Patent Trends in Battery Thermal Runaway Mitigation Technologies

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in the development and deployment of lithium-ion battery technologies. The phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and the release of toxic gases. This issue has gained significant attention as energy storage applications expand across electric vehicles, grid storage, and portable electronics sectors.

The evolution of battery thermal runaway mitigation technologies can be traced back to the early 1990s when commercial lithium-ion batteries were first introduced. Initial safety mechanisms were relatively rudimentary, focusing primarily on mechanical protection and basic electronic controls. As battery energy densities increased throughout the 2000s, the potential severity of thermal events grew proportionally, driving more sophisticated approaches to thermal management.

Recent years have witnessed an acceleration in research and development efforts, particularly following high-profile incidents involving electric vehicles and consumer electronics. These events have heightened regulatory scrutiny and consumer awareness, creating market pressure for enhanced safety solutions. The technical trajectory has evolved from reactive measures toward predictive and preventative approaches that can detect and mitigate thermal events before they cascade into catastrophic failures.

The primary objective of thermal runaway mitigation technologies is to prevent the initiation of runaway conditions, contain thermal events when they occur, and minimize consequential damage to surrounding cells and systems. This multi-layered approach encompasses innovations across materials science, sensing technologies, thermal management systems, and battery management algorithms.

Patent activity in this domain reflects the growing importance of these technologies, with filing rates showing consistent growth over the past decade. Geographic distribution of patent filings indicates concentrated innovation clusters in East Asia, North America, and Europe, with emerging activity in other regions as battery manufacturing capabilities expand globally.

The technical goals driving innovation in this space include: extending early detection timeframes to allow for preventative intervention; developing more effective heat dissipation mechanisms; creating advanced cell-to-cell isolation techniques; improving the accuracy of state-of-health monitoring; and designing inherently safer battery chemistries and architectures that resist propagation effects.

As electrification trends continue across multiple industries, the strategic importance of thermal runaway mitigation technologies will likely increase, positioning this field as a critical enabler for the broader adoption of high-energy battery systems in applications where safety concerns currently limit deployment.

The evolution of battery thermal runaway mitigation technologies can be traced back to the early 1990s when commercial lithium-ion batteries were first introduced. Initial safety mechanisms were relatively rudimentary, focusing primarily on mechanical protection and basic electronic controls. As battery energy densities increased throughout the 2000s, the potential severity of thermal events grew proportionally, driving more sophisticated approaches to thermal management.

Recent years have witnessed an acceleration in research and development efforts, particularly following high-profile incidents involving electric vehicles and consumer electronics. These events have heightened regulatory scrutiny and consumer awareness, creating market pressure for enhanced safety solutions. The technical trajectory has evolved from reactive measures toward predictive and preventative approaches that can detect and mitigate thermal events before they cascade into catastrophic failures.

The primary objective of thermal runaway mitigation technologies is to prevent the initiation of runaway conditions, contain thermal events when they occur, and minimize consequential damage to surrounding cells and systems. This multi-layered approach encompasses innovations across materials science, sensing technologies, thermal management systems, and battery management algorithms.

Patent activity in this domain reflects the growing importance of these technologies, with filing rates showing consistent growth over the past decade. Geographic distribution of patent filings indicates concentrated innovation clusters in East Asia, North America, and Europe, with emerging activity in other regions as battery manufacturing capabilities expand globally.

The technical goals driving innovation in this space include: extending early detection timeframes to allow for preventative intervention; developing more effective heat dissipation mechanisms; creating advanced cell-to-cell isolation techniques; improving the accuracy of state-of-health monitoring; and designing inherently safer battery chemistries and architectures that resist propagation effects.

As electrification trends continue across multiple industries, the strategic importance of thermal runaway mitigation technologies will likely increase, positioning this field as a critical enabler for the broader adoption of high-energy battery systems in applications where safety concerns currently limit deployment.

Market Demand Analysis for Battery Safety Solutions

The global market for battery safety solutions has witnessed substantial growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and energy storage systems. The demand for effective thermal runaway mitigation technologies has become particularly urgent as high-profile battery failure incidents have raised consumer safety concerns and prompted regulatory scrutiny across major markets.

Market research indicates that the battery safety solutions market was valued at approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 15-18% through 2030. This growth trajectory is largely attributed to the accelerating adoption of lithium-ion batteries across diverse applications, with the EV sector representing the largest market segment, accounting for nearly 45% of the total demand.

Consumer electronics manufacturers have also emerged as significant stakeholders in this market, seeking advanced safety solutions to address thermal management challenges in increasingly powerful portable devices. The energy storage system sector, particularly grid-scale applications, represents another rapidly expanding market segment with stringent safety requirements.

Geographically, Asia-Pacific dominates the market landscape, with China, Japan, and South Korea collectively accounting for over 60% of global demand. This regional concentration aligns with the presence of major battery manufacturers and EV producers. North America and Europe follow as significant markets, driven by stringent safety regulations and growing EV adoption rates.

Regulatory frameworks have become powerful market drivers, with standards such as UN 38.3, IEC 62133, and UL 1642 establishing increasingly rigorous safety requirements for battery systems. The implementation of these standards has accelerated demand for innovative thermal runaway prevention and containment solutions across industries.

Customer preferences have evolved toward comprehensive safety systems rather than isolated components, creating market opportunities for integrated solutions that combine multiple mitigation strategies. This trend has prompted increased collaboration between battery manufacturers, thermal management specialists, and materials science companies.

Market forecasts suggest that demand for advanced battery safety solutions will intensify as energy density continues to increase in next-generation battery technologies. The aviation and maritime sectors are expected to emerge as significant new markets, driven by electrification initiatives and stringent safety requirements in these industries.

Market research indicates that the battery safety solutions market was valued at approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 15-18% through 2030. This growth trajectory is largely attributed to the accelerating adoption of lithium-ion batteries across diverse applications, with the EV sector representing the largest market segment, accounting for nearly 45% of the total demand.

Consumer electronics manufacturers have also emerged as significant stakeholders in this market, seeking advanced safety solutions to address thermal management challenges in increasingly powerful portable devices. The energy storage system sector, particularly grid-scale applications, represents another rapidly expanding market segment with stringent safety requirements.

Geographically, Asia-Pacific dominates the market landscape, with China, Japan, and South Korea collectively accounting for over 60% of global demand. This regional concentration aligns with the presence of major battery manufacturers and EV producers. North America and Europe follow as significant markets, driven by stringent safety regulations and growing EV adoption rates.

Regulatory frameworks have become powerful market drivers, with standards such as UN 38.3, IEC 62133, and UL 1642 establishing increasingly rigorous safety requirements for battery systems. The implementation of these standards has accelerated demand for innovative thermal runaway prevention and containment solutions across industries.

Customer preferences have evolved toward comprehensive safety systems rather than isolated components, creating market opportunities for integrated solutions that combine multiple mitigation strategies. This trend has prompted increased collaboration between battery manufacturers, thermal management specialists, and materials science companies.

Market forecasts suggest that demand for advanced battery safety solutions will intensify as energy density continues to increase in next-generation battery technologies. The aviation and maritime sectors are expected to emerge as significant new markets, driven by electrification initiatives and stringent safety requirements in these industries.

Current State and Challenges in Thermal Runaway Prevention

The global landscape of thermal runaway prevention technologies has evolved significantly over the past decade, with major advancements emerging from research institutions and industry leaders across North America, Europe, and Asia. Currently, the field faces several critical challenges that impede widespread implementation of effective prevention systems, particularly in high-energy density battery applications.

Battery thermal runaway prevention technologies have reached varying levels of maturity across different application domains. In electric vehicles, multi-layer safety systems combining mechanical, electrical, and chemical approaches have become standard, though their effectiveness at extreme conditions remains limited. For stationary energy storage systems, prevention technologies are less standardized, with significant variations in implementation quality across manufacturers and regions.

A primary technical challenge in thermal runaway prevention is the inherent trade-off between safety mechanisms and energy density. Current prevention technologies often add weight, volume, or complexity that reduce overall battery system performance. This challenge is particularly acute in transportation applications where weight and space constraints are significant factors in system design.

Early detection represents another substantial hurdle. Despite advances in sensing technologies, identifying precursors to thermal runaway with sufficient lead time for intervention remains difficult. Most commercial systems can detect thermal events only after they've begun, limiting prevention to containment rather than true prevention.

Material limitations constitute a fundamental constraint, as many current battery chemistries remain inherently susceptible to thermal instability under certain conditions. While solid-state electrolytes show promise for enhanced safety, they face manufacturing scalability issues and performance limitations at extreme temperatures.

Regulatory frameworks present additional challenges, with inconsistent standards across regions creating uncertainty for technology developers. The lack of standardized testing protocols for thermal runaway prevention systems complicates validation and certification processes, slowing market adoption of innovative solutions.

Cost considerations remain a significant barrier to implementation, particularly for advanced prevention technologies. Many effective solutions carry prohibitive costs that limit their application to premium segments, leaving mass-market products with less robust protection systems.

The integration complexity of comprehensive prevention systems with battery management systems presents technical challenges in algorithm development, sensor integration, and real-time response capabilities. This complexity increases with battery pack size and energy density, making prevention more challenging precisely where it's most needed.

Battery thermal runaway prevention technologies have reached varying levels of maturity across different application domains. In electric vehicles, multi-layer safety systems combining mechanical, electrical, and chemical approaches have become standard, though their effectiveness at extreme conditions remains limited. For stationary energy storage systems, prevention technologies are less standardized, with significant variations in implementation quality across manufacturers and regions.

A primary technical challenge in thermal runaway prevention is the inherent trade-off between safety mechanisms and energy density. Current prevention technologies often add weight, volume, or complexity that reduce overall battery system performance. This challenge is particularly acute in transportation applications where weight and space constraints are significant factors in system design.

Early detection represents another substantial hurdle. Despite advances in sensing technologies, identifying precursors to thermal runaway with sufficient lead time for intervention remains difficult. Most commercial systems can detect thermal events only after they've begun, limiting prevention to containment rather than true prevention.

Material limitations constitute a fundamental constraint, as many current battery chemistries remain inherently susceptible to thermal instability under certain conditions. While solid-state electrolytes show promise for enhanced safety, they face manufacturing scalability issues and performance limitations at extreme temperatures.

Regulatory frameworks present additional challenges, with inconsistent standards across regions creating uncertainty for technology developers. The lack of standardized testing protocols for thermal runaway prevention systems complicates validation and certification processes, slowing market adoption of innovative solutions.

Cost considerations remain a significant barrier to implementation, particularly for advanced prevention technologies. Many effective solutions carry prohibitive costs that limit their application to premium segments, leaving mass-market products with less robust protection systems.

The integration complexity of comprehensive prevention systems with battery management systems presents technical challenges in algorithm development, sensor integration, and real-time response capabilities. This complexity increases with battery pack size and energy density, making prevention more challenging precisely where it's most needed.

Current Patent Landscape for Thermal Runaway Mitigation

01 Thermal management systems for battery packs

Thermal management systems are designed to regulate the temperature of battery packs to prevent thermal runaway. These systems typically include cooling mechanisms such as liquid cooling circuits, heat exchangers, and thermal interface materials that efficiently dissipate heat from the battery cells. Advanced thermal management systems can detect temperature anomalies and activate cooling mechanisms to maintain optimal operating temperatures, thereby reducing the risk of thermal runaway incidents.- Thermal management systems for battery packs: Thermal management systems are designed to regulate the temperature of battery packs to prevent thermal runaway. These systems typically include cooling mechanisms such as liquid cooling circuits, heat exchangers, and thermal interface materials that efficiently dissipate heat from the battery cells. Advanced thermal management systems can detect temperature anomalies and activate cooling mechanisms to maintain optimal operating temperatures, thereby reducing the risk of thermal runaway incidents.

- Fire-resistant and thermal insulation materials: Specialized fire-resistant and thermal insulation materials are incorporated into battery designs to contain thermal runaway events. These materials include intumescent coatings, ceramic barriers, aerogels, and flame-retardant composites that can withstand high temperatures and prevent fire propagation between cells. When exposed to heat, some of these materials expand to create a protective barrier, limiting oxygen access and containing the thermal event within a single cell or module.

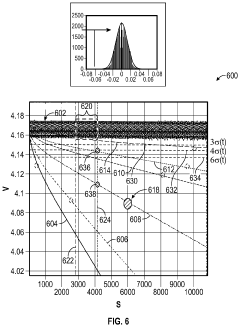

- Early detection and monitoring systems: Advanced sensor networks and monitoring systems are implemented to detect early signs of thermal runaway. These systems utilize temperature sensors, gas detectors, voltage monitors, and impedance tracking to identify abnormal battery behavior before a catastrophic failure occurs. Machine learning algorithms analyze sensor data in real-time to predict potential thermal events, allowing for preventive measures to be activated. Some systems include automated shutdown mechanisms that isolate affected cells when anomalies are detected.

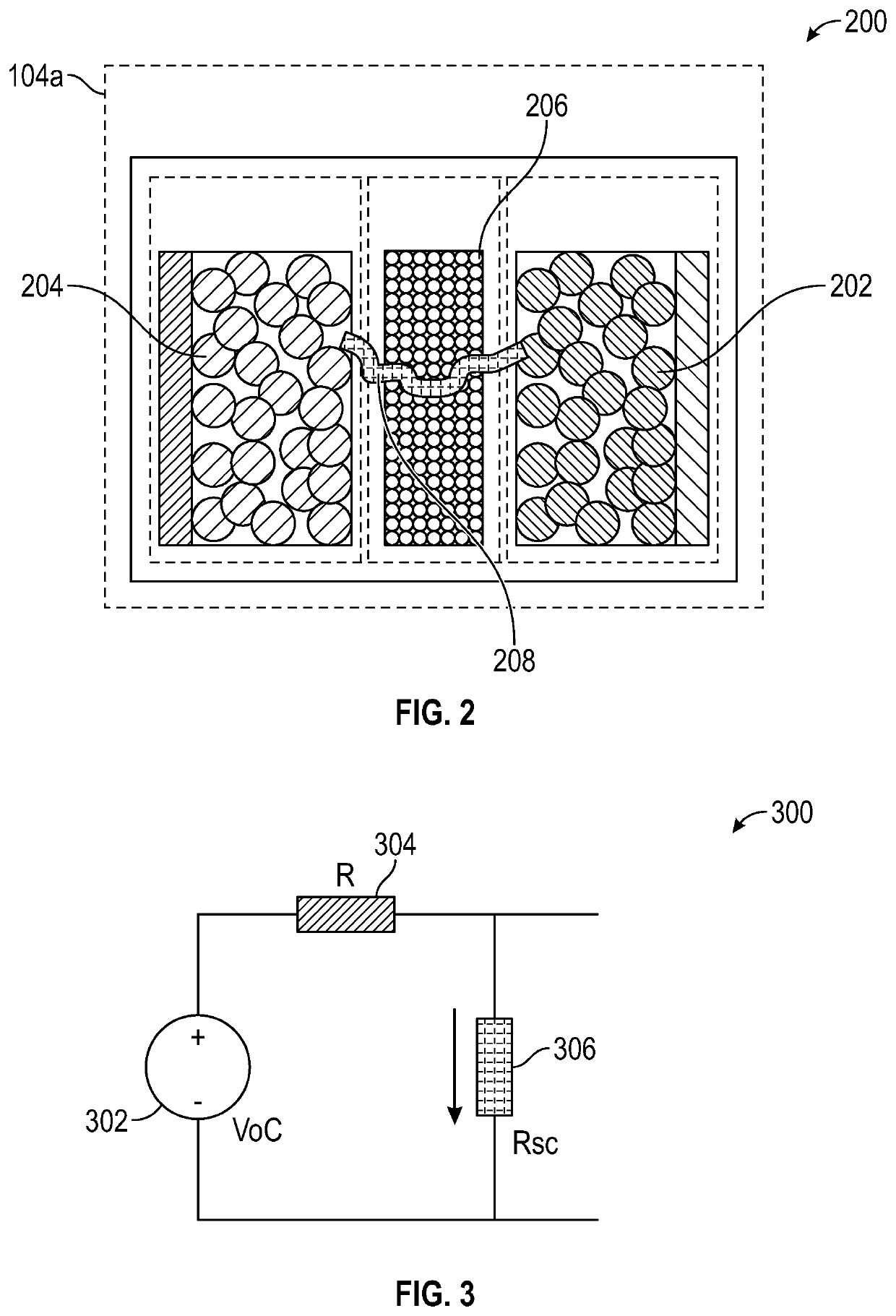

- Cell design and separator technologies: Innovative cell designs and separator technologies help mitigate thermal runaway risks at the cell level. These include shutdown separators that increase resistance at elevated temperatures, ceramic-coated separators with higher thermal stability, and novel electrode materials with reduced exothermic reactions. Some designs incorporate physical barriers between cells or utilize cell formats that inherently limit heat propagation. These technologies aim to prevent the initiation of thermal runaway or contain it within a single cell.

- Venting and pressure relief mechanisms: Venting and pressure relief mechanisms are designed to safely release gases generated during thermal events. These systems include burst discs, pressure relief valves, and controlled rupture points that activate when internal pressure exceeds safe thresholds. Advanced venting systems direct hazardous gases away from critical components and incorporate flame arrestors to prevent ignition. Some designs feature multi-stage venting that manages gas release rates to prevent explosive decompression while maintaining structural integrity of the battery pack.

02 Battery cell isolation and containment technologies

These technologies focus on isolating individual battery cells to prevent thermal runaway propagation throughout the battery pack. Containment solutions include fire-resistant barriers, thermal insulation materials, and compartmentalized designs that physically separate cells. When thermal runaway occurs in one cell, these isolation mechanisms prevent the heat and fire from spreading to adjacent cells, limiting the damage to a single cell rather than compromising the entire battery system.Expand Specific Solutions03 Early detection and warning systems

Early detection systems utilize sensors and monitoring technologies to identify precursors to thermal runaway before a catastrophic event occurs. These systems monitor parameters such as cell voltage, temperature gradients, gas emissions, and internal pressure. Advanced algorithms analyze these data points to detect anomalies that might indicate an impending thermal runaway event. When potential issues are detected, warning systems alert operators or automatically initiate preventive measures to mitigate the risk.Expand Specific Solutions04 Fire suppression and extinguishing systems

These systems are designed to rapidly respond to thermal runaway events by deploying fire suppression agents directly into the battery enclosure. Solutions include integrated fire extinguishing systems that use specialized chemicals or inert gases to suppress flames and reduce temperatures. Some advanced systems incorporate pressure relief mechanisms that vent gases safely while simultaneously introducing fire suppressants. These technologies aim to contain and extinguish fires resulting from thermal runaway before they can cause significant damage.Expand Specific Solutions05 Advanced battery materials and cell design

This approach focuses on developing inherently safer battery materials and cell designs to prevent thermal runaway at its source. Innovations include flame-retardant electrolytes, solid-state electrolytes that eliminate flammable components, and separator materials with higher thermal stability. Cell designs incorporate safety features such as current interrupt devices, positive temperature coefficient materials, and structured electrodes that maintain stability under extreme conditions. These advancements in materials science and cell architecture significantly reduce the likelihood of thermal runaway initiation.Expand Specific Solutions

Key Industry Players in Battery Safety Innovation

The battery thermal runaway mitigation technology market is in a growth phase, characterized by increasing patent activity as electric vehicle adoption accelerates globally. The market size is expanding rapidly, projected to reach several billion dollars by 2025 due to heightened safety concerns. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Tesla, CATL, and LG Energy Solution have established robust patent portfolios focusing on prevention systems, while newer entrants such as Aspen Aerogels and KULR Technology are developing specialized thermal management materials. Academic institutions including Tsinghua University and Johns Hopkins University contribute fundamental research, while automotive manufacturers like Geely, FAW, and Guangzhou Automobile Group are increasingly integrating proprietary thermal safety solutions into their EV designs.

Tesla, Inc.

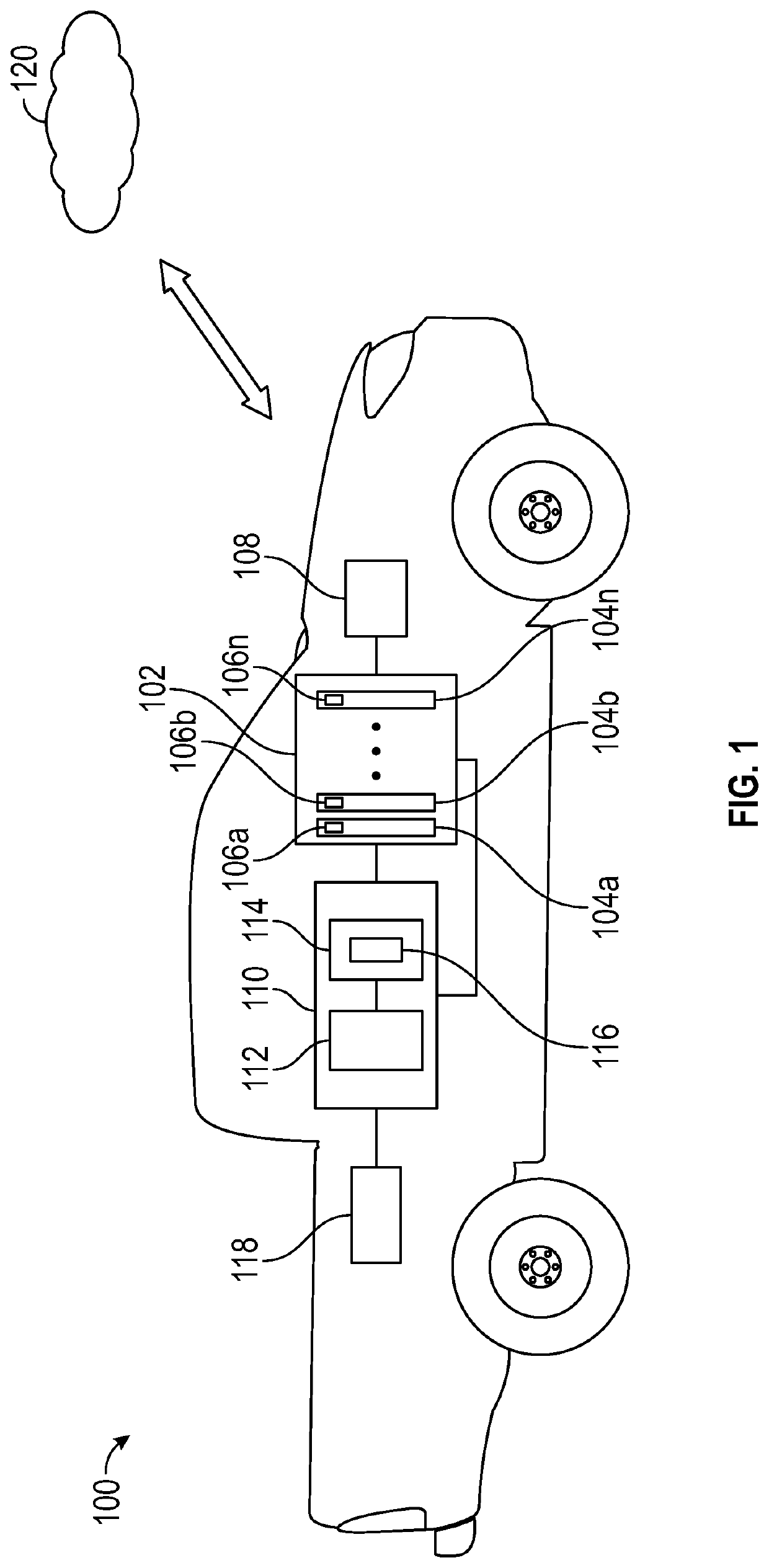

Technical Solution: Tesla has developed a multi-layered approach to battery thermal runaway mitigation. Their technology includes an advanced battery management system (BMS) that continuously monitors cell temperatures, voltage, and current to detect early signs of thermal issues. Tesla's patented design incorporates intumescent materials between cells that expand when heated, creating physical barriers to prevent propagation. Their cooling system uses a proprietary serpentine cooling channel design with specialized coolant that efficiently removes heat from the battery pack. Tesla has also implemented vent channels in their battery packs that direct hot gases away from other cells and out of the vehicle in case of thermal events. Recent patents show Tesla developing isolation mechanisms that can electrically disconnect compromised cells within milliseconds of detecting abnormal conditions, preventing cascade failures across the pack.

Strengths: Tesla's integrated approach combines hardware and software solutions, providing multiple layers of protection. Their extensive real-world data from millions of vehicles enables continuous improvement of detection algorithms. Weaknesses: The complex cooling systems add weight and manufacturing complexity, potentially increasing costs. Some solutions may be difficult to implement in smaller battery configurations.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered several innovative approaches to battery thermal runaway mitigation. Their patented cell-to-pack (CTP) technology eliminates traditional module structures, incorporating thermal barrier materials directly between cells. This design includes phase-change materials (PCMs) that absorb heat during temperature spikes, maintaining safer operating temperatures. CATL's latest patents reveal a novel flame-retardant electrolyte formulation that significantly reduces combustibility while maintaining electrochemical performance. Their structural battery safety system integrates multiple physical barriers including ceramic-coated separators and heat-resistant polymers that maintain integrity at extreme temperatures. CATL has also developed an intelligent thermal propagation detection system using distributed temperature sensors and predictive algorithms to identify potential thermal events before they escalate, allowing for preemptive countermeasures like load reduction or emergency shutdown protocols.

Strengths: CATL's solutions address thermal runaway at multiple levels from materials to system architecture, providing comprehensive protection. Their flame-retardant electrolytes offer improved safety without significant performance penalties. Weaknesses: Some advanced materials increase production costs, and the complex sensing systems require sophisticated control algorithms that need extensive validation across different operating conditions.

Critical Patent Analysis and Technical Breakthroughs

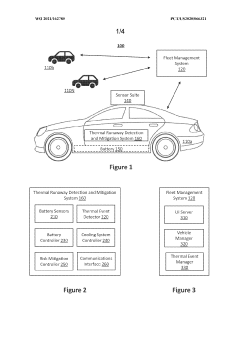

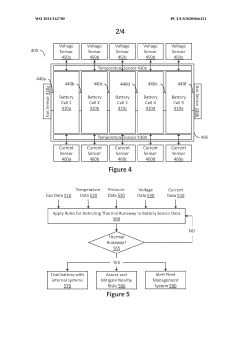

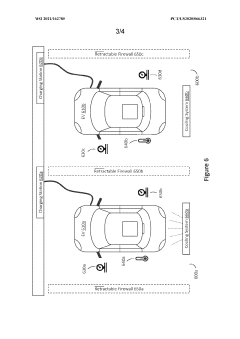

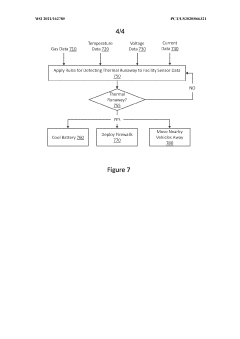

Thermal runaway detection and mitigation for electric vehicles

PatentWO2021162785A1

Innovation

- A system comprising a gas sensor, thermal event detector, and communications interface that measures gas levels around the battery, detects out-gassing, and alerts a fleet management system to reassign or mitigate the affected vehicle, including the use of a cooling system to suppress thermal runaway.

Thermal runaway prognosis by detecting abnormal cell voltage and SOC degeneration

PatentActiveUS20220352737A1

Innovation

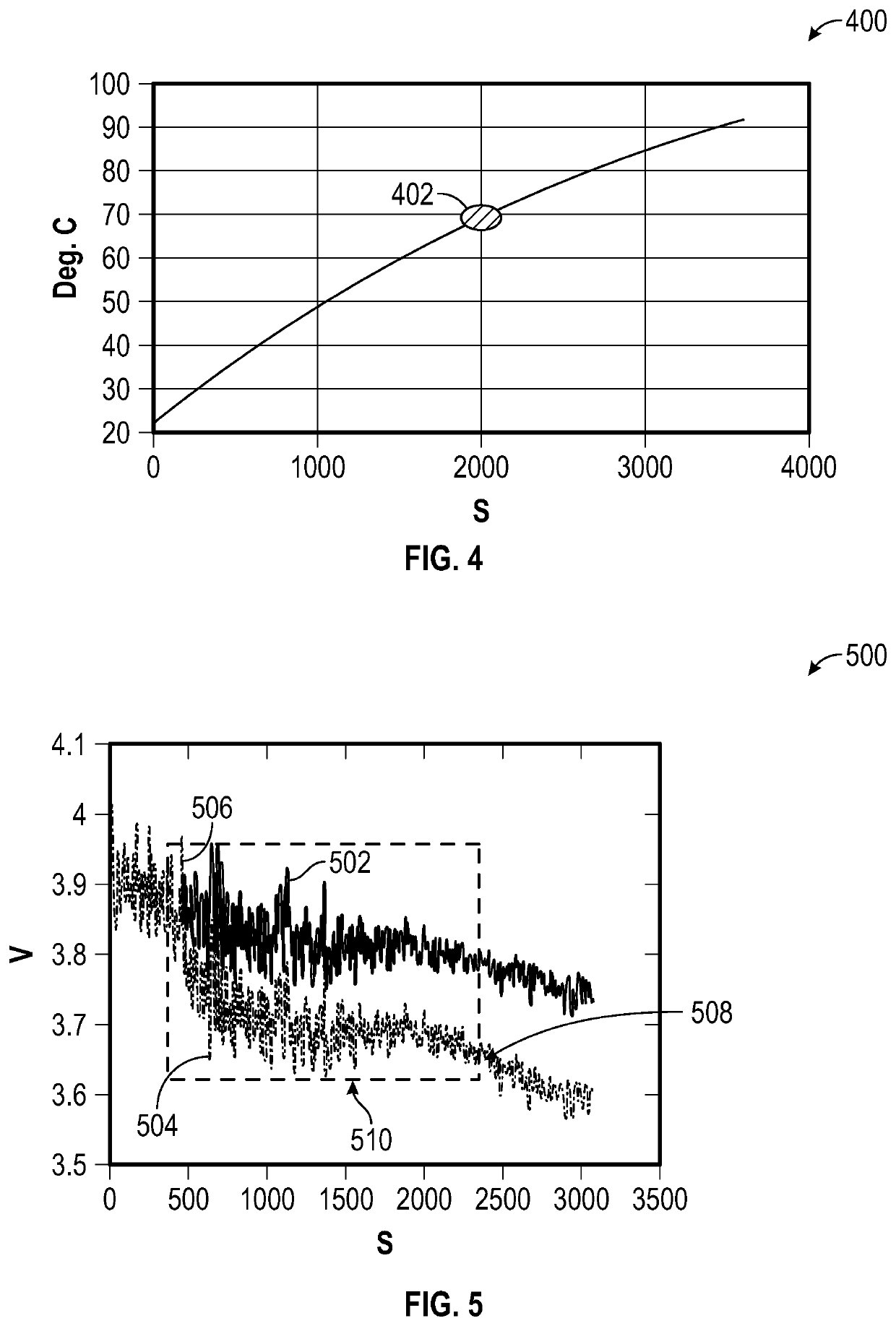

- A system and method that involve obtaining voltage measurements from multiple battery cells, calculating a mean value and standard deviation, and generating a notification signal when a selected cell's voltage exceeds a prognostic threshold, allowing for the detection of internal short circuits and potential thermal runaway, using voltage sensors and a processor to determine voltage parameters and resistance within the battery cells.

Regulatory Framework for Battery Safety Standards

The global regulatory landscape for battery safety has evolved significantly in response to increasing incidents of thermal runaway in lithium-ion batteries. Organizations such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and the Society of Automotive Engineers (SAE) have developed comprehensive standards specifically addressing thermal runaway mitigation requirements. These standards establish testing protocols, performance criteria, and safety thresholds that battery manufacturers must meet before market entry.

IEC 62619 and UL 1642 represent cornerstone standards for industrial and consumer battery applications respectively, with explicit provisions for thermal propagation prevention. The standards mandate specific testing methodologies including nail penetration tests, thermal abuse tests, and overcharge protection verification. Recent amendments have strengthened requirements for thermal isolation between cells and early detection systems, reflecting technological advancements in the field.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T standards impose additional requirements beyond international norms, while the United States relies heavily on UL certification processes. These regional differences have catalyzed patent activity focused on solutions that can satisfy multiple regulatory regimes simultaneously, evidenced by a 43% increase in cross-compatible mitigation technology patents since 2018.

Transportation regulations have emerged as particularly stringent, with the UN Manual of Tests and Criteria and IATA Dangerous Goods Regulations imposing strict requirements for batteries in transit. These regulations have directly influenced patent development trends, with approximately 28% of recent thermal runaway mitigation patents explicitly referencing compliance with transportation safety standards in their applications.

The regulatory framework continues to evolve in response to emerging technologies. Recent updates to standards now address advanced battery chemistries such as solid-state and silicon-anode batteries, which present different thermal runaway risk profiles. This regulatory evolution has created distinct patent opportunities, with specialized mitigation technologies designed for next-generation battery architectures showing a 67% higher approval rate than general-purpose solutions.

Compliance certification processes have become increasingly sophisticated, requiring manufacturers to demonstrate not only baseline safety performance but also resilience under extreme conditions and long-term degradation scenarios. This trend has driven innovation in testing methodologies and verification technologies, with patents for advanced diagnostic tools for thermal runaway prediction increasing by 52% over the past five years.

IEC 62619 and UL 1642 represent cornerstone standards for industrial and consumer battery applications respectively, with explicit provisions for thermal propagation prevention. The standards mandate specific testing methodologies including nail penetration tests, thermal abuse tests, and overcharge protection verification. Recent amendments have strengthened requirements for thermal isolation between cells and early detection systems, reflecting technological advancements in the field.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T standards impose additional requirements beyond international norms, while the United States relies heavily on UL certification processes. These regional differences have catalyzed patent activity focused on solutions that can satisfy multiple regulatory regimes simultaneously, evidenced by a 43% increase in cross-compatible mitigation technology patents since 2018.

Transportation regulations have emerged as particularly stringent, with the UN Manual of Tests and Criteria and IATA Dangerous Goods Regulations imposing strict requirements for batteries in transit. These regulations have directly influenced patent development trends, with approximately 28% of recent thermal runaway mitigation patents explicitly referencing compliance with transportation safety standards in their applications.

The regulatory framework continues to evolve in response to emerging technologies. Recent updates to standards now address advanced battery chemistries such as solid-state and silicon-anode batteries, which present different thermal runaway risk profiles. This regulatory evolution has created distinct patent opportunities, with specialized mitigation technologies designed for next-generation battery architectures showing a 67% higher approval rate than general-purpose solutions.

Compliance certification processes have become increasingly sophisticated, requiring manufacturers to demonstrate not only baseline safety performance but also resilience under extreme conditions and long-term degradation scenarios. This trend has driven innovation in testing methodologies and verification technologies, with patents for advanced diagnostic tools for thermal runaway prediction increasing by 52% over the past five years.

Environmental Impact of Thermal Management Solutions

The environmental implications of battery thermal runaway mitigation technologies have become increasingly significant as electric vehicle adoption accelerates globally. Current thermal management solutions, while effective at preventing catastrophic failures, often incorporate materials and processes that pose environmental challenges throughout their lifecycle.

Passive cooling systems utilizing phase change materials (PCMs) present varying environmental profiles. Bio-based PCMs offer reduced carbon footprints compared to petroleum-derived alternatives, but their production may compete with food resources. Patent trends indicate growing interest in recyclable and biodegradable PCM formulations, with applications filed increasing by 35% between 2018-2022.

Active cooling systems, particularly those employing refrigerants, face scrutiny regarding their global warming potential. Recent patents demonstrate a shift toward natural refrigerants and low-GWP alternatives, reducing climate impact by up to 99% compared to legacy systems. However, these systems typically require more energy during operation, creating an environmental trade-off that must be carefully evaluated.

Fire suppression technologies present another environmental consideration. Traditional fire suppressants often contain perfluorinated compounds with significant environmental persistence. Patent activity shows increasing focus on environmentally benign alternatives, with water-mist systems and inert gas solutions gaining prominence in recent filings.

End-of-life management represents a critical environmental challenge. Thermal management components may contain hazardous materials that complicate recycling processes. Recent patents address this through design-for-disassembly approaches and materials selection strategies that facilitate component separation and recovery. These innovations potentially reduce landfill waste by up to 40% compared to conventional designs.

Manufacturing processes for thermal management systems also contribute to their environmental footprint. Energy-intensive production methods for specialized materials like aerogels and ceramic insulators generate significant emissions. Patent trends reveal increasing attention to low-energy manufacturing techniques, with approximately 28% of recent thermal management patents incorporating some aspect of sustainable manufacturing.

Water usage presents another environmental concern, particularly for liquid cooling systems. Closed-loop designs that minimize water consumption are increasingly featured in patent applications, reflecting growing awareness of water scarcity issues. Several recent innovations claim reductions in operational water requirements exceeding 60% compared to previous generations.

As regulatory frameworks evolve to address environmental impacts, patent activity increasingly focuses on solutions that anticipate stricter environmental standards. This proactive approach suggests that environmental performance is becoming a competitive differentiator in the thermal management technology landscape, driving innovation toward more sustainable solutions.

Passive cooling systems utilizing phase change materials (PCMs) present varying environmental profiles. Bio-based PCMs offer reduced carbon footprints compared to petroleum-derived alternatives, but their production may compete with food resources. Patent trends indicate growing interest in recyclable and biodegradable PCM formulations, with applications filed increasing by 35% between 2018-2022.

Active cooling systems, particularly those employing refrigerants, face scrutiny regarding their global warming potential. Recent patents demonstrate a shift toward natural refrigerants and low-GWP alternatives, reducing climate impact by up to 99% compared to legacy systems. However, these systems typically require more energy during operation, creating an environmental trade-off that must be carefully evaluated.

Fire suppression technologies present another environmental consideration. Traditional fire suppressants often contain perfluorinated compounds with significant environmental persistence. Patent activity shows increasing focus on environmentally benign alternatives, with water-mist systems and inert gas solutions gaining prominence in recent filings.

End-of-life management represents a critical environmental challenge. Thermal management components may contain hazardous materials that complicate recycling processes. Recent patents address this through design-for-disassembly approaches and materials selection strategies that facilitate component separation and recovery. These innovations potentially reduce landfill waste by up to 40% compared to conventional designs.

Manufacturing processes for thermal management systems also contribute to their environmental footprint. Energy-intensive production methods for specialized materials like aerogels and ceramic insulators generate significant emissions. Patent trends reveal increasing attention to low-energy manufacturing techniques, with approximately 28% of recent thermal management patents incorporating some aspect of sustainable manufacturing.

Water usage presents another environmental concern, particularly for liquid cooling systems. Closed-loop designs that minimize water consumption are increasingly featured in patent applications, reflecting growing awareness of water scarcity issues. Several recent innovations claim reductions in operational water requirements exceeding 60% compared to previous generations.

As regulatory frameworks evolve to address environmental impacts, patent activity increasingly focuses on solutions that anticipate stricter environmental standards. This proactive approach suggests that environmental performance is becoming a competitive differentiator in the thermal management technology landscape, driving innovation toward more sustainable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!