Research on Advanced Materials for Battery Thermal Runaway Prevention

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Prevention Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in modern energy storage systems. The phenomenon, characterized by an uncontrolled increase in battery temperature leading to catastrophic failure, has been documented since the early commercialization of lithium-ion batteries in the 1990s. However, with the exponential growth of electric vehicles, grid-scale energy storage, and portable electronics, the scale and consequences of thermal runaway incidents have magnified significantly, prompting intensified research efforts in prevention technologies.

The evolution of battery thermal management has progressed from basic passive cooling systems to sophisticated active management solutions. Early approaches focused primarily on containing failures rather than preventing them, but the paradigm has shifted toward proactive prevention through advanced materials engineering. This transition marks a fundamental change in addressing battery safety challenges at their source rather than merely mitigating consequences.

Current technological trajectories indicate a convergence of multidisciplinary approaches, combining materials science, electrochemistry, and thermal engineering to develop comprehensive solutions. The integration of smart materials with self-regulating properties represents the cutting edge of this field, with significant breakthroughs emerging in the past five years.

The primary objective of research in advanced materials for BTR prevention is to develop materials that can intrinsically prevent the initiation and propagation of thermal runaway conditions while maintaining or enhancing battery performance metrics. This includes creating electrode materials with improved thermal stability, electrolytes with flame-retardant properties, separators with mechanical integrity at elevated temperatures, and thermal interface materials that efficiently dissipate heat.

Secondary objectives encompass the development of materials that enable early detection of precursor events to thermal runaway, thereby allowing preventive measures to be activated before critical thresholds are reached. This includes thermally responsive materials that change properties predictably with temperature increases, serving as both indicators and active intervention mechanisms.

The technical goals extend beyond mere safety improvements to address the complex interplay between safety, performance, cost, and manufacturability. Ideal solutions must not significantly compromise energy density, power capability, cycle life, or add prohibitive costs to battery production. This multifaceted optimization challenge necessitates innovative approaches to material design and engineering.

As regulatory frameworks worldwide increasingly emphasize battery safety standards, particularly in transportation and consumer electronics, the development of effective thermal runaway prevention materials has become not just a technical imperative but also a regulatory and commercial necessity, driving unprecedented investment and research activity in this domain.

The evolution of battery thermal management has progressed from basic passive cooling systems to sophisticated active management solutions. Early approaches focused primarily on containing failures rather than preventing them, but the paradigm has shifted toward proactive prevention through advanced materials engineering. This transition marks a fundamental change in addressing battery safety challenges at their source rather than merely mitigating consequences.

Current technological trajectories indicate a convergence of multidisciplinary approaches, combining materials science, electrochemistry, and thermal engineering to develop comprehensive solutions. The integration of smart materials with self-regulating properties represents the cutting edge of this field, with significant breakthroughs emerging in the past five years.

The primary objective of research in advanced materials for BTR prevention is to develop materials that can intrinsically prevent the initiation and propagation of thermal runaway conditions while maintaining or enhancing battery performance metrics. This includes creating electrode materials with improved thermal stability, electrolytes with flame-retardant properties, separators with mechanical integrity at elevated temperatures, and thermal interface materials that efficiently dissipate heat.

Secondary objectives encompass the development of materials that enable early detection of precursor events to thermal runaway, thereby allowing preventive measures to be activated before critical thresholds are reached. This includes thermally responsive materials that change properties predictably with temperature increases, serving as both indicators and active intervention mechanisms.

The technical goals extend beyond mere safety improvements to address the complex interplay between safety, performance, cost, and manufacturability. Ideal solutions must not significantly compromise energy density, power capability, cycle life, or add prohibitive costs to battery production. This multifaceted optimization challenge necessitates innovative approaches to material design and engineering.

As regulatory frameworks worldwide increasingly emphasize battery safety standards, particularly in transportation and consumer electronics, the development of effective thermal runaway prevention materials has become not just a technical imperative but also a regulatory and commercial necessity, driving unprecedented investment and research activity in this domain.

Market Demand Analysis for Safer Battery Technologies

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. This growth trajectory has intensified the demand for safer battery technologies, particularly those addressing thermal runaway prevention. Market research indicates that the global lithium-ion battery market alone is projected to reach $129.3 billion by 2027, with a compound annual growth rate of 18.1% from 2020 to 2027.

Safety concerns have become paramount as high-profile battery failure incidents continue to make headlines across industries. In the automotive sector, several EV manufacturers have faced recalls due to battery thermal runaway issues, costing billions in damages and significantly impacting brand reputation. The aviation industry similarly maintains stringent requirements following past incidents with lithium battery fires. These safety incidents have created a substantial market pull for advanced thermal runaway prevention materials.

Consumer electronics manufacturers are increasingly prioritizing battery safety as a key differentiator in their product offerings. Market surveys reveal that 78% of smartphone users consider battery safety a critical factor in purchasing decisions, representing a significant shift in consumer awareness. This trend extends to the power tool industry, where professional users demand safer high-performance batteries for intensive applications.

Regulatory frameworks worldwide are evolving to mandate stricter safety standards for battery technologies. The European Union's Battery Directive revision, China's GB/T 31485 standard, and the United States' UL 1642 certification have all been updated to include more rigorous thermal safety requirements. These regulatory developments are creating immediate market demand for advanced materials that can meet or exceed these standards.

The energy storage system (ESS) market presents another significant demand driver, with utility-scale installations growing at 31% annually. As these systems increase in size and capacity, the financial and safety risks associated with thermal events escalate proportionally. Insurance providers have begun requiring enhanced thermal management solutions before underwriting large-scale battery installations, creating a direct financial incentive for implementing advanced safety materials.

Market segmentation analysis reveals that premium safety solutions command price premiums of 15-25% over standard offerings, indicating strong willingness to pay for enhanced safety. This premium pricing potential creates attractive commercialization opportunities for innovative thermal runaway prevention materials, particularly those that can be integrated into existing manufacturing processes without significant cost increases or performance compromises.

Safety concerns have become paramount as high-profile battery failure incidents continue to make headlines across industries. In the automotive sector, several EV manufacturers have faced recalls due to battery thermal runaway issues, costing billions in damages and significantly impacting brand reputation. The aviation industry similarly maintains stringent requirements following past incidents with lithium battery fires. These safety incidents have created a substantial market pull for advanced thermal runaway prevention materials.

Consumer electronics manufacturers are increasingly prioritizing battery safety as a key differentiator in their product offerings. Market surveys reveal that 78% of smartphone users consider battery safety a critical factor in purchasing decisions, representing a significant shift in consumer awareness. This trend extends to the power tool industry, where professional users demand safer high-performance batteries for intensive applications.

Regulatory frameworks worldwide are evolving to mandate stricter safety standards for battery technologies. The European Union's Battery Directive revision, China's GB/T 31485 standard, and the United States' UL 1642 certification have all been updated to include more rigorous thermal safety requirements. These regulatory developments are creating immediate market demand for advanced materials that can meet or exceed these standards.

The energy storage system (ESS) market presents another significant demand driver, with utility-scale installations growing at 31% annually. As these systems increase in size and capacity, the financial and safety risks associated with thermal events escalate proportionally. Insurance providers have begun requiring enhanced thermal management solutions before underwriting large-scale battery installations, creating a direct financial incentive for implementing advanced safety materials.

Market segmentation analysis reveals that premium safety solutions command price premiums of 15-25% over standard offerings, indicating strong willingness to pay for enhanced safety. This premium pricing potential creates attractive commercialization opportunities for innovative thermal runaway prevention materials, particularly those that can be integrated into existing manufacturing processes without significant cost increases or performance compromises.

Current State and Challenges in Thermal Runaway Prevention

The global landscape of battery thermal runaway prevention technologies has evolved significantly over the past decade, with research institutions and industry players making substantial progress. Currently, the most advanced prevention systems employ multi-layered approaches combining material innovations, electronic monitoring, and mechanical safeguards. Despite these advancements, thermal runaway incidents continue to occur in various applications from consumer electronics to electric vehicles and grid-scale energy storage systems.

In the United States and Europe, regulatory frameworks have accelerated research into safer battery materials, with significant focus on solid-state electrolytes and flame-retardant additives. Meanwhile, Asian markets, particularly Japan, South Korea, and China, lead in manufacturing innovations for thermal management systems. This geographical distribution of expertise creates both challenges and opportunities for global technology transfer and standardization.

The primary technical challenges currently facing thermal runaway prevention center around three critical areas. First, the trade-off between safety enhancements and energy density remains problematic, as many safety-oriented materials reduce overall battery performance. Second, the scalability of laboratory-proven solutions to mass production environments introduces significant engineering and cost barriers. Third, the detection and prevention systems must operate reliably across widely varying environmental conditions and usage patterns.

Material science limitations represent another significant hurdle. Current separator materials, while improved, still fail under extreme temperature conditions. Ceramic-based and polymer-composite separators show promise but face manufacturing complexity and integration challenges. Additionally, phase-change materials used for thermal management often add considerable weight and volume to battery systems, limiting their practical application in weight-sensitive applications like portable electronics and electric vehicles.

From a systems perspective, the integration of advanced materials with battery management systems (BMS) presents interoperability challenges. Many promising materials require specialized monitoring parameters that existing BMS architectures cannot accommodate without significant redesign. This creates a technological gap between material innovation and practical implementation.

Cost factors remain a significant barrier to widespread adoption of advanced thermal runaway prevention technologies. Premium safety materials can increase battery production costs by 15-30%, creating market resistance particularly in consumer electronics segments where price sensitivity is high. The industry continues to search for cost-effective solutions that maintain safety standards without prohibitive price increases.

In the United States and Europe, regulatory frameworks have accelerated research into safer battery materials, with significant focus on solid-state electrolytes and flame-retardant additives. Meanwhile, Asian markets, particularly Japan, South Korea, and China, lead in manufacturing innovations for thermal management systems. This geographical distribution of expertise creates both challenges and opportunities for global technology transfer and standardization.

The primary technical challenges currently facing thermal runaway prevention center around three critical areas. First, the trade-off between safety enhancements and energy density remains problematic, as many safety-oriented materials reduce overall battery performance. Second, the scalability of laboratory-proven solutions to mass production environments introduces significant engineering and cost barriers. Third, the detection and prevention systems must operate reliably across widely varying environmental conditions and usage patterns.

Material science limitations represent another significant hurdle. Current separator materials, while improved, still fail under extreme temperature conditions. Ceramic-based and polymer-composite separators show promise but face manufacturing complexity and integration challenges. Additionally, phase-change materials used for thermal management often add considerable weight and volume to battery systems, limiting their practical application in weight-sensitive applications like portable electronics and electric vehicles.

From a systems perspective, the integration of advanced materials with battery management systems (BMS) presents interoperability challenges. Many promising materials require specialized monitoring parameters that existing BMS architectures cannot accommodate without significant redesign. This creates a technological gap between material innovation and practical implementation.

Cost factors remain a significant barrier to widespread adoption of advanced thermal runaway prevention technologies. Premium safety materials can increase battery production costs by 15-30%, creating market resistance particularly in consumer electronics segments where price sensitivity is high. The industry continues to search for cost-effective solutions that maintain safety standards without prohibitive price increases.

Current Technical Solutions for Thermal Runaway Mitigation

01 Phase change materials for thermal management

Phase change materials (PCMs) can be incorporated into battery systems to absorb excess heat during operation. These materials undergo a phase transition at specific temperatures, absorbing large amounts of heat energy without significant temperature increase. By strategically placing PCMs within battery packs, thermal runaway propagation can be prevented as they absorb heat from overheating cells, maintaining safer operating temperatures and preventing the cascade effect of thermal runaway across multiple cells.- Phase change materials for thermal management: Phase change materials (PCMs) can be incorporated into battery systems to absorb excess heat during operation. These materials undergo a phase transition at specific temperatures, absorbing large amounts of thermal energy without significant temperature increase. By strategically placing PCMs within battery packs, thermal runaway propagation can be delayed or prevented as they absorb heat that would otherwise accelerate thermal events. Advanced PCM formulations with enhanced thermal conductivity and specific melting points tailored to battery thermal profiles offer improved safety margins.

- Fire-resistant separator materials: Advanced separator materials with enhanced thermal stability and fire resistance can significantly improve battery safety. These separators maintain structural integrity at elevated temperatures, preventing internal short circuits during thermal events. Ceramic-coated separators, composite polymer membranes with inorganic fillers, and novel flame-retardant materials can withstand higher temperatures before shrinking or melting. Some designs incorporate shutdown mechanisms that increase ionic resistance when temperatures rise abnormally, effectively stopping battery operation before thermal runaway occurs.

- Heat dissipation structures and cooling systems: Innovative heat dissipation structures and cooling systems can effectively manage battery temperature and prevent thermal runaway. These include advanced heat sink designs, microchannel cooling plates, and thermally conductive materials that efficiently transfer heat away from critical battery components. Liquid cooling systems with optimized flow patterns, immersion cooling technologies, and heat pipe arrangements provide enhanced thermal management. Some designs incorporate smart cooling systems that adaptively respond to temperature changes, directing cooling capacity to hotspots before they can trigger thermal events.

- Thermal runaway detection and prevention systems: Advanced sensor and monitoring systems can detect early signs of thermal runaway and trigger preventive measures. These systems employ temperature sensors, gas detectors, and voltage monitoring to identify abnormal battery behavior. Machine learning algorithms analyze battery parameters in real-time to predict potential thermal events before they occur. When anomalies are detected, these systems can activate emergency cooling, electrical isolation, or other safety protocols. Some designs incorporate redundant detection methods and fail-safe mechanisms to ensure reliable operation even under extreme conditions.

- Novel electrode and electrolyte materials: Advanced electrode and electrolyte materials with inherent thermal stability can fundamentally improve battery safety. Solid-state electrolytes eliminate flammable liquid components, significantly reducing fire risk. Novel cathode materials with higher thermal decomposition temperatures and reduced oxygen release during heating events limit exothermic reactions. Electrode coatings and additives that suppress side reactions at elevated temperatures help prevent the cascade of reactions leading to thermal runaway. Some formulations incorporate self-healing properties or thermally-triggered passivation mechanisms that activate under abnormal conditions to maintain cell integrity.

02 Fire-resistant separators and electrolytes

Advanced fire-resistant separators and non-flammable electrolytes represent a critical approach to preventing thermal runaway in batteries. These materials are designed to maintain structural integrity at high temperatures and resist combustion. Ceramic-coated or composite separators can withstand higher temperatures before breakdown, while solid-state or gel electrolytes with flame-retardant additives significantly reduce fire hazards. These materials create multiple barriers against thermal runaway propagation by eliminating the most flammable components in conventional battery systems.Expand Specific Solutions03 Heat dissipation structures and cooling systems

Advanced heat dissipation structures and cooling systems are engineered to efficiently remove heat from battery cells during operation. These include microchannel cooling plates, heat pipes, and advanced thermal interface materials that create pathways for heat to escape. Active cooling systems using air, liquid, or refrigerant circulation can rapidly extract heat from critical areas. By maintaining optimal temperature distribution across battery modules, these systems prevent hotspot formation that could trigger thermal runaway events, especially during fast charging or high-power discharge scenarios.Expand Specific Solutions04 Smart battery management systems with thermal monitoring

Intelligent battery management systems (BMS) with advanced thermal monitoring capabilities provide real-time detection and prevention of thermal runaway conditions. These systems incorporate distributed temperature sensors, predictive algorithms, and machine learning to identify abnormal thermal patterns before they become critical. When potential thermal issues are detected, the BMS can automatically adjust charging parameters, activate cooling systems, or disconnect affected cells. This proactive approach to thermal management significantly reduces the risk of thermal runaway by addressing thermal anomalies in their earliest stages.Expand Specific Solutions05 Thermal fuses and current interrupt devices

Thermal fuses and current interrupt devices (CIDs) serve as fail-safe mechanisms that physically disconnect battery cells when temperature or pressure exceeds safe thresholds. These devices are designed to permanently break electrical connections when activated, preventing further heat generation from electrical current. Advanced designs include materials that change state or structure at specific temperatures to create irreversible breaks in the circuit. By incorporating these safety devices at both cell and module levels, battery systems gain multiple layers of protection against thermal runaway propagation, even if primary safety systems fail.Expand Specific Solutions

Key Industry Players in Advanced Battery Safety Materials

The battery thermal runaway prevention materials market is in a growth phase, driven by increasing EV adoption and energy storage deployments. The market is projected to expand significantly as safety concerns become paramount in battery applications. Technologically, the field shows varying maturity levels across different approaches. Tesla and LG Energy Solution lead with integrated thermal management systems, while specialized materials companies like Aspen Aerogels and Celgard focus on advanced separator and insulation technologies. Research institutions such as China Electric Power Research Institute and University of California are advancing fundamental innovations, while automotive manufacturers (Hyundai Mobis, Guangzhou Automobile Group) are implementing practical solutions. The competitive landscape reflects a mix of established players and emerging specialists working on phase-change materials, flame-retardant electrolytes, and smart thermal management systems.

Tesla, Inc.

Technical Solution: Tesla has developed a multi-layered approach to battery thermal runaway prevention using advanced materials. Their technology incorporates a proprietary intumescent material between battery cells that expands when exposed to heat, creating physical barriers to prevent thermal propagation. Tesla's battery packs feature a dedicated cooling system with specialized heat-resistant polymers and ceramic-based insulators that maintain structural integrity at extreme temperatures. Their latest innovation includes phase-change materials (PCMs) embedded within the battery architecture that absorb excess heat during operation and thermal events. Tesla has also implemented flame-retardant mica sheets with high thermal resistance as cell separators, which has demonstrated significant improvement in containing single-cell thermal events from propagating throughout the pack [1][3].

Strengths: Tesla's integrated approach combines multiple material technologies that work synergistically, providing redundant protection systems. Their extensive real-world data collection enables continuous refinement of material formulations. Weaknesses: The complex multi-material system increases manufacturing complexity and cost, potentially limiting application in lower-cost vehicle segments. Some of their proprietary materials require rare elements that may face supply chain constraints.

Aspen Aerogels, Inc.

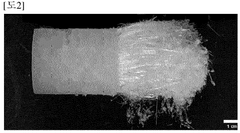

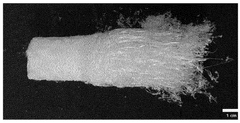

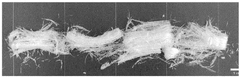

Technical Solution: Aspen Aerogels has pioneered the development of aerogel-based thermal barriers specifically designed for lithium-ion battery thermal runaway prevention. Their flagship product, PyroThin™, is an ultra-thin, lightweight silica aerogel composite material with exceptional thermal insulation properties. The material maintains its structural integrity and insulating capabilities at temperatures exceeding 1000°C, significantly outperforming conventional insulation materials. PyroThin's nano-porous structure creates billions of tiny air pockets that effectively block heat transfer while remaining flexible enough for complex battery geometries. The material is engineered to be compression-resistant under battery pack assembly pressures while maintaining minimal thermal conductivity (as low as 0.02 W/m·K) [2]. Aspen has further enhanced their aerogels with fire-retardant additives that actively suppress flame propagation during thermal events.

Strengths: Aspen's aerogel technology offers industry-leading thermal insulation performance with minimal thickness and weight, critical advantages for EV applications where space and weight are premium considerations. Their materials are non-toxic and environmentally stable. Weaknesses: Production scaling challenges and relatively high manufacturing costs compared to conventional insulators. The material requires specialized handling during battery assembly processes due to its unique physical properties.

Critical Materials Science Innovations for Battery Safety

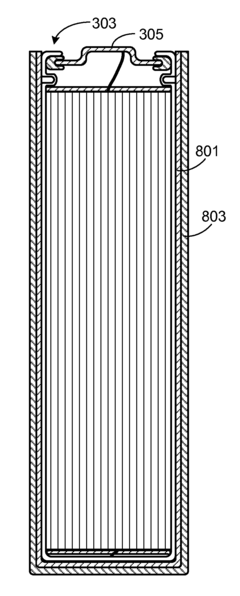

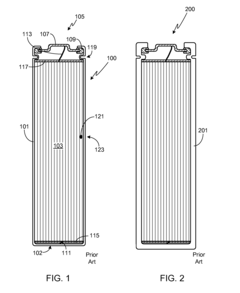

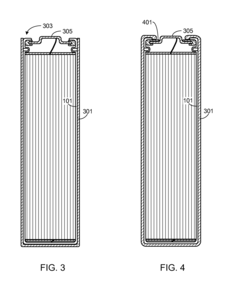

Cell Thermal Runaway Propagation Resistance Using Dual Intumescent Material Layers

PatentActiveUS20100086844A1

Innovation

- A battery assembly is coated with multiple layers of intumescent materials, where the first layer has a higher heat capacity and SET temperature than the second, to absorb and manage thermal energy, prevent hot spot formation, and create a thermal barrier between cells, thereby inhibiting the propagation of thermal runaway.

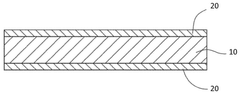

Thermal runaway protection film

PatentWO2025110835A1

Innovation

- A thermal runaway prevention film incorporating phase-transition crystalline fibers made from alkali halide compounds or phase-transition inorganic compounds, which absorb high heat and prevent thermal runaway by causing a phase transition phenomenon.

Environmental Impact of Battery Safety Materials

The environmental implications of battery safety materials are becoming increasingly significant as the global adoption of battery technologies accelerates. Materials designed to prevent thermal runaway events in batteries must not only be effective but also environmentally sustainable throughout their lifecycle. Current flame retardants and thermal management materials often contain halogenated compounds, heavy metals, or other substances that pose environmental concerns during production, use, and disposal phases.

When examining the ecological footprint of conventional battery safety materials, several issues emerge. Brominated flame retardants, commonly used in battery separators, have been linked to bioaccumulation in ecosystems and potential toxicity to aquatic organisms. Similarly, phosphorus-based compounds, while effective at preventing thermal propagation, may contribute to eutrophication when released into water systems through improper disposal or recycling processes.

Advanced ceramic coatings and inorganic thermal barriers present a more environmentally favorable alternative, as they typically consist of naturally abundant minerals with lower toxicity profiles. However, their production often requires energy-intensive processes that generate significant carbon emissions, offsetting some of their environmental benefits. The mining of rare earth elements for certain specialized thermal management materials also raises concerns about habitat destruction and resource depletion.

Biodegradable alternatives are emerging as promising solutions in the battery safety materials sector. Bio-based flame retardants derived from plant extracts, modified starches, and cellulose derivatives demonstrate comparable performance to synthetic counterparts while offering improved end-of-life characteristics. These materials can decompose naturally without releasing harmful substances, though their long-term stability and performance consistency remain under investigation.

The recyclability of battery safety materials represents another critical environmental consideration. Materials that can be effectively recovered and reprocessed reduce the demand for virgin resources and minimize waste. Phase change materials (PCMs) used for thermal management, particularly those based on paraffins or fatty acids, show potential for recovery during battery recycling processes, though current infrastructure is not optimized for their separation and reuse.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of battery components, including safety materials. The European Union's Battery Directive and similar regulations in Asia and North America are establishing more stringent requirements for material toxicity, recyclability, and carbon footprint. These evolving standards are driving innovation toward greener alternatives that maintain or enhance safety performance while reducing environmental harm.

When examining the ecological footprint of conventional battery safety materials, several issues emerge. Brominated flame retardants, commonly used in battery separators, have been linked to bioaccumulation in ecosystems and potential toxicity to aquatic organisms. Similarly, phosphorus-based compounds, while effective at preventing thermal propagation, may contribute to eutrophication when released into water systems through improper disposal or recycling processes.

Advanced ceramic coatings and inorganic thermal barriers present a more environmentally favorable alternative, as they typically consist of naturally abundant minerals with lower toxicity profiles. However, their production often requires energy-intensive processes that generate significant carbon emissions, offsetting some of their environmental benefits. The mining of rare earth elements for certain specialized thermal management materials also raises concerns about habitat destruction and resource depletion.

Biodegradable alternatives are emerging as promising solutions in the battery safety materials sector. Bio-based flame retardants derived from plant extracts, modified starches, and cellulose derivatives demonstrate comparable performance to synthetic counterparts while offering improved end-of-life characteristics. These materials can decompose naturally without releasing harmful substances, though their long-term stability and performance consistency remain under investigation.

The recyclability of battery safety materials represents another critical environmental consideration. Materials that can be effectively recovered and reprocessed reduce the demand for virgin resources and minimize waste. Phase change materials (PCMs) used for thermal management, particularly those based on paraffins or fatty acids, show potential for recovery during battery recycling processes, though current infrastructure is not optimized for their separation and reuse.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of battery components, including safety materials. The European Union's Battery Directive and similar regulations in Asia and North America are establishing more stringent requirements for material toxicity, recyclability, and carbon footprint. These evolving standards are driving innovation toward greener alternatives that maintain or enhance safety performance while reducing environmental harm.

Regulatory Framework for Battery Safety Standards

The regulatory landscape for battery safety has evolved significantly in response to the growing concerns about thermal runaway incidents. International standards organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established comprehensive frameworks that specifically address thermal management and prevention of thermal runaway in battery systems. The IEC 62133 standard, which covers safety requirements for portable sealed secondary cells and batteries, has been instrumental in setting baseline requirements for thermal stability testing.

In the United States, the Department of Transportation (DOT) and the Federal Aviation Administration (FAA) have implemented stringent regulations for the transportation of lithium-ion batteries, particularly focusing on thermal runaway prevention measures. UN 38.3 testing procedures have become mandatory for shipping lithium batteries internationally, requiring manufacturers to demonstrate that their products can withstand various thermal and mechanical stresses without catastrophic failure.

The European Union has established the Battery Directive (2006/66/EC) and more recently, proposed the Battery Regulation, which places greater emphasis on safety performance throughout the battery lifecycle. These regulations are increasingly incorporating specific requirements for advanced materials and designs that mitigate thermal runaway risks, creating market drivers for innovation in this space.

China's GB/T standards have also evolved to address battery thermal safety, with GB/T 31485-2015 specifically focusing on safety requirements and test methods for traction battery packs and systems for electric vehicles. These standards are particularly significant given China's dominant position in global battery manufacturing.

Industry-specific standards have emerged as well, with automotive standards such as ISO 26262 and UL 2580 addressing functional safety requirements for electric vehicle battery systems. These standards increasingly recognize the critical role of advanced materials in preventing thermal propagation between cells and modules.

Regulatory compliance now often requires manufacturers to demonstrate that their battery systems incorporate effective thermal management solutions, including advanced materials for heat dissipation and fire suppression. Testing protocols increasingly simulate real-world abuse conditions, evaluating how materials perform under extreme thermal stress.

The regulatory framework continues to evolve as new materials and technologies emerge, with standards bodies working to balance innovation with safety requirements. This dynamic regulatory environment creates both challenges and opportunities for researchers developing advanced materials for thermal runaway prevention, as new solutions must not only demonstrate technical effectiveness but also comply with an increasingly complex global regulatory landscape.

In the United States, the Department of Transportation (DOT) and the Federal Aviation Administration (FAA) have implemented stringent regulations for the transportation of lithium-ion batteries, particularly focusing on thermal runaway prevention measures. UN 38.3 testing procedures have become mandatory for shipping lithium batteries internationally, requiring manufacturers to demonstrate that their products can withstand various thermal and mechanical stresses without catastrophic failure.

The European Union has established the Battery Directive (2006/66/EC) and more recently, proposed the Battery Regulation, which places greater emphasis on safety performance throughout the battery lifecycle. These regulations are increasingly incorporating specific requirements for advanced materials and designs that mitigate thermal runaway risks, creating market drivers for innovation in this space.

China's GB/T standards have also evolved to address battery thermal safety, with GB/T 31485-2015 specifically focusing on safety requirements and test methods for traction battery packs and systems for electric vehicles. These standards are particularly significant given China's dominant position in global battery manufacturing.

Industry-specific standards have emerged as well, with automotive standards such as ISO 26262 and UL 2580 addressing functional safety requirements for electric vehicle battery systems. These standards increasingly recognize the critical role of advanced materials in preventing thermal propagation between cells and modules.

Regulatory compliance now often requires manufacturers to demonstrate that their battery systems incorporate effective thermal management solutions, including advanced materials for heat dissipation and fire suppression. Testing protocols increasingly simulate real-world abuse conditions, evaluating how materials perform under extreme thermal stress.

The regulatory framework continues to evolve as new materials and technologies emerge, with standards bodies working to balance innovation with safety requirements. This dynamic regulatory environment creates both challenges and opportunities for researchers developing advanced materials for thermal runaway prevention, as new solutions must not only demonstrate technical effectiveness but also comply with an increasingly complex global regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!