How Microfluidic Chips Facilitate Advanced Spectroscopic Analyses

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Spectroscopy Background and Objectives

Microfluidic technology has evolved significantly over the past three decades, transforming from simple channel-based systems to sophisticated lab-on-a-chip platforms capable of integrating multiple analytical functions. The convergence of microfluidics with spectroscopic techniques represents a particularly promising development trajectory, enabling unprecedented capabilities in chemical and biological analysis at microscale dimensions.

The historical progression of microfluidic spectroscopy began in the early 1990s with rudimentary capillary electrophoresis chips, advancing through the 2000s with the integration of optical detection methods, and reaching current state-of-the-art systems that incorporate multiple spectroscopic modalities on a single platform. This technological evolution has been driven by demands for increased analytical sensitivity, reduced sample volumes, and higher throughput capabilities across various scientific disciplines.

Spectroscopic analysis techniques—including UV-visible absorption, fluorescence, Raman, infrared, and mass spectrometry—have traditionally required bulky instrumentation and relatively large sample volumes. The miniaturization and integration of these techniques with microfluidic platforms addresses fundamental limitations of conventional spectroscopy while opening new analytical possibilities through precise fluid handling at the micro and nanoliter scale.

The primary technical objectives in this field center on enhancing detection sensitivity, improving spatial resolution, enabling real-time analysis, and facilitating multiplexed detection capabilities. Researchers aim to develop microfluidic spectroscopic systems that can detect analytes at increasingly lower concentrations while maintaining high specificity, even in complex sample matrices. Additionally, there is significant interest in creating platforms that can perform multiple types of spectroscopic measurements simultaneously on the same sample.

Current technological trends indicate movement toward greater integration of different spectroscopic modalities, development of novel materials with enhanced optical properties, implementation of advanced fabrication techniques, and incorporation of artificial intelligence for data analysis. The field is increasingly focused on creating fully automated, portable systems that can perform complex analytical workflows with minimal user intervention.

The ultimate goal of microfluidic spectroscopy development is to democratize advanced analytical capabilities by creating accessible, affordable, and user-friendly systems that maintain or exceed the performance of traditional laboratory instrumentation. This would enable applications ranging from point-of-care diagnostics and environmental monitoring to pharmaceutical development and fundamental scientific research in resource-limited settings.

The historical progression of microfluidic spectroscopy began in the early 1990s with rudimentary capillary electrophoresis chips, advancing through the 2000s with the integration of optical detection methods, and reaching current state-of-the-art systems that incorporate multiple spectroscopic modalities on a single platform. This technological evolution has been driven by demands for increased analytical sensitivity, reduced sample volumes, and higher throughput capabilities across various scientific disciplines.

Spectroscopic analysis techniques—including UV-visible absorption, fluorescence, Raman, infrared, and mass spectrometry—have traditionally required bulky instrumentation and relatively large sample volumes. The miniaturization and integration of these techniques with microfluidic platforms addresses fundamental limitations of conventional spectroscopy while opening new analytical possibilities through precise fluid handling at the micro and nanoliter scale.

The primary technical objectives in this field center on enhancing detection sensitivity, improving spatial resolution, enabling real-time analysis, and facilitating multiplexed detection capabilities. Researchers aim to develop microfluidic spectroscopic systems that can detect analytes at increasingly lower concentrations while maintaining high specificity, even in complex sample matrices. Additionally, there is significant interest in creating platforms that can perform multiple types of spectroscopic measurements simultaneously on the same sample.

Current technological trends indicate movement toward greater integration of different spectroscopic modalities, development of novel materials with enhanced optical properties, implementation of advanced fabrication techniques, and incorporation of artificial intelligence for data analysis. The field is increasingly focused on creating fully automated, portable systems that can perform complex analytical workflows with minimal user intervention.

The ultimate goal of microfluidic spectroscopy development is to democratize advanced analytical capabilities by creating accessible, affordable, and user-friendly systems that maintain or exceed the performance of traditional laboratory instrumentation. This would enable applications ranging from point-of-care diagnostics and environmental monitoring to pharmaceutical development and fundamental scientific research in resource-limited settings.

Market Applications and Demand Analysis

The integration of microfluidic chips with spectroscopic analysis techniques has created significant market opportunities across multiple industries. The global microfluidics market was valued at $20.7 billion in 2021 and is projected to reach $55.8 billion by 2028, growing at a CAGR of 15.2%. Within this broader market, spectroscopy-enabled microfluidic applications represent a rapidly expanding segment driven by increasing demand for point-of-care diagnostics and real-time analytical capabilities.

In the healthcare and pharmaceutical sectors, demand for microfluidic spectroscopy solutions is particularly strong. These industries require high-throughput screening methods for drug discovery and development, where microfluidic chips coupled with spectroscopic analysis offer substantial advantages in terms of sample volume reduction, analysis speed, and automation potential. The pharmaceutical industry's shift toward personalized medicine has further accelerated demand for these technologies, as they enable rapid analysis of biomarkers and genetic material.

Environmental monitoring represents another significant market application, with growing regulatory requirements driving adoption of portable, field-deployable analytical systems. Microfluidic spectroscopy solutions allow for on-site detection of contaminants in water, soil, and air samples, eliminating the need for laboratory-based testing and enabling faster response to environmental threats. This market segment is expected to grow at 18.3% annually through 2027.

The food and beverage industry has emerged as a promising application area, with increasing focus on food safety and quality control. Microfluidic spectroscopic systems enable rapid detection of pathogens, allergens, and adulterants throughout the supply chain. Market research indicates that approximately 65% of food manufacturers plan to implement advanced analytical technologies within the next five years, creating substantial opportunities for microfluidic spectroscopy solutions.

Academic and research institutions constitute another significant market segment, with growing investment in advanced analytical capabilities. These organizations value the reduced reagent consumption, faster analysis times, and integration capabilities offered by microfluidic spectroscopy platforms. The academic research segment accounts for approximately 22% of the current market.

Regional analysis reveals that North America currently dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, expanding research infrastructure, and growing industrial base. China and India, in particular, are investing heavily in biotechnology and pharmaceutical research, creating favorable conditions for microfluidic spectroscopy adoption.

In the healthcare and pharmaceutical sectors, demand for microfluidic spectroscopy solutions is particularly strong. These industries require high-throughput screening methods for drug discovery and development, where microfluidic chips coupled with spectroscopic analysis offer substantial advantages in terms of sample volume reduction, analysis speed, and automation potential. The pharmaceutical industry's shift toward personalized medicine has further accelerated demand for these technologies, as they enable rapid analysis of biomarkers and genetic material.

Environmental monitoring represents another significant market application, with growing regulatory requirements driving adoption of portable, field-deployable analytical systems. Microfluidic spectroscopy solutions allow for on-site detection of contaminants in water, soil, and air samples, eliminating the need for laboratory-based testing and enabling faster response to environmental threats. This market segment is expected to grow at 18.3% annually through 2027.

The food and beverage industry has emerged as a promising application area, with increasing focus on food safety and quality control. Microfluidic spectroscopic systems enable rapid detection of pathogens, allergens, and adulterants throughout the supply chain. Market research indicates that approximately 65% of food manufacturers plan to implement advanced analytical technologies within the next five years, creating substantial opportunities for microfluidic spectroscopy solutions.

Academic and research institutions constitute another significant market segment, with growing investment in advanced analytical capabilities. These organizations value the reduced reagent consumption, faster analysis times, and integration capabilities offered by microfluidic spectroscopy platforms. The academic research segment accounts for approximately 22% of the current market.

Regional analysis reveals that North America currently dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, expanding research infrastructure, and growing industrial base. China and India, in particular, are investing heavily in biotechnology and pharmaceutical research, creating favorable conditions for microfluidic spectroscopy adoption.

Technical Challenges and Global Development Status

Despite significant advancements in microfluidic chip technology for spectroscopic analyses, several technical challenges persist. Integration of optical components with microfluidic platforms remains complex, requiring precise alignment between light sources, waveguides, and detectors. Miniaturization efforts often result in reduced sensitivity compared to conventional spectroscopic instruments, creating a fundamental trade-off between device size and analytical performance.

Signal-to-noise ratio optimization presents another significant hurdle, particularly when working with small sample volumes in the nanoliter to picoliter range. The limited optical path length in microfluidic channels directly impacts detection limits according to Beer-Lambert principles, necessitating innovative approaches to enhance sensitivity without increasing device footprint.

Material compatibility issues also constrain development, as chip substrates must simultaneously satisfy optical transparency requirements while maintaining chemical resistance to various solvents and reagents. Additionally, surface adsorption phenomena can lead to sample loss and cross-contamination, particularly problematic when analyzing biomolecules or trace analytes.

The global development landscape of microfluidic spectroscopy exhibits distinct regional characteristics. North America, particularly the United States, leads in research output and commercial applications, with major academic institutions and companies focusing on biomedical applications. The region benefits from robust venture capital funding and established microelectronics infrastructure that facilitates rapid prototyping and manufacturing.

Europe demonstrates strength in fundamental research and standardization efforts, with countries like Germany, Switzerland, and the Netherlands contributing significantly to microfluidic-spectroscopic integration. European research emphasizes environmental monitoring applications and sustainable manufacturing approaches for microfluidic devices.

The Asia-Pacific region, led by China, Japan, and South Korea, has shown the fastest growth rate in patent filings related to microfluidic spectroscopy. These countries leverage their established semiconductor manufacturing capabilities to develop mass-production techniques for microfluidic chips, focusing particularly on point-of-care diagnostic applications.

Globally, the field faces standardization challenges, with limited consensus on design parameters, testing protocols, and performance metrics. This hampers interoperability between different microfluidic platforms and spectroscopic techniques. Recent international collaborations aim to address these standardization issues, with initiatives from organizations like ISO and ASTM developing frameworks for microfluidic-spectroscopic system validation and quality control.

Signal-to-noise ratio optimization presents another significant hurdle, particularly when working with small sample volumes in the nanoliter to picoliter range. The limited optical path length in microfluidic channels directly impacts detection limits according to Beer-Lambert principles, necessitating innovative approaches to enhance sensitivity without increasing device footprint.

Material compatibility issues also constrain development, as chip substrates must simultaneously satisfy optical transparency requirements while maintaining chemical resistance to various solvents and reagents. Additionally, surface adsorption phenomena can lead to sample loss and cross-contamination, particularly problematic when analyzing biomolecules or trace analytes.

The global development landscape of microfluidic spectroscopy exhibits distinct regional characteristics. North America, particularly the United States, leads in research output and commercial applications, with major academic institutions and companies focusing on biomedical applications. The region benefits from robust venture capital funding and established microelectronics infrastructure that facilitates rapid prototyping and manufacturing.

Europe demonstrates strength in fundamental research and standardization efforts, with countries like Germany, Switzerland, and the Netherlands contributing significantly to microfluidic-spectroscopic integration. European research emphasizes environmental monitoring applications and sustainable manufacturing approaches for microfluidic devices.

The Asia-Pacific region, led by China, Japan, and South Korea, has shown the fastest growth rate in patent filings related to microfluidic spectroscopy. These countries leverage their established semiconductor manufacturing capabilities to develop mass-production techniques for microfluidic chips, focusing particularly on point-of-care diagnostic applications.

Globally, the field faces standardization challenges, with limited consensus on design parameters, testing protocols, and performance metrics. This hampers interoperability between different microfluidic platforms and spectroscopic techniques. Recent international collaborations aim to address these standardization issues, with initiatives from organizations like ISO and ASTM developing frameworks for microfluidic-spectroscopic system validation and quality control.

Current Microfluidic-Spectroscopy Integration Approaches

01 Integration of spectroscopic detection in microfluidic chips

Microfluidic chips can be integrated with various spectroscopic detection methods to enable real-time analysis of samples. These integrated systems combine the advantages of microfluidics (small sample volumes, precise control of fluids) with the analytical power of spectroscopy. The integration allows for on-chip detection of analytes, reducing the need for external detection equipment and enabling portable analysis systems. These systems can be used for applications in medical diagnostics, environmental monitoring, and chemical analysis.- Integration of spectroscopic detection systems in microfluidic chips: Microfluidic chips can be integrated with various spectroscopic detection systems to enable real-time analysis of samples. These integrated systems combine the advantages of microfluidics (small sample volumes, precise control of fluid flow) with the analytical capabilities of spectroscopy. The integration allows for on-chip detection and analysis of chemical and biological samples, enhancing the efficiency and sensitivity of the analytical process.

- Microfluidic platforms for multi-parameter spectroscopic analysis: Advanced microfluidic platforms enable multi-parameter spectroscopic analyses by incorporating multiple detection channels or modalities. These platforms can perform simultaneous measurements of different spectroscopic parameters, such as absorbance, fluorescence, and Raman scattering. The multi-parameter approach provides comprehensive characterization of samples, improving the accuracy and reliability of analytical results in applications ranging from biomedical diagnostics to environmental monitoring.

- Novel fabrication techniques for spectroscopy-optimized microfluidic devices: Innovative fabrication methods are being developed to create microfluidic chips specifically optimized for spectroscopic analyses. These techniques include advanced materials processing, precision microfabrication, and surface modification approaches that enhance optical properties and reduce background interference. The resulting devices feature improved light transmission, reduced autofluorescence, and optimized channel geometries that maximize detection sensitivity and resolution for spectroscopic measurements.

- Microfluidic sample preparation for enhanced spectroscopic detection: Microfluidic chips can incorporate sample preparation functionalities that enhance subsequent spectroscopic analyses. These include on-chip filtration, concentration, separation, and chemical modification of analytes. By preparing samples directly on the microfluidic platform before spectroscopic detection, these systems minimize sample loss, reduce contamination risks, and improve the consistency of analytical results, particularly for complex biological samples or environmental specimens.

- Portable and field-deployable microfluidic spectroscopic systems: Miniaturized microfluidic spectroscopic systems are being developed for portable and field-deployable applications. These compact devices integrate microfluidic chips with miniaturized spectroscopic components, power supplies, and data processing capabilities. The portable nature of these systems enables on-site analysis in various settings, including remote locations, point-of-care diagnostics, and industrial process monitoring, eliminating the need for sample transport to centralized laboratories.

02 Microfluidic chips for Raman spectroscopy

Specialized microfluidic chips have been developed for Raman spectroscopic analysis, allowing for the identification and quantification of chemical compounds based on their vibrational properties. These chips often incorporate features such as optical windows, focusing elements, or surface-enhanced Raman spectroscopy (SERS) substrates to enhance sensitivity. The integration of Raman spectroscopy with microfluidics enables label-free detection of analytes with high specificity, making it suitable for applications in pharmaceutical analysis, biomedical research, and chemical identification.Expand Specific Solutions03 Microfluidic chips with integrated optical components

Advanced microfluidic chips incorporate integrated optical components such as waveguides, lenses, filters, and detectors to enhance spectroscopic analyses. These integrated optical elements enable precise light delivery to the sample and efficient collection of spectral information. The integration of optical components directly into the chip structure reduces alignment issues, increases sensitivity, and enables miniaturization of the entire analytical system. These chips can be used for absorbance, fluorescence, and other spectroscopic measurements in various applications.Expand Specific Solutions04 Microfluidic spectroscopic systems for biological analysis

Microfluidic chips coupled with spectroscopic detection have been developed specifically for biological sample analysis, including DNA sequencing, protein analysis, and cell studies. These systems often incorporate sample preparation steps such as mixing, separation, or concentration on the same chip as the spectroscopic detection. The integration of multiple functions enables comprehensive analysis of complex biological samples with minimal sample consumption. These systems are particularly valuable in medical diagnostics, genomics, and proteomics research.Expand Specific Solutions05 Novel fabrication methods for spectroscopic microfluidic devices

Innovative fabrication techniques have been developed to create microfluidic chips with enhanced capabilities for spectroscopic analyses. These methods include advanced materials processing, 3D printing, laser ablation, and nanofabrication approaches that enable the creation of complex microstructures optimized for spectroscopic measurements. The fabrication innovations allow for the integration of specialized features such as optical cavities, plasmonic structures, or photonic crystals that can enhance spectroscopic sensitivity and selectivity. These advanced manufacturing approaches enable the development of next-generation microfluidic spectroscopic devices with improved performance.Expand Specific Solutions

Leading Companies and Research Institutions

Microfluidic chip technology for advanced spectroscopic analyses is currently in a growth phase, with the market expanding rapidly due to increasing applications in biomedical research, diagnostics, and chemical analysis. The global market is projected to reach significant scale as integration with spectroscopic techniques enables more precise, high-throughput analyses with minimal sample volumes. Technologically, companies demonstrate varying maturity levels: established players like BOE Technology Group, FUJIFILM, and Agilent Technologies leverage their broader technological ecosystems to advance microfluidic spectroscopy, while specialized firms such as Lansion Biotechnology, Pattern Bioscience, and Nanobiose focus on innovative applications in diagnostics and bioanalysis. Academic institutions including Zhejiang University, Fudan University, and Virginia Tech are driving fundamental research, creating a competitive landscape where industry-academia partnerships accelerate commercialization of increasingly sophisticated microfluidic spectroscopic platforms.

Lansion Biotechnology Co., Ltd.

Technical Solution: Lansion Biotechnology has developed proprietary microfluidic chip technology that integrates advanced spectroscopic analysis capabilities for rapid clinical diagnostics and life science research. Their microfluidic platforms feature multi-layer chip designs with integrated optical detection zones optimized for various spectroscopic techniques including fluorescence, absorbance, and Raman spectroscopy. The company's LanFlow system incorporates microchannels with specialized surface modifications that enhance biomolecule immobilization while reducing non-specific binding, thereby improving spectroscopic signal quality. Their chips include integrated micromixers and microreactors that facilitate rapid sample preparation and chemical reactions directly on-chip before spectroscopic analysis. Lansion has pioneered the development of droplet-based microfluidic chips with integrated spectroscopic detection capabilities that enable high-throughput screening applications with significantly reduced reagent consumption. Recent innovations include their SpectroChip platform, which features embedded optical fibers and waveguides that direct light through precisely defined paths within the microfluidic channels, enhancing spectroscopic sensitivity by orders of magnitude compared to conventional approaches.

Strengths: Exceptional integration of multiple analytical functions on a single chip platform; highly sensitive detection capabilities through optimized optical pathways; cost-effective manufacturing processes enabling wider adoption. Weaknesses: More limited global market presence compared to larger competitors; narrower range of compatible sample types; requires specialized equipment for optimal performance.

NANOBIOSE

Technical Solution: NANOBIOSE has developed innovative microfluidic chip technologies specifically designed to enhance spectroscopic analyses for biological applications. Their proprietary NanoCell platform integrates microfluidic channels with specialized optical interfaces that facilitate multiple spectroscopic techniques, including Raman, infrared, and fluorescence spectroscopy. The company's chips feature precision-engineered flow cells with optical windows made from materials selected for optimal transparency across various spectral ranges. NANOBIOSE's microfluidic designs incorporate unique 3D channel architectures that maximize interaction between light and sample volumes, significantly enhancing detection sensitivity for spectroscopic measurements. Their chips include integrated concentration gradients and mixing zones that enable real-time monitoring of biochemical reactions through spectroscopic methods. The company has pioneered the development of microfluidic chips with integrated nanostructured surfaces that provide surface-enhanced Raman spectroscopy (SERS) capabilities, achieving enhancement factors exceeding 10^6 for trace analyte detection. Recent advancements include their BioSpec platform, which combines microfluidic sample handling with multimodal spectroscopic detection for comprehensive biomolecular characterization in volumes as small as nanoliters.

Strengths: Exceptional sensitivity for trace analysis through optimized optical interfaces; versatile platform supporting multiple spectroscopic techniques; specialized surface treatments enhancing signal-to-noise ratios. Weaknesses: Limited throughput compared to some competing technologies; higher complexity requiring specialized expertise; relatively new market entrant with smaller installed base.

Key Patents and Scientific Breakthroughs

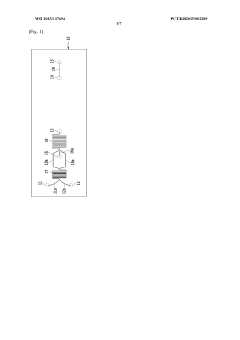

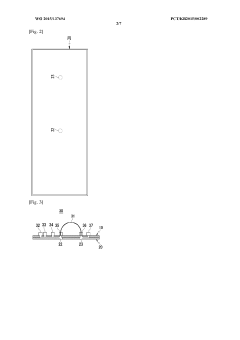

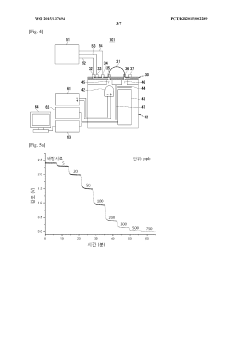

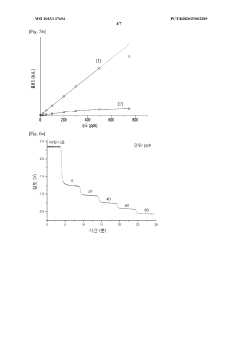

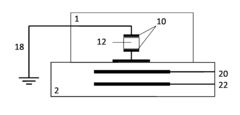

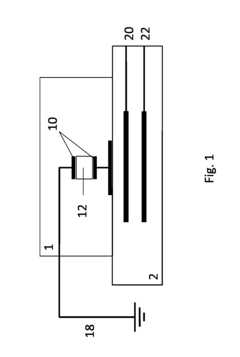

Microfluidic chip having flow cell, and using standard addition method, and absorbance detection apparatus comprising same

PatentWO2015137694A1

Innovation

- A microfluidic chip with a flow cell using a liquid core waveguide and a standard water addition method, where the flow cell can be easily extended and adjusted, combined with a blocking wall to minimize stray light, allowing for high-sensitivity analysis without additional optical devices like slits or condensing lenses.

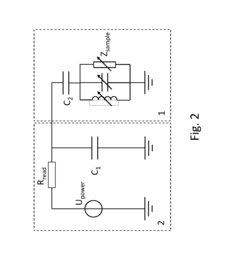

Micro-fluidic device for the analysis of a fluid sample

PatentInactiveUS20140186820A1

Innovation

- A programmable device with a capacitive touch screen is used as an interface and computing unit for micro-fluidic devices, combining detection, analysis, and display functions, reducing development costs and increasing modularity and flexibility by leveraging existing affordable and powerful capacitive touch technology.

Materials Science Considerations for Chip Fabrication

The selection of appropriate materials for microfluidic chip fabrication is critical to the success of spectroscopic analyses. Traditional materials such as glass and silicon have been widely used due to their excellent optical properties and chemical resistance. Glass offers superior optical transparency across a wide spectral range, making it ideal for UV-visible and fluorescence spectroscopy applications. Silicon, while opaque to visible light, provides excellent thermal conductivity and mechanical stability, beneficial for applications requiring precise temperature control.

Polymer-based materials have gained significant traction in recent years, with polydimethylsiloxane (PDMS) emerging as the material of choice for many applications. PDMS offers advantages including optical transparency, gas permeability, biocompatibility, and ease of fabrication through soft lithography techniques. However, PDMS presents challenges including solvent compatibility issues and potential for biomolecule adsorption, which can interfere with spectroscopic measurements.

Thermoplastics such as polymethyl methacrylate (PMMA), polycarbonate (PC), and cyclic olefin copolymer (COC) represent cost-effective alternatives with good optical properties. These materials enable mass production through injection molding or hot embossing techniques, making them suitable for commercial applications. COC, in particular, has gained attention for its exceptional UV transparency and low autofluorescence, critical properties for sensitive spectroscopic detection.

Surface modification strategies play a crucial role in optimizing material performance for spectroscopic analyses. Techniques such as plasma treatment, chemical functionalization, and coating with metallic nanostructures can enhance surface properties, reduce non-specific binding, and enable surface-enhanced spectroscopic techniques like SERS (Surface-Enhanced Raman Spectroscopy).

The integration of novel nanomaterials, including graphene, carbon nanotubes, and quantum dots, has opened new avenues for enhancing spectroscopic sensitivity. These materials can be incorporated into microfluidic platforms to create localized electromagnetic field enhancements, facilitating techniques such as plasmon-enhanced spectroscopy.

Material selection must also consider compatibility with microfabrication techniques. Photolithography, etching, and bonding processes impose specific requirements on material properties. The development of hybrid materials and multilayer structures has enabled the combination of different material advantages while mitigating their individual limitations, leading to optimized platforms for spectroscopic analyses.

Emerging biodegradable and environmentally friendly materials represent the frontier of microfluidic chip fabrication, addressing sustainability concerns while maintaining the performance requirements for advanced spectroscopic applications. These materials, including cellulose derivatives and biodegradable polymers, are being explored for single-use diagnostic applications where disposal considerations are paramount.

Polymer-based materials have gained significant traction in recent years, with polydimethylsiloxane (PDMS) emerging as the material of choice for many applications. PDMS offers advantages including optical transparency, gas permeability, biocompatibility, and ease of fabrication through soft lithography techniques. However, PDMS presents challenges including solvent compatibility issues and potential for biomolecule adsorption, which can interfere with spectroscopic measurements.

Thermoplastics such as polymethyl methacrylate (PMMA), polycarbonate (PC), and cyclic olefin copolymer (COC) represent cost-effective alternatives with good optical properties. These materials enable mass production through injection molding or hot embossing techniques, making them suitable for commercial applications. COC, in particular, has gained attention for its exceptional UV transparency and low autofluorescence, critical properties for sensitive spectroscopic detection.

Surface modification strategies play a crucial role in optimizing material performance for spectroscopic analyses. Techniques such as plasma treatment, chemical functionalization, and coating with metallic nanostructures can enhance surface properties, reduce non-specific binding, and enable surface-enhanced spectroscopic techniques like SERS (Surface-Enhanced Raman Spectroscopy).

The integration of novel nanomaterials, including graphene, carbon nanotubes, and quantum dots, has opened new avenues for enhancing spectroscopic sensitivity. These materials can be incorporated into microfluidic platforms to create localized electromagnetic field enhancements, facilitating techniques such as plasmon-enhanced spectroscopy.

Material selection must also consider compatibility with microfabrication techniques. Photolithography, etching, and bonding processes impose specific requirements on material properties. The development of hybrid materials and multilayer structures has enabled the combination of different material advantages while mitigating their individual limitations, leading to optimized platforms for spectroscopic analyses.

Emerging biodegradable and environmentally friendly materials represent the frontier of microfluidic chip fabrication, addressing sustainability concerns while maintaining the performance requirements for advanced spectroscopic applications. These materials, including cellulose derivatives and biodegradable polymers, are being explored for single-use diagnostic applications where disposal considerations are paramount.

Miniaturization and Portability Advancements

The miniaturization of spectroscopic analysis systems represents a significant advancement in analytical chemistry and biomedical diagnostics. Microfluidic chip technology has been instrumental in driving this miniaturization trend, enabling the development of portable spectroscopic devices that maintain high analytical performance while dramatically reducing size, weight, and power requirements. These advancements have transformed traditionally bulky laboratory equipment into compact, field-deployable systems suitable for point-of-care diagnostics and on-site environmental monitoring.

Recent innovations in microfabrication techniques have allowed for the integration of optical components directly onto microfluidic platforms. Silicon photonics, MEMS-based mirrors, and planar waveguides have been successfully incorporated into microfluidic chips, creating fully integrated spectroscopic systems with footprints measured in square centimeters rather than square meters. For instance, the development of on-chip Fourier Transform Infrared (FTIR) spectrometers has reduced instrument size by over 90% compared to conventional benchtop systems.

The miniaturization of pumping and fluid handling components has paralleled these optical advancements. Electroosmotic pumps, capillary forces, and centrifugal microfluidics have eliminated the need for external pumping systems, further reducing overall system size and complexity. These innovations enable truly handheld devices capable of performing complex spectroscopic analyses without sacrificing analytical performance.

Power consumption has also been dramatically reduced through miniaturization efforts. Modern microfluidic spectroscopic systems typically operate on less than 5 watts of power, compared to traditional systems requiring hundreds of watts. This reduction enables battery operation and wireless functionality, critical features for portable applications. Some advanced systems now incorporate energy harvesting technologies, further extending operational lifetimes in field deployments.

The integration of microelectronics with microfluidic spectroscopy has yielded smart systems capable of automated sample preparation, analysis, and data processing. These systems often incorporate wireless connectivity for remote monitoring and cloud-based data analysis, expanding their utility in distributed sensing networks and telemedicine applications. The combination of miniaturized optics, fluidics, and electronics creates complete analytical solutions in remarkably compact packages.

Commercial applications of these miniaturized spectroscopic systems are rapidly expanding. Portable Raman spectrometers utilizing microfluidic sample handling now enable on-site pharmaceutical verification and narcotics identification. Similarly, miniaturized near-infrared spectroscopic systems with integrated microfluidics provide real-time monitoring of industrial processes and agricultural products. The healthcare sector has particularly benefited from these advancements, with point-of-care diagnostic devices now capable of performing complex spectroscopic analyses from small biological samples.

Recent innovations in microfabrication techniques have allowed for the integration of optical components directly onto microfluidic platforms. Silicon photonics, MEMS-based mirrors, and planar waveguides have been successfully incorporated into microfluidic chips, creating fully integrated spectroscopic systems with footprints measured in square centimeters rather than square meters. For instance, the development of on-chip Fourier Transform Infrared (FTIR) spectrometers has reduced instrument size by over 90% compared to conventional benchtop systems.

The miniaturization of pumping and fluid handling components has paralleled these optical advancements. Electroosmotic pumps, capillary forces, and centrifugal microfluidics have eliminated the need for external pumping systems, further reducing overall system size and complexity. These innovations enable truly handheld devices capable of performing complex spectroscopic analyses without sacrificing analytical performance.

Power consumption has also been dramatically reduced through miniaturization efforts. Modern microfluidic spectroscopic systems typically operate on less than 5 watts of power, compared to traditional systems requiring hundreds of watts. This reduction enables battery operation and wireless functionality, critical features for portable applications. Some advanced systems now incorporate energy harvesting technologies, further extending operational lifetimes in field deployments.

The integration of microelectronics with microfluidic spectroscopy has yielded smart systems capable of automated sample preparation, analysis, and data processing. These systems often incorporate wireless connectivity for remote monitoring and cloud-based data analysis, expanding their utility in distributed sensing networks and telemedicine applications. The combination of miniaturized optics, fluidics, and electronics creates complete analytical solutions in remarkably compact packages.

Commercial applications of these miniaturized spectroscopic systems are rapidly expanding. Portable Raman spectrometers utilizing microfluidic sample handling now enable on-site pharmaceutical verification and narcotics identification. Similarly, miniaturized near-infrared spectroscopic systems with integrated microfluidics provide real-time monitoring of industrial processes and agricultural products. The healthcare sector has particularly benefited from these advancements, with point-of-care diagnostic devices now capable of performing complex spectroscopic analyses from small biological samples.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!