volume ratio in microchannels can cause significant adsorption of reagents onto channel walls, altering effective concentrations and potentially catalyzing unwanted side reactions.

Clogging and fouling represent persistent operational challenges, particularly for reactions involving precipitates or biological materials. Even microscopic particles can obstruct the narrow channels typical in microfluidic devices, leading to pressure buildup and potential system failure.

Standardization across the field remains limited, with researchers often developing custom chips for specific applications. This lack of standardization hampers reproducibility between laboratories and slows the broader adoption of microfluidic technology in chemical research and industrial applications.

Existing Microfluidic Solutions for Reaction Kinetics Enhancement

01 Microfluidic chip design for reaction kinetics analysis

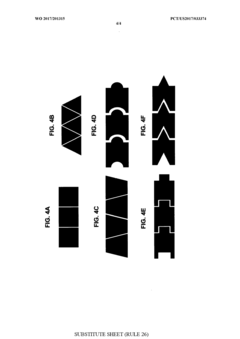

Specialized microfluidic chip designs can enhance reaction kinetics analysis by providing precise control over fluid flow, mixing, and residence time. These designs incorporate features such as gradient generators, mixing chambers, and reaction zones that allow for real-time monitoring of chemical reactions. The miniaturized environment enables rapid diffusion and efficient heat transfer, resulting in more accurate kinetic measurements with minimal sample consumption.- Microfluidic chip designs for reaction kinetics analysis: Various microfluidic chip designs have been developed specifically for studying reaction kinetics. These designs incorporate features such as multiple reaction chambers, gradient generators, and specialized channel geometries that allow for precise control of reaction conditions and real-time monitoring of chemical reactions. The designs enable researchers to study reaction kinetics with minimal reagent consumption and high throughput capabilities.

- Integration of sensors for real-time monitoring: Microfluidic chips can be integrated with various sensors to enable real-time monitoring of reaction kinetics. These sensors may include optical detectors, electrochemical sensors, or spectroscopic tools that can measure changes in reaction parameters such as concentration, temperature, or pH. The integration of these sensors allows for continuous data collection during reactions, providing detailed insights into reaction mechanisms and kinetics without the need for sampling.

- Temperature control systems for kinetic studies: Advanced temperature control systems are incorporated into microfluidic chips to study the effect of temperature on reaction kinetics. These systems may include integrated heating elements, cooling channels, or thermal gradient generators that allow precise manipulation of reaction temperatures. By controlling temperature with high spatial and temporal resolution, researchers can determine activation energies and other thermodynamic parameters of reactions occurring within the microfluidic environment.

- Droplet-based microfluidics for kinetic measurements: Droplet-based microfluidic systems enable the study of reaction kinetics in isolated microdroplets that act as individual reaction vessels. These systems can generate thousands of uniform droplets per second, each serving as a discrete reaction environment. The approach allows for high-throughput screening of reaction conditions, rapid mixing of reagents, and statistical analysis of reaction kinetics with minimal sample consumption and cross-contamination.

- Computational modeling and automation for kinetic analysis: Computational modeling and automation technologies are integrated with microfluidic chips to enhance reaction kinetics analysis. These systems include automated fluid handling, data acquisition software, and computational models that can predict reaction behaviors or interpret experimental results. Machine learning algorithms can be applied to analyze complex reaction networks, while automation enables high-throughput experimentation with minimal human intervention, increasing reproducibility and efficiency in kinetic studies.

02 Integration of sensors for real-time reaction monitoring

Microfluidic chips can be integrated with various sensing technologies to enable real-time monitoring of reaction kinetics. These sensors may include optical detectors, electrochemical sensors, or spectroscopic instruments that can measure reaction parameters continuously. The integration allows for in-situ data collection, eliminating the need for sampling and providing more accurate kinetic information by capturing transient states that might be missed in conventional batch reactions.Expand Specific Solutions03 Parallel processing for high-throughput kinetic studies

Microfluidic platforms can be designed with multiple parallel reaction channels to enable high-throughput kinetic studies. This approach allows for simultaneous testing of different reaction conditions, catalysts, or reagent concentrations, significantly accelerating the optimization process. The parallelization capability combined with precise control over reaction parameters makes these systems ideal for screening applications and kinetic model development.Expand Specific Solutions04 Temperature control systems for kinetic measurements

Advanced temperature control systems integrated into microfluidic chips enable precise manipulation of reaction conditions for kinetic studies. These systems may include heating elements, cooling channels, or thermal gradient generators that can maintain stable temperatures or create controlled temperature profiles across the chip. The ability to rapidly change temperatures allows for studying temperature-dependent kinetics and determining activation energies with high precision.Expand Specific Solutions05 Computational modeling of microfluidic reaction kinetics

Computational fluid dynamics and reaction modeling techniques can be applied to microfluidic systems to predict and analyze reaction kinetics. These models account for the unique transport phenomena in microchannels, including laminar flow patterns, diffusion limitations, and surface interactions. The integration of experimental data with computational models enables more comprehensive understanding of reaction mechanisms and facilitates the design of optimized microfluidic reactors for specific chemical processes.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidics

The microfluidic chip market for chemical reaction kinetics is currently in a growth phase, with increasing adoption across pharmaceutical, chemical, and academic research sectors. The global market size is estimated to reach $25-30 billion by 2027, expanding at a CAGR of approximately 18%. Technology maturity varies across applications, with established players like Agilent Technologies and Roche Diagnostics offering commercial solutions, while research institutions such as California Institute of Technology, Tsinghua University, and Zhejiang University drive innovation through fundamental research. Companies like Nanobiose and LC-Bio Technologies represent specialized entrants focusing on niche applications. The competitive landscape features a mix of large corporations (Siemens, Samsung Electronics) leveraging their manufacturing capabilities and smaller biotechnology firms developing proprietary microfluidic platforms for specific chemical reaction applications.

AGILENT TECHNOLOGIES INC

Technical Solution: Agilent Technologies has developed comprehensive microfluidic solutions specifically targeting chemical reaction kinetics analysis through their LabChip platform. Their technology integrates multiple analytical functions onto a single chip, including sample preparation, reagent mixing, reaction monitoring, and product analysis. Agilent's microfluidic systems feature precision-engineered flow channels with controlled geometries that ensure reproducible mixing conditions and residence times, critical for accurate kinetic measurements. Their platforms incorporate proprietary surface treatments to minimize unwanted interactions between channel walls and reactants, addressing a common challenge in microfluidic reaction studies. A key innovation in Agilent's approach is the integration of their analytical instrumentation expertise, allowing for seamless coupling of microfluidic reactors with detection technologies such as mass spectrometry and capillary electrophoresis. This enables real-time monitoring of reaction intermediates and products with high sensitivity. Agilent has demonstrated particular success in applying their microfluidic technology to enzyme kinetics studies, where their systems can determine Michaelis-Menten parameters with significantly reduced enzyme consumption compared to conventional methods.

Strengths: Seamless integration with established analytical platforms providing comprehensive data collection; robust manufacturing processes ensuring chip-to-chip reproducibility; user-friendly software interface making the technology accessible to non-specialists. Weaknesses: Higher initial investment compared to traditional batch reactors; limited flexibility for custom modifications compared to academic research platforms; challenges in handling reactions involving precipitation or gas evolution.

The Regents of the University of California

Technical Solution: The University of California has pioneered microfluidic chip technology for chemical reaction kinetics through their development of droplet-based microreactors. Their approach utilizes precisely controlled microdroplets as individual reaction vessels, allowing for high-throughput screening of reaction conditions with minimal reagent consumption. The technology incorporates integrated sensors for real-time monitoring of reaction parameters including temperature, pH, and concentration gradients. Their platforms feature programmable flow control systems that enable precise manipulation of reaction times from milliseconds to hours, facilitating the study of both fast and slow reaction kinetics. Recent innovations include the integration of spectroscopic analysis directly onto the chip, allowing for in-situ characterization of reaction intermediates and products without sample extraction. The University's microfluidic systems have demonstrated particular success in studying enzyme kinetics and catalyst optimization, where their ability to maintain precise temperature control (±0.1°C) has proven invaluable for determining accurate activation energies and reaction rate constants.

Strengths: Superior control over reaction parameters with exceptional precision in temperature and mixing conditions; significantly reduced reagent consumption (up to 1000× less than conventional methods); high-throughput capability allowing parallel testing of multiple reaction conditions. Weaknesses: Complex fabrication processes requiring specialized cleanroom facilities; potential for surface interactions between reactants and channel walls that may influence reaction kinetics; scaling challenges when transitioning from microfluidic studies to industrial production.

Key Patents and Breakthroughs in Microfluidic Reaction Control

Quantitative real time PCR amplification using an electrowetting-based device

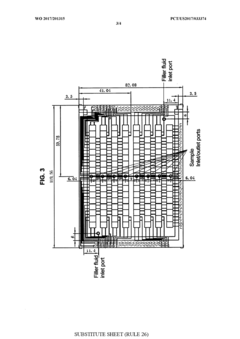

PatentWO2017201315A1

Innovation

- An electrowetting-based device is used to automate nucleic acid amplification by creating and manipulating droplets containing primers and target nucleic acids, allowing for parallel amplification, real-time quantitation, and recovery of the amplification product for further analysis.

Patent

Innovation

- Integration of microfluidic chips with precise control over reaction parameters (temperature, pressure, mixing) enabling enhanced reaction kinetics monitoring at microscale levels.

- Implementation of real-time analysis capabilities within microfluidic platforms allowing for continuous monitoring of reaction intermediates and products with minimal sample volumes.

- Parallelization of multiple reaction channels in a single microfluidic device enabling high-throughput screening and optimization of reaction conditions.

Scale-up Challenges and Industrial Implementation

Despite the promising laboratory results of microfluidic technology in enhancing chemical reaction kinetics, transitioning these systems to industrial scale presents significant challenges. The fundamental issue lies in the inherent design of microfluidic devices, which typically operate with flow rates in the microliter to milliliter range, whereas industrial processes often require throughput measured in liters or cubic meters per hour. This volume mismatch creates a substantial scaling barrier that must be addressed through innovative engineering approaches.

One primary strategy for scale-up involves "numbering up" rather than traditional scaling up. This approach utilizes multiple parallel microfluidic units operating simultaneously, maintaining the advantageous reaction conditions while increasing overall throughput. However, this method introduces complex challenges in flow distribution, ensuring uniform conditions across all parallel channels, and developing robust control systems capable of managing numerous simultaneous processes.

Material selection becomes increasingly critical at industrial scales. While laboratory prototypes often utilize PDMS (polydimethylsiloxane) or glass, these materials may be impractical for large-scale implementation due to cost, durability, or manufacturing constraints. Industrial applications typically require materials that can withstand harsh chemical environments, high pressures, and extended operational periods, such as specialized polymers, ceramics, or corrosion-resistant metals.

Manufacturing precision represents another significant hurdle. Industrial microfluidic systems must maintain the same channel dimensions and surface characteristics that enable enhanced reaction kinetics at the laboratory scale. This necessitates advanced manufacturing techniques capable of producing high-precision components consistently and cost-effectively at larger volumes, potentially including 3D printing, laser ablation, or specialized injection molding processes.

Integration with existing industrial infrastructure poses additional challenges. Microfluidic systems must interface with conventional chemical processing equipment, requiring careful design of inlet/outlet systems, pressure management, and monitoring capabilities. Furthermore, industrial implementation demands robust automation systems for continuous operation, real-time monitoring, and quality control that exceed the requirements of laboratory demonstrations.

Economic considerations ultimately determine industrial adoption. The capital investment for implementing microfluidic technology must be justified by improved yields, reduced waste, enhanced product quality, or other tangible benefits. Additionally, operational costs, maintenance requirements, and system lifespan must compare favorably with conventional batch processing methods to achieve widespread industrial acceptance.

One primary strategy for scale-up involves "numbering up" rather than traditional scaling up. This approach utilizes multiple parallel microfluidic units operating simultaneously, maintaining the advantageous reaction conditions while increasing overall throughput. However, this method introduces complex challenges in flow distribution, ensuring uniform conditions across all parallel channels, and developing robust control systems capable of managing numerous simultaneous processes.

Material selection becomes increasingly critical at industrial scales. While laboratory prototypes often utilize PDMS (polydimethylsiloxane) or glass, these materials may be impractical for large-scale implementation due to cost, durability, or manufacturing constraints. Industrial applications typically require materials that can withstand harsh chemical environments, high pressures, and extended operational periods, such as specialized polymers, ceramics, or corrosion-resistant metals.

Manufacturing precision represents another significant hurdle. Industrial microfluidic systems must maintain the same channel dimensions and surface characteristics that enable enhanced reaction kinetics at the laboratory scale. This necessitates advanced manufacturing techniques capable of producing high-precision components consistently and cost-effectively at larger volumes, potentially including 3D printing, laser ablation, or specialized injection molding processes.

Integration with existing industrial infrastructure poses additional challenges. Microfluidic systems must interface with conventional chemical processing equipment, requiring careful design of inlet/outlet systems, pressure management, and monitoring capabilities. Furthermore, industrial implementation demands robust automation systems for continuous operation, real-time monitoring, and quality control that exceed the requirements of laboratory demonstrations.

Economic considerations ultimately determine industrial adoption. The capital investment for implementing microfluidic technology must be justified by improved yields, reduced waste, enhanced product quality, or other tangible benefits. Additionally, operational costs, maintenance requirements, and system lifespan must compare favorably with conventional batch processing methods to achieve widespread industrial acceptance.

Sustainability Impact of Microfluidic Chemical Processing

Microfluidic technology represents a significant advancement in sustainable chemical processing, offering numerous environmental benefits compared to traditional batch processing methods. The miniaturization of reaction vessels in microfluidic systems dramatically reduces reagent consumption, with typical reactions requiring only microliters or nanoliters of chemicals rather than milliliters or liters. This substantial reduction in material usage directly translates to decreased waste generation and lower environmental impact across the chemical value chain.

Energy efficiency stands as another critical sustainability advantage of microfluidic systems. The precise control over reaction conditions enables optimal heat transfer due to high surface-area-to-volume ratios, reducing energy requirements by up to 30-50% compared to conventional methods. This efficiency is particularly evident in exothermic reactions where heat management is crucial, allowing for safer operations with minimal cooling resources.

The enhanced reaction selectivity achieved through microfluidic processing further contributes to sustainability by minimizing unwanted by-products. Studies have demonstrated that microfluidic reactors can improve reaction selectivity by 15-25%, significantly reducing purification requirements and associated waste streams. This improvement directly addresses one of the chemical industry's most persistent environmental challenges: the generation of difficult-to-treat waste products.

Water conservation represents another substantial environmental benefit of microfluidic technology. Traditional chemical processes often require large volumes of water for cooling, cleaning, and dilution steps. Microfluidic systems can reduce water consumption by 40-60% through more efficient thermal management and reduced cleaning requirements, addressing growing concerns about industrial water usage in water-stressed regions.

From a lifecycle perspective, microfluidic chips enable continuous processing models that align with circular economy principles. The ability to rapidly reconfigure microfluidic systems for different reactions promotes equipment reuse, while their inherent efficiency reduces the environmental footprint across production, use, and end-of-life phases. Recent lifecycle assessments indicate that microfluidic-based chemical processing can reduce overall environmental impact by 20-35% compared to batch processing for equivalent chemical outputs.

The integration of microfluidic technology with renewable energy sources presents additional sustainability opportunities. The lower energy requirements and precise control capabilities make these systems ideal candidates for solar or wind-powered operations, potentially enabling distributed, carbon-neutral chemical manufacturing models that could revolutionize how and where chemicals are produced.

Energy efficiency stands as another critical sustainability advantage of microfluidic systems. The precise control over reaction conditions enables optimal heat transfer due to high surface-area-to-volume ratios, reducing energy requirements by up to 30-50% compared to conventional methods. This efficiency is particularly evident in exothermic reactions where heat management is crucial, allowing for safer operations with minimal cooling resources.

The enhanced reaction selectivity achieved through microfluidic processing further contributes to sustainability by minimizing unwanted by-products. Studies have demonstrated that microfluidic reactors can improve reaction selectivity by 15-25%, significantly reducing purification requirements and associated waste streams. This improvement directly addresses one of the chemical industry's most persistent environmental challenges: the generation of difficult-to-treat waste products.

Water conservation represents another substantial environmental benefit of microfluidic technology. Traditional chemical processes often require large volumes of water for cooling, cleaning, and dilution steps. Microfluidic systems can reduce water consumption by 40-60% through more efficient thermal management and reduced cleaning requirements, addressing growing concerns about industrial water usage in water-stressed regions.

From a lifecycle perspective, microfluidic chips enable continuous processing models that align with circular economy principles. The ability to rapidly reconfigure microfluidic systems for different reactions promotes equipment reuse, while their inherent efficiency reduces the environmental footprint across production, use, and end-of-life phases. Recent lifecycle assessments indicate that microfluidic-based chemical processing can reduce overall environmental impact by 20-35% compared to batch processing for equivalent chemical outputs.

The integration of microfluidic technology with renewable energy sources presents additional sustainability opportunities. The lower energy requirements and precise control capabilities make these systems ideal candidates for solar or wind-powered operations, potentially enabling distributed, carbon-neutral chemical manufacturing models that could revolutionize how and where chemicals are produced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!