How Do Microfluidic Chips Influence Environmental Sustainability Efforts?

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Technology Background and Sustainability Goals

Microfluidic technology emerged in the early 1990s as an innovative approach to manipulating fluids at the microscale level, typically handling volumes ranging from picoliters to microliters. The fundamental concept involves controlling fluid flow through channels with dimensions of tens to hundreds of micrometers. This technology evolved from the semiconductor industry's microfabrication techniques, initially utilizing silicon and glass substrates before transitioning to more cost-effective polymer materials like polydimethylsiloxane (PDMS).

The evolution of microfluidic technology has been marked by significant milestones, including the development of lab-on-a-chip devices, organ-on-a-chip platforms, and digital microfluidics. These advancements have transformed various fields, particularly analytical chemistry, biomedical diagnostics, and environmental monitoring, by enabling precise control over small fluid volumes and creating miniaturized laboratory processes.

Environmental sustainability has become increasingly critical in technological development, and microfluidic chips offer substantial potential in this domain. The technology's inherent characteristics—miniaturization, reduced reagent consumption, decreased waste generation, and lower energy requirements—align perfectly with sustainability objectives. These features represent a paradigm shift from conventional laboratory methods that typically require larger volumes of potentially harmful chemicals and generate significant waste.

The sustainability goals associated with microfluidic technology encompass several dimensions. First, resource efficiency aims to minimize the consumption of chemicals, water, and energy in analytical and industrial processes. Second, waste reduction focuses on decreasing the environmental footprint of laboratory and manufacturing operations. Third, green chemistry principles are applied through the development of safer analytical methods that eliminate or reduce hazardous substances.

Current technological trends in microfluidics are moving toward more sustainable materials and manufacturing processes. Researchers are exploring biodegradable polymers, paper-based microfluidics, and environmentally friendly fabrication techniques to replace traditional methods that often involve toxic chemicals. Additionally, the integration of microfluidic systems with renewable energy sources represents an emerging area of development.

Looking forward, the field is evolving toward creating fully integrated, sustainable microfluidic platforms that can address complex environmental challenges. These include real-time environmental monitoring systems, water purification technologies, and tools for assessing ecological impacts. The convergence of microfluidics with other cutting-edge technologies such as artificial intelligence, advanced materials science, and renewable energy systems promises to further enhance its contribution to environmental sustainability efforts.

The evolution of microfluidic technology has been marked by significant milestones, including the development of lab-on-a-chip devices, organ-on-a-chip platforms, and digital microfluidics. These advancements have transformed various fields, particularly analytical chemistry, biomedical diagnostics, and environmental monitoring, by enabling precise control over small fluid volumes and creating miniaturized laboratory processes.

Environmental sustainability has become increasingly critical in technological development, and microfluidic chips offer substantial potential in this domain. The technology's inherent characteristics—miniaturization, reduced reagent consumption, decreased waste generation, and lower energy requirements—align perfectly with sustainability objectives. These features represent a paradigm shift from conventional laboratory methods that typically require larger volumes of potentially harmful chemicals and generate significant waste.

The sustainability goals associated with microfluidic technology encompass several dimensions. First, resource efficiency aims to minimize the consumption of chemicals, water, and energy in analytical and industrial processes. Second, waste reduction focuses on decreasing the environmental footprint of laboratory and manufacturing operations. Third, green chemistry principles are applied through the development of safer analytical methods that eliminate or reduce hazardous substances.

Current technological trends in microfluidics are moving toward more sustainable materials and manufacturing processes. Researchers are exploring biodegradable polymers, paper-based microfluidics, and environmentally friendly fabrication techniques to replace traditional methods that often involve toxic chemicals. Additionally, the integration of microfluidic systems with renewable energy sources represents an emerging area of development.

Looking forward, the field is evolving toward creating fully integrated, sustainable microfluidic platforms that can address complex environmental challenges. These include real-time environmental monitoring systems, water purification technologies, and tools for assessing ecological impacts. The convergence of microfluidics with other cutting-edge technologies such as artificial intelligence, advanced materials science, and renewable energy systems promises to further enhance its contribution to environmental sustainability efforts.

Market Demand for Green Microfluidic Solutions

The global market for green microfluidic solutions has witnessed substantial growth in recent years, driven by increasing environmental concerns and regulatory pressures. Environmental sustainability has become a critical factor influencing purchasing decisions across industries, with microfluidic technology emerging as a key enabler for more sustainable practices. Current market assessments indicate that the green microfluidics sector is expanding at approximately twice the rate of conventional microfluidic applications.

Primary market drivers include the significant reduction in reagent consumption offered by microfluidic systems, with typical applications requiring only picoliters to nanoliters of samples and reagents—representing up to 99% reduction compared to traditional methods. This dramatic decrease in chemical usage directly translates to reduced waste generation and lower environmental impact, creating strong market pull from environmentally conscious sectors.

Healthcare and pharmaceutical industries represent the largest market segment for green microfluidic solutions, particularly in drug discovery and personalized medicine applications. The ability to conduct thousands of parallel reactions with minimal resource consumption aligns perfectly with sustainability initiatives in these sectors. Environmental monitoring applications form the fastest-growing segment, with demand for portable, low-power microfluidic devices for real-time water and air quality analysis increasing substantially.

Consumer preference surveys reveal that organizations are increasingly willing to pay premium prices for microfluidic solutions that demonstrate quantifiable environmental benefits. This trend is particularly pronounced in regions with stringent environmental regulations, such as the European Union and parts of North America, where companies face mounting pressure to reduce their ecological footprint.

Market forecasts project continued strong growth for green microfluidic technologies, with particular emphasis on biodegradable and recyclable chip materials. The development of paper-based and other environmentally friendly substrate materials has opened new market opportunities, especially in point-of-care diagnostics for resource-limited settings.

Industrial adoption of green microfluidic solutions is accelerating as companies recognize both the environmental and economic benefits. The reduced operational costs associated with lower reagent consumption, decreased waste disposal requirements, and energy savings provide compelling economic incentives beyond regulatory compliance. This dual benefit of environmental sustainability and cost efficiency is expected to continue driving market expansion.

Regional analysis indicates that while North America currently leads in market share, the Asia-Pacific region is experiencing the fastest growth rate for green microfluidic solutions, particularly in China, Japan, and South Korea, where government initiatives supporting clean technology development have created favorable market conditions.

Primary market drivers include the significant reduction in reagent consumption offered by microfluidic systems, with typical applications requiring only picoliters to nanoliters of samples and reagents—representing up to 99% reduction compared to traditional methods. This dramatic decrease in chemical usage directly translates to reduced waste generation and lower environmental impact, creating strong market pull from environmentally conscious sectors.

Healthcare and pharmaceutical industries represent the largest market segment for green microfluidic solutions, particularly in drug discovery and personalized medicine applications. The ability to conduct thousands of parallel reactions with minimal resource consumption aligns perfectly with sustainability initiatives in these sectors. Environmental monitoring applications form the fastest-growing segment, with demand for portable, low-power microfluidic devices for real-time water and air quality analysis increasing substantially.

Consumer preference surveys reveal that organizations are increasingly willing to pay premium prices for microfluidic solutions that demonstrate quantifiable environmental benefits. This trend is particularly pronounced in regions with stringent environmental regulations, such as the European Union and parts of North America, where companies face mounting pressure to reduce their ecological footprint.

Market forecasts project continued strong growth for green microfluidic technologies, with particular emphasis on biodegradable and recyclable chip materials. The development of paper-based and other environmentally friendly substrate materials has opened new market opportunities, especially in point-of-care diagnostics for resource-limited settings.

Industrial adoption of green microfluidic solutions is accelerating as companies recognize both the environmental and economic benefits. The reduced operational costs associated with lower reagent consumption, decreased waste disposal requirements, and energy savings provide compelling economic incentives beyond regulatory compliance. This dual benefit of environmental sustainability and cost efficiency is expected to continue driving market expansion.

Regional analysis indicates that while North America currently leads in market share, the Asia-Pacific region is experiencing the fastest growth rate for green microfluidic solutions, particularly in China, Japan, and South Korea, where government initiatives supporting clean technology development have created favorable market conditions.

Current State and Challenges in Sustainable Microfluidics

Microfluidic technology has witnessed significant advancements globally, with applications spanning from healthcare diagnostics to environmental monitoring. However, the integration of sustainability principles into microfluidic chip development remains inconsistent across regions. In North America and Europe, research institutions and companies have made considerable progress in developing eco-friendly microfluidic platforms, while Asia is rapidly catching up with innovative sustainable materials research.

The current state of sustainable microfluidics faces several technical challenges. Traditional microfluidic chips predominantly utilize polydimethylsiloxane (PDMS) and other petroleum-derived polymers, which present end-of-life disposal issues. These materials are not biodegradable and contribute to persistent environmental pollution. Additionally, conventional fabrication processes involve hazardous chemicals and energy-intensive clean room operations, resulting in significant carbon footprints.

Water consumption represents another critical challenge in microfluidic manufacturing. The production of high-purity silicon wafers and other substrates requires substantial volumes of ultra-pure water, contributing to water scarcity concerns in manufacturing regions. Furthermore, the miniaturized nature of microfluidic devices often necessitates specialized equipment for recycling, which is not widely available in standard waste management facilities.

Scalability issues also constrain the environmental benefits of microfluidic technologies. While lab-scale demonstrations show promising sustainability improvements, translating these advantages to industrial-scale production remains problematic. The delicate balance between maintaining device performance and incorporating sustainable materials has created a technological bottleneck that researchers are actively working to overcome.

Regulatory frameworks present additional hurdles for sustainable microfluidics. The lack of standardized protocols for evaluating the environmental impact of microfluidic devices hampers comparative assessments and industry-wide adoption of best practices. This regulatory gap has led to fragmented approaches across different regions and applications.

Resource efficiency in microfluidic operations presents both opportunities and challenges. While these devices inherently reduce reagent consumption compared to conventional methods, the specialized nature of microfluidic components often limits their reusability. The development of modular, reusable microfluidic platforms represents an emerging trend, though technical issues related to cross-contamination and material degradation must be addressed.

The intersection of digital technologies with sustainable microfluidics offers promising directions. Advanced modeling and simulation tools are increasingly employed to optimize chip designs for minimal environmental impact, reducing the need for physical prototyping iterations. However, the computational resources required for these simulations present their own sustainability considerations that must be balanced against manufacturing improvements.

The current state of sustainable microfluidics faces several technical challenges. Traditional microfluidic chips predominantly utilize polydimethylsiloxane (PDMS) and other petroleum-derived polymers, which present end-of-life disposal issues. These materials are not biodegradable and contribute to persistent environmental pollution. Additionally, conventional fabrication processes involve hazardous chemicals and energy-intensive clean room operations, resulting in significant carbon footprints.

Water consumption represents another critical challenge in microfluidic manufacturing. The production of high-purity silicon wafers and other substrates requires substantial volumes of ultra-pure water, contributing to water scarcity concerns in manufacturing regions. Furthermore, the miniaturized nature of microfluidic devices often necessitates specialized equipment for recycling, which is not widely available in standard waste management facilities.

Scalability issues also constrain the environmental benefits of microfluidic technologies. While lab-scale demonstrations show promising sustainability improvements, translating these advantages to industrial-scale production remains problematic. The delicate balance between maintaining device performance and incorporating sustainable materials has created a technological bottleneck that researchers are actively working to overcome.

Regulatory frameworks present additional hurdles for sustainable microfluidics. The lack of standardized protocols for evaluating the environmental impact of microfluidic devices hampers comparative assessments and industry-wide adoption of best practices. This regulatory gap has led to fragmented approaches across different regions and applications.

Resource efficiency in microfluidic operations presents both opportunities and challenges. While these devices inherently reduce reagent consumption compared to conventional methods, the specialized nature of microfluidic components often limits their reusability. The development of modular, reusable microfluidic platforms represents an emerging trend, though technical issues related to cross-contamination and material degradation must be addressed.

The intersection of digital technologies with sustainable microfluidics offers promising directions. Advanced modeling and simulation tools are increasingly employed to optimize chip designs for minimal environmental impact, reducing the need for physical prototyping iterations. However, the computational resources required for these simulations present their own sustainability considerations that must be balanced against manufacturing improvements.

Current Green Microfluidic Implementation Strategies

01 Sustainable materials for microfluidic chip fabrication

Environmentally friendly materials are being used in the fabrication of microfluidic chips to reduce environmental impact. These materials include biodegradable polymers, recycled materials, and renewable resources that can replace traditional petroleum-based plastics. The use of such sustainable materials helps minimize waste generation and reduces the carbon footprint associated with microfluidic chip production while maintaining the required functionality and performance characteristics.- Sustainable materials for microfluidic chip fabrication: Environmentally friendly materials are being used in the manufacturing of microfluidic chips to reduce environmental impact. These include biodegradable polymers, recycled materials, and renewable resources that can replace traditional petroleum-based plastics. Such sustainable materials maintain the functionality of microfluidic devices while significantly reducing waste and ecological footprint throughout the product lifecycle.

- Energy-efficient microfluidic systems: Innovations in microfluidic chip design focus on minimizing energy consumption during operation. These advancements include optimized flow dynamics, passive pumping mechanisms, and integrated renewable energy sources. Energy-efficient microfluidic systems reduce power requirements while maintaining analytical performance, contributing to more sustainable laboratory practices and field applications.

- Waste reduction and recycling in microfluidic applications: Microfluidic technologies are being developed with waste minimization strategies, including reusable chip designs, reagent volume reduction, and integrated waste treatment systems. These approaches significantly decrease the environmental impact of laboratory processes by reducing chemical waste, minimizing water usage, and enabling the recycling of components, aligning with circular economy principles.

- Environmental monitoring applications of microfluidic chips: Microfluidic devices are being deployed for real-time environmental monitoring and analysis. These specialized chips can detect pollutants, analyze water quality, and monitor air contaminants with high sensitivity and specificity. The portable nature of these systems enables field testing in remote locations, providing crucial data for environmental protection efforts while using minimal resources compared to traditional laboratory methods.

- Green manufacturing processes for microfluidic devices: Sustainable manufacturing techniques are being implemented in microfluidic chip production to reduce environmental impact. These include additive manufacturing methods that minimize material waste, solvent-free bonding processes, and low-temperature fabrication techniques that reduce energy consumption. Green manufacturing approaches also incorporate life cycle assessment to optimize the environmental performance of microfluidic devices from production through disposal.

02 Energy-efficient microfluidic systems

Innovations in microfluidic chip design focus on reducing energy consumption during operation. These designs incorporate passive flow mechanisms, optimized channel geometries, and improved thermal management systems that minimize the need for external power sources. Energy-efficient microfluidic systems contribute to environmental sustainability by reducing electricity usage and enabling operation in resource-limited settings, making them suitable for point-of-care diagnostics and environmental monitoring applications.Expand Specific Solutions03 Waste reduction in microfluidic analytical processes

Microfluidic technologies significantly reduce reagent consumption and waste generation compared to conventional analytical methods. By miniaturizing reaction chambers and optimizing fluid handling, these chips require only microliters or nanoliters of samples and reagents, drastically reducing chemical waste. Additionally, integrated sample preparation and analysis capabilities minimize the need for disposable laboratory consumables, contributing to more sustainable laboratory practices and reduced environmental impact from analytical procedures.Expand Specific Solutions04 Environmental monitoring applications of microfluidic chips

Microfluidic chips are being developed specifically for environmental monitoring applications, enabling real-time detection of pollutants in air, water, and soil. These portable, field-deployable systems can detect contaminants at low concentrations with high sensitivity and specificity. The integration of sensing elements with microfluidic components allows for continuous monitoring of environmental parameters, helping in early detection of pollution events and facilitating timely remediation efforts to protect ecosystems and public health.Expand Specific Solutions05 Circular economy approaches for microfluidic devices

Innovative designs for microfluidic chips incorporate principles of circular economy, focusing on reusability, recyclability, and end-of-life considerations. These approaches include modular designs that allow for component replacement rather than whole-device disposal, materials selection that facilitates recycling, and manufacturing processes that minimize resource consumption. Some microfluidic platforms also feature self-cleaning capabilities that extend device lifespan, reducing the frequency of replacement and associated environmental impacts.Expand Specific Solutions

Key Industry Players in Sustainable Microfluidics

The microfluidic chip market is currently in a growth phase, with increasing adoption across environmental sustainability applications. The global market size is estimated to reach $25-30 billion by 2025, driven by applications in water quality monitoring, pollution detection, and sustainable manufacturing processes. Technologically, the field shows moderate maturity with established players like Rheonix and Pattern Bioscience leading commercial applications, while academic institutions including Fudan University, Yale University, and CNRS are advancing fundamental research. Industrial players such as TDK Corp and BOE Technology are integrating microfluidic technologies into sustainable manufacturing processes. Research institutions like Industrial Technology Research Institute and Shenzhen Institutes of Advanced Technology are bridging the gap between academic innovation and industrial implementation, focusing on scaling environmentally beneficial applications.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed pioneering microfluidic technologies for environmental sustainability through its interdisciplinary research networks. Their Lab-on-a-Chip Environmental Analysis Systems (LOCEAS) integrate multiple analytical functions on centimeter-sized platforms for comprehensive environmental monitoring. CNRS researchers have created paper-based microfluidic devices that utilize capillary action instead of external pumps, dramatically reducing energy requirements while enabling point-of-need testing in resource-limited settings. For atmospheric pollution monitoring, CNRS has developed microfluidic impactors that concentrate airborne particulates into liquid samples for real-time analysis of composition and toxicity. Their microreactor technology enables intensified processes for green chemistry applications, achieving reaction efficiencies up to 100 times greater than conventional batch methods while minimizing solvent usage and waste generation. Additionally, CNRS has pioneered biomimetic microfluidic systems that replicate natural filtration processes for water purification, inspired by biological structures like plant xylem and kidney nephrons.

Strengths: Diverse portfolio of environmentally-focused microfluidic technologies spanning multiple sustainability challenges; emphasis on low-cost, accessible solutions suitable for global deployment; strong integration of fundamental research with practical applications. Weaknesses: Some technologies remain in research phase rather than commercial deployment; complex systems may require specialized expertise; funding dependent on public research budgets.

Rheonix, Inc.

Technical Solution: Rheonix has developed the Chemistry and Reagent Device (CARD) microfluidic platform that automates complex laboratory procedures into simple, cost-effective, and environmentally friendly processes. Their technology integrates sample preparation, amplification, and detection within a single disposable cartridge, significantly reducing waste compared to traditional laboratory methods. The CARD system utilizes a proprietary lamination technology that creates microchannels and reaction chambers with minimal material usage. For environmental applications, Rheonix has adapted their platform for water quality monitoring, detecting contaminants such as heavy metals, pesticides, and microbial pathogens at parts-per-billion levels while consuming only microliters of reagents compared to milliliters in conventional testing.

Strengths: Significantly reduces chemical reagent consumption (up to 95% less than traditional methods) and plastic waste; automated processes minimize human error and exposure to hazardous materials. Weaknesses: Initial implementation costs can be high; requires specialized training for operation and maintenance; limited throughput compared to some industrial-scale systems.

Core Innovations in Sustainable Microfluidic Design

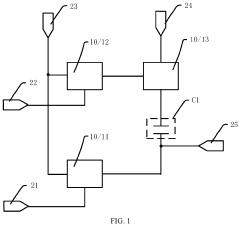

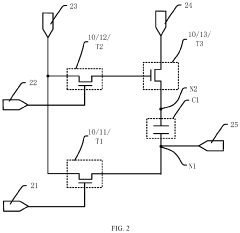

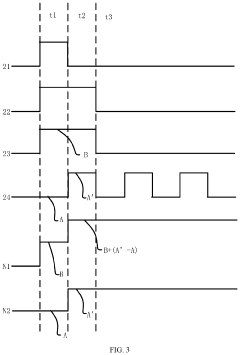

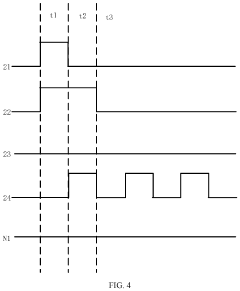

Driving circuit and driving method thereof, and electrowetting panel and driving method thereof

PatentActiveUS11366306B2

Innovation

- A driving circuit with a voltage-boosting unit, comprising multiple modules and a capacitor, that enhances the electric potential output by controlling signal transmission periods to achieve high voltage levels, allowing for efficient droplet movement and reduced signal channel requirements.

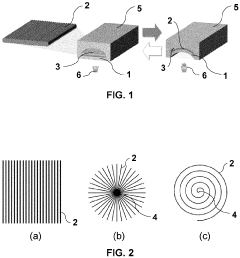

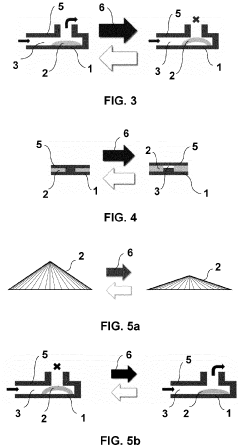

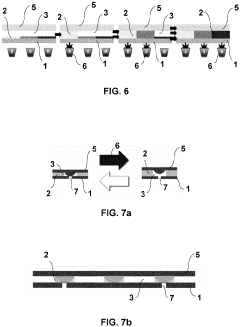

Microfluidic valve, method for its manufacture, and uses thereof

PatentActiveEP4170212A1

Innovation

- The use of liquid crystal networks or elastomers (LCN/LCE) with controlled polymer chain cross-linking, enabled by additive layer manufacturing, to create microfluidic valves that respond to stimuli such as light, temperature, and pH, allowing for precise regulation of fluid flow through 4D printing processes.

Life Cycle Assessment of Microfluidic Systems

Life Cycle Assessment (LCA) of microfluidic systems provides critical insights into the environmental impacts of these technologies throughout their entire existence. The assessment typically begins with raw material extraction, where the environmental footprint of obtaining polymers, glass, silicon, and other materials used in chip fabrication is evaluated. These materials often require energy-intensive mining and refining processes that contribute significantly to the overall environmental impact.

Manufacturing processes for microfluidic chips involve multiple steps including photolithography, etching, bonding, and surface treatments. Each step consumes energy and may utilize hazardous chemicals such as photoresists, organic solvents, and acids. Recent studies indicate that the fabrication phase can account for up to 70% of the total environmental impact of microfluidic systems, primarily due to cleanroom operations and specialized equipment requirements.

Distribution impacts, while less significant than manufacturing, still merit consideration. The global supply chain for microfluidic components often involves international shipping, contributing to carbon emissions. However, the compact size and lightweight nature of these devices helps minimize transportation-related environmental burdens compared to conventional laboratory equipment.

Usage phase analysis reveals that microfluidic systems generally demonstrate superior environmental performance compared to traditional analytical methods. They typically require smaller sample volumes, reduced reagent consumption (often by 90-99%), and lower energy requirements. For instance, a microfluidic PCR system can reduce reagent usage by up to 95% while maintaining comparable analytical performance to conventional systems.

End-of-life considerations present significant challenges for microfluidic sustainability. Many chips are designed for single-use applications, creating disposal issues. The composite nature of these devices—often containing multiple materials bonded together—complicates recycling efforts. Biodegradable materials and design-for-disassembly approaches are emerging as potential solutions to this challenge.

Comparative LCA studies demonstrate that microfluidic technologies generally offer net environmental benefits despite manufacturing impacts. For example, point-of-care diagnostic chips reduce the need for sample transportation to centralized laboratories, decreasing associated emissions. Additionally, the miniaturization of analytical processes leads to substantial reductions in laboratory waste generation and energy consumption across multiple application domains.

Manufacturing processes for microfluidic chips involve multiple steps including photolithography, etching, bonding, and surface treatments. Each step consumes energy and may utilize hazardous chemicals such as photoresists, organic solvents, and acids. Recent studies indicate that the fabrication phase can account for up to 70% of the total environmental impact of microfluidic systems, primarily due to cleanroom operations and specialized equipment requirements.

Distribution impacts, while less significant than manufacturing, still merit consideration. The global supply chain for microfluidic components often involves international shipping, contributing to carbon emissions. However, the compact size and lightweight nature of these devices helps minimize transportation-related environmental burdens compared to conventional laboratory equipment.

Usage phase analysis reveals that microfluidic systems generally demonstrate superior environmental performance compared to traditional analytical methods. They typically require smaller sample volumes, reduced reagent consumption (often by 90-99%), and lower energy requirements. For instance, a microfluidic PCR system can reduce reagent usage by up to 95% while maintaining comparable analytical performance to conventional systems.

End-of-life considerations present significant challenges for microfluidic sustainability. Many chips are designed for single-use applications, creating disposal issues. The composite nature of these devices—often containing multiple materials bonded together—complicates recycling efforts. Biodegradable materials and design-for-disassembly approaches are emerging as potential solutions to this challenge.

Comparative LCA studies demonstrate that microfluidic technologies generally offer net environmental benefits despite manufacturing impacts. For example, point-of-care diagnostic chips reduce the need for sample transportation to centralized laboratories, decreasing associated emissions. Additionally, the miniaturization of analytical processes leads to substantial reductions in laboratory waste generation and energy consumption across multiple application domains.

Policy Framework for Green Microfluidic Technologies

The development of effective policy frameworks is crucial for promoting and regulating green microfluidic technologies in environmental sustainability efforts. Current regulatory landscapes across major economies demonstrate varying approaches to integrating microfluidic innovations into environmental policies, with the European Union leading through its Circular Economy Action Plan that specifically addresses miniaturized analytical systems.

National policies increasingly recognize microfluidic chips as critical tools for environmental monitoring and resource optimization. Several countries have implemented incentive programs that reward companies developing microfluidic solutions for water quality assessment, air pollution detection, and waste reduction. These policies typically combine financial incentives such as tax credits for research and development with streamlined approval processes for environmentally beneficial applications.

Standardization represents a significant challenge in policy development. The International Organization for Standardization (ISO) has established working groups focused on creating unified standards for microfluidic devices with environmental applications. These standards address manufacturing processes, material selection criteria, and performance metrics specifically for sustainability-oriented microfluidic technologies.

Funding mechanisms constitute another essential policy component. Government grants increasingly target research institutions and companies developing microfluidic solutions for environmental challenges. The United States' Environmental Protection Agency has established dedicated funding streams for microfluidic technologies that reduce chemical waste in analytical procedures, while similar programs exist in Japan, South Korea, and Singapore focusing on water conservation applications.

Regulatory frameworks must balance innovation encouragement with environmental protection. Policies increasingly incorporate life-cycle assessment requirements for microfluidic devices, ensuring that their production, use, and disposal generate net environmental benefits. Some jurisdictions have implemented extended producer responsibility schemes specifically for microfluidic chip manufacturers, requiring end-of-life management plans.

Cross-border policy harmonization remains an ongoing challenge. International agreements like the Paris Climate Accord increasingly recognize the role of miniaturized technologies in achieving sustainability targets, though specific provisions for microfluidic technologies remain limited. Regional cooperation frameworks, particularly in Southeast Asia and the European Union, have begun establishing shared regulatory approaches to maximize the environmental benefits of microfluidic innovations while minimizing regulatory barriers to implementation.

Future policy directions point toward more integrated approaches that connect microfluidic technology development with broader sustainability objectives. This includes creating regulatory sandboxes for testing novel applications, developing certification systems for environmentally beneficial microfluidic products, and establishing international knowledge-sharing platforms to accelerate adoption of best practices across jurisdictions.

National policies increasingly recognize microfluidic chips as critical tools for environmental monitoring and resource optimization. Several countries have implemented incentive programs that reward companies developing microfluidic solutions for water quality assessment, air pollution detection, and waste reduction. These policies typically combine financial incentives such as tax credits for research and development with streamlined approval processes for environmentally beneficial applications.

Standardization represents a significant challenge in policy development. The International Organization for Standardization (ISO) has established working groups focused on creating unified standards for microfluidic devices with environmental applications. These standards address manufacturing processes, material selection criteria, and performance metrics specifically for sustainability-oriented microfluidic technologies.

Funding mechanisms constitute another essential policy component. Government grants increasingly target research institutions and companies developing microfluidic solutions for environmental challenges. The United States' Environmental Protection Agency has established dedicated funding streams for microfluidic technologies that reduce chemical waste in analytical procedures, while similar programs exist in Japan, South Korea, and Singapore focusing on water conservation applications.

Regulatory frameworks must balance innovation encouragement with environmental protection. Policies increasingly incorporate life-cycle assessment requirements for microfluidic devices, ensuring that their production, use, and disposal generate net environmental benefits. Some jurisdictions have implemented extended producer responsibility schemes specifically for microfluidic chip manufacturers, requiring end-of-life management plans.

Cross-border policy harmonization remains an ongoing challenge. International agreements like the Paris Climate Accord increasingly recognize the role of miniaturized technologies in achieving sustainability targets, though specific provisions for microfluidic technologies remain limited. Regional cooperation frameworks, particularly in Southeast Asia and the European Union, have begun establishing shared regulatory approaches to maximize the environmental benefits of microfluidic innovations while minimizing regulatory barriers to implementation.

Future policy directions point toward more integrated approaches that connect microfluidic technology development with broader sustainability objectives. This includes creating regulatory sandboxes for testing novel applications, developing certification systems for environmentally beneficial microfluidic products, and establishing international knowledge-sharing platforms to accelerate adoption of best practices across jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!