Analysis of Thermal Runaway Incidents in Battery Manufacturing

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Thermal runaway in battery manufacturing represents one of the most critical safety challenges facing the energy storage industry today. This phenomenon, characterized by an uncontrolled positive feedback loop of increasing temperature, has been responsible for numerous incidents ranging from consumer electronics failures to large-scale energy storage system fires. The evolution of this technical challenge traces back to the early commercialization of lithium-ion batteries in the 1990s, with incident frequency accelerating as battery production volumes have grown exponentially over the past decade.

The technical progression in understanding thermal runaway has moved from initial recognition of the risk factors to sophisticated multi-physics modeling approaches that can predict failure cascades. Early research focused primarily on electrolyte flammability, while contemporary investigations examine the complex interplay between cathode material decomposition, solid-electrolyte interface (SEI) layer breakdown, and internal short circuit propagation mechanisms.

Industry trends indicate a shift toward higher energy density chemistries, particularly nickel-rich cathodes and silicon-enhanced anodes, which inherently carry elevated thermal stability risks. Simultaneously, manufacturing scales have increased dramatically, with gigafactories now producing batteries at unprecedented volumes, thereby amplifying the potential consequences of thermal events during production.

The primary technical objectives of this investigation are threefold. First, to systematically categorize and analyze the root causes of thermal runaway incidents specifically occurring during the manufacturing process, distinguishing between material defects, process control failures, and equipment malfunctions. Second, to evaluate the effectiveness of current detection and prevention technologies employed in production environments, including thermal imaging systems, gas sensors, and early-intervention cooling mechanisms.

Third, to establish quantitative risk assessment frameworks that can be integrated into manufacturing execution systems (MES) to enable real-time monitoring and predictive analytics for thermal event prevention. This includes developing standardized testing protocols that can accurately simulate manufacturing conditions rather than merely end-use scenarios.

The ultimate goal is to develop a comprehensive technical roadmap that addresses thermal runaway risks across the entire manufacturing value chain, from raw material qualification to cell formation and aging. This roadmap must balance the competing demands of production throughput, cost efficiency, and safety assurance while accommodating the industry's rapid pace of innovation in battery chemistry and design.

The technical progression in understanding thermal runaway has moved from initial recognition of the risk factors to sophisticated multi-physics modeling approaches that can predict failure cascades. Early research focused primarily on electrolyte flammability, while contemporary investigations examine the complex interplay between cathode material decomposition, solid-electrolyte interface (SEI) layer breakdown, and internal short circuit propagation mechanisms.

Industry trends indicate a shift toward higher energy density chemistries, particularly nickel-rich cathodes and silicon-enhanced anodes, which inherently carry elevated thermal stability risks. Simultaneously, manufacturing scales have increased dramatically, with gigafactories now producing batteries at unprecedented volumes, thereby amplifying the potential consequences of thermal events during production.

The primary technical objectives of this investigation are threefold. First, to systematically categorize and analyze the root causes of thermal runaway incidents specifically occurring during the manufacturing process, distinguishing between material defects, process control failures, and equipment malfunctions. Second, to evaluate the effectiveness of current detection and prevention technologies employed in production environments, including thermal imaging systems, gas sensors, and early-intervention cooling mechanisms.

Third, to establish quantitative risk assessment frameworks that can be integrated into manufacturing execution systems (MES) to enable real-time monitoring and predictive analytics for thermal event prevention. This includes developing standardized testing protocols that can accurately simulate manufacturing conditions rather than merely end-use scenarios.

The ultimate goal is to develop a comprehensive technical roadmap that addresses thermal runaway risks across the entire manufacturing value chain, from raw material qualification to cell formation and aging. This roadmap must balance the competing demands of production throughput, cost efficiency, and safety assurance while accommodating the industry's rapid pace of innovation in battery chemistry and design.

Market Demand for Safe Battery Manufacturing

The global battery market has witnessed unprecedented growth, with projections indicating a market value exceeding $310 billion by 2030, growing at a CAGR of approximately 14% from 2023. This remarkable expansion is primarily driven by the accelerating adoption of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. However, this growth trajectory is increasingly tempered by safety concerns, particularly regarding thermal runaway incidents in battery manufacturing.

Safety has emerged as a critical market differentiator, with manufacturers who can demonstrate superior safety protocols commanding premium pricing and preferred supplier status. Recent industry surveys reveal that 87% of EV manufacturers rank battery safety as their top priority when selecting suppliers, surpassing even cost considerations. This shift in procurement priorities reflects the substantial financial and reputational risks associated with battery failures.

The economic impact of thermal runaway incidents extends far beyond immediate manufacturing losses. The average cost of a major battery recall is estimated at $90 million, not including brand damage and market share erosion. Notable incidents, such as the 2016 Samsung Galaxy Note 7 recall, resulted in losses exceeding $5.3 billion and a 7% drop in global smartphone market share.

Insurance providers have responded to these risks by increasing premiums for battery manufacturers by an average of 35% over the past three years, with facilities lacking advanced thermal runaway prevention systems facing even steeper increases. This financial pressure is creating market-driven incentives for enhanced safety investments.

Regulatory frameworks worldwide are simultaneously tightening, with the EU Battery Directive, China's GB/T standards, and the US DOE's battery safety protocols all implementing more stringent safety requirements between 2023-2025. These regulations are increasingly focusing on manufacturing processes rather than just end-product testing, creating demand for comprehensive safety solutions throughout the production chain.

Consumer awareness regarding battery safety has reached unprecedented levels, with 73% of EV buyers citing battery safety records as a "very important" purchase consideration. This awareness extends to energy storage systems, where utility-scale projects increasingly require extensive safety documentation and certifications before procurement approval.

The market for specialized thermal runaway prevention technologies is projected to grow at 22% annually through 2028, outpacing the broader battery market. This includes advanced monitoring systems, fire suppression technologies, and manufacturing process controls specifically designed to mitigate thermal runaway risks. Venture capital investment in battery safety startups has tripled since 2020, reaching $1.2 billion in 2022, indicating strong financial backing for innovation in this space.

Safety has emerged as a critical market differentiator, with manufacturers who can demonstrate superior safety protocols commanding premium pricing and preferred supplier status. Recent industry surveys reveal that 87% of EV manufacturers rank battery safety as their top priority when selecting suppliers, surpassing even cost considerations. This shift in procurement priorities reflects the substantial financial and reputational risks associated with battery failures.

The economic impact of thermal runaway incidents extends far beyond immediate manufacturing losses. The average cost of a major battery recall is estimated at $90 million, not including brand damage and market share erosion. Notable incidents, such as the 2016 Samsung Galaxy Note 7 recall, resulted in losses exceeding $5.3 billion and a 7% drop in global smartphone market share.

Insurance providers have responded to these risks by increasing premiums for battery manufacturers by an average of 35% over the past three years, with facilities lacking advanced thermal runaway prevention systems facing even steeper increases. This financial pressure is creating market-driven incentives for enhanced safety investments.

Regulatory frameworks worldwide are simultaneously tightening, with the EU Battery Directive, China's GB/T standards, and the US DOE's battery safety protocols all implementing more stringent safety requirements between 2023-2025. These regulations are increasingly focusing on manufacturing processes rather than just end-product testing, creating demand for comprehensive safety solutions throughout the production chain.

Consumer awareness regarding battery safety has reached unprecedented levels, with 73% of EV buyers citing battery safety records as a "very important" purchase consideration. This awareness extends to energy storage systems, where utility-scale projects increasingly require extensive safety documentation and certifications before procurement approval.

The market for specialized thermal runaway prevention technologies is projected to grow at 22% annually through 2028, outpacing the broader battery market. This includes advanced monitoring systems, fire suppression technologies, and manufacturing process controls specifically designed to mitigate thermal runaway risks. Venture capital investment in battery safety startups has tripled since 2020, reaching $1.2 billion in 2022, indicating strong financial backing for innovation in this space.

Current Thermal Runaway Prevention Challenges

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in battery manufacturing. Current prevention strategies face several limitations that hinder their effectiveness in completely eliminating thermal runaway incidents. The primary challenge lies in early detection systems, which often struggle to identify precursors to thermal events with sufficient lead time for intervention. Conventional temperature monitoring systems may detect abnormal heat generation too late in the thermal runaway cascade process.

Material limitations present another significant obstacle. While manufacturers have developed more stable cathode materials and improved electrolyte formulations, these materials still have inherent thermal stability thresholds. Under certain conditions of mechanical stress, electrical abuse, or manufacturing defects, even advanced materials can succumb to thermal runaway events. The trade-off between energy density and safety continues to challenge material scientists and battery engineers.

Quality control processes in high-volume manufacturing environments face considerable challenges in detecting microscopic defects that can lead to internal short circuits. Current inspection technologies, including X-ray and ultrasonic scanning, have resolution limitations that may miss nanoscale defects capable of initiating thermal events. The speed requirements of modern production lines further complicate thorough inspection protocols.

Battery management systems (BMS), while increasingly sophisticated, still face limitations in predictive capabilities. Most systems rely on voltage, current, and temperature measurements that may not provide sufficient early indicators of potential failure modes. Advanced algorithms for thermal runaway prediction require more comprehensive sensor data than is typically available in commercial battery systems.

Scaling safety solutions from laboratory to mass production introduces additional complexities. Safety features that prove effective in controlled research environments may be difficult to implement cost-effectively at scale or may compromise other battery performance metrics such as energy density or charging speed. This creates a challenging balance between safety, performance, and manufacturing economics.

Regulatory frameworks and testing standards also present challenges, as they often lag behind technological developments. Current test protocols may not adequately simulate all real-world abuse conditions or aging-related degradation mechanisms that contribute to thermal runaway incidents. The lack of globally harmonized safety standards further complicates manufacturing compliance across international markets.

Thermal management systems face their own set of challenges, particularly in high-density battery packs. Heat dissipation pathways may be insufficient during extreme operating conditions or rapid charging scenarios. Cooling systems add weight, complexity, and cost to battery systems, creating design constraints that limit their implementation in certain applications.

Material limitations present another significant obstacle. While manufacturers have developed more stable cathode materials and improved electrolyte formulations, these materials still have inherent thermal stability thresholds. Under certain conditions of mechanical stress, electrical abuse, or manufacturing defects, even advanced materials can succumb to thermal runaway events. The trade-off between energy density and safety continues to challenge material scientists and battery engineers.

Quality control processes in high-volume manufacturing environments face considerable challenges in detecting microscopic defects that can lead to internal short circuits. Current inspection technologies, including X-ray and ultrasonic scanning, have resolution limitations that may miss nanoscale defects capable of initiating thermal events. The speed requirements of modern production lines further complicate thorough inspection protocols.

Battery management systems (BMS), while increasingly sophisticated, still face limitations in predictive capabilities. Most systems rely on voltage, current, and temperature measurements that may not provide sufficient early indicators of potential failure modes. Advanced algorithms for thermal runaway prediction require more comprehensive sensor data than is typically available in commercial battery systems.

Scaling safety solutions from laboratory to mass production introduces additional complexities. Safety features that prove effective in controlled research environments may be difficult to implement cost-effectively at scale or may compromise other battery performance metrics such as energy density or charging speed. This creates a challenging balance between safety, performance, and manufacturing economics.

Regulatory frameworks and testing standards also present challenges, as they often lag behind technological developments. Current test protocols may not adequately simulate all real-world abuse conditions or aging-related degradation mechanisms that contribute to thermal runaway incidents. The lack of globally harmonized safety standards further complicates manufacturing compliance across international markets.

Thermal management systems face their own set of challenges, particularly in high-density battery packs. Heat dissipation pathways may be insufficient during extreme operating conditions or rapid charging scenarios. Cooling systems add weight, complexity, and cost to battery systems, creating design constraints that limit their implementation in certain applications.

Current Thermal Runaway Detection and Prevention Methods

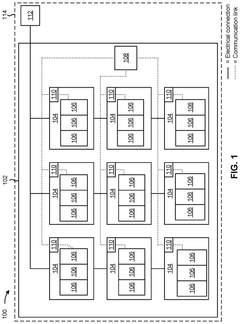

01 Thermal management systems for battery packs

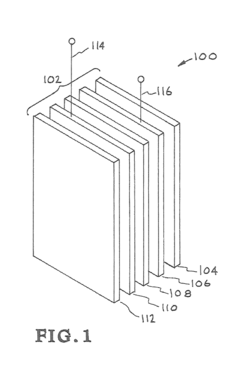

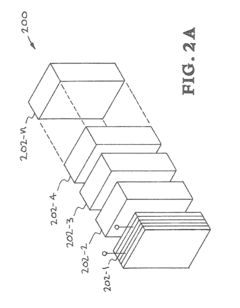

Various thermal management systems are designed to prevent thermal runaway in battery packs. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal operating temperatures. Advanced designs incorporate phase change materials, liquid cooling circuits, or air flow channels to efficiently remove excess heat from battery cells, preventing the cascade effect of thermal runaway across multiple cells.- Thermal management systems for preventing thermal runaway: Various thermal management systems can be implemented to prevent thermal runaway in batteries. These systems monitor temperature changes and provide cooling mechanisms to maintain optimal operating conditions. Advanced cooling technologies including liquid cooling, phase change materials, and heat dissipation structures help regulate battery temperature and prevent the cascade of thermal events that lead to runaway conditions. These systems often incorporate sensors for early detection of temperature anomalies.

- Battery cell design and materials to mitigate thermal runaway: Innovative battery cell designs and materials can significantly reduce the risk of thermal runaway. This includes the use of flame-retardant electrolytes, separator materials with higher thermal stability, and electrode materials engineered to resist thermal decomposition. Structural modifications to battery cells, such as improved insulation between cells and specialized current collectors, can also help contain thermal events and prevent propagation throughout a battery pack.

- Detection and early warning systems for thermal events: Advanced detection systems can identify the early signs of potential thermal runaway before it occurs. These systems utilize various sensors to monitor parameters such as temperature, voltage, current, and gas emissions. Machine learning algorithms can analyze these parameters to predict and prevent thermal events. Early warning systems can trigger automated responses or alert operators to take preventive actions, significantly reducing the risk of catastrophic battery failures.

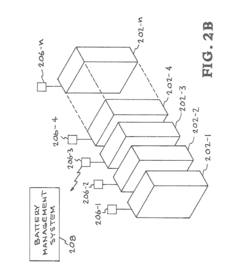

- Battery management systems (BMS) for thermal runaway prevention: Sophisticated battery management systems play a crucial role in preventing thermal runaway by continuously monitoring and controlling battery operating conditions. These systems regulate charging and discharging rates, balance cell voltages, and implement protective measures when abnormal conditions are detected. Advanced BMS solutions incorporate thermal models and predictive algorithms to anticipate potential issues and take preemptive actions to maintain safe operation across various environmental conditions.

- Safety mechanisms and containment strategies for thermal runaway: Various safety mechanisms and containment strategies can be implemented to minimize the impact of thermal runaway events. These include pressure relief valves, thermal fuses, and physical barriers between cells to prevent propagation. Specialized battery enclosures designed to contain fires and vent gases safely can significantly reduce the risk to surrounding components and systems. Some designs incorporate sacrificial materials that absorb heat or fire-suppression systems that activate automatically when thermal events are detected.

02 Safety mechanisms for detecting and preventing thermal runaway

Safety mechanisms are implemented to detect early signs of thermal runaway and take preventive actions. These include temperature sensors, voltage monitoring systems, and pressure relief devices that can identify abnormal conditions before they escalate. Some designs incorporate automatic shutdown features that isolate affected cells, while others use specialized materials that activate at specific temperature thresholds to suppress thermal events.Expand Specific Solutions03 Battery cell design and materials to enhance thermal stability

Innovative battery cell designs and materials are developed to enhance thermal stability and reduce the risk of thermal runaway. These include advanced electrode materials, separator technologies with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. Some approaches focus on structural modifications to battery cells that can better withstand mechanical stress and prevent internal short circuits that often trigger thermal events.Expand Specific Solutions04 Fire suppression and containment systems

Fire suppression and containment systems are designed to mitigate the consequences of thermal runaway events. These systems include specialized enclosures that can contain fires, venting mechanisms to release pressure safely, and fire-resistant materials that prevent propagation between cells. Some advanced solutions incorporate automatic fire extinguishing agents that activate when thermal runaway is detected, limiting damage to surrounding components and enhancing overall battery safety.Expand Specific Solutions05 Battery management systems for thermal runaway prevention

Sophisticated battery management systems (BMS) are developed to monitor and control battery parameters to prevent thermal runaway. These systems use algorithms to analyze real-time data from multiple sensors, predicting potential thermal issues before they occur. The BMS can adjust charging rates, load distribution, and cooling system operation based on operating conditions. Some advanced systems incorporate machine learning capabilities to improve prediction accuracy and implement preventive measures more effectively.Expand Specific Solutions

Key Players in Battery Safety Solutions

The thermal runaway incidents in battery manufacturing landscape is currently in a growth phase, with the market expected to reach significant scale as electric vehicle adoption accelerates. The competitive environment features established players like Tesla and Samsung SDI focusing on advanced safety systems, while specialized companies such as Aspen Aerogels and Celgard develop critical thermal management materials. Research institutions including Industrial Technology Research Institute and Newcastle University are advancing fundamental safety technologies. Technical maturity varies significantly, with companies like Microvast and Automotive Cells Company leading in commercial implementation of thermal runaway prevention systems, while Beijing WeLion and others are developing next-generation solid-state batteries that inherently reduce thermal risks. This fragmented ecosystem reflects the industry's transition toward standardized safety protocols.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive thermal runaway prevention and management system for battery manufacturing that integrates multiple layers of protection. Their approach includes advanced cell design with proprietary electrode materials and electrolyte formulations that increase thermal stability thresholds. Tesla implements real-time monitoring systems using distributed temperature sensors and AI algorithms to detect thermal anomalies before they escalate into runaway events. Their manufacturing process incorporates automated quality control with high-precision imaging and impedance testing to identify defective cells. Tesla's battery packs feature physical isolation barriers between cells and dedicated thermal management systems that can rapidly cool specific modules when temperature spikes are detected. Additionally, they've developed venting mechanisms that direct thermal events away from other cells to prevent propagation throughout the battery pack[1][3]. Tesla also utilizes machine learning algorithms trained on manufacturing data to predict potential failure points and optimize production parameters accordingly.

Strengths: Integrated approach combining cell design, manufacturing processes, and battery management systems; extensive real-world data from vehicle fleet to inform safety improvements; proprietary cooling technology. Weaknesses: Highly proprietary systems limit industry-wide adoption of safety practices; resource-intensive approach may be difficult for smaller manufacturers to implement; still vulnerable to extreme external conditions despite multiple safeguards.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a multi-faceted approach to thermal runaway prevention in battery manufacturing centered around their "Safety Reinforced Separator" (SRS) technology. This proprietary ceramic-coated separator maintains structural integrity at high temperatures, preventing internal short circuits that typically trigger thermal events. Their manufacturing process employs X-ray diffraction and computed tomography scanning to detect microscopic metal particle contamination and structural defects that could lead to thermal runaway. Samsung has implemented an advanced Battery Management System (BMS) that incorporates predictive analytics to identify cells exhibiting abnormal behavior patterns before thermal issues manifest. Their facilities utilize automated production lines with thermal imaging cameras that continuously monitor cell temperature profiles during manufacturing stages[2]. Samsung's thermal runaway mitigation strategy also includes innovative cell-to-cell isolation techniques and flame-retardant materials in battery pack construction. They've developed specialized electrolyte additives that release fire-suppressing compounds when exposed to high temperatures, effectively creating self-extinguishing capabilities within the cell chemistry.

Strengths: Industry-leading separator technology specifically designed to prevent thermal propagation; extensive quality control infrastructure throughout manufacturing process; significant R&D investment in safety technologies. Weaknesses: Higher production costs associated with advanced safety features; some solutions add weight and volume to battery packs; historical incidents have demonstrated that even sophisticated systems can fail under certain conditions.

Critical Patents in Thermal Runaway Mitigation

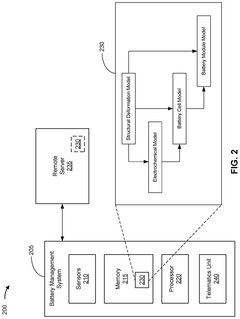

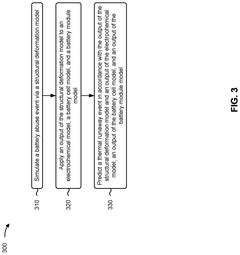

Battery thermal runaway prediction

PatentPendingUS20250200244A1

Innovation

- A battery management system that includes processors and memories configured to monitor attributes of battery cells and predict thermal runaway events using a thermal runaway model that integrates structural deformation, electrochemical, battery cell, and battery module models to simulate abuse events and predict thermal runaway.

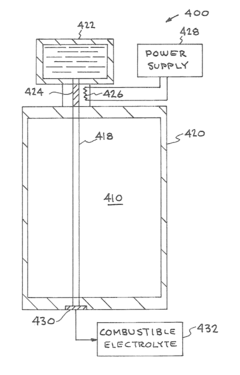

Li-ion battery thermal runaway suppression system using microchannel coolers and refrigerant injections

PatentInactiveUS9490507B2

Innovation

- A battery management system with thermally integrated fire suppression, featuring cooling passages between cells, sensors to detect thermal runaway, and a mechanism to inject coolant into these passages to rapidly quench the event, preventing cell-to-cell propagation and mitigating thermal runaway.

Regulatory Framework for Battery Manufacturing Safety

The regulatory landscape for battery manufacturing safety has evolved significantly in response to the increasing frequency of thermal runaway incidents. International standards such as IEC 62133 and UL 1642 establish baseline safety requirements for lithium-ion batteries, covering aspects from design validation to production testing. These standards mandate specific safety features including pressure relief mechanisms, thermal fuses, and current interrupt devices that activate during abnormal conditions.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have implemented stringent regulations for battery transportation, requiring manufacturers to conduct comprehensive testing under UN 38.3 protocols. The Consumer Product Safety Commission (CPSC) provides additional oversight regarding consumer-facing battery products, with recall authority for products demonstrating thermal runaway risks.

The European Union's regulatory framework centers around the Battery Directive (2006/66/EC) and its 2023 update, which introduces more rigorous safety requirements and establishes a battery passport system for traceability. Additionally, the EU's REACH and RoHS directives restrict hazardous substances in battery manufacturing that could exacerbate thermal runaway incidents.

Asian manufacturing hubs have developed region-specific regulations. China's GB/T 31241-2014 standard addresses lithium battery safety with particular emphasis on thermal management systems. Japan's industrial standards (JIS) incorporate detailed thermal runaway prevention protocols, while South Korea has established the KC certification system with mandatory safety testing requirements.

Recent regulatory trends show a shift toward lifecycle management approaches. Emerging frameworks increasingly focus on battery design safety, manufacturing process controls, and end-of-life considerations. The International Electrotechnical Commission's IEC 63056 specifically addresses stationary energy storage applications, recognizing the unique thermal risks in large-scale installations.

Compliance verification mechanisms have also strengthened, with third-party certification becoming standard practice. Manufacturers must now document thermal runaway mitigation strategies throughout the production process, conduct regular safety audits, and implement traceability systems that enable rapid response to identified safety issues.

The regulatory landscape continues to evolve, with pending legislation in multiple jurisdictions aimed at addressing emerging thermal runaway risks associated with higher energy density batteries and faster charging technologies. These developing frameworks emphasize predictive safety systems and real-time monitoring capabilities as essential components of comprehensive battery safety management.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have implemented stringent regulations for battery transportation, requiring manufacturers to conduct comprehensive testing under UN 38.3 protocols. The Consumer Product Safety Commission (CPSC) provides additional oversight regarding consumer-facing battery products, with recall authority for products demonstrating thermal runaway risks.

The European Union's regulatory framework centers around the Battery Directive (2006/66/EC) and its 2023 update, which introduces more rigorous safety requirements and establishes a battery passport system for traceability. Additionally, the EU's REACH and RoHS directives restrict hazardous substances in battery manufacturing that could exacerbate thermal runaway incidents.

Asian manufacturing hubs have developed region-specific regulations. China's GB/T 31241-2014 standard addresses lithium battery safety with particular emphasis on thermal management systems. Japan's industrial standards (JIS) incorporate detailed thermal runaway prevention protocols, while South Korea has established the KC certification system with mandatory safety testing requirements.

Recent regulatory trends show a shift toward lifecycle management approaches. Emerging frameworks increasingly focus on battery design safety, manufacturing process controls, and end-of-life considerations. The International Electrotechnical Commission's IEC 63056 specifically addresses stationary energy storage applications, recognizing the unique thermal risks in large-scale installations.

Compliance verification mechanisms have also strengthened, with third-party certification becoming standard practice. Manufacturers must now document thermal runaway mitigation strategies throughout the production process, conduct regular safety audits, and implement traceability systems that enable rapid response to identified safety issues.

The regulatory landscape continues to evolve, with pending legislation in multiple jurisdictions aimed at addressing emerging thermal runaway risks associated with higher energy density batteries and faster charging technologies. These developing frameworks emphasize predictive safety systems and real-time monitoring capabilities as essential components of comprehensive battery safety management.

Economic Impact of Thermal Runaway Incidents

Thermal runaway incidents in battery manufacturing facilities represent a significant economic burden across multiple dimensions. The direct financial impact of these incidents is substantial, with the average cost of a single major thermal event estimated between $2-5 million for mid-sized manufacturing operations. These costs encompass immediate facility damage, equipment replacement, and production line reconstruction, which can require complete rebuilding of affected manufacturing sections.

Production disruptions constitute perhaps the most severe economic consequence, with manufacturing facilities experiencing downtime ranging from several weeks to six months following serious thermal events. For large-scale battery manufacturers, each day of production stoppage translates to revenue losses of approximately $300,000-$700,000, creating cascading effects throughout supply chains and potentially triggering contractual penalties for missed delivery targets.

Insurance premiums represent another significant economic factor affected by thermal runaway incidents. Manufacturing facilities with histories of thermal events face premium increases averaging 30-45% following major incidents, with some facilities becoming effectively uninsurable without implementing comprehensive safety overhauls costing millions of dollars. This creates a persistent financial burden extending years beyond the initial incident.

Regulatory fines and compliance costs further compound the economic impact. Government agencies typically impose penalties ranging from $50,000 to over $1 million for safety violations identified following thermal incidents. Additionally, manufacturers must invest in enhanced safety systems, improved monitoring technologies, and more rigorous testing protocols to meet updated regulatory requirements and prevent future occurrences.

The reputational damage from publicized thermal runaway incidents carries substantial long-term economic consequences. Market analysis indicates that battery manufacturers experiencing high-profile safety incidents typically suffer 15-25% reductions in new contracts during the subsequent 18 months. This market share erosion often benefits competitors who can demonstrate superior safety records and more robust thermal management protocols.

Worker compensation and potential litigation expenses represent additional economic burdens. Serious thermal incidents resulting in worker injuries generate average compensation costs of $150,000-$500,000 per affected employee, while class-action lawsuits from surrounding communities affected by chemical releases or evacuations can result in settlements exceeding $10 million in severe cases, not including legal defense costs that typically range from $2-5 million regardless of outcome.

Production disruptions constitute perhaps the most severe economic consequence, with manufacturing facilities experiencing downtime ranging from several weeks to six months following serious thermal events. For large-scale battery manufacturers, each day of production stoppage translates to revenue losses of approximately $300,000-$700,000, creating cascading effects throughout supply chains and potentially triggering contractual penalties for missed delivery targets.

Insurance premiums represent another significant economic factor affected by thermal runaway incidents. Manufacturing facilities with histories of thermal events face premium increases averaging 30-45% following major incidents, with some facilities becoming effectively uninsurable without implementing comprehensive safety overhauls costing millions of dollars. This creates a persistent financial burden extending years beyond the initial incident.

Regulatory fines and compliance costs further compound the economic impact. Government agencies typically impose penalties ranging from $50,000 to over $1 million for safety violations identified following thermal incidents. Additionally, manufacturers must invest in enhanced safety systems, improved monitoring technologies, and more rigorous testing protocols to meet updated regulatory requirements and prevent future occurrences.

The reputational damage from publicized thermal runaway incidents carries substantial long-term economic consequences. Market analysis indicates that battery manufacturers experiencing high-profile safety incidents typically suffer 15-25% reductions in new contracts during the subsequent 18 months. This market share erosion often benefits competitors who can demonstrate superior safety records and more robust thermal management protocols.

Worker compensation and potential litigation expenses represent additional economic burdens. Serious thermal incidents resulting in worker injuries generate average compensation costs of $150,000-$500,000 per affected employee, while class-action lawsuits from surrounding communities affected by chemical releases or evacuations can result in settlements exceeding $10 million in severe cases, not including legal defense costs that typically range from $2-5 million regardless of outcome.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!