How Material Compatibility Impacts Battery Thermal Runaway Occurrences

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Material Compatibility Background and Objectives

Battery thermal runaway incidents have emerged as a critical safety concern in the energy storage industry, with material compatibility playing a pivotal role in these occurrences. The evolution of battery technology has progressed from simple galvanic cells in the 18th century to today's sophisticated lithium-ion configurations, with each advancement bringing new challenges in material interactions. This technical evolution has consistently been driven by demands for higher energy density, longer cycle life, and enhanced safety profiles.

The fundamental challenge lies in the complex electrochemical environment within batteries, where multiple materials must coexist under varying thermal, electrical, and mechanical stresses. Historical data indicates that approximately 30% of battery failures resulting in thermal runaway can be attributed to material incompatibility issues, highlighting the significance of this technical domain.

Recent technological trends show an accelerated development of advanced battery chemistries, including solid-state batteries, silicon anodes, and high-nickel cathodes. Each innovation introduces new material interfaces that must be thoroughly evaluated for compatibility to prevent catastrophic failures. The industry has witnessed a 40% increase in research publications focused on material compatibility over the past five years, demonstrating growing recognition of this challenge.

The primary objective of this technical investigation is to comprehensively analyze how interactions between battery components—including electrodes, electrolytes, separators, and current collectors—contribute to thermal runaway events. We aim to establish quantifiable correlations between specific material combinations and failure modes, providing a scientific foundation for safer battery designs.

Secondary objectives include mapping the degradation mechanisms that occur at material interfaces under various operating conditions, identifying early indicators of potential compatibility issues, and developing predictive models that can forecast failure probabilities based on material selection. These insights will enable more informed design decisions in battery manufacturing.

The scope encompasses both established battery technologies currently in commercial use and emerging chemistries approaching market readiness. Special attention will be given to high-energy density applications where thermal management challenges are most pronounced, such as electric vehicles and grid-scale energy storage systems.

By establishing clear technical targets for material compatibility standards, this research aims to contribute to the development of next-generation batteries with significantly reduced thermal runaway risk, supporting the broader industry goal of achieving a 99.9999% safety reliability rate for energy storage systems by 2030.

The fundamental challenge lies in the complex electrochemical environment within batteries, where multiple materials must coexist under varying thermal, electrical, and mechanical stresses. Historical data indicates that approximately 30% of battery failures resulting in thermal runaway can be attributed to material incompatibility issues, highlighting the significance of this technical domain.

Recent technological trends show an accelerated development of advanced battery chemistries, including solid-state batteries, silicon anodes, and high-nickel cathodes. Each innovation introduces new material interfaces that must be thoroughly evaluated for compatibility to prevent catastrophic failures. The industry has witnessed a 40% increase in research publications focused on material compatibility over the past five years, demonstrating growing recognition of this challenge.

The primary objective of this technical investigation is to comprehensively analyze how interactions between battery components—including electrodes, electrolytes, separators, and current collectors—contribute to thermal runaway events. We aim to establish quantifiable correlations between specific material combinations and failure modes, providing a scientific foundation for safer battery designs.

Secondary objectives include mapping the degradation mechanisms that occur at material interfaces under various operating conditions, identifying early indicators of potential compatibility issues, and developing predictive models that can forecast failure probabilities based on material selection. These insights will enable more informed design decisions in battery manufacturing.

The scope encompasses both established battery technologies currently in commercial use and emerging chemistries approaching market readiness. Special attention will be given to high-energy density applications where thermal management challenges are most pronounced, such as electric vehicles and grid-scale energy storage systems.

By establishing clear technical targets for material compatibility standards, this research aims to contribute to the development of next-generation batteries with significantly reduced thermal runaway risk, supporting the broader industry goal of achieving a 99.9999% safety reliability rate for energy storage systems by 2030.

Market Analysis of Battery Safety Requirements

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. This growth has intensified scrutiny on battery safety requirements across various industries. Current market analysis indicates that the global lithium-ion battery market reached approximately $46.2 billion in 2022 and is projected to grow at a CAGR of 18.1% through 2030, with safety considerations becoming increasingly paramount.

Consumer electronics manufacturers face stringent safety regulations, particularly after high-profile thermal runaway incidents involving smartphones and laptops. These incidents have resulted in costly product recalls, brand damage, and increased regulatory oversight. For instance, the consumer electronics industry has seen safety-related recalls costing manufacturers over $500 million in the past five years alone, creating strong market pressure for improved battery safety solutions.

The automotive sector represents the most demanding market segment for battery safety requirements. With EV sales growing at over 40% annually in major markets, automakers are investing heavily in battery safety technologies. Premium automotive manufacturers are willing to pay 15-20% more for battery systems with advanced thermal management and material compatibility features that significantly reduce thermal runaway risks. This premium pricing reflects both consumer demand for safety and regulatory compliance requirements.

Energy storage system (ESS) applications present another critical market segment with distinct safety requirements. Grid-scale installations must meet rigorous safety standards due to their size and proximity to infrastructure. The ESS market is expected to grow at 32.8% CAGR through 2028, with safety certification becoming a key differentiator for suppliers. Insurance providers are increasingly offering reduced premiums for systems employing advanced material compatibility solutions that minimize thermal runaway risks.

Regional variations in safety requirements create market segmentation opportunities. European markets emphasize comprehensive safety testing and certification, while North American markets focus on performance standards and liability concerns. Asian markets, particularly China, are rapidly evolving their safety requirements as domestic battery production expands, creating opportunities for safety technology providers.

Market analysis reveals that customers are increasingly willing to pay premium prices for batteries with demonstrated safety advantages. This trend is particularly evident in high-value applications such as medical devices, aerospace, and defense, where material compatibility solutions command price premiums of 25-40% compared to standard battery technologies. The market for specialized safety testing services related to material compatibility has grown by 27% annually since 2020.

Consumer electronics manufacturers face stringent safety regulations, particularly after high-profile thermal runaway incidents involving smartphones and laptops. These incidents have resulted in costly product recalls, brand damage, and increased regulatory oversight. For instance, the consumer electronics industry has seen safety-related recalls costing manufacturers over $500 million in the past five years alone, creating strong market pressure for improved battery safety solutions.

The automotive sector represents the most demanding market segment for battery safety requirements. With EV sales growing at over 40% annually in major markets, automakers are investing heavily in battery safety technologies. Premium automotive manufacturers are willing to pay 15-20% more for battery systems with advanced thermal management and material compatibility features that significantly reduce thermal runaway risks. This premium pricing reflects both consumer demand for safety and regulatory compliance requirements.

Energy storage system (ESS) applications present another critical market segment with distinct safety requirements. Grid-scale installations must meet rigorous safety standards due to their size and proximity to infrastructure. The ESS market is expected to grow at 32.8% CAGR through 2028, with safety certification becoming a key differentiator for suppliers. Insurance providers are increasingly offering reduced premiums for systems employing advanced material compatibility solutions that minimize thermal runaway risks.

Regional variations in safety requirements create market segmentation opportunities. European markets emphasize comprehensive safety testing and certification, while North American markets focus on performance standards and liability concerns. Asian markets, particularly China, are rapidly evolving their safety requirements as domestic battery production expands, creating opportunities for safety technology providers.

Market analysis reveals that customers are increasingly willing to pay premium prices for batteries with demonstrated safety advantages. This trend is particularly evident in high-value applications such as medical devices, aerospace, and defense, where material compatibility solutions command price premiums of 25-40% compared to standard battery technologies. The market for specialized safety testing services related to material compatibility has grown by 27% annually since 2020.

Current Challenges in Battery Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in battery safety engineering. Current prevention strategies face multiple technical barriers that limit their effectiveness across diverse operating conditions and battery chemistries. The primary challenge lies in developing comprehensive early detection systems capable of identifying precursors to thermal events before they cascade into catastrophic failures.

Material interface issues present substantial difficulties, particularly in high-energy density batteries where electrode-electrolyte interactions become increasingly complex under thermal and mechanical stress. The industry struggles with developing separator materials that maintain mechanical integrity at elevated temperatures while simultaneously providing adequate ionic conductivity for normal operation. Current ceramic-polymer composite separators show promise but face manufacturing scalability issues and long-term stability concerns.

Thermal management systems face inherent limitations in their response time to rapid temperature excursions. Conventional cooling systems typically operate on timescales of seconds to minutes, whereas thermal runaway propagation can occur within milliseconds once initiated. This fundamental mismatch in response dynamics creates a significant engineering challenge that current technologies have not fully resolved.

Battery management systems (BMS) face challenges in accurately predicting incipient failure conditions due to limited sensing capabilities within cell structures. Most commercial BMS rely on external temperature and voltage measurements that may not detect internal short circuits or localized heating until thermal runaway becomes inevitable. Advanced sensing technologies such as fiber optic temperature sensors and acoustic emission monitoring show promise but face integration challenges in mass-produced battery systems.

Standardization of safety protocols presents another significant hurdle. Current testing methodologies often fail to replicate real-world abuse conditions adequately, leading to potential gaps in safety validation. The industry lacks consensus on which failure modes should be prioritized in testing regimes, resulting in inconsistent safety approaches across manufacturers and applications.

Aging effects and degradation mechanisms further complicate prevention strategies. As batteries age, their thermal stability characteristics change in ways that are difficult to predict and monitor. Current models inadequately account for these time-dependent changes in material properties and internal resistance, potentially rendering initially effective safety measures insufficient over a battery's operational lifetime.

Cost constraints significantly limit the implementation of comprehensive safety solutions, particularly in consumer electronics and mass-market electric vehicles. Many advanced safety technologies remain prohibitively expensive for widespread adoption, creating tension between safety engineering and commercial viability that continues to challenge the industry.

Material interface issues present substantial difficulties, particularly in high-energy density batteries where electrode-electrolyte interactions become increasingly complex under thermal and mechanical stress. The industry struggles with developing separator materials that maintain mechanical integrity at elevated temperatures while simultaneously providing adequate ionic conductivity for normal operation. Current ceramic-polymer composite separators show promise but face manufacturing scalability issues and long-term stability concerns.

Thermal management systems face inherent limitations in their response time to rapid temperature excursions. Conventional cooling systems typically operate on timescales of seconds to minutes, whereas thermal runaway propagation can occur within milliseconds once initiated. This fundamental mismatch in response dynamics creates a significant engineering challenge that current technologies have not fully resolved.

Battery management systems (BMS) face challenges in accurately predicting incipient failure conditions due to limited sensing capabilities within cell structures. Most commercial BMS rely on external temperature and voltage measurements that may not detect internal short circuits or localized heating until thermal runaway becomes inevitable. Advanced sensing technologies such as fiber optic temperature sensors and acoustic emission monitoring show promise but face integration challenges in mass-produced battery systems.

Standardization of safety protocols presents another significant hurdle. Current testing methodologies often fail to replicate real-world abuse conditions adequately, leading to potential gaps in safety validation. The industry lacks consensus on which failure modes should be prioritized in testing regimes, resulting in inconsistent safety approaches across manufacturers and applications.

Aging effects and degradation mechanisms further complicate prevention strategies. As batteries age, their thermal stability characteristics change in ways that are difficult to predict and monitor. Current models inadequately account for these time-dependent changes in material properties and internal resistance, potentially rendering initially effective safety measures insufficient over a battery's operational lifetime.

Cost constraints significantly limit the implementation of comprehensive safety solutions, particularly in consumer electronics and mass-market electric vehicles. Many advanced safety technologies remain prohibitively expensive for widespread adoption, creating tension between safety engineering and commercial viability that continues to challenge the industry.

Existing Material Compatibility Solutions

01 Electrode materials for thermal runaway prevention

Specific electrode materials can be engineered to minimize thermal runaway risks in batteries. These materials include modified cathodes with thermal stability enhancers and anodes designed to prevent lithium dendrite formation. The incorporation of these specialized materials can significantly reduce the likelihood of thermal events by maintaining structural integrity at elevated temperatures and preventing internal short circuits.- Electrode materials for thermal runaway prevention: Specific electrode materials can be engineered to minimize thermal runaway risks in batteries. These materials include modified cathodes with thermal stability enhancers and anodes designed to prevent lithium dendrite formation. By incorporating thermally stable compounds and structures, these electrode materials can withstand higher temperatures before decomposition, significantly reducing the risk of thermal runaway events during battery operation.

- Electrolyte additives and flame retardants: Specialized electrolyte formulations containing flame-retardant additives can suppress thermal runaway propagation. These additives work by increasing the thermal decomposition temperature of the electrolyte, reducing flammability, and creating protective layers during high-temperature events. Some formulations include phosphorus-based compounds, fluorinated additives, and ionic liquids that can effectively mitigate heat generation and prevent cascading thermal failures in battery cells.

- Thermal management systems and heat dissipation: Advanced thermal management systems can be integrated into battery designs to prevent thermal runaway. These systems include phase change materials, cooling channels, heat sinks, and thermally conductive layers that efficiently dissipate heat. By maintaining optimal operating temperatures and quickly removing excess heat, these systems prevent the initiation and propagation of thermal runaway events, particularly in high-power applications and fast-charging scenarios.

- Safety mechanisms and separator technologies: Innovative separator designs and safety mechanisms can physically prevent thermal runaway propagation. These include ceramic-coated separators, shutdown separators that increase resistance at elevated temperatures, and multi-layer designs with thermal fuses. Some technologies incorporate materials that expand when heated to create physical barriers between cells, while others feature pressure relief mechanisms to prevent catastrophic failures during thermal events.

- Sensing and early detection systems: Advanced sensing technologies can detect early signs of thermal abnormalities before they escalate to thermal runaway. These systems monitor parameters such as temperature gradients, gas evolution, pressure changes, and electrical impedance. By integrating these sensors with battery management systems, potential thermal events can be identified and mitigated through preventive measures such as load reduction, circuit disconnection, or controlled discharge, significantly enhancing battery safety.

02 Thermal management systems and heat dissipation

Advanced thermal management systems are crucial for preventing battery thermal runaway. These systems include phase change materials, heat spreaders, and active cooling mechanisms that efficiently dissipate heat from battery cells. By maintaining optimal operating temperatures and preventing localized hot spots, these systems can effectively reduce the risk of thermal runaway events in battery packs.Expand Specific Solutions03 Safety additives and electrolyte modifications

Specialized additives and modified electrolytes can enhance battery safety by suppressing thermal runaway. These include flame retardants, shutdown additives that increase resistance at elevated temperatures, and electrolyte formulations with higher thermal stability. These components can prevent cascading thermal reactions by limiting heat generation or creating protective barriers when temperature thresholds are exceeded.Expand Specific Solutions04 Separator technologies for thermal stability

Advanced separator technologies play a critical role in preventing thermal runaway propagation. These include ceramic-coated separators, thermally stable polymer membranes, and multi-layer designs with shutdown capabilities. These separators maintain physical separation between electrodes even at high temperatures and can increase resistance or melt in controlled ways to prevent current flow during thermal events.Expand Specific Solutions05 Battery monitoring and early detection systems

Sophisticated monitoring systems can detect early signs of thermal runaway and trigger preventive measures. These systems utilize temperature sensors, gas detection, impedance tracking, and predictive algorithms to identify abnormal battery behavior before catastrophic failure occurs. Early detection allows for intervention strategies such as load disconnection, cooling activation, or controlled discharge to prevent thermal runaway progression.Expand Specific Solutions

Leading Organizations in Battery Safety Technology

Battery thermal runaway safety is evolving rapidly in a market projected to exceed $200 billion by 2030, currently transitioning from early commercialization to mainstream adoption. Technology maturity varies significantly among key players: Tesla and CATL lead with advanced battery management systems and thermal propagation prevention, while BYD and Samsung SDI have developed innovative cell-to-pack architectures. Aspen Aerogels offers specialized thermal barrier materials, and emerging players like Svolt and NeoGraf are introducing novel safety solutions. Research institutions such as ITRI are advancing fundamental understanding of material compatibility issues, while automotive OEMs including BMW and GM are integrating thermal management systems into vehicle designs, creating a competitive landscape focused on balancing energy density with thermal stability.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive approach to battery thermal runaway mitigation through material compatibility optimization. Their battery packs incorporate a multi-layered protection system with flame-retardant materials between cells and modules. Tesla's patented technology includes intumescent materials that expand when heated, creating physical barriers to prevent thermal propagation. Their cooling systems utilize dielectric fluids with high thermal conductivity that remain chemically stable during temperature spikes. Tesla has pioneered the use of silicon-based anodes with specialized binders that maintain structural integrity during thermal expansion, reducing mechanical stress that could trigger thermal events. Their battery management system continuously monitors cell-level impedance changes that might indicate material degradation or incompatibility issues developing over time. Recent improvements include nano-engineered separator materials with ceramic coatings that remain stable at temperatures exceeding 500°C, significantly higher than conventional polyolefin separators.

Strengths: Tesla's integrated approach combining advanced materials science with sophisticated thermal management systems provides multiple layers of protection. Their extensive real-world data collection enables continuous refinement of material compatibility models. Weaknesses: The proprietary nature of their solutions increases costs and creates supply chain dependencies. Some of their advanced materials require rare elements with limited availability.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed innovative material compatibility solutions focused on preventing thermal runaway in lithium-ion batteries. Their flagship technology is the cell-to-pack (CTP) design that incorporates flame-retardant materials directly into the battery structure, eliminating traditional module components that could contribute to thermal propagation. CATL's research has identified specific electrolyte formulations that remain stable at higher temperatures, with additives that suppress exothermic reactions between electrode materials and electrolytes during thermal events. Their patented separator technology features ceramic-coated polyolefin materials with mechanical stability at elevated temperatures, preventing internal short circuits during thermal stress. CATL has also pioneered the use of thermally conductive yet electrically insulating materials in cell-to-cell interfaces, allowing heat dissipation while preventing electrical fault propagation. Their latest innovation includes phase-change materials integrated into battery pack structures that absorb excess heat during potential thermal events, maintaining surrounding cells below critical temperatures. CATL's material compatibility research extends to the molecular level, with computational models predicting long-term degradation patterns between electrode materials and electrolyte components.

Strengths: CATL's vertical integration allows for comprehensive material compatibility testing across the entire battery system. Their high production volume enables rapid iteration and validation of material improvements. Weaknesses: Some of their advanced material solutions increase manufacturing complexity and cost. Their focus on high-energy density sometimes creates trade-offs with thermal stability in extreme conditions.

Critical Material Interface Mechanisms Analysis

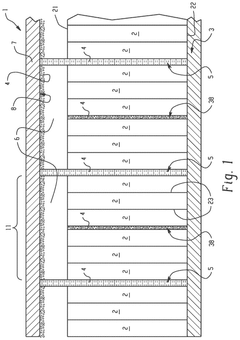

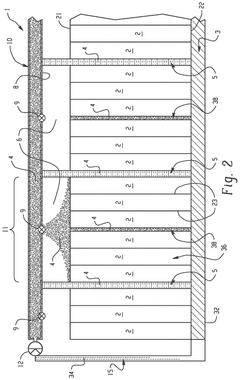

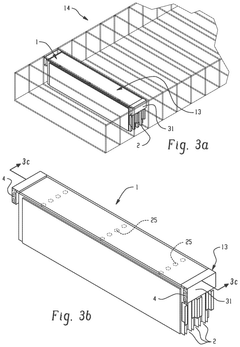

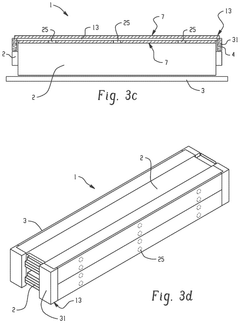

Battery pack system with thermal runaway mitigation features

PatentActiveUS12308412B2

Innovation

- Incorporation of a thermochemical material within the battery pack system that undergoes an endothermic reaction at temperatures above 50°C, located either within the stack of battery cells, exterior to the cells, or adjacent to the stack, to absorb energy and inhibit thermal runaway propagation.

Battery pack system with thermal runaway mitigation features

PatentActiveUS12308412B2

Innovation

- Incorporation of a thermochemical material within the battery pack system that undergoes an endothermic reaction at temperatures above 50°C, located either within the stack of battery cells, exterior to the cells, or adjacent to the stack, to absorb energy and inhibit thermal runaway propagation.

Regulatory Standards for Battery Safety

The regulatory landscape for battery safety has evolved significantly in response to increasing incidents of thermal runaway events. International standards such as IEC 62133 and UL 1642 establish comprehensive testing protocols specifically designed to evaluate battery resistance to thermal events. These standards mandate rigorous testing procedures including short circuit tests, overcharge protection, crush tests, and thermal abuse scenarios that directly address material compatibility issues.

The UN Transportation Testing (UN 38.3) requirements have become particularly critical for lithium battery manufacturers, requiring cells and batteries to undergo altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. These tests specifically evaluate how different battery materials interact under extreme conditions that could potentially trigger thermal runaway.

Regional regulations have implemented varying degrees of stringency. The European Union's Battery Directive (2006/66/EC) and its recent update emphasize material safety requirements and compatibility considerations throughout the battery lifecycle. Similarly, China's GB/T 31241 standard establishes specific requirements for lithium-ion battery safety, with particular attention to material selection and compatibility to prevent thermal incidents.

In the United States, the Consumer Product Safety Commission (CPSC) has issued specific guidelines addressing battery material safety, while the Department of Transportation (DOT) has implemented strict regulations for battery transportation that consider material stability. The National Fire Protection Association (NFPA) has also developed standards specifically addressing battery fire hazards related to material interactions.

Industry-specific standards have emerged to address unique application environments. For example, SAE J2929 for electric vehicle batteries includes specific provisions for material compatibility under automotive conditions, while IEEE 1625 and 1725 address portable computing and cellular telephone applications respectively, with detailed requirements for material selection and compatibility testing.

Regulatory compliance now increasingly requires manufacturers to document comprehensive material compatibility studies as part of safety certification processes. This includes detailed analysis of electrode materials, separator properties, electrolyte composition, and their interactions under various operational and failure conditions. The trend toward unified global standards is accelerating, with international bodies working to harmonize requirements specifically addressing material compatibility as a critical factor in thermal runaway prevention.

The UN Transportation Testing (UN 38.3) requirements have become particularly critical for lithium battery manufacturers, requiring cells and batteries to undergo altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests. These tests specifically evaluate how different battery materials interact under extreme conditions that could potentially trigger thermal runaway.

Regional regulations have implemented varying degrees of stringency. The European Union's Battery Directive (2006/66/EC) and its recent update emphasize material safety requirements and compatibility considerations throughout the battery lifecycle. Similarly, China's GB/T 31241 standard establishes specific requirements for lithium-ion battery safety, with particular attention to material selection and compatibility to prevent thermal incidents.

In the United States, the Consumer Product Safety Commission (CPSC) has issued specific guidelines addressing battery material safety, while the Department of Transportation (DOT) has implemented strict regulations for battery transportation that consider material stability. The National Fire Protection Association (NFPA) has also developed standards specifically addressing battery fire hazards related to material interactions.

Industry-specific standards have emerged to address unique application environments. For example, SAE J2929 for electric vehicle batteries includes specific provisions for material compatibility under automotive conditions, while IEEE 1625 and 1725 address portable computing and cellular telephone applications respectively, with detailed requirements for material selection and compatibility testing.

Regulatory compliance now increasingly requires manufacturers to document comprehensive material compatibility studies as part of safety certification processes. This includes detailed analysis of electrode materials, separator properties, electrolyte composition, and their interactions under various operational and failure conditions. The trend toward unified global standards is accelerating, with international bodies working to harmonize requirements specifically addressing material compatibility as a critical factor in thermal runaway prevention.

Environmental Impact of Battery Thermal Events

Battery thermal runaway events pose significant environmental hazards that extend far beyond the immediate safety concerns. When thermal runaway occurs, batteries release a complex mixture of toxic substances including heavy metals, volatile organic compounds (VOCs), and particulate matter into the surrounding environment. These emissions can contaminate soil, water sources, and air quality, creating long-term ecological damage that may persist for decades.

The environmental impact varies significantly based on the battery chemistry involved. Lithium-ion batteries, particularly those containing cobalt and nickel compounds, release more environmentally persistent toxins compared to lithium iron phosphate (LFP) formulations. Material compatibility issues that trigger thermal events can exacerbate these environmental consequences, as incompatible materials often produce more toxic byproducts during combustion reactions.

Water contamination represents one of the most concerning environmental impacts. Firefighting efforts to control battery fires typically involve large quantities of water, which becomes contaminated with dissolved metals and toxic compounds. This runoff can enter groundwater systems and surface water bodies, potentially affecting drinking water supplies and aquatic ecosystems. Studies have documented elevated levels of lithium, cobalt, manganese, and fluoride compounds in water samples collected near battery fire sites.

Air quality degradation presents another significant environmental challenge. Thermal events generate dense plumes containing particulate matter, hydrogen fluoride, carbon monoxide, and various metal oxides. These airborne contaminants can travel considerable distances depending on atmospheric conditions, affecting communities far from the original incident site. Respiratory health impacts on both humans and wildlife have been documented following major battery thermal events.

The environmental remediation costs associated with battery thermal runaway incidents are substantial. Cleanup operations often require specialized hazardous materials handling procedures, soil excavation, and long-term monitoring programs. The financial burden of these remediation efforts frequently exceeds the direct property damage caused by the thermal event itself, creating significant economic externalities.

Regulatory frameworks addressing the environmental aspects of battery thermal events remain inconsistent globally. While some jurisdictions have implemented comprehensive protocols for containment, cleanup, and disposal following such incidents, many regions lack specific guidelines. This regulatory gap has led to inconsistent environmental protection measures and hampered the development of standardized remediation approaches.

The environmental impact varies significantly based on the battery chemistry involved. Lithium-ion batteries, particularly those containing cobalt and nickel compounds, release more environmentally persistent toxins compared to lithium iron phosphate (LFP) formulations. Material compatibility issues that trigger thermal events can exacerbate these environmental consequences, as incompatible materials often produce more toxic byproducts during combustion reactions.

Water contamination represents one of the most concerning environmental impacts. Firefighting efforts to control battery fires typically involve large quantities of water, which becomes contaminated with dissolved metals and toxic compounds. This runoff can enter groundwater systems and surface water bodies, potentially affecting drinking water supplies and aquatic ecosystems. Studies have documented elevated levels of lithium, cobalt, manganese, and fluoride compounds in water samples collected near battery fire sites.

Air quality degradation presents another significant environmental challenge. Thermal events generate dense plumes containing particulate matter, hydrogen fluoride, carbon monoxide, and various metal oxides. These airborne contaminants can travel considerable distances depending on atmospheric conditions, affecting communities far from the original incident site. Respiratory health impacts on both humans and wildlife have been documented following major battery thermal events.

The environmental remediation costs associated with battery thermal runaway incidents are substantial. Cleanup operations often require specialized hazardous materials handling procedures, soil excavation, and long-term monitoring programs. The financial burden of these remediation efforts frequently exceeds the direct property damage caused by the thermal event itself, creating significant economic externalities.

Regulatory frameworks addressing the environmental aspects of battery thermal events remain inconsistent globally. While some jurisdictions have implemented comprehensive protocols for containment, cleanup, and disposal following such incidents, many regions lack specific guidelines. This regulatory gap has led to inconsistent environmental protection measures and hampered the development of standardized remediation approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!