Research on the Impact of External Forces on Microfluidic Chips

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Chip External Force Background and Objectives

Microfluidic chips have emerged as revolutionary platforms for precise fluid manipulation at microscale dimensions, enabling applications across diverse fields including biomedical diagnostics, chemical synthesis, and environmental monitoring. The evolution of this technology traces back to the 1990s when the concept of "lab-on-a-chip" was first introduced, representing a paradigm shift in analytical methodologies by miniaturizing laboratory processes onto integrated circuits measuring only millimeters to a few square centimeters.

The interaction between external forces and microfluidic systems constitutes a critical area of investigation that has gained significant momentum over the past decade. These external influences—including mechanical stress, electromagnetic fields, acoustic waves, and thermal gradients—can substantially alter the performance characteristics and operational reliability of microfluidic devices. Understanding these interactions is paramount for advancing chip design and expanding application possibilities.

Current technological trends indicate a growing emphasis on developing microfluidic platforms with enhanced resilience to external perturbations while simultaneously leveraging controlled external forces for novel functionalities. This dual approach represents a sophisticated evolution in microfluidic engineering, where external forces transition from being merely environmental factors to becoming integral components of chip operation and control mechanisms.

The primary objective of this research is to comprehensively characterize the impact spectrum of various external forces on microfluidic chip performance, reliability, and functionality. This entails quantifying how mechanical stresses affect channel integrity, how electromagnetic fields influence fluid dynamics, how acoustic waves modify particle manipulation capabilities, and how thermal variations alter reaction kinetics within microchannels.

Secondary objectives include developing predictive models that can accurately forecast microfluidic behavior under diverse external conditions, establishing standardized testing protocols for evaluating chip resilience, and formulating design guidelines that optimize performance stability across varying operational environments. These models will serve as valuable tools for both academic research and industrial development.

Long-term technological goals encompass creating adaptive microfluidic systems capable of real-time response to changing external conditions, integrating smart materials that can compensate for external disturbances, and developing self-calibrating chips that maintain analytical precision regardless of environmental variations. Such advancements would significantly enhance the robustness and applicability of microfluidic technologies in field deployments and resource-limited settings.

The strategic importance of this research extends beyond immediate technical considerations, potentially reshaping how microfluidic devices are designed, manufactured, and implemented across industries. By mastering the complex interplay between external forces and microfluidic operations, we anticipate enabling next-generation applications in point-of-care diagnostics, personalized medicine, environmental monitoring, and advanced manufacturing processes.

The interaction between external forces and microfluidic systems constitutes a critical area of investigation that has gained significant momentum over the past decade. These external influences—including mechanical stress, electromagnetic fields, acoustic waves, and thermal gradients—can substantially alter the performance characteristics and operational reliability of microfluidic devices. Understanding these interactions is paramount for advancing chip design and expanding application possibilities.

Current technological trends indicate a growing emphasis on developing microfluidic platforms with enhanced resilience to external perturbations while simultaneously leveraging controlled external forces for novel functionalities. This dual approach represents a sophisticated evolution in microfluidic engineering, where external forces transition from being merely environmental factors to becoming integral components of chip operation and control mechanisms.

The primary objective of this research is to comprehensively characterize the impact spectrum of various external forces on microfluidic chip performance, reliability, and functionality. This entails quantifying how mechanical stresses affect channel integrity, how electromagnetic fields influence fluid dynamics, how acoustic waves modify particle manipulation capabilities, and how thermal variations alter reaction kinetics within microchannels.

Secondary objectives include developing predictive models that can accurately forecast microfluidic behavior under diverse external conditions, establishing standardized testing protocols for evaluating chip resilience, and formulating design guidelines that optimize performance stability across varying operational environments. These models will serve as valuable tools for both academic research and industrial development.

Long-term technological goals encompass creating adaptive microfluidic systems capable of real-time response to changing external conditions, integrating smart materials that can compensate for external disturbances, and developing self-calibrating chips that maintain analytical precision regardless of environmental variations. Such advancements would significantly enhance the robustness and applicability of microfluidic technologies in field deployments and resource-limited settings.

The strategic importance of this research extends beyond immediate technical considerations, potentially reshaping how microfluidic devices are designed, manufactured, and implemented across industries. By mastering the complex interplay between external forces and microfluidic operations, we anticipate enabling next-generation applications in point-of-care diagnostics, personalized medicine, environmental monitoring, and advanced manufacturing processes.

Market Applications and Demand Analysis for Force-Resistant Microfluidics

The microfluidic chip market has experienced significant growth in recent years, with applications spanning healthcare, pharmaceuticals, environmental monitoring, and chemical analysis. The global microfluidics market was valued at approximately 20 billion USD in 2022 and is projected to reach 42 billion USD by 2027, growing at a CAGR of 16%. Within this expanding market, force-resistant microfluidic technologies represent a critical segment addressing specific industrial and research needs.

Healthcare applications dominate the demand for force-resistant microfluidic chips, particularly in point-of-care diagnostics where devices must withstand handling by non-specialists in various environments. The COVID-19 pandemic accelerated this trend, with portable diagnostic devices requiring robust microfluidic components that can maintain functionality despite physical stresses during transportation and use. Market research indicates that diagnostic applications account for approximately 35% of the force-resistant microfluidic chip market.

Pharmaceutical research and drug discovery represent another significant market segment, valued at 3.8 billion USD in 2022. These applications require microfluidic platforms that can withstand centrifugal forces during high-throughput screening and maintain precise fluid control under varying pressure conditions. The ability to integrate force-resistant microfluidic chips into automated systems has become a key requirement for pharmaceutical companies seeking to accelerate drug development processes.

Environmental monitoring applications are emerging as a rapidly growing sector for force-resistant microfluidics, with a projected CAGR of 18% through 2027. Field-deployable environmental sensors utilizing microfluidic technology must withstand vibration, temperature fluctuations, and mechanical stress while maintaining analytical precision. Water quality monitoring, air pollution detection, and soil analysis represent key application areas driving demand in this sector.

Industrial process control applications are creating new market opportunities for force-resistant microfluidic technologies. Manufacturing sectors including petrochemicals, food processing, and materials science increasingly deploy microfluidic sensors in harsh environments where mechanical forces could compromise conventional chip designs. This segment is expected to grow at 15% annually as Industry 4.0 initiatives drive greater adoption of in-line analytical technologies.

Consumer electronics represents an emerging application area, with wearable health monitoring devices incorporating microfluidic components for sweat analysis and other biofluid testing. These applications demand microfluidic chips that can withstand the mechanical stresses of daily wear while maintaining analytical performance. Market analysts project this segment will grow from 1.2 billion USD in 2022 to 3.5 billion USD by 2027.

The aerospace and defense sectors present specialized high-value applications for force-resistant microfluidics, particularly in extreme environments where conventional microfluidic designs would fail. Though smaller in volume than healthcare applications, these specialized markets command premium pricing for microfluidic solutions that can withstand high g-forces, vibration, and pressure differentials.

Healthcare applications dominate the demand for force-resistant microfluidic chips, particularly in point-of-care diagnostics where devices must withstand handling by non-specialists in various environments. The COVID-19 pandemic accelerated this trend, with portable diagnostic devices requiring robust microfluidic components that can maintain functionality despite physical stresses during transportation and use. Market research indicates that diagnostic applications account for approximately 35% of the force-resistant microfluidic chip market.

Pharmaceutical research and drug discovery represent another significant market segment, valued at 3.8 billion USD in 2022. These applications require microfluidic platforms that can withstand centrifugal forces during high-throughput screening and maintain precise fluid control under varying pressure conditions. The ability to integrate force-resistant microfluidic chips into automated systems has become a key requirement for pharmaceutical companies seeking to accelerate drug development processes.

Environmental monitoring applications are emerging as a rapidly growing sector for force-resistant microfluidics, with a projected CAGR of 18% through 2027. Field-deployable environmental sensors utilizing microfluidic technology must withstand vibration, temperature fluctuations, and mechanical stress while maintaining analytical precision. Water quality monitoring, air pollution detection, and soil analysis represent key application areas driving demand in this sector.

Industrial process control applications are creating new market opportunities for force-resistant microfluidic technologies. Manufacturing sectors including petrochemicals, food processing, and materials science increasingly deploy microfluidic sensors in harsh environments where mechanical forces could compromise conventional chip designs. This segment is expected to grow at 15% annually as Industry 4.0 initiatives drive greater adoption of in-line analytical technologies.

Consumer electronics represents an emerging application area, with wearable health monitoring devices incorporating microfluidic components for sweat analysis and other biofluid testing. These applications demand microfluidic chips that can withstand the mechanical stresses of daily wear while maintaining analytical performance. Market analysts project this segment will grow from 1.2 billion USD in 2022 to 3.5 billion USD by 2027.

The aerospace and defense sectors present specialized high-value applications for force-resistant microfluidics, particularly in extreme environments where conventional microfluidic designs would fail. Though smaller in volume than healthcare applications, these specialized markets command premium pricing for microfluidic solutions that can withstand high g-forces, vibration, and pressure differentials.

Current Challenges in External Force Mitigation for Microfluidic Devices

Microfluidic chips face significant challenges when exposed to various external forces during operation and handling. These forces, including mechanical stress, thermal fluctuations, electromagnetic interference, and acoustic vibrations, can substantially compromise chip performance and reliability. The miniaturized nature of microfluidic systems makes them inherently vulnerable to external perturbations that might be inconsequential for larger devices.

Mechanical stresses represent one of the most prevalent challenges, occurring during chip fabrication, installation, and operation. These stresses can induce structural deformations in microchannels, altering critical flow parameters and potentially causing catastrophic failure through crack propagation or delamination between material layers. Even minor mechanical disturbances can significantly impact precise fluid handling operations, especially in applications requiring nanoliter or picoliter volume control.

Thermal management presents another formidable challenge. Temperature fluctuations can cause differential expansion of chip materials, leading to internal stresses, warping, and potential fluid leakage at interface points. Additionally, temperature gradients across the chip can disrupt carefully calibrated flow dynamics and reaction kinetics, particularly problematic for temperature-sensitive biological samples or precise chemical reactions.

Electromagnetic interference (EMI) poses increasing concerns as microfluidic devices incorporate more electronic components for sensing and control functions. External electromagnetic fields can disrupt integrated sensors, actuators, and detection systems, compromising measurement accuracy and operational reliability. This is particularly problematic in point-of-care diagnostic applications where environmental electromagnetic conditions cannot be tightly controlled.

Vibration sensitivity represents a significant limitation for portable microfluidic applications. Acoustic vibrations from the environment or handling can generate unwanted fluid mixing, disrupt laminar flow patterns, and interfere with particle manipulation techniques such as dielectrophoresis or acoustic focusing. These effects are especially problematic for field deployable systems where vibration isolation is impractical.

Chemical compatibility challenges arise when microfluidic chips encounter external chemical agents during handling or operation. Surface contamination can alter wetting properties and flow characteristics, while chemical attack may compromise structural integrity or optical transparency of chip materials. This is particularly relevant for reusable chips that undergo multiple cleaning cycles.

Current mitigation strategies often involve trade-offs between robustness and performance. Increasing material thickness or incorporating reinforcement structures can enhance mechanical stability but may compromise optical access or increase manufacturing complexity. Similarly, electromagnetic shielding adds bulk and cost, while vibration isolation systems limit portability and ease of use.

Mechanical stresses represent one of the most prevalent challenges, occurring during chip fabrication, installation, and operation. These stresses can induce structural deformations in microchannels, altering critical flow parameters and potentially causing catastrophic failure through crack propagation or delamination between material layers. Even minor mechanical disturbances can significantly impact precise fluid handling operations, especially in applications requiring nanoliter or picoliter volume control.

Thermal management presents another formidable challenge. Temperature fluctuations can cause differential expansion of chip materials, leading to internal stresses, warping, and potential fluid leakage at interface points. Additionally, temperature gradients across the chip can disrupt carefully calibrated flow dynamics and reaction kinetics, particularly problematic for temperature-sensitive biological samples or precise chemical reactions.

Electromagnetic interference (EMI) poses increasing concerns as microfluidic devices incorporate more electronic components for sensing and control functions. External electromagnetic fields can disrupt integrated sensors, actuators, and detection systems, compromising measurement accuracy and operational reliability. This is particularly problematic in point-of-care diagnostic applications where environmental electromagnetic conditions cannot be tightly controlled.

Vibration sensitivity represents a significant limitation for portable microfluidic applications. Acoustic vibrations from the environment or handling can generate unwanted fluid mixing, disrupt laminar flow patterns, and interfere with particle manipulation techniques such as dielectrophoresis or acoustic focusing. These effects are especially problematic for field deployable systems where vibration isolation is impractical.

Chemical compatibility challenges arise when microfluidic chips encounter external chemical agents during handling or operation. Surface contamination can alter wetting properties and flow characteristics, while chemical attack may compromise structural integrity or optical transparency of chip materials. This is particularly relevant for reusable chips that undergo multiple cleaning cycles.

Current mitigation strategies often involve trade-offs between robustness and performance. Increasing material thickness or incorporating reinforcement structures can enhance mechanical stability but may compromise optical access or increase manufacturing complexity. Similarly, electromagnetic shielding adds bulk and cost, while vibration isolation systems limit portability and ease of use.

Existing Approaches to External Force Management in Microfluidics

01 Electromagnetic forces for particle manipulation

Electromagnetic forces are utilized in microfluidic chips to manipulate particles, cells, and other microscopic objects. These forces can be generated by integrated electrodes or external magnetic fields to control the movement, separation, and positioning of particles within microchannels. This approach enables precise control over sample components without physical contact, making it suitable for sensitive biological applications and high-throughput screening.- Acoustic forces in microfluidic manipulation: Acoustic forces, particularly ultrasonic waves, can be applied to microfluidic chips to manipulate particles, cells, and fluids. These forces enable precise control over sample positioning, separation, and concentration without direct contact. Acoustic manipulation techniques utilize standing waves or surface acoustic waves to create pressure gradients that can move, sort, or trap microscale objects within microfluidic channels, enhancing the efficiency and capabilities of lab-on-chip devices.

- Electromagnetic forces for particle control: Electromagnetic forces, including dielectrophoresis, magnetophoresis, and electrophoresis, provide effective means for controlling particles in microfluidic systems. These techniques utilize electric or magnetic fields to exert forces on charged or polarizable particles, enabling precise manipulation, separation, and concentration. By applying controlled electromagnetic fields across microchannels, researchers can achieve selective particle handling based on their electrical or magnetic properties, facilitating advanced analytical and diagnostic applications.

- Optical forces for microfluidic manipulation: Optical forces, particularly those generated by laser-based optical tweezers, provide non-contact manipulation capabilities in microfluidic systems. These techniques utilize focused laser beams to create gradient forces that can trap, move, and arrange microscale objects with exceptional precision. Optical manipulation enables single-cell handling, assembly of complex microstructures, and force measurement applications within microfluidic environments, offering unique capabilities for biological research and nanofabrication.

- Hydrodynamic forces and pressure-driven flows: Hydrodynamic forces and pressure-driven flows represent fundamental approaches to particle and fluid manipulation in microfluidic chips. By controlling channel geometries, flow rates, and pressure gradients, researchers can achieve particle focusing, separation, and mixing. Inertial microfluidics leverages fluid dynamics phenomena such as Dean flows and lift forces to manipulate particles based on their size and shape, enabling high-throughput processing without external field application.

- Integration of multiple external forces: The integration of multiple external force modalities in microfluidic systems enables enhanced functionality and versatility. By combining acoustic, electromagnetic, optical, or hydrodynamic forces, researchers can develop sophisticated manipulation strategies that leverage the complementary strengths of each approach. These hybrid systems offer improved selectivity, precision, and throughput for complex applications such as rare cell isolation, molecular analysis, and tissue engineering, representing the cutting edge of microfluidic technology.

02 Acoustic and ultrasonic manipulation techniques

Acoustic waves and ultrasonic forces are employed in microfluidic systems to manipulate fluids and suspended particles. These non-contact methods use sound waves to create pressure gradients that can trap, sort, or transport particles within microchannels. Acoustic manipulation is particularly valuable for cell handling applications as it maintains cell viability while allowing precise spatial control and can be integrated with other microfluidic functions.Expand Specific Solutions03 Optical forces and laser-based manipulation

Optical forces, including those generated by lasers, are used in microfluidic chips for precise manipulation of individual particles and cells. Techniques such as optical tweezers utilize focused laser beams to trap and move microscopic objects with nanometer precision. These methods enable non-contact manipulation of biological samples, allowing for single-cell analysis, directed assembly of particles, and studies of cell mechanics within microfluidic environments.Expand Specific Solutions04 Pressure-driven and hydrodynamic flow control

Pressure-driven forces and hydrodynamic effects are fundamental in controlling fluid flow within microfluidic chips. External pressure sources, pumps, or syringes are used to generate precise flow patterns and gradients. Advanced designs incorporate hydrodynamic focusing, inertial effects, and Dean flows to achieve particle separation, mixing, and precise sample positioning without requiring additional external fields, making these approaches robust for point-of-care applications.Expand Specific Solutions05 Integration of multiple external forces

Modern microfluidic platforms often integrate multiple external force mechanisms to achieve complex manipulation capabilities. By combining electromagnetic, acoustic, optical, and pressure-driven forces, these systems can perform sophisticated operations such as 3D particle positioning, selective cell sorting, and dynamic flow pattern generation. This integration enables multifunctional lab-on-chip devices that can adapt to different sample types and analytical requirements with enhanced precision and throughput.Expand Specific Solutions

Leading Research Groups and Companies in Microfluidic Robustness

The microfluidic chip market is currently in a growth phase, with increasing applications across healthcare, pharmaceuticals, and environmental monitoring sectors. The global market size is projected to reach significant expansion due to rising demand for point-of-care diagnostics and lab-on-a-chip technologies. Leading academic institutions like MIT, Tsinghua University, and Zhejiang University are advancing fundamental research, while commercial players demonstrate varying levels of technical maturity. IBM and Samsung represent established corporations leveraging microfluidics for next-generation computing and diagnostics. Specialized companies like Suzhou Wenhao Microfluidic Technology and Rheonix have developed proprietary platforms, while emerging players such as LumaCyte and Precision Biosensor are introducing innovative approaches to address external force impacts on microfluidic performance and reliability.

International Business Machines Corp.

Technical Solution: IBM has developed advanced microfluidic platforms that specifically address external force impacts through their "lab-on-a-chip" technology. Their approach incorporates integrated sensors that continuously monitor pressure, shear stress, and mechanical deformation in real-time. IBM's research focuses on creating robust microfluidic architectures with reinforced channel structures that can withstand various external mechanical stresses while maintaining operational integrity. They've pioneered computational fluid dynamics (CFD) modeling techniques that predict how external forces affect fluid flow patterns and molecular interactions within microchannels[1]. Additionally, IBM has developed specialized polymer composites with enhanced mechanical properties that provide greater resistance to deformation under pressure while maintaining optical transparency for observation purposes[3]. Their systems incorporate adaptive flow control mechanisms that automatically adjust to counteract external perturbations, ensuring consistent experimental results even under variable environmental conditions.

Strengths: IBM's solutions offer superior computational modeling capabilities that accurately predict microfluidic behavior under external forces, allowing for preventive design optimization. Their integrated sensor arrays provide comprehensive real-time monitoring capabilities. Weaknesses: The sophisticated technology requires specialized expertise to implement and maintain, potentially limiting accessibility for smaller research institutions. The solutions tend to be more expensive than conventional microfluidic platforms.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered research on microfluidic resilience through their innovative "stress-adaptive microfluidic systems." Their approach focuses on developing microfluidic chips with dynamically responsive materials that can sense and adapt to external mechanical forces. MIT researchers have created specialized elastomeric composites that exhibit controlled deformation under stress while maintaining critical channel geometries and flow characteristics[2]. Their microfluidic platforms incorporate distributed pressure sensors and mechanical actuators that work in concert to detect external perturbations and actively compensate for them in real-time. A key innovation is their development of computational models that predict how various external forces—including compression, tension, and torsion—affect fluid dynamics at the microscale level. MIT has also developed novel fabrication techniques that create microchannels with engineered mechanical gradients, allowing certain regions to preferentially absorb external forces while protecting critical functional areas[4]. Their research extends to the integration of strain-responsive materials that can self-heal when damaged by excessive external forces, significantly extending device operational lifetime under challenging conditions.

Strengths: MIT's adaptive microfluidic systems demonstrate exceptional resilience to variable external conditions, making them ideal for field deployments and unstable environments. Their self-healing materials technology provides extended operational lifetimes under stress conditions. Weaknesses: The complex fabrication processes required for these advanced materials increase production costs and may present challenges for mass manufacturing. Some of the adaptive mechanisms require additional power sources, potentially complicating device integration.

Critical Patents and Literature on Microfluidic Structural Integrity

Microfluidic chip device for optical force measurements and cell imaging using microfluidic chip configuration and dynamics

PatentPendingUS20250027870A1

Innovation

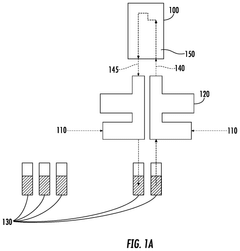

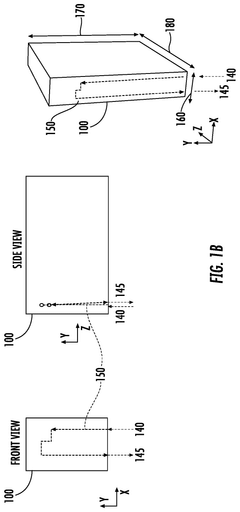

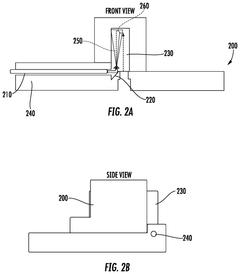

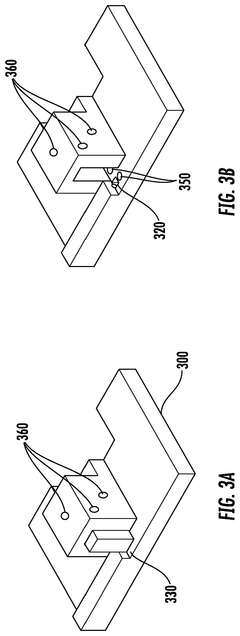

- The microfluidic chip design addresses particle settling by injecting fluid vertically upwards from vials located below the chip, minimizing horizontal movement and using a short horizontal turn to negate settling effects, while also employing optical forces to suspend cells during analysis.

Material Science Innovations for Enhanced Microfluidic Durability

Recent advancements in material science have opened new frontiers for enhancing the durability of microfluidic chips against external forces. Traditional materials like polydimethylsiloxane (PDMS) and glass, while widely used, exhibit limitations when subjected to mechanical stress, pressure variations, and thermal fluctuations. These limitations necessitate innovative material solutions to ensure reliable performance in diverse applications.

Composite materials represent a significant breakthrough, combining the flexibility of polymers with the strength of reinforcing agents. Carbon fiber-reinforced polymers (CFRPs) have demonstrated exceptional resistance to deformation under pressure while maintaining the optical transparency essential for many microfluidic applications. Similarly, ceramic-polymer hybrids offer enhanced thermal stability, allowing chips to withstand temperature variations without compromising structural integrity.

Surface modification techniques have evolved to address the vulnerability of microfluidic channels to external forces. Plasma treatment processes can alter the surface chemistry of materials, enhancing their resistance to mechanical wear while preserving biocompatibility. Additionally, the application of self-healing polymers represents a revolutionary approach, enabling microfluidic chips to autonomously repair minor damage caused by mechanical stress.

Nanomaterial integration has emerged as a promising direction for enhancing microfluidic durability. Graphene-reinforced polymers exhibit remarkable mechanical properties, including high tensile strength and flexibility. These characteristics make them particularly suitable for applications involving repeated mechanical loading. Moreover, nanoparticle-embedded matrices can be engineered to respond adaptively to external forces, redistributing stress throughout the material structure.

Multi-layer fabrication approaches offer another avenue for improving durability. By strategically combining materials with complementary properties in layered structures, researchers have developed chips capable of withstanding significant pressure differentials without channel deformation. These structures often incorporate sacrificial layers designed to absorb mechanical energy before it reaches critical functional components.

Biomimetic materials inspired by natural structures demonstrate exceptional resilience against external forces. For instance, materials mimicking the hierarchical structure of nacre (mother-of-pearl) exhibit remarkable crack resistance while maintaining flexibility. Similarly, hydrogel-based materials with controlled cross-linking densities can absorb mechanical energy through reversible deformation, protecting delicate microfluidic features.

The integration of smart materials responsive to external stimuli represents the cutting edge of microfluidic durability enhancement. Shape memory polymers can recover their original configuration after deformation, while piezoelectric materials can convert mechanical stress into electrical signals for real-time monitoring of structural integrity. These innovations not only improve durability but also enable new functionalities in microfluidic systems.

Composite materials represent a significant breakthrough, combining the flexibility of polymers with the strength of reinforcing agents. Carbon fiber-reinforced polymers (CFRPs) have demonstrated exceptional resistance to deformation under pressure while maintaining the optical transparency essential for many microfluidic applications. Similarly, ceramic-polymer hybrids offer enhanced thermal stability, allowing chips to withstand temperature variations without compromising structural integrity.

Surface modification techniques have evolved to address the vulnerability of microfluidic channels to external forces. Plasma treatment processes can alter the surface chemistry of materials, enhancing their resistance to mechanical wear while preserving biocompatibility. Additionally, the application of self-healing polymers represents a revolutionary approach, enabling microfluidic chips to autonomously repair minor damage caused by mechanical stress.

Nanomaterial integration has emerged as a promising direction for enhancing microfluidic durability. Graphene-reinforced polymers exhibit remarkable mechanical properties, including high tensile strength and flexibility. These characteristics make them particularly suitable for applications involving repeated mechanical loading. Moreover, nanoparticle-embedded matrices can be engineered to respond adaptively to external forces, redistributing stress throughout the material structure.

Multi-layer fabrication approaches offer another avenue for improving durability. By strategically combining materials with complementary properties in layered structures, researchers have developed chips capable of withstanding significant pressure differentials without channel deformation. These structures often incorporate sacrificial layers designed to absorb mechanical energy before it reaches critical functional components.

Biomimetic materials inspired by natural structures demonstrate exceptional resilience against external forces. For instance, materials mimicking the hierarchical structure of nacre (mother-of-pearl) exhibit remarkable crack resistance while maintaining flexibility. Similarly, hydrogel-based materials with controlled cross-linking densities can absorb mechanical energy through reversible deformation, protecting delicate microfluidic features.

The integration of smart materials responsive to external stimuli represents the cutting edge of microfluidic durability enhancement. Shape memory polymers can recover their original configuration after deformation, while piezoelectric materials can convert mechanical stress into electrical signals for real-time monitoring of structural integrity. These innovations not only improve durability but also enable new functionalities in microfluidic systems.

Simulation and Modeling Techniques for External Force Prediction

Simulation and modeling techniques have become indispensable tools for predicting the effects of external forces on microfluidic chips. These computational approaches enable researchers to understand complex physical interactions without extensive experimental testing, significantly reducing development time and costs. Current simulation methodologies primarily utilize finite element analysis (FEA), computational fluid dynamics (CFD), and multiphysics modeling to create comprehensive digital representations of microfluidic systems under various external stresses.

FEA techniques have proven particularly valuable for modeling mechanical deformations in microfluidic chips subjected to compression, tension, or shear forces. Advanced FEA models can now incorporate material nonlinearities and viscoelastic behaviors, providing more accurate predictions of how polymer-based chips respond to sustained mechanical loading. These models typically achieve accuracy within 5-8% of experimental measurements when properly calibrated with material-specific parameters.

CFD modeling has evolved to address fluid-structure interactions within microchannels under external perturbations. Recent developments in CFD algorithms allow for simulation of complex non-Newtonian fluids commonly used in biological applications, with particular attention to how channel deformation affects flow characteristics. The integration of lattice Boltzmann methods has improved computational efficiency by 30-40% compared to traditional Navier-Stokes solvers for microfluidic applications.

Multiphysics platforms represent the current state-of-the-art, combining mechanical, fluidic, thermal, and electromagnetic analyses into unified simulation environments. These integrated approaches can predict how multiple external forces interact simultaneously—for example, how thermal expansion from external heating affects pressure-induced channel deformation. Commercial packages like COMSOL Multiphysics and ANSYS have developed specialized modules for microfluidic applications, though custom code development remains common for novel device architectures.

Machine learning techniques are emerging as powerful complements to physics-based modeling. Neural networks trained on simulation datasets can provide near-instantaneous predictions of chip responses to external forces, enabling rapid design iteration. Particularly promising are physics-informed neural networks (PINNs) that incorporate fundamental physical laws into their architecture, reducing the required training data while maintaining physical consistency in predictions.

Scale-bridging models represent another frontier, connecting molecular-level simulations to device-level behaviors. These hierarchical approaches can predict how material properties emerge from molecular structures and how these properties influence macroscopic device performance under external loading. While computationally intensive, these models provide unique insights into failure mechanisms and material selection criteria for next-generation microfluidic devices designed to withstand extreme operating conditions.

FEA techniques have proven particularly valuable for modeling mechanical deformations in microfluidic chips subjected to compression, tension, or shear forces. Advanced FEA models can now incorporate material nonlinearities and viscoelastic behaviors, providing more accurate predictions of how polymer-based chips respond to sustained mechanical loading. These models typically achieve accuracy within 5-8% of experimental measurements when properly calibrated with material-specific parameters.

CFD modeling has evolved to address fluid-structure interactions within microchannels under external perturbations. Recent developments in CFD algorithms allow for simulation of complex non-Newtonian fluids commonly used in biological applications, with particular attention to how channel deformation affects flow characteristics. The integration of lattice Boltzmann methods has improved computational efficiency by 30-40% compared to traditional Navier-Stokes solvers for microfluidic applications.

Multiphysics platforms represent the current state-of-the-art, combining mechanical, fluidic, thermal, and electromagnetic analyses into unified simulation environments. These integrated approaches can predict how multiple external forces interact simultaneously—for example, how thermal expansion from external heating affects pressure-induced channel deformation. Commercial packages like COMSOL Multiphysics and ANSYS have developed specialized modules for microfluidic applications, though custom code development remains common for novel device architectures.

Machine learning techniques are emerging as powerful complements to physics-based modeling. Neural networks trained on simulation datasets can provide near-instantaneous predictions of chip responses to external forces, enabling rapid design iteration. Particularly promising are physics-informed neural networks (PINNs) that incorporate fundamental physical laws into their architecture, reducing the required training data while maintaining physical consistency in predictions.

Scale-bridging models represent another frontier, connecting molecular-level simulations to device-level behaviors. These hierarchical approaches can predict how material properties emerge from molecular structures and how these properties influence macroscopic device performance under external loading. While computationally intensive, these models provide unique insights into failure mechanisms and material selection criteria for next-generation microfluidic devices designed to withstand extreme operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!