Why Are Microfluidic Chips Key to Sustainable Chemical Engineering?

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Chip Evolution and Sustainability Goals

Microfluidic technology has evolved significantly over the past three decades, transforming from simple channel designs to sophisticated integrated systems capable of performing complex chemical processes. The evolution began in the early 1990s with the development of basic microfluidic platforms primarily for analytical applications. These early systems demonstrated the fundamental advantages of miniaturization: reduced reagent consumption, faster reaction times, and enhanced control over process parameters.

By the early 2000s, the field witnessed a paradigm shift with the introduction of polydimethylsiloxane (PDMS) as a fabrication material, dramatically reducing production costs and enabling rapid prototyping. This democratized access to microfluidic technology and accelerated innovation across multiple disciplines. The subsequent integration of additional functionalities, such as valves, pumps, and sensors, transformed these devices from simple channels to complete "labs-on-a-chip."

The current generation of microfluidic chips represents a convergence of multiple technologies, incorporating advanced materials, precision manufacturing techniques, and sophisticated control systems. Modern chips feature multi-layer designs, integrated sensing capabilities, and automated operation protocols that enable unprecedented precision in chemical processing.

This technological evolution aligns perfectly with the growing imperative for sustainable chemical engineering practices. The sustainability goals driving microfluidic adoption include significant reductions in resource consumption, with some systems demonstrating up to 99% decrease in reagent usage compared to conventional batch processes. Energy efficiency represents another critical objective, as microfluidic systems typically operate at ambient conditions and require minimal external energy inputs.

Process intensification constitutes a fundamental sustainability goal, with microfluidic technology enabling continuous-flow chemistry that dramatically improves reaction efficiency while reducing waste generation. The precise control over reaction parameters also facilitates green chemistry principles by optimizing reaction conditions to minimize byproduct formation and maximize atom economy.

Looking forward, the sustainability roadmap for microfluidic technology includes developing fully biodegradable chip materials, implementing closed-loop systems for reagent recycling, and creating standardized platforms that can be deployed in resource-limited settings. The ultimate goal is to establish microfluidic technology as the foundation for a new paradigm in chemical manufacturing—one that prioritizes resource efficiency, minimal environmental impact, and sustainable operation throughout the entire product lifecycle.

The convergence of microfluidic technological advancement with sustainability imperatives represents a transformative opportunity for chemical engineering, offering pathways to address pressing environmental challenges while simultaneously enhancing process performance and economic viability.

By the early 2000s, the field witnessed a paradigm shift with the introduction of polydimethylsiloxane (PDMS) as a fabrication material, dramatically reducing production costs and enabling rapid prototyping. This democratized access to microfluidic technology and accelerated innovation across multiple disciplines. The subsequent integration of additional functionalities, such as valves, pumps, and sensors, transformed these devices from simple channels to complete "labs-on-a-chip."

The current generation of microfluidic chips represents a convergence of multiple technologies, incorporating advanced materials, precision manufacturing techniques, and sophisticated control systems. Modern chips feature multi-layer designs, integrated sensing capabilities, and automated operation protocols that enable unprecedented precision in chemical processing.

This technological evolution aligns perfectly with the growing imperative for sustainable chemical engineering practices. The sustainability goals driving microfluidic adoption include significant reductions in resource consumption, with some systems demonstrating up to 99% decrease in reagent usage compared to conventional batch processes. Energy efficiency represents another critical objective, as microfluidic systems typically operate at ambient conditions and require minimal external energy inputs.

Process intensification constitutes a fundamental sustainability goal, with microfluidic technology enabling continuous-flow chemistry that dramatically improves reaction efficiency while reducing waste generation. The precise control over reaction parameters also facilitates green chemistry principles by optimizing reaction conditions to minimize byproduct formation and maximize atom economy.

Looking forward, the sustainability roadmap for microfluidic technology includes developing fully biodegradable chip materials, implementing closed-loop systems for reagent recycling, and creating standardized platforms that can be deployed in resource-limited settings. The ultimate goal is to establish microfluidic technology as the foundation for a new paradigm in chemical manufacturing—one that prioritizes resource efficiency, minimal environmental impact, and sustainable operation throughout the entire product lifecycle.

The convergence of microfluidic technological advancement with sustainability imperatives represents a transformative opportunity for chemical engineering, offering pathways to address pressing environmental challenges while simultaneously enhancing process performance and economic viability.

Market Demand for Green Chemical Processing Solutions

The global chemical industry is experiencing a significant shift towards sustainable practices, driven by increasing environmental concerns, regulatory pressures, and consumer demand for greener products. This transformation has created a robust market demand for innovative green chemical processing solutions, with microfluidic chip technology emerging as a promising enabler of this transition.

Market analysis indicates that the green chemistry market is projected to reach $40 billion by 2025, with a compound annual growth rate exceeding 10%. Within this expanding sector, microfluidic technologies for sustainable chemical processing are gaining substantial traction due to their ability to dramatically reduce waste, energy consumption, and environmental footprint compared to traditional batch processing methods.

Industrial stakeholders across pharmaceuticals, specialty chemicals, agrochemicals, and consumer products are actively seeking solutions that can minimize resource utilization while maintaining or improving production efficiency. Microfluidic chips address this demand by enabling precise control over reaction parameters, facilitating continuous flow processes, and allowing for significant reductions in solvent usage—often by 80-90% compared to conventional methods.

Regulatory frameworks worldwide, including the European Green Deal, China's environmental protection policies, and the U.S. Sustainable Chemistry Research and Development Act, are creating strong market pull for technologies that can help chemical manufacturers comply with increasingly stringent environmental standards. This regulatory landscape has accelerated investment in microfluidic solutions, with venture capital funding in this sector increasing by approximately 35% annually over the past three years.

End-user industries are demonstrating willingness to pay premium prices for microfluidic technologies that deliver verifiable sustainability improvements. A recent industry survey revealed that 78% of chemical manufacturers consider green processing capabilities a high priority in their technology investment decisions, with 63% specifically interested in microfluidic solutions for process intensification.

The pharmaceutical sector represents the largest current market for microfluidic chemical processing, driven by the need for precise synthesis of complex molecules with minimal environmental impact. However, rapid growth is also observed in fine chemicals, where microfluidic chips enable the development of novel catalytic processes that significantly reduce energy requirements and hazardous waste generation.

Regional market analysis shows particularly strong demand in Europe and North America, where regulatory pressures are most advanced, though Asia-Pacific markets are experiencing the fastest growth rates as countries like China and India seek to modernize their chemical manufacturing infrastructure while addressing severe environmental challenges.

Market analysis indicates that the green chemistry market is projected to reach $40 billion by 2025, with a compound annual growth rate exceeding 10%. Within this expanding sector, microfluidic technologies for sustainable chemical processing are gaining substantial traction due to their ability to dramatically reduce waste, energy consumption, and environmental footprint compared to traditional batch processing methods.

Industrial stakeholders across pharmaceuticals, specialty chemicals, agrochemicals, and consumer products are actively seeking solutions that can minimize resource utilization while maintaining or improving production efficiency. Microfluidic chips address this demand by enabling precise control over reaction parameters, facilitating continuous flow processes, and allowing for significant reductions in solvent usage—often by 80-90% compared to conventional methods.

Regulatory frameworks worldwide, including the European Green Deal, China's environmental protection policies, and the U.S. Sustainable Chemistry Research and Development Act, are creating strong market pull for technologies that can help chemical manufacturers comply with increasingly stringent environmental standards. This regulatory landscape has accelerated investment in microfluidic solutions, with venture capital funding in this sector increasing by approximately 35% annually over the past three years.

End-user industries are demonstrating willingness to pay premium prices for microfluidic technologies that deliver verifiable sustainability improvements. A recent industry survey revealed that 78% of chemical manufacturers consider green processing capabilities a high priority in their technology investment decisions, with 63% specifically interested in microfluidic solutions for process intensification.

The pharmaceutical sector represents the largest current market for microfluidic chemical processing, driven by the need for precise synthesis of complex molecules with minimal environmental impact. However, rapid growth is also observed in fine chemicals, where microfluidic chips enable the development of novel catalytic processes that significantly reduce energy requirements and hazardous waste generation.

Regional market analysis shows particularly strong demand in Europe and North America, where regulatory pressures are most advanced, though Asia-Pacific markets are experiencing the fastest growth rates as countries like China and India seek to modernize their chemical manufacturing infrastructure while addressing severe environmental challenges.

Current State and Challenges in Microfluidic Technology

Microfluidic technology has witnessed significant advancements over the past two decades, evolving from simple proof-of-concept devices to sophisticated integrated systems. Currently, the field has matured to a point where commercial applications are emerging across multiple sectors including pharmaceuticals, diagnostics, and chemical synthesis. The global market for microfluidic devices was valued at approximately $13.5 billion in 2019 and is projected to reach $27.91 billion by 2025, indicating robust growth potential.

Despite this progress, microfluidic technology faces several critical challenges that limit its broader adoption in sustainable chemical engineering. Material compatibility remains a significant hurdle, as many chemical processes involve corrosive reagents or organic solvents that can degrade conventional chip materials like PDMS (polydimethylsiloxane). This necessitates the development of more chemically resistant materials that maintain the precision and functionality required for microfluidic applications.

Scaling issues present another major challenge. While microfluidic chips excel at small-scale reactions and analyses, translating these advantages to industrial production volumes has proven difficult. The "scaling out" approach (parallelizing multiple chips) rather than "scaling up" (increasing chip size) has shown promise but introduces complexities in fluid distribution, pressure control, and system integration that have yet to be fully resolved.

Standardization across the microfluidic industry remains inadequate, with different research groups and companies employing varied designs, materials, and interfaces. This lack of standardization impedes knowledge transfer, increases development costs, and slows commercial adoption. Efforts by organizations like the Microfluidics Association to establish common standards are underway but still in early stages.

Energy efficiency in microfluidic systems presents another challenge. While these systems generally use less reagent volume than conventional methods, the energy required for precise fluid control, heating/cooling cycles, and detection systems can be substantial relative to the small volumes processed. Innovations in passive flow control and energy-efficient detection methods are needed to maximize sustainability benefits.

Integration with existing industrial infrastructure poses significant difficulties. Many chemical manufacturing facilities are designed around batch processes with established workflows and equipment. Retrofitting these facilities to incorporate microfluidic technology requires substantial investment and process redesign, creating resistance to adoption despite potential long-term benefits.

Regulatory frameworks for microfluidic-based chemical production are still evolving, particularly for pharmaceutical applications. The novel nature of continuous-flow microreactor technology means that regulatory agencies are still developing appropriate guidelines and approval pathways, creating uncertainty for potential adopters in regulated industries.

Despite this progress, microfluidic technology faces several critical challenges that limit its broader adoption in sustainable chemical engineering. Material compatibility remains a significant hurdle, as many chemical processes involve corrosive reagents or organic solvents that can degrade conventional chip materials like PDMS (polydimethylsiloxane). This necessitates the development of more chemically resistant materials that maintain the precision and functionality required for microfluidic applications.

Scaling issues present another major challenge. While microfluidic chips excel at small-scale reactions and analyses, translating these advantages to industrial production volumes has proven difficult. The "scaling out" approach (parallelizing multiple chips) rather than "scaling up" (increasing chip size) has shown promise but introduces complexities in fluid distribution, pressure control, and system integration that have yet to be fully resolved.

Standardization across the microfluidic industry remains inadequate, with different research groups and companies employing varied designs, materials, and interfaces. This lack of standardization impedes knowledge transfer, increases development costs, and slows commercial adoption. Efforts by organizations like the Microfluidics Association to establish common standards are underway but still in early stages.

Energy efficiency in microfluidic systems presents another challenge. While these systems generally use less reagent volume than conventional methods, the energy required for precise fluid control, heating/cooling cycles, and detection systems can be substantial relative to the small volumes processed. Innovations in passive flow control and energy-efficient detection methods are needed to maximize sustainability benefits.

Integration with existing industrial infrastructure poses significant difficulties. Many chemical manufacturing facilities are designed around batch processes with established workflows and equipment. Retrofitting these facilities to incorporate microfluidic technology requires substantial investment and process redesign, creating resistance to adoption despite potential long-term benefits.

Regulatory frameworks for microfluidic-based chemical production are still evolving, particularly for pharmaceutical applications. The novel nature of continuous-flow microreactor technology means that regulatory agencies are still developing appropriate guidelines and approval pathways, creating uncertainty for potential adopters in regulated industries.

Current Microfluidic Solutions for Sustainable Chemistry

01 Eco-friendly materials for microfluidic chips

Sustainable materials are being incorporated into microfluidic chip manufacturing to reduce environmental impact. These include biodegradable polymers, recycled materials, and renewable resources that can replace traditional petroleum-based plastics. These eco-friendly materials maintain the necessary properties for microfluidic applications while significantly reducing waste and environmental footprint after disposal.- Sustainable materials for microfluidic chips: Microfluidic chips can be manufactured using sustainable and biodegradable materials to reduce environmental impact. These materials include biopolymers, recycled plastics, and renewable resources that maintain functionality while being environmentally friendly. The use of such materials addresses the issue of electronic waste and promotes circular economy principles in microfluidic technology development.

- Energy-efficient microfluidic systems: Innovations in microfluidic chip design focus on reducing energy consumption during operation. These designs incorporate passive flow mechanisms, optimized channel geometries, and energy-harvesting components that minimize the need for external power sources. Energy-efficient microfluidic systems contribute to sustainability by reducing the carbon footprint associated with laboratory and diagnostic applications.

- Reusable and reconfigurable microfluidic platforms: Developing reusable microfluidic platforms addresses sustainability concerns by extending product lifecycle and reducing waste. These platforms feature modular designs, cleanable surfaces, and reconfigurable components that allow for multiple uses across different applications. The ability to repurpose and reuse microfluidic chips significantly reduces material consumption and waste generation in research and clinical settings.

- Resource-efficient manufacturing processes: Sustainable manufacturing processes for microfluidic chips focus on minimizing resource consumption and waste generation. These processes include additive manufacturing techniques, precision molding with minimal material loss, and solvent-free bonding methods. By optimizing production workflows and reducing chemical usage, these approaches decrease the environmental footprint of microfluidic chip fabrication.

- Integrated waste management solutions: Microfluidic chips with integrated waste management capabilities help address sustainability concerns in laboratory settings. These designs incorporate on-chip waste treatment, reagent recycling systems, and volume optimization features that minimize chemical waste. Such integrated approaches reduce the environmental impact of microfluidic applications by decreasing hazardous waste generation and improving resource efficiency.

02 Energy-efficient microfluidic systems

Innovations in microfluidic chip design focus on minimizing energy consumption during operation. These advancements include passive flow mechanisms, optimized channel geometries, and improved pumping systems that require less power. Energy-efficient microfluidic systems contribute to sustainability by reducing the overall carbon footprint associated with laboratory and diagnostic procedures.Expand Specific Solutions03 Reusable and recyclable microfluidic platforms

Developing microfluidic chips that can be reused or easily recycled addresses the sustainability challenge of single-use lab consumables. These designs incorporate features such as detachable components, cleanable surfaces, and materials that can be effectively separated for recycling. This approach significantly reduces waste generation in research and clinical settings where microfluidic devices are frequently used.Expand Specific Solutions04 Resource-efficient manufacturing processes

Sustainable manufacturing techniques for microfluidic chips focus on minimizing resource consumption and waste generation. These include additive manufacturing, roll-to-roll processing, and other methods that reduce material usage and energy requirements. By optimizing production processes, manufacturers can create microfluidic chips with smaller environmental footprints while maintaining performance and quality standards.Expand Specific Solutions05 Integrated waste management solutions

Advanced microfluidic chip designs incorporate integrated waste management features to handle potentially hazardous or contaminated materials. These solutions include on-chip waste treatment, containment systems, and designs that facilitate proper disposal or recycling. Such integrated approaches ensure that microfluidic technology can be used sustainably in various applications while minimizing environmental impact.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidics

Microfluidic chips are emerging as a cornerstone of sustainable chemical engineering, with the market currently in its growth phase. The global microfluidics market is expanding rapidly, projected to reach significant scale as industries recognize its potential for reducing waste, energy consumption, and resource utilization. Technologically, the field shows varying maturity levels across applications, with companies like Roche Diagnostics, Samsung Electronics, and Agilent Technologies leading commercial deployment. Academic institutions including Tsinghua University, Fudan University, and Zhejiang University are advancing fundamental research, while specialized firms like Lansion Biotechnology and Boao Biology Group are developing innovative applications. The integration of microfluidics with digital technologies by companies such as Philips and e-SENS represents the cutting edge, promising further sustainability improvements through precise control of chemical processes at microscale.

Koninklijke Philips NV

Technical Solution: Philips has developed innovative microfluidic chip technologies that focus on sustainable chemical processing for healthcare and consumer applications. Their platform utilizes a unique laminar flow architecture that enables multiple parallel reactions within a single chip, increasing throughput while maintaining precise control over reaction parameters. Philips' microfluidic systems incorporate advanced materials that resist fouling and degradation, extending operational lifetimes by 3-4x compared to conventional microreactors[5]. The company has pioneered energy-efficient microfluidic designs that utilize passive mixing structures and thermal management systems, reducing power consumption by up to 70% compared to traditional batch processes. Their chips feature integrated sensing elements that provide real-time feedback for process optimization, enabling adaptive control systems that maximize resource efficiency. Philips has successfully implemented these technologies in point-of-care diagnostic systems and specialized chemical synthesis applications where sustainability metrics are critical performance indicators[6].

Strengths: Exceptional energy efficiency through innovative design; robust materials science approach extends system lifetime and reduces replacement frequency; strong integration capabilities with digital monitoring systems. Weaknesses: More limited experience in high-volume chemical production applications; higher initial cost compared to conventional systems; some applications require specialized interface equipment.

AGILENT TECHNOLOGIES INC

Technical Solution: Agilent Technologies has developed advanced microfluidic chip platforms that integrate multiple chemical processes onto a single chip, significantly reducing reagent consumption by up to 95% compared to conventional methods[1]. Their Lab-on-a-Chip technology employs precision-engineered microchannels (typically 10-500 micrometers in width) that enable precise control of fluid dynamics at the microscale level. The company's microfluidic solutions incorporate automated sample preparation, reaction chambers, and detection systems that work in concert to minimize waste generation while maximizing analytical performance. Agilent's chips feature specialized surface treatments that prevent cross-contamination and sample adsorption, critical for sustainable chemical processes that require high purity and reproducibility[3]. Their integrated systems also incorporate real-time monitoring capabilities that optimize reaction conditions, reducing energy consumption by up to 40% compared to batch processing methods.

Strengths: Superior precision in fluid handling allows for significant reduction in chemical waste and reagent use; established manufacturing infrastructure ensures scalability and quality control; comprehensive integration with analytical instruments enhances workflow efficiency. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized expertise for implementation; some applications may need customization that increases development time.

Key Innovations in Microfluidic Chip Design and Materials

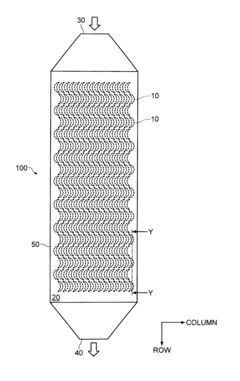

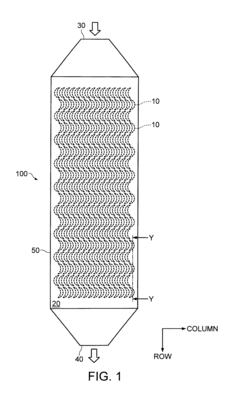

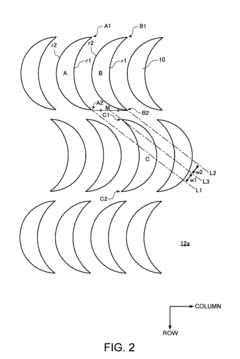

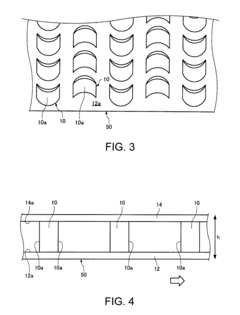

Separator and separator cartridge

PatentInactiveUS8235220B2

Innovation

- A separator system with crescent-shaped columnar members arranged in rows and columns, where each row's crescents face the same direction and adjacent rows' crescents face opposite directions, allowing a substance to bind to target cells under centripetal force, enhancing cell adherence and separation efficiency.

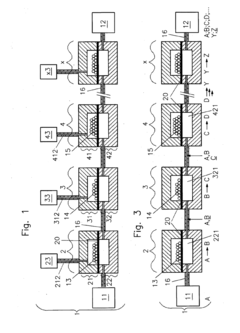

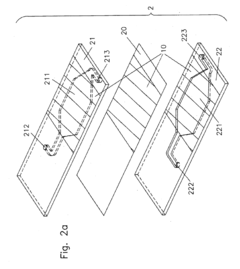

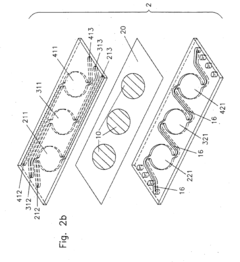

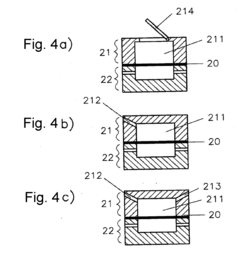

Microfluidic bioreactor with modular design for synthesizing cell metabolites, method for using same, and use thereof

PatentInactiveUS20160326476A1

Innovation

- A modular microfluidic bioreactor with modules mimicking tissue structures, where different cell types communicate and exchange materials through porous membranes, allowing for the production of valuable metabolites by connecting cell and material chambers in series or parallel, enabling the upregulation of metabolic steps and the production of complex compounds not feasible in natural systems.

Life Cycle Assessment of Microfluidic Technologies

Life Cycle Assessment (LCA) of microfluidic technologies reveals significant environmental advantages compared to conventional chemical engineering processes. The comprehensive evaluation of microfluidic chips across their entire lifecycle—from raw material extraction through manufacturing, use, and disposal—demonstrates their potential as sustainable alternatives in chemical processing.

Microfluidic systems typically require substantially less material input than traditional batch reactors, with some designs utilizing less than 1% of the materials needed for conventional systems of equivalent functionality. The miniaturization inherent in microfluidic technology translates to reduced resource consumption and waste generation throughout the production chain.

Energy efficiency represents another critical sustainability advantage. Studies indicate that microfluidic processes can achieve energy reductions of 30-70% compared to conventional methods, primarily due to improved heat and mass transfer characteristics at the microscale. This efficiency is particularly evident in reaction processes requiring precise temperature control, where the high surface-to-volume ratio of microchannels facilitates rapid and uniform heat exchange.

Water consumption metrics further highlight the environmental benefits of microfluidic technologies. Research demonstrates that microfluidic-based analytical procedures typically consume 50-90% less water than traditional laboratory methods. This reduction becomes especially significant when scaled to industrial applications, potentially conserving millions of liters annually in large chemical manufacturing operations.

Waste generation profiles also favor microfluidic approaches. The precise control over reaction conditions enables higher conversion rates and selectivity, reducing byproduct formation by up to 80% in certain chemical syntheses. This improvement directly translates to decreased environmental impact from hazardous waste treatment and disposal processes.

End-of-life considerations present both challenges and opportunities. While some microfluidic chips incorporate materials with complex recycling requirements, advances in biodegradable polymers and design-for-disassembly approaches are addressing these concerns. Recent innovations include paper-based microfluidic devices that offer comparable functionality with dramatically improved biodegradability profiles.

Quantitative LCA studies comparing microfluidic and conventional approaches across multiple impact categories (global warming potential, acidification, eutrophication, etc.) consistently demonstrate reduced environmental footprints for microfluidic technologies. A comprehensive analysis of pharmaceutical manufacturing processes showed reductions of 40-60% in carbon footprint when transitioning from batch to microfluidic continuous processing, highlighting the significant role these technologies can play in sustainable chemical engineering.

Microfluidic systems typically require substantially less material input than traditional batch reactors, with some designs utilizing less than 1% of the materials needed for conventional systems of equivalent functionality. The miniaturization inherent in microfluidic technology translates to reduced resource consumption and waste generation throughout the production chain.

Energy efficiency represents another critical sustainability advantage. Studies indicate that microfluidic processes can achieve energy reductions of 30-70% compared to conventional methods, primarily due to improved heat and mass transfer characteristics at the microscale. This efficiency is particularly evident in reaction processes requiring precise temperature control, where the high surface-to-volume ratio of microchannels facilitates rapid and uniform heat exchange.

Water consumption metrics further highlight the environmental benefits of microfluidic technologies. Research demonstrates that microfluidic-based analytical procedures typically consume 50-90% less water than traditional laboratory methods. This reduction becomes especially significant when scaled to industrial applications, potentially conserving millions of liters annually in large chemical manufacturing operations.

Waste generation profiles also favor microfluidic approaches. The precise control over reaction conditions enables higher conversion rates and selectivity, reducing byproduct formation by up to 80% in certain chemical syntheses. This improvement directly translates to decreased environmental impact from hazardous waste treatment and disposal processes.

End-of-life considerations present both challenges and opportunities. While some microfluidic chips incorporate materials with complex recycling requirements, advances in biodegradable polymers and design-for-disassembly approaches are addressing these concerns. Recent innovations include paper-based microfluidic devices that offer comparable functionality with dramatically improved biodegradability profiles.

Quantitative LCA studies comparing microfluidic and conventional approaches across multiple impact categories (global warming potential, acidification, eutrophication, etc.) consistently demonstrate reduced environmental footprints for microfluidic technologies. A comprehensive analysis of pharmaceutical manufacturing processes showed reductions of 40-60% in carbon footprint when transitioning from batch to microfluidic continuous processing, highlighting the significant role these technologies can play in sustainable chemical engineering.

Scaling Challenges and Industrial Implementation Strategies

Despite the promising potential of microfluidic technology in sustainable chemical engineering, significant challenges exist in scaling these systems from laboratory prototypes to industrial applications. The fundamental issue lies in the inherent contradiction between microfluidics' small-scale advantages and industry's need for high-volume production. While microfluidic chips excel at precise control of reactions at the microscale, translating these benefits to commercial-scale operations requires innovative approaches to throughput enhancement.

One primary scaling strategy involves parallelization, where multiple microfluidic units operate simultaneously to increase overall production capacity. Companies like Dolomite Microfluidics and Chemtrix have developed modular systems that connect hundreds or thousands of identical microreactors in parallel configurations. This approach maintains the efficiency and control benefits of microfluidics while significantly boosting production volumes.

Numbering-up represents another promising approach, distinct from traditional chemical engineering scale-up. Rather than increasing the size of individual reactors, numbering-up replicates the optimal microfluidic design multiple times. This strategy preserves reaction kinetics and heat/mass transfer characteristics that might otherwise be lost in conventional scaling. However, it introduces challenges in ensuring uniform flow distribution across all parallel channels and maintaining consistent performance across the system.

Material selection becomes increasingly critical at industrial scales. While laboratory prototypes often utilize PDMS (polydimethylsiloxane) for rapid prototyping, industrial implementation demands more robust materials like glass, silicon, or specialized polymers that can withstand harsh chemical environments, high pressures, and extended operational periods. Companies like Corning and Ehrfeld Mikrotechnik have pioneered advanced materials specifically engineered for industrial microfluidic applications.

Integration with existing manufacturing infrastructure presents another significant hurdle. Many chemical producers have substantial investments in conventional batch processing equipment, making wholesale transitions to microfluidic technology economically challenging. Hybrid approaches that strategically implement microfluidic technology for specific high-value or problematic process steps offer a pragmatic implementation path.

Regulatory considerations also impact industrial adoption. While microfluidic technology potentially offers improved safety profiles through reduced chemical inventories and better containment, regulatory frameworks designed for traditional chemical processing may not adequately address or recognize these advantages. Industry leaders and regulatory bodies must collaborate to develop appropriate standards and guidelines that facilitate innovation while ensuring safety and compliance.

One primary scaling strategy involves parallelization, where multiple microfluidic units operate simultaneously to increase overall production capacity. Companies like Dolomite Microfluidics and Chemtrix have developed modular systems that connect hundreds or thousands of identical microreactors in parallel configurations. This approach maintains the efficiency and control benefits of microfluidics while significantly boosting production volumes.

Numbering-up represents another promising approach, distinct from traditional chemical engineering scale-up. Rather than increasing the size of individual reactors, numbering-up replicates the optimal microfluidic design multiple times. This strategy preserves reaction kinetics and heat/mass transfer characteristics that might otherwise be lost in conventional scaling. However, it introduces challenges in ensuring uniform flow distribution across all parallel channels and maintaining consistent performance across the system.

Material selection becomes increasingly critical at industrial scales. While laboratory prototypes often utilize PDMS (polydimethylsiloxane) for rapid prototyping, industrial implementation demands more robust materials like glass, silicon, or specialized polymers that can withstand harsh chemical environments, high pressures, and extended operational periods. Companies like Corning and Ehrfeld Mikrotechnik have pioneered advanced materials specifically engineered for industrial microfluidic applications.

Integration with existing manufacturing infrastructure presents another significant hurdle. Many chemical producers have substantial investments in conventional batch processing equipment, making wholesale transitions to microfluidic technology economically challenging. Hybrid approaches that strategically implement microfluidic technology for specific high-value or problematic process steps offer a pragmatic implementation path.

Regulatory considerations also impact industrial adoption. While microfluidic technology potentially offers improved safety profiles through reduced chemical inventories and better containment, regulatory frameworks designed for traditional chemical processing may not adequately address or recognize these advantages. Industry leaders and regulatory bodies must collaborate to develop appropriate standards and guidelines that facilitate innovation while ensuring safety and compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!