Integration of Microfluidic Chips in Aerospace Systems

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Aerospace Integration Background & Objectives

Microfluidic technology has evolved significantly since its inception in the 1990s, transitioning from simple lab-on-a-chip concepts to sophisticated integrated systems capable of performing complex fluid manipulation tasks. The integration of microfluidic chips in aerospace systems represents a convergence of miniaturization technologies with the demanding requirements of space and aviation applications. This technological intersection has gained momentum over the past decade as aerospace manufacturers seek more efficient, lightweight, and reliable systems for fluid handling, analysis, and control in extreme environments.

The evolution trajectory of microfluidic aerospace integration has been characterized by progressive improvements in materials science, fabrication techniques, and system integration approaches. Early applications focused primarily on basic fluid handling for life support systems, but recent advancements have expanded to include propellant management, thermal regulation, environmental monitoring, and biomedical applications for crew health assessment. The miniaturization benefits of microfluidics align perfectly with aerospace requirements for mass and volume reduction.

Current technological trends indicate a shift toward multi-functional microfluidic platforms that can perform several operations simultaneously while maintaining reliability under the harsh conditions of aerospace environments. These include extreme temperature variations, radiation exposure, microgravity effects, and high vibration loads during launch and operation. The development of radiation-hardened microfluidic components and materials capable of withstanding these conditions represents a significant focus area in current research.

The primary technical objectives for microfluidic aerospace integration include: reducing system mass and volume by at least 60% compared to conventional fluid handling systems; enhancing reliability through redundant design and fault-tolerant architectures; developing microfluidic platforms capable of operating continuously for extended missions (3-5 years) without maintenance; and creating standardized interfaces for modular integration with existing aerospace systems.

Additionally, there are specific performance targets related to fluid handling precision, such as achieving flow rate control with accuracy better than ±1% across a wide dynamic range, and maintaining stable operation under varying gravitational conditions from 0g to 9g. Power consumption reduction represents another critical objective, with goals to operate complex microfluidic systems under 5W for portable applications and under 20W for integrated vehicle systems.

The long-term vision for this technology encompasses fully autonomous microfluidic systems capable of self-diagnosis, self-healing, and adaptive reconfiguration based on mission parameters and environmental conditions. This would enable transformative capabilities for long-duration space missions, advanced aircraft environmental control systems, and next-generation propulsion technologies that leverage precise microfluidic control for enhanced efficiency and performance.

The evolution trajectory of microfluidic aerospace integration has been characterized by progressive improvements in materials science, fabrication techniques, and system integration approaches. Early applications focused primarily on basic fluid handling for life support systems, but recent advancements have expanded to include propellant management, thermal regulation, environmental monitoring, and biomedical applications for crew health assessment. The miniaturization benefits of microfluidics align perfectly with aerospace requirements for mass and volume reduction.

Current technological trends indicate a shift toward multi-functional microfluidic platforms that can perform several operations simultaneously while maintaining reliability under the harsh conditions of aerospace environments. These include extreme temperature variations, radiation exposure, microgravity effects, and high vibration loads during launch and operation. The development of radiation-hardened microfluidic components and materials capable of withstanding these conditions represents a significant focus area in current research.

The primary technical objectives for microfluidic aerospace integration include: reducing system mass and volume by at least 60% compared to conventional fluid handling systems; enhancing reliability through redundant design and fault-tolerant architectures; developing microfluidic platforms capable of operating continuously for extended missions (3-5 years) without maintenance; and creating standardized interfaces for modular integration with existing aerospace systems.

Additionally, there are specific performance targets related to fluid handling precision, such as achieving flow rate control with accuracy better than ±1% across a wide dynamic range, and maintaining stable operation under varying gravitational conditions from 0g to 9g. Power consumption reduction represents another critical objective, with goals to operate complex microfluidic systems under 5W for portable applications and under 20W for integrated vehicle systems.

The long-term vision for this technology encompasses fully autonomous microfluidic systems capable of self-diagnosis, self-healing, and adaptive reconfiguration based on mission parameters and environmental conditions. This would enable transformative capabilities for long-duration space missions, advanced aircraft environmental control systems, and next-generation propulsion technologies that leverage precise microfluidic control for enhanced efficiency and performance.

Market Analysis for Aerospace Microfluidic Applications

The aerospace microfluidic applications market is experiencing significant growth, driven by increasing demand for miniaturized, lightweight, and efficient systems in aircraft and spacecraft. Current market valuations indicate that the global aerospace microfluidics sector reached approximately 2.3 billion USD in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth trajectory is supported by the aerospace industry's continuous pursuit of fuel efficiency, reduced emissions, and enhanced performance capabilities.

Primary market segments for aerospace microfluidic applications include propulsion systems, environmental control systems, thermal management, and health monitoring systems. The propulsion segment currently dominates with nearly 35% market share, as microfluidic technologies enable precise fuel delivery, combustion optimization, and thrust vector control. Environmental control systems represent the fastest-growing segment at 12.4% annual growth, driven by the need for advanced air quality monitoring and management in enclosed aerospace environments.

Regional analysis reveals North America as the leading market with 42% share, followed by Europe (28%) and Asia-Pacific (21%). The North American dominance stems from substantial defense budgets, presence of major aerospace manufacturers, and significant R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming decade due to expanding aerospace industries in China, Japan, and India.

Key customer segments include commercial aircraft manufacturers, military aerospace contractors, space agencies, and satellite developers. Commercial aviation represents the largest customer segment (47%), followed by military applications (32%) and space systems (21%). The commercial sector's demand is primarily driven by fuel efficiency requirements and environmental regulations, while military applications focus on enhanced performance and reliability in extreme conditions.

Market barriers include high initial development costs, stringent certification requirements, and long product development cycles. The average time from concept to market for aerospace microfluidic systems ranges from 5-7 years, significantly longer than in consumer electronics or automotive applications. This extended timeline necessitates substantial upfront investment and creates high barriers to entry for new market participants.

Future market growth will be catalyzed by emerging applications in electric propulsion systems, advanced life support for long-duration space missions, and autonomous aircraft systems. The integration of artificial intelligence with microfluidic systems for predictive maintenance and self-healing capabilities represents a particularly promising market opportunity, with potential to create new revenue streams exceeding 500 million USD annually by 2028.

Primary market segments for aerospace microfluidic applications include propulsion systems, environmental control systems, thermal management, and health monitoring systems. The propulsion segment currently dominates with nearly 35% market share, as microfluidic technologies enable precise fuel delivery, combustion optimization, and thrust vector control. Environmental control systems represent the fastest-growing segment at 12.4% annual growth, driven by the need for advanced air quality monitoring and management in enclosed aerospace environments.

Regional analysis reveals North America as the leading market with 42% share, followed by Europe (28%) and Asia-Pacific (21%). The North American dominance stems from substantial defense budgets, presence of major aerospace manufacturers, and significant R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming decade due to expanding aerospace industries in China, Japan, and India.

Key customer segments include commercial aircraft manufacturers, military aerospace contractors, space agencies, and satellite developers. Commercial aviation represents the largest customer segment (47%), followed by military applications (32%) and space systems (21%). The commercial sector's demand is primarily driven by fuel efficiency requirements and environmental regulations, while military applications focus on enhanced performance and reliability in extreme conditions.

Market barriers include high initial development costs, stringent certification requirements, and long product development cycles. The average time from concept to market for aerospace microfluidic systems ranges from 5-7 years, significantly longer than in consumer electronics or automotive applications. This extended timeline necessitates substantial upfront investment and creates high barriers to entry for new market participants.

Future market growth will be catalyzed by emerging applications in electric propulsion systems, advanced life support for long-duration space missions, and autonomous aircraft systems. The integration of artificial intelligence with microfluidic systems for predictive maintenance and self-healing capabilities represents a particularly promising market opportunity, with potential to create new revenue streams exceeding 500 million USD annually by 2028.

Current Microfluidic Technology Challenges in Aerospace

Despite significant advancements in microfluidic technology, its integration into aerospace systems presents unique challenges that must be addressed for successful implementation. The harsh operating conditions of aerospace environments impose severe constraints on microfluidic systems. Extreme temperature variations, ranging from -50°C in high-altitude flight to potentially over 100°C in certain aircraft components, can affect fluid properties, material integrity, and reaction kinetics within microfluidic channels.

Mechanical stress poses another significant challenge, as vibrations and g-forces during launch, flight, and landing can disrupt fluid flow patterns and potentially damage delicate microfluidic structures. These forces may cause channel deformation, seal failures, or bubble formation that compromise system functionality. Current microfluidic chip materials often lack the necessary robustness to withstand these conditions consistently over extended operational periods.

Power constraints represent a critical limitation for aerospace microfluidic applications. While terrestrial systems can rely on stable power sources, aerospace implementations must operate with minimal power consumption. This restricts the use of active pumping mechanisms, heating elements, and sophisticated detection systems commonly employed in laboratory settings. The development of passive flow control mechanisms that can function reliably without external power remains an ongoing challenge.

Radiation exposure in aerospace environments can degrade both the structural materials and any integrated electronic components of microfluidic systems. Current radiation-hardening approaches often add significant weight or complexity, contradicting the aerospace industry's drive toward miniaturization and weight reduction. Additionally, the long-term effects of radiation on microfluidic channel surfaces may alter their chemical properties and fluid dynamics characteristics.

Size and weight limitations are paramount concerns in aerospace applications. While microfluidic technology inherently offers miniaturization benefits, the supporting infrastructure—including pumps, valves, sensors, and control electronics—often negates these advantages. The challenge lies in developing truly integrated systems where all components maintain the small form factor promised by microfluidic technology.

Reliability and maintenance requirements present particular difficulties. Aerospace systems demand exceptional reliability with minimal maintenance, yet current microfluidic technologies often require regular calibration, cleaning, or component replacement. The inaccessibility of systems once deployed in aerospace platforms makes traditional maintenance approaches impractical, necessitating novel self-diagnostic and self-healing capabilities.

Standardization remains underdeveloped in the microfluidic field, with many solutions being custom-designed for specific applications. This lack of standardized interfaces, components, and testing protocols hinders widespread adoption in the aerospace industry, where certification and interoperability are essential considerations for new technologies.

Mechanical stress poses another significant challenge, as vibrations and g-forces during launch, flight, and landing can disrupt fluid flow patterns and potentially damage delicate microfluidic structures. These forces may cause channel deformation, seal failures, or bubble formation that compromise system functionality. Current microfluidic chip materials often lack the necessary robustness to withstand these conditions consistently over extended operational periods.

Power constraints represent a critical limitation for aerospace microfluidic applications. While terrestrial systems can rely on stable power sources, aerospace implementations must operate with minimal power consumption. This restricts the use of active pumping mechanisms, heating elements, and sophisticated detection systems commonly employed in laboratory settings. The development of passive flow control mechanisms that can function reliably without external power remains an ongoing challenge.

Radiation exposure in aerospace environments can degrade both the structural materials and any integrated electronic components of microfluidic systems. Current radiation-hardening approaches often add significant weight or complexity, contradicting the aerospace industry's drive toward miniaturization and weight reduction. Additionally, the long-term effects of radiation on microfluidic channel surfaces may alter their chemical properties and fluid dynamics characteristics.

Size and weight limitations are paramount concerns in aerospace applications. While microfluidic technology inherently offers miniaturization benefits, the supporting infrastructure—including pumps, valves, sensors, and control electronics—often negates these advantages. The challenge lies in developing truly integrated systems where all components maintain the small form factor promised by microfluidic technology.

Reliability and maintenance requirements present particular difficulties. Aerospace systems demand exceptional reliability with minimal maintenance, yet current microfluidic technologies often require regular calibration, cleaning, or component replacement. The inaccessibility of systems once deployed in aerospace platforms makes traditional maintenance approaches impractical, necessitating novel self-diagnostic and self-healing capabilities.

Standardization remains underdeveloped in the microfluidic field, with many solutions being custom-designed for specific applications. This lack of standardized interfaces, components, and testing protocols hinders widespread adoption in the aerospace industry, where certification and interoperability are essential considerations for new technologies.

Current Microfluidic Integration Solutions for Aerospace

01 Fabrication techniques for microfluidic chips

Various fabrication methods are employed to create microfluidic chips with precise channel geometries and surface properties. These techniques include soft lithography, injection molding, hot embossing, and 3D printing. The choice of fabrication method depends on the desired application, material properties, and production scale. Advanced manufacturing approaches enable the creation of complex microstructures with high resolution and reproducibility, which are essential for effective fluid handling and analysis.- Fabrication techniques for microfluidic chips: Various fabrication methods are employed to create microfluidic chips with precise channel geometries and surface properties. These techniques include soft lithography, injection molding, hot embossing, and 3D printing. The choice of fabrication method affects the chip's performance characteristics, material compatibility, and production scalability. Advanced manufacturing approaches enable the creation of complex microstructures with feature sizes in the micrometer range, essential for applications requiring precise fluid control.

- Integration of sensing and detection systems: Microfluidic chips incorporate various sensing and detection systems to monitor and analyze samples in real-time. These systems include optical sensors, electrochemical detectors, impedance-based sensors, and fluorescence detection modules. The integration of these sensing technologies enables quantitative analysis of biological samples, chemical reactions, and environmental contaminants with high sensitivity and specificity. These detection capabilities are crucial for applications in diagnostics, environmental monitoring, and pharmaceutical development.

- Sample preparation and handling systems: Microfluidic chips feature specialized components for sample preparation and handling, including mixing chambers, separation channels, and filtration structures. These systems enable the processing of complex biological samples through operations such as cell lysis, DNA extraction, protein purification, and particle separation. The miniaturized format reduces sample volume requirements while improving processing efficiency. Advanced designs incorporate multiple sample preparation steps in a single integrated platform, minimizing contamination risks and operator intervention.

- Flow control and manipulation mechanisms: Microfluidic chips employ various mechanisms to control and manipulate fluid flow within their channels. These include passive techniques like capillary forces and geometric constraints, as well as active methods such as pneumatic valves, electrokinetic pumping, and centrifugal forces. Advanced chips incorporate programmable valve systems that enable complex fluid routing and sequential operations. These flow control mechanisms are essential for precise sample handling, reagent delivery, and maintaining consistent reaction conditions across the chip.

- Application-specific microfluidic designs: Microfluidic chips are designed with specialized architectures tailored to specific applications such as point-of-care diagnostics, drug discovery, organ-on-a-chip models, and environmental monitoring. These application-specific designs incorporate features optimized for particular analytical or biological processes, including cell culture chambers, gradient generators, and droplet formation junctions. The customized architectures enable improved performance for targeted applications while maintaining the general benefits of microfluidic technology such as reduced reagent consumption and faster analysis times.

02 Integration of sensing and detection systems

Microfluidic chips incorporate various sensing and detection systems to monitor and analyze samples in real-time. These systems include optical sensors, electrochemical detectors, impedance-based sensors, and fluorescence detection modules. The integration of these sensing technologies enables quantitative analysis of biological samples, chemical reactions, and environmental contaminants with high sensitivity and specificity. This capability is crucial for applications in diagnostics, environmental monitoring, and pharmaceutical development.Expand Specific Solutions03 Microfluidic chip designs for biological applications

Specialized microfluidic chip designs have been developed for various biological applications, including cell culture, DNA analysis, protein separation, and organ-on-a-chip systems. These designs feature chambers, channels, and barriers that mimic physiological conditions and enable controlled manipulation of biological samples. The chips can incorporate gradient generators, cell trapping structures, and perfusion systems to create microenvironments suitable for studying cellular behavior, drug responses, and disease mechanisms.Expand Specific Solutions04 Flow control and sample manipulation techniques

Advanced flow control and sample manipulation techniques are essential components of microfluidic chip technology. These include passive methods like capillary forces and geometric constraints, as well as active methods such as electrokinetic control, pneumatic valves, and acoustic manipulation. These techniques enable precise control over fluid movement, droplet generation, mixing, separation, and concentration of samples within the microchannels. Effective flow control is critical for ensuring reproducible results and optimal performance in analytical and diagnostic applications.Expand Specific Solutions05 Materials and surface modifications for microfluidic chips

The selection of materials and surface modifications significantly impacts the performance of microfluidic chips. Common materials include glass, silicon, polymers (PDMS, PMMA, COC), and paper. Surface modifications such as plasma treatment, chemical functionalization, and coating with biomolecules can alter wettability, prevent non-specific adsorption, and enable specific molecular interactions. These material choices and surface treatments determine critical properties like optical transparency, biocompatibility, chemical resistance, and mechanical stability, which are essential for various applications.Expand Specific Solutions

Leading Aerospace Microfluidic Technology Providers

The microfluidic chip integration in aerospace systems market is currently in its early growth phase, characterized by increasing R&D activities and emerging commercial applications. The global market size is projected to expand significantly as aerospace manufacturers seek miniaturized, lightweight analytical systems for environmental monitoring, crew health assessment, and propulsion control. Technologically, the field remains moderately mature, with key players demonstrating varying levels of expertise. Research institutions like Fudan University, Zhejiang University, and the University of Maryland are advancing fundamental science, while commercial entities including Siemens Medical Solutions, Corning, and 10X Genomics are developing practical applications. The Agency for Science, Technology & Research and IFP Energies Nouvelles are bridging the gap between academic research and industrial implementation, focusing on adapting microfluidic technologies to withstand the harsh conditions of aerospace environments.

Corning, Inc.

Technical Solution: Corning has leveraged its expertise in advanced materials to develop specialized glass-based microfluidic platforms for aerospace applications. Their aerospace microfluidic solutions utilize proprietary glass formulations with exceptional thermal stability and radiation resistance, critical for extended operation in space environments. Corning's microfluidic chips feature precision-etched channels with extraordinarily smooth surfaces that minimize bubble formation and fluid flow anomalies in microgravity conditions. The company has developed specialized bonding techniques that create hermetically sealed microfluidic structures capable of withstanding the extreme pressure differentials and mechanical stresses encountered during launch and reentry. Their aerospace microfluidic platforms incorporate integrated optical sensing elements fabricated directly into the glass substrate, enabling label-free detection methods that reduce reagent requirements and simplify operation in resource-constrained space environments. Corning's systems feature modular designs that allow for customization and reconfiguration to support multiple mission profiles without requiring complete redesign.

Strengths: Exceptional material stability and durability in extreme environments; superior optical properties enabling integrated sensing capabilities; highly resistant to chemical degradation and radiation damage. Weaknesses: Higher mass compared to polymer-based microfluidic systems; more complex and energy-intensive manufacturing processes; limited flexibility compared to some polymer-based alternatives.

Rheonix, Inc.

Technical Solution: Rheonix has pioneered the development of fully automated microfluidic platforms adaptable for aerospace environmental monitoring and crew health assessment. Their proprietary CARD® (Chemistry and Reagent Device) technology has been modified for aerospace applications, featuring robust microfluidic channels and reservoirs that maintain structural integrity under high G-forces and vibration. The system incorporates specialized pumping mechanisms that function reliably in variable gravity conditions, utilizing a combination of pneumatic displacement and capillary action. Rheonix's aerospace microfluidic solutions include integrated sample processing capabilities that can extract, purify, and analyze biological samples with minimal crew intervention. The company has developed specialized sealing technologies to prevent fluid leakage during pressure changes experienced during launch and reentry, while their chips incorporate redundant flow paths to ensure operational reliability in critical aerospace applications.

Strengths: Highly automated systems requiring minimal human intervention; versatile platform adaptable to multiple testing protocols; proven reliability in challenging environments. Weaknesses: Higher power consumption compared to passive microfluidic systems; relatively larger footprint than some competing technologies; complex manufacturing process increasing unit costs.

Key Patents in Aerospace Microfluidic Systems

Systems and methods for cleaning microfluidic chips

PatentWO2024013323A1

Innovation

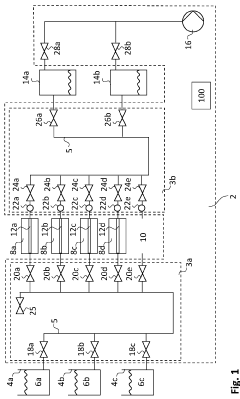

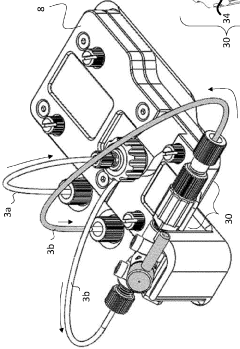

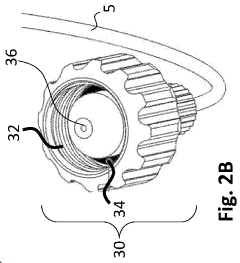

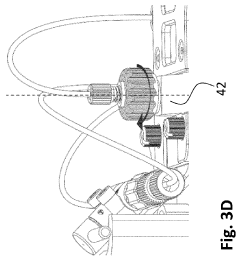

- An automated system and method for cleaning microfluidic chips using a tube system with actuators controlled by a cleaning program, which transports cleaning agents through the chips and manages volumetric flow rates to ensure thorough cleaning without manual intervention, allowing for parallel or sequential cleaning of multiple chips.

An integrated microfluidic chip and methods of use

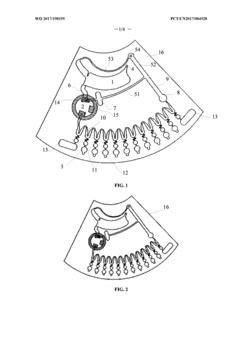

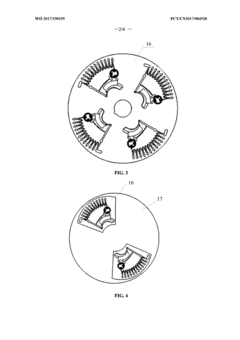

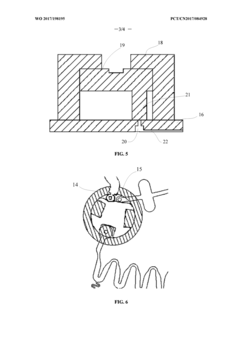

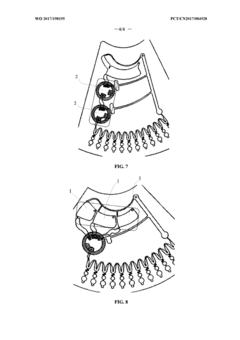

PatentWO2017198195A1

Innovation

- Parallel-connected sample cells with a common mixing cell design that enables efficient sample processing and mixing in aerospace microfluidic applications.

- Strategic positioning of liquid inlet and exhaust vent relative to rotation center to optimize fluid flow dynamics under microgravity or varying g-force conditions.

- Buffer zone implementation that prevents liquid backflow into air circuits, ensuring system integrity during aerospace operation conditions.

Space Environment Effects on Microfluidic Performance

The space environment presents unique challenges for microfluidic systems integrated into aerospace applications. Microgravity conditions fundamentally alter fluid behavior by eliminating buoyancy-driven convection and sedimentation, resulting in dominance of surface tension and capillary forces. These altered fluid dynamics necessitate redesigned channel geometries and flow control mechanisms specifically optimized for space operations.

Radiation exposure represents another critical concern for microfluidic performance in aerospace systems. The high-energy particles and cosmic radiation prevalent in space can degrade polymer-based microfluidic chips through chain scission and cross-linking, potentially compromising structural integrity and surface properties. Materials such as PDMS (polydimethylsiloxane) and PMMA (polymethyl methacrylate) exhibit varying degrees of radiation resistance, with specialized radiation-hardened polymers showing promise for extended missions.

Temperature extremes and rapid thermal cycling in space environments further challenge microfluidic system reliability. Orbital spacecraft experience temperature fluctuations ranging from -150°C to +150°C, inducing thermal expansion mismatches between different chip materials. These thermal stresses can lead to delamination, channel deformation, and seal failures. Recent research has focused on developing composite materials with matched thermal expansion coefficients and implementing active thermal management systems to maintain operational stability.

Vacuum conditions in space affect both the materials and operational parameters of microfluidic systems. Outgassing from polymers can contaminate sensitive aerospace instruments and alter fluid properties within channels. Additionally, the absence of atmospheric pressure impacts bubble formation and removal dynamics, requiring specialized degassing protocols and bubble trap designs to maintain consistent fluid flow.

Long-duration space missions introduce concerns regarding microfluidic chip degradation over time. Studies aboard the International Space Station have demonstrated that extended exposure to the combined effects of microgravity, radiation, and thermal cycling accelerates material aging processes. This has prompted development of predictive degradation models and implementation of redundant system architectures to ensure mission-critical functionality throughout operational lifespans.

Vibration and shock during launch and landing phases pose significant risks to microfluidic chip integrity. Resonant frequencies can induce catastrophic channel collapse or connection failures. Aerospace-grade microfluidic systems now incorporate shock-absorbing mounting systems and reinforced channel structures validated through extensive vibration testing protocols that simulate launch conditions.

Radiation exposure represents another critical concern for microfluidic performance in aerospace systems. The high-energy particles and cosmic radiation prevalent in space can degrade polymer-based microfluidic chips through chain scission and cross-linking, potentially compromising structural integrity and surface properties. Materials such as PDMS (polydimethylsiloxane) and PMMA (polymethyl methacrylate) exhibit varying degrees of radiation resistance, with specialized radiation-hardened polymers showing promise for extended missions.

Temperature extremes and rapid thermal cycling in space environments further challenge microfluidic system reliability. Orbital spacecraft experience temperature fluctuations ranging from -150°C to +150°C, inducing thermal expansion mismatches between different chip materials. These thermal stresses can lead to delamination, channel deformation, and seal failures. Recent research has focused on developing composite materials with matched thermal expansion coefficients and implementing active thermal management systems to maintain operational stability.

Vacuum conditions in space affect both the materials and operational parameters of microfluidic systems. Outgassing from polymers can contaminate sensitive aerospace instruments and alter fluid properties within channels. Additionally, the absence of atmospheric pressure impacts bubble formation and removal dynamics, requiring specialized degassing protocols and bubble trap designs to maintain consistent fluid flow.

Long-duration space missions introduce concerns regarding microfluidic chip degradation over time. Studies aboard the International Space Station have demonstrated that extended exposure to the combined effects of microgravity, radiation, and thermal cycling accelerates material aging processes. This has prompted development of predictive degradation models and implementation of redundant system architectures to ensure mission-critical functionality throughout operational lifespans.

Vibration and shock during launch and landing phases pose significant risks to microfluidic chip integrity. Resonant frequencies can induce catastrophic channel collapse or connection failures. Aerospace-grade microfluidic systems now incorporate shock-absorbing mounting systems and reinforced channel structures validated through extensive vibration testing protocols that simulate launch conditions.

Certification Standards for Aerospace Microfluidic Systems

The certification landscape for microfluidic systems in aerospace applications presents a complex regulatory framework that manufacturers and integrators must navigate. Currently, there is no unified certification standard specifically designed for microfluidic technologies in aerospace, requiring compliance with multiple overlapping standards from different regulatory bodies. The Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international aviation authorities maintain stringent requirements for all onboard systems, with microfluidics falling under several categories including avionics, fluid systems, and laboratory equipment.

DO-160 Environmental Conditions and Test Procedures for Airborne Equipment serves as a foundational standard, with sections particularly relevant to microfluidic systems including vibration resistance, pressure variation tolerance, and electromagnetic compatibility. For space applications, NASA's standards for spacecraft equipment qualification (NASA-STD-5001) provide additional requirements focusing on radiation hardness and vacuum compatibility essential for microfluidic operations in space environments.

Material certification represents a critical aspect of aerospace microfluidic systems. All materials must comply with flammability standards (FAR 25.853), outgassing specifications (ASTM E595), and demonstrate compatibility with aerospace fluids. Polymers commonly used in microfluidic fabrication, such as PDMS and PMMA, require special consideration as they may not meet traditional aerospace material requirements without modifications or protective enclosures.

Reliability testing frameworks for microfluidic systems must address unique failure modes not covered by traditional aerospace standards. These include channel clogging, surface degradation affecting fluid flow characteristics, and interface integrity between the microfluidic chip and external systems. The SAE Aerospace Standard AS9100 quality management system provides a framework for reliability assurance, though specific test protocols for microfluidic components remain under development.

Safety certification presents particular challenges, especially for systems handling biological samples or hazardous chemicals. Containment requirements must be demonstrated under all flight conditions, including emergency scenarios. The International Air Transport Association's Dangerous Goods Regulations provide guidance for chemical handling, while biological samples fall under biosafety regulations that vary by jurisdiction.

Emerging certification pathways are being developed through industry-academic collaborations. The Aerospace Microfluidic Consortium, comprising major aerospace manufacturers and research institutions, is working to establish standardized testing protocols specifically for microfluidic systems. Their draft framework, expected to be published next year, aims to provide a certification roadmap that addresses the unique characteristics of microfluidic technologies while ensuring compatibility with existing aerospace standards.

DO-160 Environmental Conditions and Test Procedures for Airborne Equipment serves as a foundational standard, with sections particularly relevant to microfluidic systems including vibration resistance, pressure variation tolerance, and electromagnetic compatibility. For space applications, NASA's standards for spacecraft equipment qualification (NASA-STD-5001) provide additional requirements focusing on radiation hardness and vacuum compatibility essential for microfluidic operations in space environments.

Material certification represents a critical aspect of aerospace microfluidic systems. All materials must comply with flammability standards (FAR 25.853), outgassing specifications (ASTM E595), and demonstrate compatibility with aerospace fluids. Polymers commonly used in microfluidic fabrication, such as PDMS and PMMA, require special consideration as they may not meet traditional aerospace material requirements without modifications or protective enclosures.

Reliability testing frameworks for microfluidic systems must address unique failure modes not covered by traditional aerospace standards. These include channel clogging, surface degradation affecting fluid flow characteristics, and interface integrity between the microfluidic chip and external systems. The SAE Aerospace Standard AS9100 quality management system provides a framework for reliability assurance, though specific test protocols for microfluidic components remain under development.

Safety certification presents particular challenges, especially for systems handling biological samples or hazardous chemicals. Containment requirements must be demonstrated under all flight conditions, including emergency scenarios. The International Air Transport Association's Dangerous Goods Regulations provide guidance for chemical handling, while biological samples fall under biosafety regulations that vary by jurisdiction.

Emerging certification pathways are being developed through industry-academic collaborations. The Aerospace Microfluidic Consortium, comprising major aerospace manufacturers and research institutions, is working to establish standardized testing protocols specifically for microfluidic systems. Their draft framework, expected to be published next year, aims to provide a certification roadmap that addresses the unique characteristics of microfluidic technologies while ensuring compatibility with existing aerospace standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!