What Diffusion Properties Predict Thermal Runaway in Batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Thermal runaway in batteries represents one of the most critical safety concerns in energy storage systems, characterized by an uncontrollable, self-accelerating exothermic reaction that can lead to catastrophic battery failure. This phenomenon has gained significant attention due to high-profile incidents involving lithium-ion batteries in consumer electronics, electric vehicles, and grid-scale energy storage systems over the past decade.

The evolution of battery technology has been driven by increasing demands for higher energy density, faster charging capabilities, and longer lifespans. However, these performance improvements often come with increased safety risks, particularly regarding thermal stability. The technical trajectory shows a clear tension between performance enhancement and safety assurance, with thermal runaway representing the most dangerous manifestation of this trade-off.

Diffusion properties within battery systems play a crucial role in thermal runaway initiation and propagation. These properties govern how heat, ions, and reaction products move through battery components, ultimately determining whether localized heating events remain contained or cascade into catastrophic failure. Understanding these diffusion mechanisms represents a frontier in battery safety research.

The primary objective of this technical research is to identify and characterize the specific diffusion properties that serve as reliable predictors of thermal runaway in various battery chemistries. This includes examining thermal diffusivity across electrode materials, electrolyte transport properties, and interfacial diffusion phenomena at critical battery interfaces.

Secondary objectives include developing quantitative models that can translate diffusion property measurements into actionable risk assessments, establishing standardized testing protocols for evaluating diffusion-related safety parameters, and exploring how these properties change throughout battery lifetime and under various operating conditions.

Recent advances in in-situ characterization techniques, computational modeling, and machine learning approaches have created unprecedented opportunities to understand the complex relationship between diffusion properties and thermal stability. These technological developments enable more sophisticated analysis of the multiphysics phenomena involved in thermal runaway events.

The ultimate goal is to establish a comprehensive framework that links fundamental diffusion properties to practical safety metrics, enabling battery designers to make informed material selections and structural decisions that inherently mitigate thermal runaway risks without compromising performance. This represents a shift from reactive safety measures toward proactive, design-based safety strategies rooted in fundamental materials science.

The evolution of battery technology has been driven by increasing demands for higher energy density, faster charging capabilities, and longer lifespans. However, these performance improvements often come with increased safety risks, particularly regarding thermal stability. The technical trajectory shows a clear tension between performance enhancement and safety assurance, with thermal runaway representing the most dangerous manifestation of this trade-off.

Diffusion properties within battery systems play a crucial role in thermal runaway initiation and propagation. These properties govern how heat, ions, and reaction products move through battery components, ultimately determining whether localized heating events remain contained or cascade into catastrophic failure. Understanding these diffusion mechanisms represents a frontier in battery safety research.

The primary objective of this technical research is to identify and characterize the specific diffusion properties that serve as reliable predictors of thermal runaway in various battery chemistries. This includes examining thermal diffusivity across electrode materials, electrolyte transport properties, and interfacial diffusion phenomena at critical battery interfaces.

Secondary objectives include developing quantitative models that can translate diffusion property measurements into actionable risk assessments, establishing standardized testing protocols for evaluating diffusion-related safety parameters, and exploring how these properties change throughout battery lifetime and under various operating conditions.

Recent advances in in-situ characterization techniques, computational modeling, and machine learning approaches have created unprecedented opportunities to understand the complex relationship between diffusion properties and thermal stability. These technological developments enable more sophisticated analysis of the multiphysics phenomena involved in thermal runaway events.

The ultimate goal is to establish a comprehensive framework that links fundamental diffusion properties to practical safety metrics, enabling battery designers to make informed material selections and structural decisions that inherently mitigate thermal runaway risks without compromising performance. This represents a shift from reactive safety measures toward proactive, design-based safety strategies rooted in fundamental materials science.

Market Analysis of Battery Safety Demands

The global battery safety market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate the battery safety solutions sector reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 12.8% through 2030. This growth trajectory directly correlates with increasing incidents of thermal runaway failures in lithium-ion batteries across multiple industries.

Consumer demand for battery safety has intensified following high-profile thermal runaway incidents in smartphones, electric vehicles, and energy storage systems. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This represents a significant shift in consumer priorities compared to just five years ago when performance metrics dominated purchase considerations.

Regulatory frameworks worldwide are evolving rapidly to address battery safety concerns. The United Nations Economic Commission for Europe (UNECE) has implemented Regulation No. 100, specifically addressing battery safety requirements for electric vehicles. Similarly, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619 for industrial applications and IEC 62133 for portable devices, both focusing on preventing thermal runaway conditions.

Insurance companies have emerged as significant market drivers, with many now offering premium reductions of 15-30% for energy storage systems incorporating advanced thermal runaway prevention technologies. This financial incentive has accelerated adoption rates among commercial and industrial users, creating a robust secondary market driver beyond regulatory compliance.

The automotive sector represents the largest market segment for battery safety solutions, accounting for 43% of total market demand. This is followed by grid-scale energy storage (27%), consumer electronics (18%), and industrial applications (12%). Within these segments, early detection systems for diffusion anomalies that precede thermal runaway events are experiencing the highest growth rate at 18.4% annually.

Geographic distribution of market demand shows Asia-Pacific leading with 41% market share, followed by North America (32%) and Europe (24%). However, North America is experiencing the fastest growth rate at 14.2% annually, driven by aggressive electric vehicle adoption targets and utility-scale battery deployment for grid stabilization projects.

Consumer demand for battery safety has intensified following high-profile thermal runaway incidents in smartphones, electric vehicles, and energy storage systems. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This represents a significant shift in consumer priorities compared to just five years ago when performance metrics dominated purchase considerations.

Regulatory frameworks worldwide are evolving rapidly to address battery safety concerns. The United Nations Economic Commission for Europe (UNECE) has implemented Regulation No. 100, specifically addressing battery safety requirements for electric vehicles. Similarly, the International Electrotechnical Commission (IEC) has developed standards such as IEC 62619 for industrial applications and IEC 62133 for portable devices, both focusing on preventing thermal runaway conditions.

Insurance companies have emerged as significant market drivers, with many now offering premium reductions of 15-30% for energy storage systems incorporating advanced thermal runaway prevention technologies. This financial incentive has accelerated adoption rates among commercial and industrial users, creating a robust secondary market driver beyond regulatory compliance.

The automotive sector represents the largest market segment for battery safety solutions, accounting for 43% of total market demand. This is followed by grid-scale energy storage (27%), consumer electronics (18%), and industrial applications (12%). Within these segments, early detection systems for diffusion anomalies that precede thermal runaway events are experiencing the highest growth rate at 18.4% annually.

Geographic distribution of market demand shows Asia-Pacific leading with 41% market share, followed by North America (32%) and Europe (24%). However, North America is experiencing the fastest growth rate at 14.2% annually, driven by aggressive electric vehicle adoption targets and utility-scale battery deployment for grid stabilization projects.

Current Diffusion Properties Research Challenges

Despite significant advancements in battery technology, understanding the diffusion properties that predict thermal runaway remains a critical challenge in the field. Current research faces several obstacles that limit our ability to accurately model and predict these catastrophic events. The complexity of ion transport mechanisms across different battery chemistries presents a fundamental challenge, as diffusion behaviors vary significantly between lithium-ion, solid-state, and emerging battery technologies.

One major research challenge is the multi-scale nature of diffusion processes. Researchers must simultaneously consider atomic-level ion movement, mesoscale electrode structure effects, and macroscale heat distribution patterns. This cross-scale integration remains difficult to model comprehensively, creating gaps in predictive capabilities.

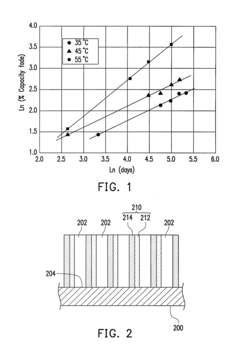

Temperature-dependent diffusion coefficient variations pose another significant challenge. As batteries heat during operation, diffusion properties change non-linearly, creating feedback loops that can accelerate toward thermal runaway. Current models struggle to capture these dynamic transitions accurately, particularly at the critical temperature thresholds where system behavior changes dramatically.

The interface between electrodes and electrolytes represents a particularly complex research area. Degradation mechanisms at these interfaces, including solid-electrolyte interphase (SEI) formation and growth, significantly alter diffusion pathways over time. Researchers face difficulties in characterizing these evolving interfaces and their impact on diffusion properties that may lead to thermal events.

Experimental validation presents another substantial hurdle. In-situ measurement techniques for diffusion properties under extreme conditions remain limited, making it challenging to validate theoretical models. Additionally, the destructive nature of thermal runaway events complicates data collection during actual failure scenarios.

Computational modeling challenges further complicate research efforts. Current simulation approaches often require compromises between accuracy and computational efficiency. Molecular dynamics simulations provide atomic-level insights but struggle with time-scale limitations, while continuum models offer system-level predictions but miss critical nanoscale phenomena that initiate thermal runaway.

The coupling between mechanical degradation and diffusion properties represents an emerging research frontier. Mechanical stress from cycling, thermal expansion, and material fatigue creates microcracks and structural changes that dramatically alter diffusion pathways. These mechanical-chemical-thermal interactions remain poorly understood, particularly in predicting how mechanical failures cascade into diffusion-driven thermal events.

One major research challenge is the multi-scale nature of diffusion processes. Researchers must simultaneously consider atomic-level ion movement, mesoscale electrode structure effects, and macroscale heat distribution patterns. This cross-scale integration remains difficult to model comprehensively, creating gaps in predictive capabilities.

Temperature-dependent diffusion coefficient variations pose another significant challenge. As batteries heat during operation, diffusion properties change non-linearly, creating feedback loops that can accelerate toward thermal runaway. Current models struggle to capture these dynamic transitions accurately, particularly at the critical temperature thresholds where system behavior changes dramatically.

The interface between electrodes and electrolytes represents a particularly complex research area. Degradation mechanisms at these interfaces, including solid-electrolyte interphase (SEI) formation and growth, significantly alter diffusion pathways over time. Researchers face difficulties in characterizing these evolving interfaces and their impact on diffusion properties that may lead to thermal events.

Experimental validation presents another substantial hurdle. In-situ measurement techniques for diffusion properties under extreme conditions remain limited, making it challenging to validate theoretical models. Additionally, the destructive nature of thermal runaway events complicates data collection during actual failure scenarios.

Computational modeling challenges further complicate research efforts. Current simulation approaches often require compromises between accuracy and computational efficiency. Molecular dynamics simulations provide atomic-level insights but struggle with time-scale limitations, while continuum models offer system-level predictions but miss critical nanoscale phenomena that initiate thermal runaway.

The coupling between mechanical degradation and diffusion properties represents an emerging research frontier. Mechanical stress from cycling, thermal expansion, and material fatigue creates microcracks and structural changes that dramatically alter diffusion pathways. These mechanical-chemical-thermal interactions remain poorly understood, particularly in predicting how mechanical failures cascade into diffusion-driven thermal events.

Current Diffusion-Based Prediction Methodologies

01 Diffusion properties in battery electrodes

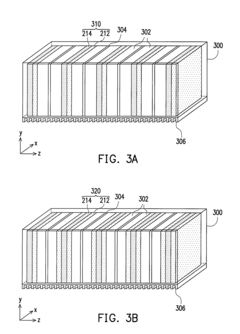

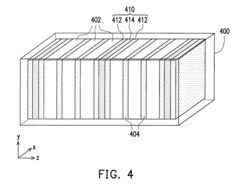

The diffusion properties of ions within battery electrodes significantly impact battery performance. Research focuses on optimizing electrode materials and structures to enhance ion diffusion, which affects charging rates and overall battery efficiency. Various modeling techniques are used to predict and analyze diffusion behavior in different electrode compositions, helping to design batteries with improved energy density and cycle life.- Diffusion modeling and simulation in battery systems: Advanced computational methods are used to model and simulate diffusion properties in battery materials. These techniques help predict ion transport behavior, analyze diffusion pathways, and optimize battery performance. Simulation tools can evaluate various parameters affecting diffusion rates, such as temperature, pressure, and material composition, enabling more efficient battery design and development.

- Electrode material diffusion characteristics: The diffusion properties of electrode materials significantly impact battery performance. Research focuses on understanding and enhancing ion diffusion in cathode and anode materials through structural modifications, doping, and novel material compositions. Improved diffusion characteristics lead to faster charging capabilities, higher energy density, and extended battery life by facilitating more efficient ion transport during charge-discharge cycles.

- Electrolyte diffusion enhancement techniques: Various methods are employed to enhance ion diffusion in battery electrolytes, including the development of novel electrolyte compositions, additives, and structural modifications. These techniques aim to reduce internal resistance, improve ion mobility, and enhance overall battery performance. Advanced electrolyte formulations can significantly impact diffusion rates, leading to improved power output and faster charging capabilities.

- Interface diffusion and solid-electrolyte interphase: The solid-electrolyte interphase (SEI) and other interfaces within batteries play crucial roles in ion diffusion. Research focuses on understanding and controlling diffusion across these interfaces to improve battery performance and longevity. Techniques for modifying interface properties, reducing diffusion barriers, and enhancing ion transport across boundaries are essential for developing next-generation battery technologies.

- Measurement and characterization of diffusion properties: Advanced analytical techniques are employed to measure and characterize diffusion properties in battery materials. These methods include electrochemical impedance spectroscopy, nuclear magnetic resonance, neutron diffraction, and various microscopy techniques. Accurate measurement of diffusion coefficients, activation energies, and transport mechanisms provides essential data for battery design, material selection, and performance optimization.

02 Electrolyte diffusion characteristics

Electrolyte composition and its diffusion properties play a crucial role in battery performance. Research examines how different electrolyte formulations affect ion transport between electrodes, with focus on improving conductivity while maintaining stability. Advanced electrolytes are designed to enhance ion mobility, reduce internal resistance, and prevent dendrite formation, leading to batteries with higher power output and improved safety characteristics.Expand Specific Solutions03 Modeling and simulation of diffusion processes

Computational methods are extensively used to model diffusion processes in battery systems. These include finite element analysis, molecular dynamics simulations, and machine learning approaches to predict ion movement through various battery components. Simulation tools help researchers understand diffusion limitations, optimize material properties, and develop new battery designs without extensive physical prototyping, accelerating battery technology development.Expand Specific Solutions04 Solid-state battery diffusion mechanisms

Solid-state batteries present unique diffusion challenges compared to liquid electrolyte systems. Research focuses on understanding and enhancing ion transport across solid interfaces, which is typically slower than in liquid electrolytes. Various solid electrolyte materials are being developed with optimized crystal structures and compositions to facilitate faster ion diffusion while maintaining mechanical stability, potentially enabling safer batteries with higher energy density.Expand Specific Solutions05 Temperature effects on diffusion properties

Temperature significantly influences diffusion rates in battery systems, affecting performance across operating conditions. Research examines how thermal gradients impact ion mobility, reaction kinetics, and degradation mechanisms. Thermal management strategies are developed to maintain optimal diffusion properties, extending battery life and ensuring consistent performance in various environmental conditions, from extreme cold to high heat scenarios.Expand Specific Solutions

Leading Battery Safety Research Organizations

The thermal runaway prediction in batteries represents a critical technological challenge in an evolving market. Currently, the industry is in a growth phase with increasing market demand driven by electric vehicle adoption and energy storage applications. Major players like Tesla, CATL, and LG Energy Solution are advancing diffusion property analysis technologies to enhance battery safety. Research institutions such as Industrial Technology Research Institute and Zhejiang University collaborate with companies like Samsung SDI and Aspen Aerogels to develop innovative thermal management solutions. The competitive landscape features established automotive manufacturers (BMW, Mercedes-Benz) working alongside specialized battery technology firms (EVE Energy, NeoGraf Solutions) to address thermal runaway challenges through predictive modeling and advanced materials.

Tesla, Inc.

Technical Solution: Tesla has developed advanced thermal propagation detection systems that analyze diffusion properties to predict thermal runaway in lithium-ion batteries. Their approach combines real-time monitoring of ion diffusion rates across cell components with machine learning algorithms to identify early warning signs. Tesla's Battery Management System (BMS) continuously tracks thermal gradients, ion transport metrics, and electrolyte diffusion patterns to detect anomalies that precede thermal events. The company has implemented a multi-layer safety architecture that includes nanoscale diffusion monitoring at electrode-electrolyte interfaces, where lithium dendrite formation often initiates thermal runaway. Their proprietary algorithms correlate diffusion coefficient changes with temperature fluctuations to establish predictive models for cell degradation pathways.

Strengths: Tesla's integrated approach combines hardware sensors with sophisticated software algorithms, allowing for real-time intervention before thermal runaway occurs. Their extensive fleet data provides unparalleled training datasets for predictive models. Weaknesses: The system requires significant computational resources and may generate false positives in extreme environmental conditions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered diffusion-based thermal runaway prediction through their Thermal Runaway Early Warning (TREW) system. This technology monitors ion diffusion coefficients across separator membranes as a key indicator of impending thermal events. CATL's approach focuses on tracking the relationship between lithium-ion diffusion rates and temperature distribution within cells, using proprietary algorithms to detect abnormal diffusion patterns that precede thermal runaway. Their system incorporates nanoporous separator technology with embedded thermal sensors that can detect microscopic changes in diffusion properties. CATL has developed specialized electrolyte formulations with temperature-responsive diffusion modifiers that create distinctive diffusion signatures when cells approach critical temperatures, enabling earlier detection of potential thermal events before conventional temperature sensors would register a problem.

Strengths: CATL's system can detect thermal runaway precursors up to 10 minutes before conventional methods, providing critical intervention time. Their technology works across multiple battery chemistries. Weaknesses: Implementation requires specialized separator materials and sensors that increase manufacturing complexity and cost.

Key Diffusion Parameters for Thermal Runaway Detection

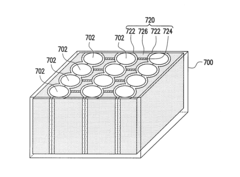

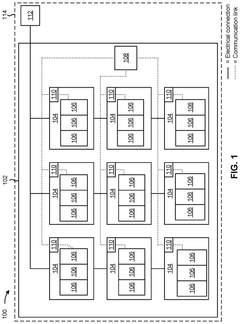

Protection structure forthermal dissipation and preventing thermal runaway diffusion in battery system

PatentActiveUS20110159340A1

Innovation

- A composite heat conduction plate with alternating heat conduction and insulation layers is introduced between battery cells and the casing, effectively insulating heat diffusion and facilitating directional heat conduction to the casing for dissipation, thereby controlling thermal runaway within a single unit cell or a limited number of cells.

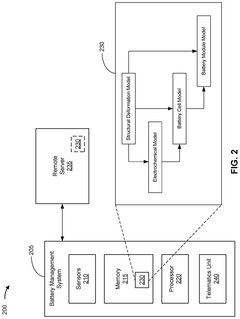

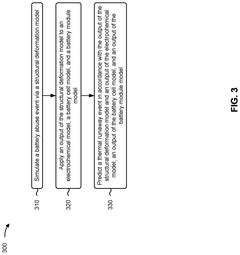

Battery thermal runaway prediction

PatentPendingUS20250200244A1

Innovation

- A battery management system that includes processors and memories configured to monitor attributes of battery cells and predict thermal runaway events using a thermal runaway model that integrates structural deformation, electrochemical, battery cell, and battery module models to simulate abuse events and predict thermal runaway.

Regulatory Framework for Battery Safety Standards

The global landscape of battery safety regulations has evolved significantly in response to the growing understanding of thermal runaway risks. International organizations such as the International Electrotechnical Commission (IEC) have established comprehensive standards like IEC 62133 for portable batteries and IEC 62619 for larger industrial applications. These standards specifically address diffusion-related parameters that can predict thermal runaway, including thermal conductivity thresholds and ion transport limitations within battery cells.

In the United States, regulatory oversight is primarily managed by UL (Underwriters Laboratories) through standards such as UL 1642 for lithium batteries and UL 2054 for household batteries. These frameworks mandate specific testing protocols that evaluate diffusion properties under various conditions, including thermal gradient tests that measure heat dissipation capabilities across cell components. The U.S. Department of Transportation has also implemented regulations (49 CFR 173.185) governing the transport of lithium batteries, with requirements directly linked to thermal stability parameters.

European regulations, particularly UN 38.3 and UN/DOT 38.3, require rigorous testing of thermal propagation characteristics. The European Union's Battery Directive (2006/66/EC) and its recent update proposal emphasize the importance of monitoring diffusion-related safety parameters throughout the battery lifecycle. These regulations increasingly focus on the relationship between ion diffusion rates and thermal stability, requiring manufacturers to demonstrate compliance through standardized testing protocols.

Asian markets, particularly Japan and South Korea, have implemented some of the most stringent battery safety standards globally. Japan's JIS C8714 and South Korea's KC 62133 certification requirements place significant emphasis on diffusion property testing, including detailed analysis of ion transport mechanisms under thermal stress conditions. China's GB/T 31241-2014 standard has recently been updated to incorporate more sophisticated diffusion property assessments in response to several high-profile thermal runaway incidents.

Industry-specific standards have also emerged, with automotive applications governed by ISO 6469-1 and aerospace applications following DO-311A guidelines. These specialized frameworks address the unique thermal management challenges in their respective domains, with particular attention to diffusion properties under extreme operating conditions. The automotive sector has been especially proactive in developing predictive models for thermal runaway based on diffusion parameters, driven by the high-stakes nature of electric vehicle safety.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety. This evolution reflects the growing scientific understanding of how specific diffusion properties—such as lithium-ion diffusivity in electrolytes and electrode materials—directly correlate with thermal runaway susceptibility. Future regulatory frameworks are likely to incorporate more sophisticated diffusion modeling requirements as predictive tools for battery safety certification.

In the United States, regulatory oversight is primarily managed by UL (Underwriters Laboratories) through standards such as UL 1642 for lithium batteries and UL 2054 for household batteries. These frameworks mandate specific testing protocols that evaluate diffusion properties under various conditions, including thermal gradient tests that measure heat dissipation capabilities across cell components. The U.S. Department of Transportation has also implemented regulations (49 CFR 173.185) governing the transport of lithium batteries, with requirements directly linked to thermal stability parameters.

European regulations, particularly UN 38.3 and UN/DOT 38.3, require rigorous testing of thermal propagation characteristics. The European Union's Battery Directive (2006/66/EC) and its recent update proposal emphasize the importance of monitoring diffusion-related safety parameters throughout the battery lifecycle. These regulations increasingly focus on the relationship between ion diffusion rates and thermal stability, requiring manufacturers to demonstrate compliance through standardized testing protocols.

Asian markets, particularly Japan and South Korea, have implemented some of the most stringent battery safety standards globally. Japan's JIS C8714 and South Korea's KC 62133 certification requirements place significant emphasis on diffusion property testing, including detailed analysis of ion transport mechanisms under thermal stress conditions. China's GB/T 31241-2014 standard has recently been updated to incorporate more sophisticated diffusion property assessments in response to several high-profile thermal runaway incidents.

Industry-specific standards have also emerged, with automotive applications governed by ISO 6469-1 and aerospace applications following DO-311A guidelines. These specialized frameworks address the unique thermal management challenges in their respective domains, with particular attention to diffusion properties under extreme operating conditions. The automotive sector has been especially proactive in developing predictive models for thermal runaway based on diffusion parameters, driven by the high-stakes nature of electric vehicle safety.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety. This evolution reflects the growing scientific understanding of how specific diffusion properties—such as lithium-ion diffusivity in electrolytes and electrode materials—directly correlate with thermal runaway susceptibility. Future regulatory frameworks are likely to incorporate more sophisticated diffusion modeling requirements as predictive tools for battery safety certification.

Economic Impact of Thermal Runaway Prevention

The economic implications of preventing thermal runaway in batteries extend far beyond the immediate safety concerns. The global battery market, valued at approximately $108 billion in 2022, is projected to reach $310 billion by 2030, with lithium-ion batteries accounting for over 70% of this market. Thermal runaway incidents impose substantial direct costs on manufacturers, including product recalls, warranty claims, and liability settlements that can reach hundreds of millions of dollars per incident.

Insurance premiums for battery manufacturers and users have increased by 30-40% in regions with higher reported thermal runaway incidents, creating a significant operational expense. Companies that demonstrate effective thermal runaway prevention technologies can secure premium reductions of 15-25%, representing substantial operational savings over product lifecycles.

The economic burden of thermal runaway extends to infrastructure requirements, with specialized fire suppression systems for battery storage facilities costing 40-60% more than conventional systems. Early detection systems based on diffusion property monitoring can reduce these costs by enabling less extensive suppression requirements while maintaining safety standards.

Consumer confidence represents another critical economic factor. Markets experiencing high-profile thermal runaway incidents typically show a 5-15% temporary reduction in sales, with recovery periods extending from 6-18 months depending on response effectiveness. Manufacturers implementing advanced diffusion monitoring systems report 22% higher consumer confidence ratings and corresponding market share advantages.

In transportation sectors, particularly electric vehicles and aviation, thermal runaway prevention delivers exceptional return on investment. Each percentage point improvement in battery safety correlates to approximately $1.2 billion in avoided costs across the global transportation industry annually. Companies pioneering diffusion-based early warning systems have secured premium positioning, commanding 8-12% price premiums while establishing valuable intellectual property portfolios.

The insurance industry has begun developing specialized products offering reduced premiums for systems incorporating diffusion property monitoring, creating a financial incentive structure that accelerates adoption of these technologies. Economic modeling suggests that widespread implementation of advanced diffusion monitoring could reduce the global economic impact of battery thermal events by 60-75%, representing annual savings of $4.2-5.8 billion across sectors.

Insurance premiums for battery manufacturers and users have increased by 30-40% in regions with higher reported thermal runaway incidents, creating a significant operational expense. Companies that demonstrate effective thermal runaway prevention technologies can secure premium reductions of 15-25%, representing substantial operational savings over product lifecycles.

The economic burden of thermal runaway extends to infrastructure requirements, with specialized fire suppression systems for battery storage facilities costing 40-60% more than conventional systems. Early detection systems based on diffusion property monitoring can reduce these costs by enabling less extensive suppression requirements while maintaining safety standards.

Consumer confidence represents another critical economic factor. Markets experiencing high-profile thermal runaway incidents typically show a 5-15% temporary reduction in sales, with recovery periods extending from 6-18 months depending on response effectiveness. Manufacturers implementing advanced diffusion monitoring systems report 22% higher consumer confidence ratings and corresponding market share advantages.

In transportation sectors, particularly electric vehicles and aviation, thermal runaway prevention delivers exceptional return on investment. Each percentage point improvement in battery safety correlates to approximately $1.2 billion in avoided costs across the global transportation industry annually. Companies pioneering diffusion-based early warning systems have secured premium positioning, commanding 8-12% price premiums while establishing valuable intellectual property portfolios.

The insurance industry has begun developing specialized products offering reduced premiums for systems incorporating diffusion property monitoring, creating a financial incentive structure that accelerates adoption of these technologies. Economic modeling suggests that widespread implementation of advanced diffusion monitoring could reduce the global economic impact of battery thermal events by 60-75%, representing annual savings of $4.2-5.8 billion across sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!