Battery Thermal Runaway in Telecommunication Systems: An Overview

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

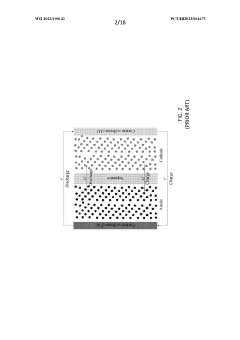

Battery thermal runaway (BTR) has emerged as a critical safety concern in telecommunication systems over the past two decades. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and catastrophic system failure. The evolution of battery technology, particularly the widespread adoption of lithium-ion batteries in telecommunications infrastructure since the early 2000s, has introduced new safety challenges alongside performance improvements.

The telecommunications industry has witnessed a significant shift toward higher energy density batteries to support the increasing power demands of modern network equipment. This transition began with the deployment of 3G networks in the early 2000s and accelerated with 4G and 5G implementations, requiring more compact yet powerful energy storage solutions for base stations, data centers, and network equipment.

Historical data indicates a concerning trend: between 2010 and 2022, over 200 significant incidents involving battery thermal runaway in telecommunication facilities were reported globally, with approximately 40% resulting in service disruptions and 15% causing extensive infrastructure damage. These incidents have prompted regulatory bodies, including the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), to develop increasingly stringent safety standards.

The technical progression of battery systems in telecommunications has followed a clear trajectory from lead-acid batteries to advanced lithium-ion chemistries, with each generation presenting unique thermal management challenges. Current research indicates that thermal runaway events typically initiate at temperatures between 130-200°C, with propagation mechanisms varying based on battery chemistry, cell design, and system integration approaches.

This technical pre-research aims to comprehensively examine the battery thermal runaway phenomenon in telecommunication contexts, with specific objectives to: identify primary triggering mechanisms and propagation pathways; evaluate existing detection and prevention technologies; assess the effectiveness of current industry standards and safety protocols; and explore emerging technologies for enhanced thermal management and early warning systems.

The ultimate goal is to establish a technical foundation for developing next-generation battery safety systems specifically tailored to telecommunication environments, where continuous operation is critical and physical access for maintenance may be limited. This research will inform strategic decisions regarding battery technology selection, system design parameters, and risk mitigation approaches for future telecommunication infrastructure deployments.

The telecommunications industry has witnessed a significant shift toward higher energy density batteries to support the increasing power demands of modern network equipment. This transition began with the deployment of 3G networks in the early 2000s and accelerated with 4G and 5G implementations, requiring more compact yet powerful energy storage solutions for base stations, data centers, and network equipment.

Historical data indicates a concerning trend: between 2010 and 2022, over 200 significant incidents involving battery thermal runaway in telecommunication facilities were reported globally, with approximately 40% resulting in service disruptions and 15% causing extensive infrastructure damage. These incidents have prompted regulatory bodies, including the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), to develop increasingly stringent safety standards.

The technical progression of battery systems in telecommunications has followed a clear trajectory from lead-acid batteries to advanced lithium-ion chemistries, with each generation presenting unique thermal management challenges. Current research indicates that thermal runaway events typically initiate at temperatures between 130-200°C, with propagation mechanisms varying based on battery chemistry, cell design, and system integration approaches.

This technical pre-research aims to comprehensively examine the battery thermal runaway phenomenon in telecommunication contexts, with specific objectives to: identify primary triggering mechanisms and propagation pathways; evaluate existing detection and prevention technologies; assess the effectiveness of current industry standards and safety protocols; and explore emerging technologies for enhanced thermal management and early warning systems.

The ultimate goal is to establish a technical foundation for developing next-generation battery safety systems specifically tailored to telecommunication environments, where continuous operation is critical and physical access for maintenance may be limited. This research will inform strategic decisions regarding battery technology selection, system design parameters, and risk mitigation approaches for future telecommunication infrastructure deployments.

Telecom Market Demand for Battery Safety Solutions

The telecommunications industry has witnessed a significant surge in demand for advanced battery safety solutions, primarily driven by the exponential growth in network infrastructure and the critical need for uninterrupted service availability. Market research indicates that the global telecom battery market is projected to reach $10.8 billion by 2027, with safety solutions comprising approximately 18% of this valuation.

This growing demand stems from several key factors within the telecommunications sector. Firstly, the rapid deployment of 5G infrastructure has necessitated more distributed power systems and backup solutions, increasing the overall battery footprint across networks. These installations often operate in varying environmental conditions, from urban heat islands to remote locations with extreme temperature fluctuations, creating diverse thermal management challenges.

Network reliability requirements have become increasingly stringent, with major telecom operators targeting 99.999% uptime ("five nines"). Battery failures, particularly thermal runaway events, represent a significant threat to this reliability benchmark. Industry data reveals that battery-related incidents account for approximately 14% of network outages, translating to substantial revenue losses and customer dissatisfaction.

The financial implications of battery thermal events extend beyond immediate service disruptions. Insurance providers have begun implementing premium adjustments for telecom operators based on their battery safety protocols, with potential premium reductions of 8-12% for companies deploying advanced thermal runaway prevention systems. This economic incentive has further accelerated market demand for comprehensive safety solutions.

Regulatory pressures have also shaped market requirements, with telecommunications regulatory bodies in North America, Europe, and parts of Asia implementing stricter safety standards for battery installations in critical infrastructure. These regulations often mandate specific monitoring capabilities, thermal management systems, and emergency response protocols.

The shift toward edge computing and distributed network architectures has created additional demand vectors. As computing resources move closer to end-users, smaller, more numerous battery installations are required, each needing appropriate safety measures. This trend has expanded the market for scalable, cost-effective safety solutions suitable for diverse deployment scenarios.

Customer expectations regarding environmental sustainability have further influenced market demands. Telecom operators increasingly seek battery safety solutions that not only prevent catastrophic failures but also extend battery lifespan, reduce replacement frequency, and facilitate safer recycling processes, aligning with broader corporate sustainability objectives.

This growing demand stems from several key factors within the telecommunications sector. Firstly, the rapid deployment of 5G infrastructure has necessitated more distributed power systems and backup solutions, increasing the overall battery footprint across networks. These installations often operate in varying environmental conditions, from urban heat islands to remote locations with extreme temperature fluctuations, creating diverse thermal management challenges.

Network reliability requirements have become increasingly stringent, with major telecom operators targeting 99.999% uptime ("five nines"). Battery failures, particularly thermal runaway events, represent a significant threat to this reliability benchmark. Industry data reveals that battery-related incidents account for approximately 14% of network outages, translating to substantial revenue losses and customer dissatisfaction.

The financial implications of battery thermal events extend beyond immediate service disruptions. Insurance providers have begun implementing premium adjustments for telecom operators based on their battery safety protocols, with potential premium reductions of 8-12% for companies deploying advanced thermal runaway prevention systems. This economic incentive has further accelerated market demand for comprehensive safety solutions.

Regulatory pressures have also shaped market requirements, with telecommunications regulatory bodies in North America, Europe, and parts of Asia implementing stricter safety standards for battery installations in critical infrastructure. These regulations often mandate specific monitoring capabilities, thermal management systems, and emergency response protocols.

The shift toward edge computing and distributed network architectures has created additional demand vectors. As computing resources move closer to end-users, smaller, more numerous battery installations are required, each needing appropriate safety measures. This trend has expanded the market for scalable, cost-effective safety solutions suitable for diverse deployment scenarios.

Customer expectations regarding environmental sustainability have further influenced market demands. Telecom operators increasingly seek battery safety solutions that not only prevent catastrophic failures but also extend battery lifespan, reduce replacement frequency, and facilitate safer recycling processes, aligning with broader corporate sustainability objectives.

Current Challenges in Battery Thermal Management

Despite significant advancements in battery technology, thermal management remains one of the most critical challenges in telecommunication systems. The high-density power requirements of modern telecom infrastructure create substantial heat generation within battery systems, particularly in base stations and data centers where continuous operation is essential. Current lithium-ion battery technologies used in these applications face thermal runaway risks when operating temperatures exceed 60°C, a threshold increasingly difficult to maintain in compact, high-power installations.

The primary challenge lies in the inherent trade-off between cooling system effectiveness and energy efficiency. Traditional air cooling systems are becoming inadequate for high-density battery installations, while liquid cooling solutions introduce complexity, maintenance concerns, and potential points of failure in mission-critical systems. This dilemma is particularly pronounced in remote telecommunication installations where maintenance access is limited and system reliability is paramount.

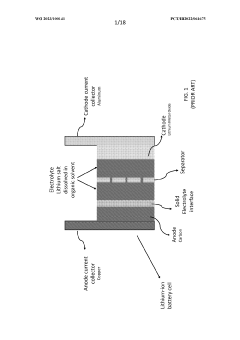

Material limitations present another significant obstacle. Current electrode and electrolyte materials demonstrate accelerated degradation at elevated temperatures, creating a negative feedback loop where performance degradation leads to increased heat generation. The thermal conductivity of battery components remains suboptimal, with thermal gradients within individual cells creating localized hotspots that can trigger cascading failures.

Monitoring and early detection systems face substantial technical hurdles in accurately predicting thermal events before they reach critical stages. Current sensor technologies often provide insufficient spatial resolution to detect localized heating, while predictive algorithms struggle to balance sensitivity with false alarm prevention. The integration of these monitoring systems with automated response mechanisms remains underdeveloped in most commercial installations.

Regulatory and safety standards further complicate thermal management approaches. The UL 9540A test method for evaluating thermal runaway fire propagation in battery energy storage systems imposes stringent requirements that often necessitate conservative design approaches, potentially limiting energy density and system performance. International standards vary significantly, creating compliance challenges for global telecommunication providers.

Economic considerations also constrain thermal management solutions. The telecommunications industry faces intense cost pressures, limiting the implementation of advanced cooling technologies despite their technical merits. The total cost of ownership calculation must balance initial implementation costs against operational efficiency and system longevity, creating complex decision matrices for system designers and operators.

The primary challenge lies in the inherent trade-off between cooling system effectiveness and energy efficiency. Traditional air cooling systems are becoming inadequate for high-density battery installations, while liquid cooling solutions introduce complexity, maintenance concerns, and potential points of failure in mission-critical systems. This dilemma is particularly pronounced in remote telecommunication installations where maintenance access is limited and system reliability is paramount.

Material limitations present another significant obstacle. Current electrode and electrolyte materials demonstrate accelerated degradation at elevated temperatures, creating a negative feedback loop where performance degradation leads to increased heat generation. The thermal conductivity of battery components remains suboptimal, with thermal gradients within individual cells creating localized hotspots that can trigger cascading failures.

Monitoring and early detection systems face substantial technical hurdles in accurately predicting thermal events before they reach critical stages. Current sensor technologies often provide insufficient spatial resolution to detect localized heating, while predictive algorithms struggle to balance sensitivity with false alarm prevention. The integration of these monitoring systems with automated response mechanisms remains underdeveloped in most commercial installations.

Regulatory and safety standards further complicate thermal management approaches. The UL 9540A test method for evaluating thermal runaway fire propagation in battery energy storage systems imposes stringent requirements that often necessitate conservative design approaches, potentially limiting energy density and system performance. International standards vary significantly, creating compliance challenges for global telecommunication providers.

Economic considerations also constrain thermal management solutions. The telecommunications industry faces intense cost pressures, limiting the implementation of advanced cooling technologies despite their technical merits. The total cost of ownership calculation must balance initial implementation costs against operational efficiency and system longevity, creating complex decision matrices for system designers and operators.

Existing Thermal Runaway Prevention Solutions

01 Battery thermal management systems

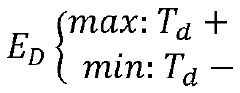

Thermal management systems are designed to prevent and control thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management systems can detect early signs of thermal instability and take preventive measures to avoid catastrophic failure, such as activating cooling systems or reducing electrical load on affected cells.- Battery thermal management systems: Thermal management systems are designed to prevent and control thermal runaway in batteries. These systems include cooling mechanisms, temperature monitoring, and heat dissipation technologies that maintain optimal operating temperatures. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling systems to efficiently remove excess heat from battery cells, preventing the cascade effect that leads to thermal runaway.

- Safety mechanisms and protective devices: Various safety mechanisms and protective devices are implemented to prevent or mitigate battery thermal runaway. These include current interrupt devices, pressure relief valves, thermal fuses, and shutdown separators that activate when abnormal conditions are detected. These protective elements can isolate affected cells, vent gases safely, or completely disconnect the battery system before thermal runaway propagates throughout the battery pack.

- Advanced battery materials and designs: Innovative battery materials and structural designs are developed to enhance thermal stability and reduce the risk of thermal runaway. These include flame-retardant electrolytes, thermally stable electrode materials, and novel separator designs with improved heat resistance. Multi-layer safety structures and cell-to-cell isolation techniques are also employed to prevent thermal propagation between adjacent cells in a battery pack.

- Detection and early warning systems: Advanced detection and early warning systems are crucial for identifying potential thermal runaway conditions before they escalate. These systems utilize temperature sensors, gas detectors, voltage monitoring, and impedance tracking to detect abnormal battery behavior. Machine learning algorithms and predictive analytics are increasingly being employed to recognize patterns that precede thermal runaway events, allowing for preventive measures to be taken before critical conditions are reached.

- Thermal runaway propagation prevention: Preventing the propagation of thermal runaway from one cell to neighboring cells is essential for battery safety. This is achieved through thermal barriers, insulating materials, and strategic cell arrangement within battery packs. Fire-resistant materials, heat-absorbing structures, and compartmentalization techniques are implemented to contain thermal events and prevent system-wide failures, particularly important in large battery installations for electric vehicles and energy storage systems.

02 Safety materials and structures for thermal runaway prevention

Specialized materials and structural designs are incorporated into battery systems to prevent thermal runaway propagation. These include flame-retardant separators, thermal insulation layers, and heat-resistant barriers between cells. Some designs feature phase change materials that absorb excess heat during temperature spikes, while others implement physical isolation mechanisms that prevent thermal runaway from spreading between adjacent cells in a battery pack.Expand Specific Solutions03 Detection and early warning systems

Advanced sensing technologies are employed to detect early signs of thermal runaway before it becomes catastrophic. These systems monitor parameters such as temperature gradients, gas emissions, voltage fluctuations, and internal pressure changes. When abnormal conditions are detected, early warning systems trigger alerts and can initiate automated safety protocols to prevent thermal runaway progression, potentially disconnecting affected cells or activating emergency cooling systems.Expand Specific Solutions04 Novel electrode and electrolyte formulations

Innovative electrode materials and electrolyte formulations are developed to enhance thermal stability of batteries. These include solid-state electrolytes that eliminate flammable liquid components, electrode coatings that prevent exothermic reactions, and additives that increase the thermal decomposition temperature of battery components. Some formulations incorporate self-healing properties or chemical shutdown mechanisms that activate at elevated temperatures to prevent thermal runaway progression.Expand Specific Solutions05 Battery management systems with thermal runaway control algorithms

Sophisticated battery management systems (BMS) employ advanced algorithms to predict, prevent and mitigate thermal runaway events. These systems continuously monitor cell parameters and use predictive modeling to identify potential thermal issues before they escalate. The BMS can implement adaptive charging protocols, load balancing between cells, and emergency shutdown procedures based on real-time thermal analysis. Some systems incorporate machine learning algorithms that improve thermal event prediction accuracy over time.Expand Specific Solutions

Key Industry Players in Telecom Battery Systems

Battery thermal runaway in telecommunication systems represents a critical challenge in the evolving energy storage landscape. The market is currently in a growth phase, with an estimated global value exceeding $5 billion and projected annual growth of 15-20%. Leading players like Tesla, Samsung SDI, LG Energy Solution, and BYD are driving technological innovation through advanced battery management systems and thermal control technologies. Established telecommunications equipment providers such as Huawei and Nokia are partnering with battery specialists to enhance safety protocols. The technology maturity varies significantly, with companies like Microvast and ITRI focusing on novel thermal management solutions, while Tesla and BYD have deployed commercial-scale prevention systems. Regulatory pressures and high-profile incidents are accelerating development, with most major players investing in predictive analytics and early detection systems to mitigate risks.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive thermal management system for telecommunication battery systems that combines multiple safety mechanisms. Their approach includes a multi-layered cell design with ceramic-coated separators that maintain structural integrity at high temperatures, preventing internal short circuits. For thermal runaway prevention, they've implemented an advanced Battery Management System (BMS) that continuously monitors cell temperature, voltage, and current with millisecond-level response times. The system employs predictive algorithms to detect thermal anomalies before they escalate into runaway conditions. Samsung's solution also features physical isolation barriers between cells and modules, using flame-retardant materials that can withstand temperatures up to 1300°C. Their cooling system utilizes phase-change materials combined with liquid cooling channels that can rapidly dissipate heat from hotspots within the battery pack.

Strengths: Superior early detection capabilities through advanced BMS algorithms; excellent thermal isolation between cells prevents propagation; integrated cooling system provides efficient heat dissipation. Weaknesses: Higher manufacturing costs due to complex multi-layer design; additional weight from comprehensive safety systems may impact overall system efficiency; requires more sophisticated maintenance protocols.

BYD Co., Ltd.

Technical Solution: BYD has developed the Blade Battery technology that fundamentally addresses thermal runaway concerns in telecommunication systems. This lithium iron phosphate (LFP) battery utilizes a unique cell-to-pack design where long, thin cells ("blades") are arranged in parallel and inserted directly into the battery pack. This architecture significantly improves heat dissipation by increasing surface area and reducing thermal pathways between cells. For telecommunication applications, BYD has enhanced this technology with a specialized cooling system that maintains optimal operating temperatures even under high-load conditions. Their solution includes a multi-level safety monitoring system with redundant temperature sensors and an intelligent Battery Management System (BMS) that can isolate individual blade cells if abnormal conditions are detected. The system also features flame-retardant materials between cells and an emergency ventilation system that activates automatically to release pressure and heat if thermal events occur. BYD's approach emphasizes inherent safety through chemistry choice (LFP is inherently more thermally stable than other lithium-ion chemistries) combined with structural innovations that physically prevent thermal propagation.

Strengths: Inherently safer LFP chemistry reduces thermal runaway risk; unique blade design provides excellent thermal isolation between cells; system can continue operation even if individual cells fail. Weaknesses: Lower energy density compared to some competing technologies; larger footprint may be challenging in space-constrained telecommunication installations; higher initial cost compared to conventional battery systems.

Critical Patents in Battery Thermal Management

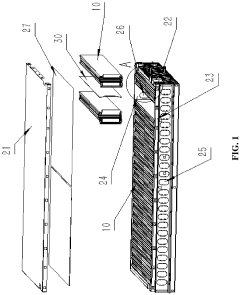

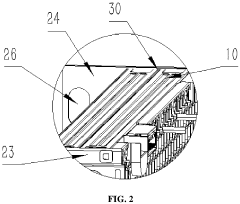

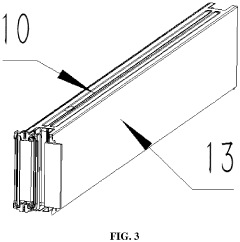

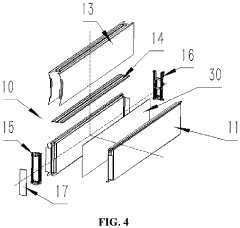

Mechanical barrier elements with flow-through cooling for use in electrical power systems

PatentWO2023100141A1

Innovation

- A novel barrier system using aerogel compositions with reinforced insulation layers and compressible layers, including rigid plates and spring elements, to dissipate heat and resist compression deformation, thereby mitigating thermal propagation and enhancing safety.

Battery module capable of delaying thermal runaway and vehicle using same

PatentInactiveEP4044346A1

Innovation

- A battery module design featuring thermal runaway sealing assemblies with U-shaped enclosures, foam for buffering and heat insulation, and multi-layer structures for directional heat management, including aerogel and mica sheets, to slow down heat diffusion and control thermal runaway.

Regulatory Standards for Telecom Battery Safety

The regulatory landscape for battery safety in telecommunications systems has evolved significantly in response to increasing incidents of thermal runaway. The International Electrotechnical Commission (IEC) has established IEC 62133, which specifically addresses safety requirements for portable sealed secondary cells and batteries containing alkaline or non-acid electrolytes. This standard mandates rigorous testing protocols including short circuit, abnormal charging, and forced discharge tests to evaluate battery resilience under extreme conditions.

In the United States, UL 1642 (Standard for Lithium Batteries) and UL 2054 (Household and Commercial Batteries) provide comprehensive frameworks for battery safety certification. These standards have been increasingly referenced in telecom equipment specifications, with UL 1973 specifically addressing batteries for use in stationary applications, including telecommunications infrastructure.

The European Union has implemented EN 62619, which focuses on safety requirements for large-format lithium-ion cells and batteries used in industrial applications, including telecom systems. This standard is complemented by the broader regulatory framework of the ATEX Directive (2014/34/EU) for equipment in potentially explosive atmospheres, which has implications for battery installations in certain telecom environments.

Telecommunications Industry Association (TIA) has developed TIA-942, which includes specific provisions for battery safety in data centers and telecom facilities. These guidelines address installation requirements, ventilation systems, and fire suppression mechanisms necessary to mitigate thermal runaway risks in battery energy storage systems.

The National Fire Protection Association (NFPA) has established NFPA 855, which provides standards for the installation of stationary energy storage systems, including battery systems in telecom facilities. This standard addresses minimum separation distances, fire detection, and suppression requirements specifically designed to contain thermal runaway events.

In Asia, China's GB/T 36276-2018 standard addresses safety requirements for lithium-ion batteries in telecommunications applications, while Japan's JIS C8715-2 provides similar regulatory frameworks with particular emphasis on thermal management systems.

Recent regulatory trends indicate a shift toward more stringent requirements for battery management systems (BMS) that can predict and prevent thermal runaway conditions. The International Telecommunication Union (ITU) has published ITU-T L.1220, which provides guidelines for sustainable power feeding solutions for telecom equipment, including safety considerations for battery systems.

Compliance with these standards typically requires third-party certification, with regular audits and testing to ensure ongoing adherence. Telecommunications operators must navigate this complex regulatory landscape while balancing operational requirements, as non-compliance can result in significant legal liabilities and operational disruptions.

In the United States, UL 1642 (Standard for Lithium Batteries) and UL 2054 (Household and Commercial Batteries) provide comprehensive frameworks for battery safety certification. These standards have been increasingly referenced in telecom equipment specifications, with UL 1973 specifically addressing batteries for use in stationary applications, including telecommunications infrastructure.

The European Union has implemented EN 62619, which focuses on safety requirements for large-format lithium-ion cells and batteries used in industrial applications, including telecom systems. This standard is complemented by the broader regulatory framework of the ATEX Directive (2014/34/EU) for equipment in potentially explosive atmospheres, which has implications for battery installations in certain telecom environments.

Telecommunications Industry Association (TIA) has developed TIA-942, which includes specific provisions for battery safety in data centers and telecom facilities. These guidelines address installation requirements, ventilation systems, and fire suppression mechanisms necessary to mitigate thermal runaway risks in battery energy storage systems.

The National Fire Protection Association (NFPA) has established NFPA 855, which provides standards for the installation of stationary energy storage systems, including battery systems in telecom facilities. This standard addresses minimum separation distances, fire detection, and suppression requirements specifically designed to contain thermal runaway events.

In Asia, China's GB/T 36276-2018 standard addresses safety requirements for lithium-ion batteries in telecommunications applications, while Japan's JIS C8715-2 provides similar regulatory frameworks with particular emphasis on thermal management systems.

Recent regulatory trends indicate a shift toward more stringent requirements for battery management systems (BMS) that can predict and prevent thermal runaway conditions. The International Telecommunication Union (ITU) has published ITU-T L.1220, which provides guidelines for sustainable power feeding solutions for telecom equipment, including safety considerations for battery systems.

Compliance with these standards typically requires third-party certification, with regular audits and testing to ensure ongoing adherence. Telecommunications operators must navigate this complex regulatory landscape while balancing operational requirements, as non-compliance can result in significant legal liabilities and operational disruptions.

Environmental Impact of Battery Thermal Events

Battery thermal runaway events in telecommunication systems pose significant environmental hazards that extend beyond immediate safety concerns. When lithium-ion batteries experience thermal events, they release a complex mixture of toxic gases including hydrogen fluoride, carbon monoxide, and various volatile organic compounds. These emissions can contaminate surrounding air quality, creating hazardous conditions that may persist long after the initial incident has been contained.

The environmental impact extends to water systems when firefighting efforts generate contaminated runoff. This runoff often contains heavy metals such as cobalt, nickel, and manganese from damaged battery cells, along with toxic electrolyte components. Studies have documented cases where this contamination has entered local watersheds, affecting aquatic ecosystems and potentially threatening drinking water supplies in areas surrounding telecommunication facilities.

Soil contamination represents another significant environmental concern. The leaching of battery materials into soil can persist for years, creating long-term environmental liabilities for telecommunication companies. Research indicates that remediation of battery-contaminated soil is particularly challenging due to the complex mixture of inorganic and organic contaminants involved.

The carbon footprint of thermal events must also be considered in environmental impact assessments. A single large-scale thermal runaway incident in a telecommunication battery system can release greenhouse gas emissions equivalent to several tons of CO2. This contributes to climate change impacts beyond the immediate environmental damage at the incident site.

Waste management challenges compound these environmental concerns. Damaged batteries from thermal events are classified as hazardous waste in most jurisdictions, requiring specialized handling and disposal procedures. The lack of standardized protocols for managing post-thermal event battery waste has led to inconsistent practices across the industry, potentially exacerbating environmental impacts.

Recent environmental impact studies have begun quantifying these effects more precisely. For instance, a 2022 analysis of a major thermal runaway event at a telecommunications facility found measurable soil contamination extending up to 500 meters from the incident site, with groundwater impacts detected in monitoring wells for more than 18 months following the event.

Regulatory frameworks addressing these environmental impacts are evolving rapidly. The European Union's Battery Directive now includes specific provisions for thermal event management, while the EPA in the United States has issued updated guidance on environmental remediation requirements following battery thermal incidents in critical infrastructure settings.

The environmental impact extends to water systems when firefighting efforts generate contaminated runoff. This runoff often contains heavy metals such as cobalt, nickel, and manganese from damaged battery cells, along with toxic electrolyte components. Studies have documented cases where this contamination has entered local watersheds, affecting aquatic ecosystems and potentially threatening drinking water supplies in areas surrounding telecommunication facilities.

Soil contamination represents another significant environmental concern. The leaching of battery materials into soil can persist for years, creating long-term environmental liabilities for telecommunication companies. Research indicates that remediation of battery-contaminated soil is particularly challenging due to the complex mixture of inorganic and organic contaminants involved.

The carbon footprint of thermal events must also be considered in environmental impact assessments. A single large-scale thermal runaway incident in a telecommunication battery system can release greenhouse gas emissions equivalent to several tons of CO2. This contributes to climate change impacts beyond the immediate environmental damage at the incident site.

Waste management challenges compound these environmental concerns. Damaged batteries from thermal events are classified as hazardous waste in most jurisdictions, requiring specialized handling and disposal procedures. The lack of standardized protocols for managing post-thermal event battery waste has led to inconsistent practices across the industry, potentially exacerbating environmental impacts.

Recent environmental impact studies have begun quantifying these effects more precisely. For instance, a 2022 analysis of a major thermal runaway event at a telecommunications facility found measurable soil contamination extending up to 500 meters from the incident site, with groundwater impacts detected in monitoring wells for more than 18 months following the event.

Regulatory frameworks addressing these environmental impacts are evolving rapidly. The European Union's Battery Directive now includes specific provisions for thermal event management, while the EPA in the United States has issued updated guidance on environmental remediation requirements following battery thermal incidents in critical infrastructure settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!