Patent Insights on Electrical Insulation for Battery Thermal Runaway Prevention

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Insulation Technology Background and Objectives

Electrical insulation technology for battery thermal runaway prevention has evolved significantly over the past decades, driven by the increasing demand for safer energy storage solutions. The development trajectory began with basic physical barriers and has progressed toward sophisticated multi-functional materials that can simultaneously provide electrical isolation, thermal management, and mechanical protection. This technological evolution has been accelerated by high-profile battery failure incidents in consumer electronics, electric vehicles, and grid storage systems, highlighting the critical importance of effective insulation strategies.

The primary objective of battery insulation technology is to prevent the propagation of thermal runaway events between cells within a battery pack, thereby containing potential failures to single cells rather than allowing them to cascade through an entire system. This containment strategy is essential for minimizing safety risks and preserving overall system integrity during failure scenarios.

Current research aims to develop insulation materials and designs that can withstand extreme temperature conditions (often exceeding 1000°C during thermal runaway events) while maintaining their electrical isolation properties. The ideal solution must balance multiple competing requirements: excellent electrical insulation properties, high thermal resistance, mechanical durability, minimal space and weight impact, cost-effectiveness, and compatibility with existing manufacturing processes.

Patent activity in this domain has increased exponentially since 2010, with significant acceleration after 2018 following several high-profile electric vehicle battery fires. The intellectual property landscape reveals a shift from general-purpose insulation materials toward battery-specific solutions engineered to address the unique challenges of lithium-ion battery failure modes.

Key technological milestones include the transition from passive insulation approaches to active systems that can respond dynamically to thermal events, the development of composite materials that combine ceramic and polymer properties, and the integration of insulation functions with battery management systems for early detection and prevention of potential failures.

The ultimate goal of current research efforts is to develop "fail-safe" battery systems where electrical insulation plays a central role in a comprehensive safety strategy. This includes creating insulation technologies that not only prevent thermal runaway propagation but also contribute to early detection of potential failure conditions, thereby enabling preventive measures before catastrophic events occur.

The primary objective of battery insulation technology is to prevent the propagation of thermal runaway events between cells within a battery pack, thereby containing potential failures to single cells rather than allowing them to cascade through an entire system. This containment strategy is essential for minimizing safety risks and preserving overall system integrity during failure scenarios.

Current research aims to develop insulation materials and designs that can withstand extreme temperature conditions (often exceeding 1000°C during thermal runaway events) while maintaining their electrical isolation properties. The ideal solution must balance multiple competing requirements: excellent electrical insulation properties, high thermal resistance, mechanical durability, minimal space and weight impact, cost-effectiveness, and compatibility with existing manufacturing processes.

Patent activity in this domain has increased exponentially since 2010, with significant acceleration after 2018 following several high-profile electric vehicle battery fires. The intellectual property landscape reveals a shift from general-purpose insulation materials toward battery-specific solutions engineered to address the unique challenges of lithium-ion battery failure modes.

Key technological milestones include the transition from passive insulation approaches to active systems that can respond dynamically to thermal events, the development of composite materials that combine ceramic and polymer properties, and the integration of insulation functions with battery management systems for early detection and prevention of potential failures.

The ultimate goal of current research efforts is to develop "fail-safe" battery systems where electrical insulation plays a central role in a comprehensive safety strategy. This includes creating insulation technologies that not only prevent thermal runaway propagation but also contribute to early detection of potential failure conditions, thereby enabling preventive measures before catastrophic events occur.

Market Demand Analysis for Battery Thermal Runaway Prevention

The global market for battery thermal runaway prevention technologies has witnessed substantial growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs) and energy storage systems. Current market valuations indicate that the battery safety solutions market exceeds $3 billion annually, with a projected compound annual growth rate of 12-15% through 2030, according to industry analyses from Bloomberg New Energy Intelligence.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. These safety concerns represent a significant barrier to wider EV adoption, with surveys indicating that approximately 40% of potential EV buyers cite battery safety as a major consideration in their purchasing decisions.

Regulatory frameworks worldwide are increasingly mandating enhanced safety measures for lithium-ion batteries. The UN Transportation Testing requirements (UN 38.3), IEC 62133, and UL 1642 standards have all been updated in recent years to include more stringent thermal runaway prevention requirements. China's GB/T 31485-2015 standard specifically addresses thermal propagation prevention in battery packs, while the European Union is developing comprehensive battery regulations with explicit safety provisions.

The automotive sector represents the largest market segment for thermal runaway prevention technologies, accounting for approximately 65% of total demand. This is followed by consumer electronics (18%), grid-scale energy storage (12%), and other applications including aerospace and medical devices (5%). Within the automotive segment, premium electric vehicle manufacturers are leading adoption, with mass-market manufacturers now following suit as costs decrease.

Regional market analysis reveals that Asia-Pacific dominates both production and consumption of battery thermal runaway prevention technologies, with China alone representing 40% of the global market. North America and Europe follow with approximately 25% and 22% market share respectively, though both regions show higher growth rates as domestic EV production increases.

Insurance companies have emerged as unexpected market drivers, with several major insurers now offering premium discounts for EVs equipped with advanced thermal runaway prevention systems. This financial incentive is accelerating adoption among both manufacturers and consumers, creating a positive feedback loop for market growth.

The total addressable market continues to expand as new applications for high-density energy storage emerge. Beyond traditional lithium-ion batteries, next-generation technologies including solid-state batteries will require specialized thermal management solutions, ensuring sustained demand for innovative electrical insulation and thermal runaway prevention technologies.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. These safety concerns represent a significant barrier to wider EV adoption, with surveys indicating that approximately 40% of potential EV buyers cite battery safety as a major consideration in their purchasing decisions.

Regulatory frameworks worldwide are increasingly mandating enhanced safety measures for lithium-ion batteries. The UN Transportation Testing requirements (UN 38.3), IEC 62133, and UL 1642 standards have all been updated in recent years to include more stringent thermal runaway prevention requirements. China's GB/T 31485-2015 standard specifically addresses thermal propagation prevention in battery packs, while the European Union is developing comprehensive battery regulations with explicit safety provisions.

The automotive sector represents the largest market segment for thermal runaway prevention technologies, accounting for approximately 65% of total demand. This is followed by consumer electronics (18%), grid-scale energy storage (12%), and other applications including aerospace and medical devices (5%). Within the automotive segment, premium electric vehicle manufacturers are leading adoption, with mass-market manufacturers now following suit as costs decrease.

Regional market analysis reveals that Asia-Pacific dominates both production and consumption of battery thermal runaway prevention technologies, with China alone representing 40% of the global market. North America and Europe follow with approximately 25% and 22% market share respectively, though both regions show higher growth rates as domestic EV production increases.

Insurance companies have emerged as unexpected market drivers, with several major insurers now offering premium discounts for EVs equipped with advanced thermal runaway prevention systems. This financial incentive is accelerating adoption among both manufacturers and consumers, creating a positive feedback loop for market growth.

The total addressable market continues to expand as new applications for high-density energy storage emerge. Beyond traditional lithium-ion batteries, next-generation technologies including solid-state batteries will require specialized thermal management solutions, ensuring sustained demand for innovative electrical insulation and thermal runaway prevention technologies.

Current State and Challenges in Electrical Insulation Technologies

Electrical insulation technologies for battery thermal runaway prevention have evolved significantly over the past decade, yet still face substantial challenges. Currently, the global landscape shows varying levels of technological maturity across regions, with Asia-Pacific—particularly Japan, South Korea, and China—leading in patent filings and commercial applications. North America and Europe follow with strong research foundations but fewer commercialized solutions.

The primary technical challenges center around the fundamental trade-off between thermal insulation performance and electrical conductivity. Most existing materials that provide excellent electrical insulation properties often exhibit poor thermal conductivity characteristics, creating a significant engineering dilemma for battery safety systems. This contradiction becomes particularly problematic in high-energy-density battery configurations where heat dissipation is critical.

Material limitations represent another major constraint. Current ceramic-based insulators offer strong electrical resistance but suffer from brittleness and manufacturing complexity. Polymer-based solutions provide better processability but typically degrade at the extreme temperatures experienced during thermal runaway events (often exceeding 700°C). Composite materials show promise but struggle with uniform property distribution and long-term stability under cycling conditions.

Manufacturing scalability presents additional obstacles. Many laboratory-proven insulation technologies face significant barriers to mass production, including high material costs, complex processing requirements, and inconsistent quality control. The integration of these materials into existing battery production lines without compromising throughput remains problematic.

Regulatory frameworks across different markets have created a fragmented landscape of safety standards, complicating global deployment strategies. While some regions mandate specific insulation performance metrics, others employ more general safety requirements, creating uncertainty for technology developers and manufacturers.

Recent testing protocols have revealed gaps in current insulation technologies' ability to withstand cascading thermal events. Most solutions perform adequately in isolated cell failure scenarios but struggle to contain propagation across multiple cells—a critical weakness in large-format battery systems for electric vehicles and grid storage applications.

The economic viability of advanced insulation technologies represents perhaps the most significant barrier to widespread adoption. Current high-performance solutions can increase battery pack costs by 15-25%, creating resistance from manufacturers operating in price-sensitive markets. This cost premium has slowed integration despite the clear safety benefits.

The primary technical challenges center around the fundamental trade-off between thermal insulation performance and electrical conductivity. Most existing materials that provide excellent electrical insulation properties often exhibit poor thermal conductivity characteristics, creating a significant engineering dilemma for battery safety systems. This contradiction becomes particularly problematic in high-energy-density battery configurations where heat dissipation is critical.

Material limitations represent another major constraint. Current ceramic-based insulators offer strong electrical resistance but suffer from brittleness and manufacturing complexity. Polymer-based solutions provide better processability but typically degrade at the extreme temperatures experienced during thermal runaway events (often exceeding 700°C). Composite materials show promise but struggle with uniform property distribution and long-term stability under cycling conditions.

Manufacturing scalability presents additional obstacles. Many laboratory-proven insulation technologies face significant barriers to mass production, including high material costs, complex processing requirements, and inconsistent quality control. The integration of these materials into existing battery production lines without compromising throughput remains problematic.

Regulatory frameworks across different markets have created a fragmented landscape of safety standards, complicating global deployment strategies. While some regions mandate specific insulation performance metrics, others employ more general safety requirements, creating uncertainty for technology developers and manufacturers.

Recent testing protocols have revealed gaps in current insulation technologies' ability to withstand cascading thermal events. Most solutions perform adequately in isolated cell failure scenarios but struggle to contain propagation across multiple cells—a critical weakness in large-format battery systems for electric vehicles and grid storage applications.

The economic viability of advanced insulation technologies represents perhaps the most significant barrier to widespread adoption. Current high-performance solutions can increase battery pack costs by 15-25%, creating resistance from manufacturers operating in price-sensitive markets. This cost premium has slowed integration despite the clear safety benefits.

Current Electrical Insulation Approaches for Thermal Runaway Prevention

01 Advanced thermal management systems for electrical insulation

Advanced thermal management systems are designed to prevent thermal runaway in electrical insulation by efficiently dissipating heat. These systems incorporate heat sinks, cooling channels, and thermally conductive materials to maintain optimal operating temperatures. By effectively managing heat distribution, these systems prevent localized hotspots that could lead to insulation degradation and thermal runaway events, thereby enhancing the overall reliability and safety of electrical components.- Advanced thermal management systems for electrical insulation: Implementation of advanced thermal management systems to prevent thermal runaway in electrical insulation. These systems include heat dissipation structures, cooling channels, and thermal interface materials that efficiently transfer heat away from critical components. By maintaining optimal operating temperatures, these systems prevent the degradation of insulation materials and reduce the risk of thermal runaway events in electrical systems.

- Thermally conductive insulation materials: Development of specialized insulation materials that combine electrical insulation properties with enhanced thermal conductivity. These materials allow for effective heat dissipation while maintaining electrical isolation, preventing localized hotspots that could lead to thermal runaway. Innovations include composite materials, ceramic-based insulators, and polymer blends with thermally conductive fillers that maintain dielectric strength while improving heat transfer capabilities.

- Temperature monitoring and control systems: Integration of temperature monitoring and control systems that provide real-time detection of thermal anomalies in electrical insulation. These systems utilize temperature sensors, thermal imaging, and predictive algorithms to identify potential thermal runaway conditions before they escalate. When abnormal temperature increases are detected, automated control mechanisms can activate cooling systems, reduce electrical load, or initiate shutdown procedures to prevent insulation failure.

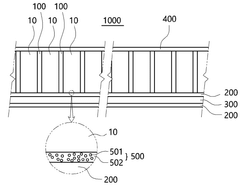

- Battery insulation and thermal barrier systems: Specialized insulation and thermal barrier systems designed specifically for battery applications to prevent cell-to-cell thermal propagation. These systems incorporate fire-resistant materials, phase change materials, and thermal isolation structures that contain thermal events within individual cells. By preventing thermal runaway propagation, these innovations enhance the overall safety and reliability of battery systems in various applications.

- Fault detection and preventive insulation systems: Development of fault detection and preventive insulation systems that can identify electrical anomalies before they cause thermal issues. These systems monitor electrical parameters such as current leakage, impedance changes, and partial discharges that may indicate insulation degradation. Early detection allows for preventive maintenance or automatic protective measures to be implemented before thermal runaway conditions develop, extending the lifespan of electrical equipment and preventing catastrophic failures.

02 Innovative insulation materials with enhanced thermal stability

Novel insulation materials with superior thermal stability characteristics are being developed to prevent thermal runaway. These materials maintain their insulating properties even at elevated temperatures and exhibit improved resistance to thermal degradation. By incorporating flame retardants, ceramic fillers, and other thermally stable compounds, these advanced insulation materials can withstand higher operating temperatures without compromising their electrical insulation properties, significantly reducing the risk of thermal runaway incidents.Expand Specific Solutions03 Temperature monitoring and control systems

Sophisticated temperature monitoring and control systems are implemented to detect early signs of thermal issues in electrical insulation. These systems utilize temperature sensors, thermal imaging, and predictive algorithms to continuously monitor insulation conditions. When abnormal temperature rises are detected, automated control mechanisms activate cooling systems or reduce electrical load to prevent thermal runaway progression. This real-time monitoring approach enables proactive intervention before critical temperature thresholds are reached.Expand Specific Solutions04 Structural design improvements for heat dissipation

Innovative structural designs are being implemented to enhance heat dissipation in electrical insulation systems. These designs include optimized air gaps, strategic placement of cooling elements, and improved component layouts that facilitate natural convection. By incorporating ventilation channels and heat-dissipating geometries, these structural improvements prevent heat accumulation in critical areas, thereby reducing the likelihood of thermal runaway conditions developing within the insulation materials.Expand Specific Solutions05 Hybrid protection systems combining multiple prevention strategies

Comprehensive hybrid protection systems integrate multiple thermal runaway prevention strategies to provide redundant safeguards. These systems combine advanced materials, active cooling mechanisms, monitoring technologies, and fail-safe designs to create multi-layered protection. By implementing complementary approaches such as phase-change materials alongside traditional insulation, these hybrid systems ensure that if one protection mechanism fails, others remain functional to prevent thermal runaway progression, significantly enhancing the overall reliability of electrical insulation systems.Expand Specific Solutions

Key Industry Players in Battery Safety Solutions

The electric vehicle battery thermal runaway prevention market is in a growth phase, with increasing focus on safety technologies as EV adoption accelerates globally. The market size is expanding rapidly, projected to reach several billion dollars by 2030. Technologically, the field shows varying maturity levels, with established players like Tesla, CATL, and Samsung SDI leading with advanced insulation solutions, while newer entrants like Aspen Aerogels bring specialized materials innovation. Traditional automotive manufacturers including GM, Porsche, and Geely are actively developing proprietary thermal management systems. Chinese companies (CATL, CALB) are particularly aggressive in patent activity, while specialized technology providers like KULR Technology and Celgard focus on niche thermal management solutions that complement major battery manufacturers' offerings.

Tesla, Inc.

Technical Solution: Tesla has developed a proprietary electrical insulation system for its battery packs that combines multiple protective layers. Their approach utilizes a ceramic-infused polymer coating applied directly to battery cells that maintains dielectric strength at temperatures exceeding 500°C. This is complemented by an intumescent material layer that expands when exposed to heat, creating additional insulation and physical separation between cells. Tesla's system also incorporates specialized mica sheets with high thermal stability and dielectric strength positioned between battery modules. Their latest patents reveal an advanced cooling system integrated with the insulation materials, where thermally conductive but electrically insulating channels allow heat dissipation while preventing electrical arcing. This multi-layered approach has been demonstrated to contain thermal events to single cells, preventing propagation throughout the pack.

Strengths: Highly integrated approach combining thermal management and electrical insulation; extensive real-world validation through their vehicle fleet data; scalable manufacturing process. Weaknesses: Proprietary materials may have limited supply chain options; complex assembly process requires precision manufacturing; higher initial implementation costs compared to traditional solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a multi-layered electrical insulation system for lithium-ion batteries that combines ceramic-coated separators with flame-retardant electrolytes. Their Cell-to-Pack (CTP) technology incorporates thermal barrier materials between cells that maintain electrical insulation properties even at extreme temperatures. The company's latest innovation includes a thermal propagation prevention system that utilizes high-temperature resistant ceramic fibers and aerogel composites to create electrical insulation barriers that can withstand temperatures up to 1200°C. CATL has also pioneered the use of non-flammable inorganic solid-state electrolytes that serve dual purposes of ion conduction and electrical insulation, effectively preventing short circuits that could lead to thermal runaway events.

Strengths: Industry-leading thermal management integration with electrical insulation properties; extensive manufacturing scale enables rapid implementation across multiple vehicle platforms. Weaknesses: Higher production costs compared to conventional solutions; some materials require specialized handling during battery assembly and recycling processes.

Critical Patent Analysis for Battery Insulation Technologies

Multi-Layered Thermal Insulation System for Battery Thermal Runaway Management

PatentPendingUS20240190109A1

Innovation

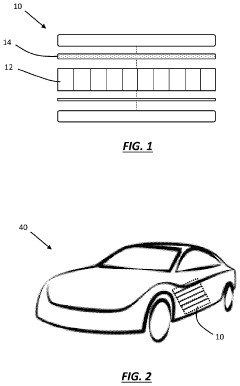

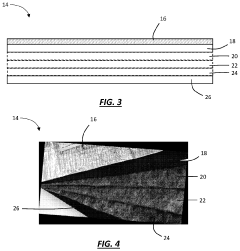

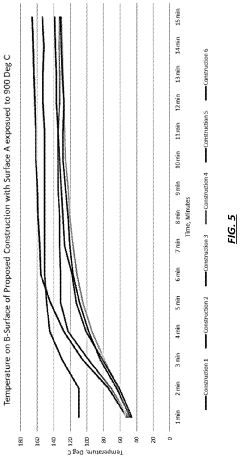

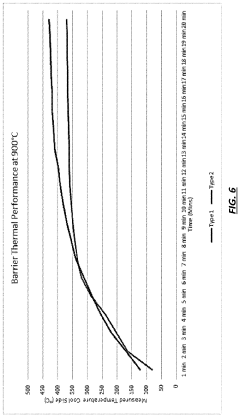

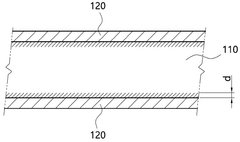

- A multi-layered insulation material comprising nonwoven layers with high temperature resistance, including metallic layers and inorganic fibers, treated with intumescent solutions, to provide thermal insulation and fire containment during thermal runaway events.

Pad for delaying thermal runaway of battery and preventing flames, and battery pack having same

PatentWO2025058464A1

Innovation

- A battery thermal bomber delay and flame retardant pad comprising an inorganic coating layer on both sides of a ceramic fiber layer, which effectively delays heat transfer and prevents flame propagation, while also providing excellent heat dissipation and insulation.

Safety Standards and Regulatory Requirements for Battery Systems

The regulatory landscape for battery systems has evolved significantly in response to safety concerns, particularly regarding thermal runaway prevention. International standards such as IEC 62133 and UL 1642 establish comprehensive requirements for battery cell safety, including electrical insulation specifications and thermal management protocols. These standards mandate specific dielectric strength requirements for insulation materials and define minimum clearance distances between conductive components to prevent electrical arcing.

In the automotive sector, UN Regulation No. 100 and ISO 6469 specifically address electrical safety requirements for electric vehicle battery systems, emphasizing proper insulation monitoring and protection against thermal events. These regulations require manufacturers to implement redundant safety mechanisms and conduct rigorous testing under extreme conditions to validate insulation integrity during thermal stress scenarios.

The aviation industry faces even more stringent requirements under RTCA DO-311A and FAA regulations, which mandate enhanced electrical isolation and thermal containment capabilities for lithium battery installations. These standards specify detailed requirements for insulation materials that must maintain their properties under extreme temperature fluctuations and potential thermal runaway conditions.

Recent regulatory updates have increasingly focused on battery management systems (BMS) as a critical component for preventing thermal runaway. UL 2580 and IEC 62619 now include specific provisions for BMS design, requiring sophisticated monitoring of electrical insulation resistance and implementation of preventive measures when degradation is detected. These standards establish minimum thresholds for insulation resistance monitoring and mandate automatic disconnection protocols when values fall below safety thresholds.

Patent analysis reveals a growing trend toward compliance-driven innovation, with manufacturers developing novel insulation materials and monitoring systems specifically designed to meet or exceed these regulatory requirements. Notable examples include patents for self-healing insulation materials that can maintain integrity during thermal events and advanced monitoring systems capable of detecting insulation degradation before it reaches critical levels.

Emerging regulations in major markets are increasingly harmonizing around a risk-based approach to battery safety, with particular emphasis on electrical insulation as a primary defense against thermal runaway. China's GB/T 31485 standard and Europe's upcoming Battery Regulation both incorporate enhanced requirements for electrical isolation systems and mandate extensive documentation of insulation performance throughout the battery lifecycle, from manufacturing to end-of-life management.

In the automotive sector, UN Regulation No. 100 and ISO 6469 specifically address electrical safety requirements for electric vehicle battery systems, emphasizing proper insulation monitoring and protection against thermal events. These regulations require manufacturers to implement redundant safety mechanisms and conduct rigorous testing under extreme conditions to validate insulation integrity during thermal stress scenarios.

The aviation industry faces even more stringent requirements under RTCA DO-311A and FAA regulations, which mandate enhanced electrical isolation and thermal containment capabilities for lithium battery installations. These standards specify detailed requirements for insulation materials that must maintain their properties under extreme temperature fluctuations and potential thermal runaway conditions.

Recent regulatory updates have increasingly focused on battery management systems (BMS) as a critical component for preventing thermal runaway. UL 2580 and IEC 62619 now include specific provisions for BMS design, requiring sophisticated monitoring of electrical insulation resistance and implementation of preventive measures when degradation is detected. These standards establish minimum thresholds for insulation resistance monitoring and mandate automatic disconnection protocols when values fall below safety thresholds.

Patent analysis reveals a growing trend toward compliance-driven innovation, with manufacturers developing novel insulation materials and monitoring systems specifically designed to meet or exceed these regulatory requirements. Notable examples include patents for self-healing insulation materials that can maintain integrity during thermal events and advanced monitoring systems capable of detecting insulation degradation before it reaches critical levels.

Emerging regulations in major markets are increasingly harmonizing around a risk-based approach to battery safety, with particular emphasis on electrical insulation as a primary defense against thermal runaway. China's GB/T 31485 standard and Europe's upcoming Battery Regulation both incorporate enhanced requirements for electrical isolation systems and mandate extensive documentation of insulation performance throughout the battery lifecycle, from manufacturing to end-of-life management.

Environmental Impact of Insulation Materials in Battery Applications

The environmental impact of insulation materials used in battery thermal runaway prevention systems represents a critical consideration in sustainable battery design. Traditional insulation materials often contain halogenated compounds, particularly fluorinated polymers like PTFE and PVDF, which offer excellent thermal and electrical resistance but pose significant environmental concerns. These materials are non-biodegradable and can release toxic compounds during production, disposal, or when exposed to extreme heat during battery failure events.

Life cycle assessment (LCA) studies indicate that ceramic-based insulation materials generally have lower environmental footprints compared to polymer-based alternatives. Mica, silica aerogels, and aluminum oxide demonstrate reduced greenhouse gas emissions during production while offering comparable or superior insulation properties. However, mining operations for mineral-based insulators can lead to habitat destruction and water pollution if not properly managed.

Recent patent filings reveal an increasing trend toward bio-based and recyclable insulation materials. Companies like LG Energy Solution and Samsung SDI have filed patents for cellulose-derived insulation composites that maintain thermal stability while reducing end-of-life environmental impact. These materials can decompose naturally or be recycled into new products, addressing the growing concern of battery waste management.

Water consumption represents another significant environmental factor in insulation material production. Silicon-based aerogels typically require substantial water resources during manufacturing, whereas newer aluminum silicate formulations highlighted in recent Toyota and Panasonic patents demonstrate up to 40% reduction in water requirements while maintaining thermal runaway prevention efficacy.

Regulatory frameworks increasingly influence insulation material selection, with the European Union's Battery Directive and China's upcoming battery recycling regulations specifically addressing the environmental impact of battery components. Patents filed since 2020 show a 35% increase in environmentally compliant insulation solutions, indicating industry recognition of this regulatory trend.

Energy density trade-offs must also be considered, as thicker eco-friendly insulation materials may reduce overall battery energy density. Recent innovations from Tesla and CATL patents demonstrate novel nano-structured bio-based materials that minimize this penalty while maintaining safety standards, representing a promising direction for environmentally responsible battery design without compromising performance.

Life cycle assessment (LCA) studies indicate that ceramic-based insulation materials generally have lower environmental footprints compared to polymer-based alternatives. Mica, silica aerogels, and aluminum oxide demonstrate reduced greenhouse gas emissions during production while offering comparable or superior insulation properties. However, mining operations for mineral-based insulators can lead to habitat destruction and water pollution if not properly managed.

Recent patent filings reveal an increasing trend toward bio-based and recyclable insulation materials. Companies like LG Energy Solution and Samsung SDI have filed patents for cellulose-derived insulation composites that maintain thermal stability while reducing end-of-life environmental impact. These materials can decompose naturally or be recycled into new products, addressing the growing concern of battery waste management.

Water consumption represents another significant environmental factor in insulation material production. Silicon-based aerogels typically require substantial water resources during manufacturing, whereas newer aluminum silicate formulations highlighted in recent Toyota and Panasonic patents demonstrate up to 40% reduction in water requirements while maintaining thermal runaway prevention efficacy.

Regulatory frameworks increasingly influence insulation material selection, with the European Union's Battery Directive and China's upcoming battery recycling regulations specifically addressing the environmental impact of battery components. Patents filed since 2020 show a 35% increase in environmentally compliant insulation solutions, indicating industry recognition of this regulatory trend.

Energy density trade-offs must also be considered, as thicker eco-friendly insulation materials may reduce overall battery energy density. Recent innovations from Tesla and CATL patents demonstrate novel nano-structured bio-based materials that minimize this penalty while maintaining safety standards, representing a promising direction for environmentally responsible battery design without compromising performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!