The Influence of Electrochemical Stability on Battery Thermal Runaway

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Electrochemical Stability Background and Objectives

Electrochemical stability represents a fundamental property in battery systems that has gained increasing attention due to its critical role in battery safety, particularly in thermal runaway events. The evolution of battery technology has witnessed significant advancements from primary cells to today's sophisticated lithium-ion batteries, with electrochemical stability emerging as a key factor influencing performance and safety parameters. This technological progression has been driven by growing demands for higher energy densities, faster charging capabilities, and enhanced safety profiles across various applications from consumer electronics to electric vehicles and grid-scale energy storage.

The electrochemical stability of battery components—including electrodes, electrolytes, separators, and interfacial layers—determines their resistance to degradation under operational conditions. Historically, research has focused primarily on energy density improvements, with safety considerations often becoming prominent only after high-profile failure incidents. The correlation between electrochemical stability and thermal runaway has become increasingly evident through extensive research over the past two decades, establishing that degradation of electrochemical stability often serves as the initiating factor in catastrophic thermal events.

Current technological trends indicate a shift toward developing advanced materials and battery management systems that prioritize electrochemical stability alongside traditional performance metrics. This includes novel electrolyte formulations with wider electrochemical windows, electrode materials with enhanced structural integrity during cycling, and sophisticated monitoring systems capable of detecting early signs of stability compromise. The integration of artificial intelligence and machine learning approaches has further accelerated progress in predicting and preventing stability-related failures.

The primary objective of this technical investigation is to comprehensively analyze the mechanisms through which electrochemical stability influences thermal runaway in modern battery systems. This includes identifying critical stability parameters, understanding degradation pathways, and establishing quantifiable relationships between stability metrics and thermal safety margins. Additionally, we aim to evaluate emerging technologies and methodologies designed to enhance electrochemical stability without compromising performance characteristics.

Secondary objectives include developing predictive models for stability-related failure modes, establishing standardized testing protocols specifically targeting electrochemical stability assessment, and formulating design guidelines for next-generation battery systems with inherently improved stability profiles. Through this analysis, we seek to bridge the gap between fundamental electrochemical understanding and practical safety engineering in battery applications, ultimately contributing to the development of safer, more reliable energy storage solutions.

The electrochemical stability of battery components—including electrodes, electrolytes, separators, and interfacial layers—determines their resistance to degradation under operational conditions. Historically, research has focused primarily on energy density improvements, with safety considerations often becoming prominent only after high-profile failure incidents. The correlation between electrochemical stability and thermal runaway has become increasingly evident through extensive research over the past two decades, establishing that degradation of electrochemical stability often serves as the initiating factor in catastrophic thermal events.

Current technological trends indicate a shift toward developing advanced materials and battery management systems that prioritize electrochemical stability alongside traditional performance metrics. This includes novel electrolyte formulations with wider electrochemical windows, electrode materials with enhanced structural integrity during cycling, and sophisticated monitoring systems capable of detecting early signs of stability compromise. The integration of artificial intelligence and machine learning approaches has further accelerated progress in predicting and preventing stability-related failures.

The primary objective of this technical investigation is to comprehensively analyze the mechanisms through which electrochemical stability influences thermal runaway in modern battery systems. This includes identifying critical stability parameters, understanding degradation pathways, and establishing quantifiable relationships between stability metrics and thermal safety margins. Additionally, we aim to evaluate emerging technologies and methodologies designed to enhance electrochemical stability without compromising performance characteristics.

Secondary objectives include developing predictive models for stability-related failure modes, establishing standardized testing protocols specifically targeting electrochemical stability assessment, and formulating design guidelines for next-generation battery systems with inherently improved stability profiles. Through this analysis, we seek to bridge the gap between fundamental electrochemical understanding and practical safety engineering in battery applications, ultimately contributing to the development of safer, more reliable energy storage solutions.

Market Analysis of High-Safety Battery Demand

The global market for high-safety batteries has experienced significant growth in recent years, driven primarily by increasing concerns over battery thermal runaway incidents in consumer electronics, electric vehicles, and energy storage systems. The demand for batteries with enhanced electrochemical stability has surged, with the market value reaching approximately $45 billion in 2022 and projected to grow at a compound annual growth rate of 18% through 2030.

Electric vehicle manufacturers represent the largest segment of this market, accounting for nearly 40% of demand. Following several high-profile thermal runaway incidents, automotive companies have prioritized battery safety in their procurement decisions, often willing to pay premium prices for cells with proven stability under extreme conditions. Tesla, BYD, and Volkswagen have all announced specific safety requirements related to electrochemical stability in their battery supplier agreements.

Consumer electronics constitutes the second-largest market segment at 30%, with manufacturers increasingly marketing battery safety as a key differentiator. Apple, Samsung, and other major brands have implemented stringent testing protocols specifically targeting electrochemical stability parameters to prevent thermal events in their devices.

Stationary energy storage systems represent a rapidly growing segment (22% of current market) where the consequences of thermal runaway can be particularly severe due to the scale of installations. Utility companies and grid operators have established new safety standards that explicitly address electrochemical stability requirements.

Geographically, Asia-Pacific dominates the high-safety battery market with 45% share, followed by North America (28%) and Europe (22%). China leads manufacturing capacity, while South Korea and Japan maintain technological advantages in specialized high-stability chemistries.

Market research indicates consumers are increasingly aware of battery safety issues, with 67% of EV buyers citing safety concerns as "very important" in purchasing decisions. This represents a significant shift from just five years ago when this figure was only 38%.

The regulatory landscape is also evolving rapidly, with the European Union's proposed Battery Regulation including specific provisions for thermal runaway prevention. Similarly, UL and other standards organizations have developed new testing protocols specifically addressing electrochemical stability factors that contribute to thermal events.

Industry analysts project that manufacturers capable of demonstrating superior electrochemical stability in their battery products can command price premiums of 15-25% compared to standard offerings, highlighting the strong market incentives for addressing this technical challenge.

Electric vehicle manufacturers represent the largest segment of this market, accounting for nearly 40% of demand. Following several high-profile thermal runaway incidents, automotive companies have prioritized battery safety in their procurement decisions, often willing to pay premium prices for cells with proven stability under extreme conditions. Tesla, BYD, and Volkswagen have all announced specific safety requirements related to electrochemical stability in their battery supplier agreements.

Consumer electronics constitutes the second-largest market segment at 30%, with manufacturers increasingly marketing battery safety as a key differentiator. Apple, Samsung, and other major brands have implemented stringent testing protocols specifically targeting electrochemical stability parameters to prevent thermal events in their devices.

Stationary energy storage systems represent a rapidly growing segment (22% of current market) where the consequences of thermal runaway can be particularly severe due to the scale of installations. Utility companies and grid operators have established new safety standards that explicitly address electrochemical stability requirements.

Geographically, Asia-Pacific dominates the high-safety battery market with 45% share, followed by North America (28%) and Europe (22%). China leads manufacturing capacity, while South Korea and Japan maintain technological advantages in specialized high-stability chemistries.

Market research indicates consumers are increasingly aware of battery safety issues, with 67% of EV buyers citing safety concerns as "very important" in purchasing decisions. This represents a significant shift from just five years ago when this figure was only 38%.

The regulatory landscape is also evolving rapidly, with the European Union's proposed Battery Regulation including specific provisions for thermal runaway prevention. Similarly, UL and other standards organizations have developed new testing protocols specifically addressing electrochemical stability factors that contribute to thermal events.

Industry analysts project that manufacturers capable of demonstrating superior electrochemical stability in their battery products can command price premiums of 15-25% compared to standard offerings, highlighting the strong market incentives for addressing this technical challenge.

Current Challenges in Battery Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in battery safety engineering. The electrochemical stability of battery components plays a pivotal role in this phenomenon, as instability at the electrode-electrolyte interface often serves as the initial trigger for cascading thermal events. Current prevention strategies face substantial limitations in addressing the complex interplay between electrochemical reactions and thermal behavior.

A primary challenge lies in real-time detection systems that can accurately predict imminent thermal runaway conditions before they reach critical thresholds. Existing battery management systems (BMS) typically rely on monitoring external parameters such as temperature, voltage, and current, which often fail to detect internal electrochemical anomalies until they manifest as measurable thermal changes—by which point intervention may be too late.

Material stability presents another significant hurdle. Conventional lithium-ion batteries utilize electrolytes with relatively low flash points and thermal decomposition temperatures. When subjected to abuse conditions or internal short circuits, these materials rapidly decompose, generating heat and releasing flammable gases. The development of inherently stable materials that maintain electrochemical performance while enhancing safety margins remains elusive.

The trade-off between energy density and safety continues to challenge researchers and manufacturers. High-energy-density batteries, which are increasingly demanded by consumer electronics and electric vehicle markets, typically contain more reactive materials and operate closer to stability limits, thereby increasing thermal runaway susceptibility. Balancing these competing priorities without compromising performance metrics presents a formidable engineering challenge.

Scale-up issues further complicate prevention strategies. Safety mechanisms that prove effective in laboratory-scale cells often encounter implementation difficulties in commercial battery packs. Heat dissipation pathways, thermal gradients, and propagation dynamics change dramatically with increasing battery size, rendering some prevention approaches impractical at production scale.

Aging effects introduce additional complexity, as electrochemical stability deteriorates over a battery's lifetime. Degradation mechanisms such as solid-electrolyte interphase (SEI) layer breakdown, lithium plating, and electrode particle cracking can create new vulnerabilities to thermal runaway that were not present in fresh cells. Current prevention systems rarely account for these time-dependent changes in stability profiles.

Regulatory frameworks and testing protocols also present challenges, as standardized safety tests may not adequately represent real-world abuse scenarios or capture the full spectrum of failure modes related to electrochemical stability. This gap between certification requirements and actual usage conditions creates uncertainty in safety assurance.

A primary challenge lies in real-time detection systems that can accurately predict imminent thermal runaway conditions before they reach critical thresholds. Existing battery management systems (BMS) typically rely on monitoring external parameters such as temperature, voltage, and current, which often fail to detect internal electrochemical anomalies until they manifest as measurable thermal changes—by which point intervention may be too late.

Material stability presents another significant hurdle. Conventional lithium-ion batteries utilize electrolytes with relatively low flash points and thermal decomposition temperatures. When subjected to abuse conditions or internal short circuits, these materials rapidly decompose, generating heat and releasing flammable gases. The development of inherently stable materials that maintain electrochemical performance while enhancing safety margins remains elusive.

The trade-off between energy density and safety continues to challenge researchers and manufacturers. High-energy-density batteries, which are increasingly demanded by consumer electronics and electric vehicle markets, typically contain more reactive materials and operate closer to stability limits, thereby increasing thermal runaway susceptibility. Balancing these competing priorities without compromising performance metrics presents a formidable engineering challenge.

Scale-up issues further complicate prevention strategies. Safety mechanisms that prove effective in laboratory-scale cells often encounter implementation difficulties in commercial battery packs. Heat dissipation pathways, thermal gradients, and propagation dynamics change dramatically with increasing battery size, rendering some prevention approaches impractical at production scale.

Aging effects introduce additional complexity, as electrochemical stability deteriorates over a battery's lifetime. Degradation mechanisms such as solid-electrolyte interphase (SEI) layer breakdown, lithium plating, and electrode particle cracking can create new vulnerabilities to thermal runaway that were not present in fresh cells. Current prevention systems rarely account for these time-dependent changes in stability profiles.

Regulatory frameworks and testing protocols also present challenges, as standardized safety tests may not adequately represent real-world abuse scenarios or capture the full spectrum of failure modes related to electrochemical stability. This gap between certification requirements and actual usage conditions creates uncertainty in safety assurance.

Current Approaches to Enhance Electrochemical Stability

01 Electrolyte additives for improved stability

Various electrolyte additives can be incorporated into battery systems to enhance electrochemical stability and mitigate thermal runaway risks. These additives can form protective films on electrode surfaces, scavenge harmful reaction products, or suppress exothermic reactions. By carefully selecting and optimizing these additives, battery safety can be significantly improved while maintaining performance characteristics.- Electrolyte additives for improved stability: Various additives can be incorporated into battery electrolytes to enhance electrochemical stability and prevent thermal runaway. These additives can form protective films on electrode surfaces, scavenge harmful reaction products, or suppress exothermic reactions. Examples include flame retardants, film-forming compounds, and redox shuttle molecules that can significantly improve the safety profile of lithium-ion batteries by preventing uncontrolled temperature increases.

- Advanced electrode materials and coatings: Novel electrode materials and protective coatings can be designed to enhance thermal stability and prevent catastrophic failure. These materials include modified cathodes with reduced oxygen release at high temperatures, anodes with improved structural integrity, and specialized coatings that maintain electrode integrity under extreme conditions. Such materials can effectively mitigate thermal runaway by increasing the temperature threshold at which decomposition reactions occur.

- Battery management systems for thermal control: Sophisticated battery management systems can monitor and control temperature distribution within battery cells to prevent thermal runaway. These systems employ sensors, algorithms, and control mechanisms to detect abnormal temperature increases, regulate charging/discharging rates, and activate cooling systems when necessary. Early detection of potential thermal events allows for preventive measures before cascading thermal failures occur.

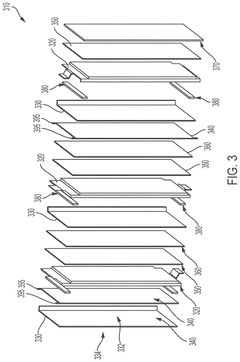

- Separator technologies for enhanced safety: Advanced separator designs incorporate thermal shutdown mechanisms and improved mechanical properties to prevent internal short circuits during thermal events. These separators can include ceramic coatings, polymer blends with controlled melting behavior, or composite structures that maintain integrity at elevated temperatures. When thermal runaway conditions begin to develop, these separators can help isolate electrodes and interrupt the electrochemical reactions driving the thermal event.

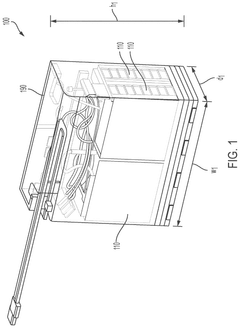

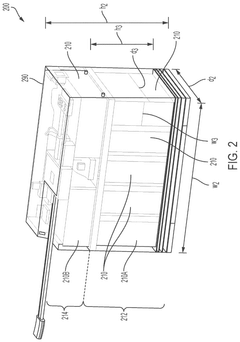

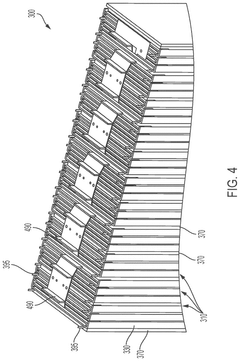

- Novel cell designs and thermal management strategies: Innovative cell architectures and thermal management approaches can fundamentally improve battery safety. These designs include cells with integrated heat dissipation pathways, phase-change materials for temperature regulation, and compartmentalized structures that prevent thermal propagation between cells. External cooling systems and thermally conductive materials can also be incorporated to efficiently remove heat and maintain stable operating temperatures across battery packs.

02 Thermal management systems

Advanced thermal management systems are crucial for preventing thermal runaway in batteries. These systems include heat dissipation structures, cooling channels, phase change materials, and intelligent temperature monitoring. Effective thermal management ensures uniform temperature distribution across battery cells and modules, preventing hotspots that could trigger cascading thermal failures.Expand Specific Solutions03 Separator technologies for enhanced safety

Specialized separator materials and designs can significantly improve battery safety by preventing internal short circuits and providing thermal shutdown capabilities. These separators may incorporate ceramic coatings, flame-retardant polymers, or meltable shutdown layers that activate at elevated temperatures to halt ion transport before thermal runaway occurs.Expand Specific Solutions04 Advanced electrode materials and structures

Novel electrode materials and structural designs can enhance electrochemical stability and reduce thermal runaway risks. These innovations include modified cathode materials with improved thermal stability, structured anodes that minimize dendrite formation, and gradient or core-shell particle designs that maintain structural integrity under stress conditions.Expand Specific Solutions05 Battery management systems for early detection

Sophisticated battery management systems employ sensors, algorithms, and control strategies to detect early signs of thermal instability and electrochemical anomalies. These systems can monitor parameters such as voltage, current, temperature gradients, and internal resistance to identify potential failure modes before they escalate to thermal runaway events, enabling preventive measures or safe shutdown.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The electrochemical stability of batteries and thermal runaway prevention represents a critical technological challenge in the maturing energy storage industry, currently valued at over $50 billion globally. The market is in a growth phase with increasing demand for safer battery technologies across automotive, consumer electronics, and grid storage applications. Leading companies like Tesla, CATL (Ningde Amperex Technology), and SK On have achieved significant advancements in thermal management systems and cell chemistry optimization. Emerging players including ProLogium Technology and 24M Technologies are developing innovative solid-state and semi-solid battery architectures to fundamentally address thermal stability issues. Traditional automotive manufacturers (BMW, Hyundai Mobis) and specialized component suppliers (Celgard, Murata Manufacturing) are forming strategic partnerships to accelerate commercialization of technologies that enhance electrochemical stability and mitigate thermal runaway risks.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive battery thermal management system that addresses electrochemical stability to prevent thermal runaway. Their approach includes advanced cell chemistry optimization with NCA (Nickel Cobalt Aluminum) and NMC (Nickel Manganese Cobalt) cathodes specifically engineered to maintain stability at high temperatures. Tesla implements multi-layer safety mechanisms including a proprietary flame-retardant electrolyte formulation that significantly reduces combustibility during thermal events. Their battery packs feature sophisticated thermal management with interwoven cooling channels that maintain optimal temperature distribution across all cells, preventing localized hotspots that could trigger cascading thermal failures. Tesla's Battery Management System (BMS) continuously monitors individual cell voltage, temperature, and impedance to detect early signs of electrochemical instability, implementing preventive measures before thermal runaway can occur.

Strengths: Industry-leading integration of hardware and software for thermal management; proprietary cell chemistry with enhanced stability; extensive real-world data collection enabling continuous improvement. Weaknesses: Reliance on liquid cooling systems adds complexity and weight; higher production costs compared to simpler thermal management approaches; system effectiveness can degrade over vehicle lifetime.

Prologium Technology Co. Ltd.

Technical Solution: ProLogium has pioneered solid-state lithium ceramic battery (LCB) technology that fundamentally addresses electrochemical stability issues leading to thermal runaway. Their proprietary ceramic electrolyte completely eliminates the flammable liquid electrolytes that are the primary fuel source in conventional battery thermal events. ProLogium's batteries maintain structural and chemical stability at temperatures exceeding 300°C, dramatically higher than the 80-100°C threshold where conventional lithium-ion cells begin degrading toward thermal runaway. Their multi-layer ceramic electrolyte design creates inherent short-circuit prevention by physically blocking dendrite growth that typically initiates catastrophic failure chains. ProLogium has developed specialized manufacturing techniques that enable the creation of bipolar cell structures, reducing internal resistance and heat generation during high-current operations. Their latest generation technology incorporates self-regulating thermal properties in the ceramic electrolyte that increase ionic resistance at elevated temperatures, creating an automatic throttling effect that prevents runaway reactions without requiring external control systems.

Strengths: Revolutionary approach that eliminates fundamental thermal runaway mechanisms; inherently safer chemistry without performance compromises; simplified thermal management requirements reducing system complexity. Weaknesses: Higher manufacturing costs compared to conventional lithium-ion technologies; less mature production scaling; different mechanical properties requiring redesigned battery pack architectures.

Key Innovations in Thermal Runaway Mitigation

Electrochemical battery of which the liquid-electrolyte-impregnated separator has zones with different thermal stability properties

PatentWO2024094877A1

Innovation

- The integration of separator zones with lower melting temperatures at the lateral ends of the electrochemical beam, which are less thermally stable than the rest of the separator, to facilitate controlled short-circuiting and heat dissipation, thereby mitigating thermal runaway effects within a battery module or pack.

Thermal runaway mitigation system for high capacity energy cell

PatentPendingUS20240380036A1

Innovation

- A cell assembly design featuring an electrochemical cell with a ceramic-coated polyethylene terephthalate flame barrier and aramid fiber outer wrap, along with heat plates and a polymeric resin that ruptures to direct gases away during off-gassing events, is used to mitigate thermal runaway by isolating and containing heat and flames.

Safety Standards and Regulatory Framework

The regulatory landscape surrounding battery safety has evolved significantly in response to thermal runaway incidents, with electrochemical stability becoming a central focus of safety standards worldwide. International organizations such as the International Electrotechnical Commission (IEC) have established comprehensive standards like IEC 62133 for portable batteries and IEC 62619 for larger industrial applications, which specifically address electrochemical stability parameters and testing protocols.

These standards mandate rigorous testing procedures including overcharge tests, short circuit evaluations, and thermal abuse simulations—all designed to assess how electrochemical instability might trigger thermal runaway events. The UN Transportation Testing standards (UN 38.3) further regulate the safe transport of lithium batteries by requiring cells and battery packs to demonstrate stability under various mechanical and environmental stresses.

Regional frameworks have also emerged with distinctive approaches. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize electrochemical safety throughout the battery lifecycle, while incorporating sustainability requirements. In North America, UL 1642 and UL 2054 standards have become industry benchmarks, with the UL 9540A test method specifically developed to evaluate thermal runaway propagation in energy storage systems.

Asian markets, particularly China, Japan, and South Korea, have implemented increasingly stringent national standards. China's GB/T 31485 standard specifically addresses thermal runaway prevention mechanisms and electrochemical stability requirements for electric vehicle batteries, reflecting the country's dominant position in battery manufacturing.

Recent regulatory trends show a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety. Regulatory bodies are increasingly requiring Battery Management Systems (BMS) with advanced monitoring capabilities to detect electrochemical instability before it progresses to thermal runaway.

Industry-specific regulations have also emerged, with aviation authorities implementing particularly strict requirements following incidents involving lithium batteries in aircraft. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established specialized testing protocols focusing on electrochemical stability under aviation-specific conditions.

Compliance with these evolving standards presents significant challenges for manufacturers, requiring substantial investment in testing infrastructure and expertise in electrochemical stability assessment. However, these regulatory frameworks have proven essential in driving technological improvements that enhance battery safety across consumer electronics, electric vehicles, and grid-scale energy storage applications.

These standards mandate rigorous testing procedures including overcharge tests, short circuit evaluations, and thermal abuse simulations—all designed to assess how electrochemical instability might trigger thermal runaway events. The UN Transportation Testing standards (UN 38.3) further regulate the safe transport of lithium batteries by requiring cells and battery packs to demonstrate stability under various mechanical and environmental stresses.

Regional frameworks have also emerged with distinctive approaches. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize electrochemical safety throughout the battery lifecycle, while incorporating sustainability requirements. In North America, UL 1642 and UL 2054 standards have become industry benchmarks, with the UL 9540A test method specifically developed to evaluate thermal runaway propagation in energy storage systems.

Asian markets, particularly China, Japan, and South Korea, have implemented increasingly stringent national standards. China's GB/T 31485 standard specifically addresses thermal runaway prevention mechanisms and electrochemical stability requirements for electric vehicle batteries, reflecting the country's dominant position in battery manufacturing.

Recent regulatory trends show a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety. Regulatory bodies are increasingly requiring Battery Management Systems (BMS) with advanced monitoring capabilities to detect electrochemical instability before it progresses to thermal runaway.

Industry-specific regulations have also emerged, with aviation authorities implementing particularly strict requirements following incidents involving lithium batteries in aircraft. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established specialized testing protocols focusing on electrochemical stability under aviation-specific conditions.

Compliance with these evolving standards presents significant challenges for manufacturers, requiring substantial investment in testing infrastructure and expertise in electrochemical stability assessment. However, these regulatory frameworks have proven essential in driving technological improvements that enhance battery safety across consumer electronics, electric vehicles, and grid-scale energy storage applications.

Environmental Impact of Battery Thermal Events

Battery thermal events pose significant environmental challenges that extend far beyond the immediate safety concerns. When thermal runaway occurs, batteries release a complex mixture of toxic substances including heavy metals (lithium, cobalt, nickel), fluorinated compounds, and volatile organic compounds. These contaminants can persist in soil and water systems for decades, disrupting ecosystems and potentially entering food chains.

Air quality degradation represents another critical environmental impact, as thermal events generate dense smoke containing particulate matter, carbon monoxide, and hydrogen fluoride. Studies have documented that a single electric vehicle battery fire can release particulate concentrations exceeding ambient air quality standards by 1000-fold within a 100-meter radius, creating both acute and chronic exposure risks.

Water contamination occurs when firefighting efforts wash battery materials into drainage systems. Research from the University of Michigan demonstrated that runoff from lithium-ion battery fires contains concentrations of heavy metals up to 300 times higher than environmental safety limits, with particular concerns for aquatic ecosystems where even low concentrations can trigger reproductive abnormalities in fish and amphibians.

The carbon footprint of thermal events extends beyond the immediate incident. The premature destruction of batteries necessitates replacement production, generating additional manufacturing emissions. Analysis from the Swedish Environmental Research Institute indicates that each kilogram of battery capacity lost to thermal events represents approximately 15-20 kg of CO₂ equivalent emissions when replacement production is considered.

Waste management challenges are compounded by the difficulty in handling thermally damaged batteries. These materials often cannot enter standard recycling streams due to contamination and structural degradation, resulting in increased landfill disposal. The European Battery Directive has recently acknowledged this gap, proposing specialized protocols for thermally compromised battery materials.

Long-term environmental monitoring data remains limited, but preliminary studies suggest that sites of major battery thermal events show elevated soil concentrations of cobalt and lithium for 3-5 years post-incident. This highlights the need for standardized environmental remediation protocols specifically designed for battery thermal events, particularly as energy storage deployments accelerate globally.

Air quality degradation represents another critical environmental impact, as thermal events generate dense smoke containing particulate matter, carbon monoxide, and hydrogen fluoride. Studies have documented that a single electric vehicle battery fire can release particulate concentrations exceeding ambient air quality standards by 1000-fold within a 100-meter radius, creating both acute and chronic exposure risks.

Water contamination occurs when firefighting efforts wash battery materials into drainage systems. Research from the University of Michigan demonstrated that runoff from lithium-ion battery fires contains concentrations of heavy metals up to 300 times higher than environmental safety limits, with particular concerns for aquatic ecosystems where even low concentrations can trigger reproductive abnormalities in fish and amphibians.

The carbon footprint of thermal events extends beyond the immediate incident. The premature destruction of batteries necessitates replacement production, generating additional manufacturing emissions. Analysis from the Swedish Environmental Research Institute indicates that each kilogram of battery capacity lost to thermal events represents approximately 15-20 kg of CO₂ equivalent emissions when replacement production is considered.

Waste management challenges are compounded by the difficulty in handling thermally damaged batteries. These materials often cannot enter standard recycling streams due to contamination and structural degradation, resulting in increased landfill disposal. The European Battery Directive has recently acknowledged this gap, proposing specialized protocols for thermally compromised battery materials.

Long-term environmental monitoring data remains limited, but preliminary studies suggest that sites of major battery thermal events show elevated soil concentrations of cobalt and lithium for 3-5 years post-incident. This highlights the need for standardized environmental remediation protocols specifically designed for battery thermal events, particularly as energy storage deployments accelerate globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!