What Thermodynamic Factors Lead to Battery Thermal Runaway

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway represents one of the most critical safety challenges in the energy storage industry. This phenomenon has evolved from a niche technical concern to a mainstream safety issue as lithium-ion batteries have proliferated across consumer electronics, electric vehicles, and grid-scale energy storage systems over the past three decades. The thermodynamic principles underlying thermal runaway have been studied since the 1990s, but understanding has accelerated dramatically in the past decade due to high-profile battery failures in consumer products and electric vehicles.

The evolution of battery technology has consistently pushed toward higher energy densities, faster charging capabilities, and reduced costs, often prioritizing performance over safety margins. This trend has inadvertently increased the thermodynamic instability potential within battery systems, particularly as manufacturers adopt new chemistries with higher specific energies such as lithium-nickel-manganese-cobalt oxide (NMC) and lithium-nickel-cobalt-aluminum oxide (NCA).

Historically, thermal runaway incidents have served as critical inflection points in battery technology development. The 2006 Sony laptop battery recalls, 2013 Boeing 787 Dreamliner battery fires, and more recent electric vehicle spontaneous combustion events have each prompted significant research investment and regulatory attention. These incidents highlight the persistent gap between theoretical understanding of battery thermodynamics and practical safety engineering in commercial applications.

The primary technical objective of thermal runaway research is to develop comprehensive models that can accurately predict the onset conditions and progression dynamics of thermal instability across different battery chemistries, form factors, and operating conditions. This includes understanding the complex interplay between chemical kinetics, heat transfer mechanisms, and material phase transitions that occur during thermal excursions.

Secondary objectives include establishing standardized testing protocols that can reliably reproduce thermal runaway conditions in laboratory settings, developing early detection systems based on thermodynamic precursors, and creating advanced thermal management strategies that can effectively prevent or mitigate runaway events. The ultimate goal is to establish design principles that inherently limit the thermodynamic potential for runaway while maintaining high energy density and performance.

Recent advances in computational modeling, in-situ diagnostic techniques, and calorimetry methods have significantly enhanced our ability to characterize the thermodynamic pathways leading to thermal runaway. However, substantial challenges remain in translating this understanding into practical safety improvements for commercial battery systems, particularly as the industry continues to push the boundaries of energy density and fast-charging capabilities.

The evolution of battery technology has consistently pushed toward higher energy densities, faster charging capabilities, and reduced costs, often prioritizing performance over safety margins. This trend has inadvertently increased the thermodynamic instability potential within battery systems, particularly as manufacturers adopt new chemistries with higher specific energies such as lithium-nickel-manganese-cobalt oxide (NMC) and lithium-nickel-cobalt-aluminum oxide (NCA).

Historically, thermal runaway incidents have served as critical inflection points in battery technology development. The 2006 Sony laptop battery recalls, 2013 Boeing 787 Dreamliner battery fires, and more recent electric vehicle spontaneous combustion events have each prompted significant research investment and regulatory attention. These incidents highlight the persistent gap between theoretical understanding of battery thermodynamics and practical safety engineering in commercial applications.

The primary technical objective of thermal runaway research is to develop comprehensive models that can accurately predict the onset conditions and progression dynamics of thermal instability across different battery chemistries, form factors, and operating conditions. This includes understanding the complex interplay between chemical kinetics, heat transfer mechanisms, and material phase transitions that occur during thermal excursions.

Secondary objectives include establishing standardized testing protocols that can reliably reproduce thermal runaway conditions in laboratory settings, developing early detection systems based on thermodynamic precursors, and creating advanced thermal management strategies that can effectively prevent or mitigate runaway events. The ultimate goal is to establish design principles that inherently limit the thermodynamic potential for runaway while maintaining high energy density and performance.

Recent advances in computational modeling, in-situ diagnostic techniques, and calorimetry methods have significantly enhanced our ability to characterize the thermodynamic pathways leading to thermal runaway. However, substantial challenges remain in translating this understanding into practical safety improvements for commercial battery systems, particularly as the industry continues to push the boundaries of energy density and fast-charging capabilities.

Market Analysis of Battery Safety Demands

The global battery safety market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and energy storage systems. Current market valuations indicate that the battery safety solutions sector is expected to reach $25 billion by 2030, with a compound annual growth rate of approximately 18% from 2023 to 2030. This growth trajectory reflects the increasing awareness and regulatory focus on battery thermal management and safety systems.

Consumer demand for battery safety features has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This represents a significant shift in consumer priorities compared to just five years ago when performance metrics dominated purchase considerations.

Regulatory frameworks worldwide are evolving rapidly to address battery thermal runaway concerns. The United Nations Global Technical Regulation No. 20 (GTR 20) has established stringent safety requirements for electric vehicle batteries, while the International Electrotechnical Commission (IEC) continues to update standards such as IEC 62133 for portable batteries. These regulations are becoming increasingly stringent, with thermal management requirements becoming more specific and comprehensive.

The automotive sector represents the largest market segment for battery safety solutions, accounting for approximately 65% of the total market value. This dominance is expected to continue as EV adoption accelerates globally. Consumer electronics follows at 20%, with grid-scale energy storage systems representing the fastest-growing segment at a 25% annual growth rate.

Geographically, Asia-Pacific leads the market demand with China, Japan, and South Korea collectively accounting for 45% of global battery safety solution implementations. North America and Europe follow closely, with particularly strong growth in regions with aggressive EV adoption targets and stringent safety regulations.

Insurance companies have emerged as significant market drivers, with many now offering premium reductions of up to 15% for vehicles and systems incorporating advanced thermal runaway prevention technologies. This financial incentive is creating additional market pull for sophisticated battery safety solutions across multiple industries.

The market is increasingly segmenting between preventative solutions (thermal management systems, advanced BMS) and containment solutions (fire suppression, thermal barriers), with preventative technologies commanding higher margins and experiencing faster growth due to their ability to address thermal runaway before it occurs rather than merely containing its effects.

Consumer demand for battery safety features has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This represents a significant shift in consumer priorities compared to just five years ago when performance metrics dominated purchase considerations.

Regulatory frameworks worldwide are evolving rapidly to address battery thermal runaway concerns. The United Nations Global Technical Regulation No. 20 (GTR 20) has established stringent safety requirements for electric vehicle batteries, while the International Electrotechnical Commission (IEC) continues to update standards such as IEC 62133 for portable batteries. These regulations are becoming increasingly stringent, with thermal management requirements becoming more specific and comprehensive.

The automotive sector represents the largest market segment for battery safety solutions, accounting for approximately 65% of the total market value. This dominance is expected to continue as EV adoption accelerates globally. Consumer electronics follows at 20%, with grid-scale energy storage systems representing the fastest-growing segment at a 25% annual growth rate.

Geographically, Asia-Pacific leads the market demand with China, Japan, and South Korea collectively accounting for 45% of global battery safety solution implementations. North America and Europe follow closely, with particularly strong growth in regions with aggressive EV adoption targets and stringent safety regulations.

Insurance companies have emerged as significant market drivers, with many now offering premium reductions of up to 15% for vehicles and systems incorporating advanced thermal runaway prevention technologies. This financial incentive is creating additional market pull for sophisticated battery safety solutions across multiple industries.

The market is increasingly segmenting between preventative solutions (thermal management systems, advanced BMS) and containment solutions (fire suppression, thermal barriers), with preventative technologies commanding higher margins and experiencing faster growth due to their ability to address thermal runaway before it occurs rather than merely containing its effects.

Current Challenges in Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in battery safety engineering. Current prevention strategies face multiple limitations that hinder their effectiveness across diverse operational conditions. The fundamental challenge lies in the complex interplay between detection systems and mitigation mechanisms, where even milliseconds of delay can lead to catastrophic failure cascades.

Temperature monitoring systems currently deployed in commercial battery packs often suffer from insufficient spatial resolution. Most systems utilize a limited number of sensors that cannot adequately capture temperature gradients across large battery arrays, creating blind spots where thermal anomalies can develop undetected. This challenge is particularly pronounced in electric vehicle applications where cost and weight constraints limit sensor deployment.

Early warning algorithms face significant hurdles in distinguishing between normal thermal fluctuations and precursors to thermal runaway. The thermodynamic signatures preceding runaway events often manifest subtly and can be masked by normal operational variations, especially during high-power charging or discharging cycles. Current predictive models struggle with the non-linear nature of thermal propagation within battery systems.

Material limitations present another substantial barrier to effective prevention. Conventional separator materials typically begin to lose mechanical integrity at temperatures well below the onset of full thermal runaway, creating a narrow intervention window. The development of advanced separator materials with higher thermal stability has been constrained by trade-offs with ionic conductivity and manufacturing scalability.

Heat dissipation systems face efficiency boundaries dictated by fundamental thermodynamic principles. As battery energy densities continue to increase, the challenge of removing heat at sufficient rates becomes more pronounced. Current cooling technologies struggle to maintain uniform temperature distributions in high-density battery packs, creating potential hotspots that can trigger localized thermal events.

The integration of multiple safety systems presents compatibility challenges that often compromise overall effectiveness. Flame-retardant additives may reduce electrolyte flammability but frequently degrade battery performance and longevity. Similarly, physical protection mechanisms like phase-change materials add significant weight and volume, conflicting with the industry drive toward higher energy density.

Standardization of testing protocols represents another significant challenge. Current abuse testing methodologies vary widely across regulatory frameworks, creating inconsistencies in safety validation. The development of universally accepted testing standards that accurately reflect real-world failure modes remains an ongoing challenge for the industry.

Temperature monitoring systems currently deployed in commercial battery packs often suffer from insufficient spatial resolution. Most systems utilize a limited number of sensors that cannot adequately capture temperature gradients across large battery arrays, creating blind spots where thermal anomalies can develop undetected. This challenge is particularly pronounced in electric vehicle applications where cost and weight constraints limit sensor deployment.

Early warning algorithms face significant hurdles in distinguishing between normal thermal fluctuations and precursors to thermal runaway. The thermodynamic signatures preceding runaway events often manifest subtly and can be masked by normal operational variations, especially during high-power charging or discharging cycles. Current predictive models struggle with the non-linear nature of thermal propagation within battery systems.

Material limitations present another substantial barrier to effective prevention. Conventional separator materials typically begin to lose mechanical integrity at temperatures well below the onset of full thermal runaway, creating a narrow intervention window. The development of advanced separator materials with higher thermal stability has been constrained by trade-offs with ionic conductivity and manufacturing scalability.

Heat dissipation systems face efficiency boundaries dictated by fundamental thermodynamic principles. As battery energy densities continue to increase, the challenge of removing heat at sufficient rates becomes more pronounced. Current cooling technologies struggle to maintain uniform temperature distributions in high-density battery packs, creating potential hotspots that can trigger localized thermal events.

The integration of multiple safety systems presents compatibility challenges that often compromise overall effectiveness. Flame-retardant additives may reduce electrolyte flammability but frequently degrade battery performance and longevity. Similarly, physical protection mechanisms like phase-change materials add significant weight and volume, conflicting with the industry drive toward higher energy density.

Standardization of testing protocols represents another significant challenge. Current abuse testing methodologies vary widely across regulatory frameworks, creating inconsistencies in safety validation. The development of universally accepted testing standards that accurately reflect real-world failure modes remains an ongoing challenge for the industry.

Existing Thermal Management Systems and Approaches

01 Thermal management systems for batteries

Various thermal management systems are designed to prevent or mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade effect that leads to thermal runaway.- Thermal management systems for batteries: Various thermal management systems can be implemented to prevent thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that help maintain optimal operating temperatures. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, thereby reducing the risk of thermal runaway events.

- Battery cell design and materials to prevent thermal runaway: Innovative battery cell designs and materials can significantly reduce the risk of thermal runaway. These include specialized electrode materials, separator technologies with thermal shutdown properties, and flame-retardant electrolytes. The use of advanced cathode and anode materials with higher thermal stability, along with structural modifications to battery cells, can help contain thermal events and prevent propagation between cells in a battery pack.

- Detection and early warning systems: Early detection systems for thermal runaway employ various sensors and monitoring technologies to identify precursors to thermal events. These systems monitor parameters such as temperature gradients, gas emissions, voltage fluctuations, and internal pressure changes. Advanced algorithms analyze these parameters to predict potential thermal runaway conditions before they occur, allowing for preventive measures to be taken. Integration with battery management systems enables automated responses to detected anomalies.

- Safety mechanisms and containment strategies: Various safety mechanisms and containment strategies are employed to mitigate the effects of thermal runaway events. These include pressure relief valves, thermal fuses, current interrupt devices, and physical barriers between cells. Specialized battery enclosures with fire-resistant materials can contain flames and prevent propagation to adjacent systems. Some designs incorporate sacrificial elements that safely absorb or redirect thermal energy during failure events.

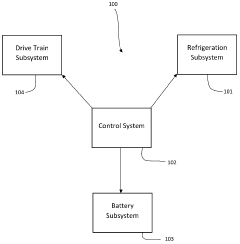

- Battery management systems for thermal runaway prevention: Advanced battery management systems (BMS) play a crucial role in preventing thermal runaway by continuously monitoring and controlling battery operating conditions. These systems regulate charging and discharging rates, balance cell voltages, and implement protective measures when abnormal conditions are detected. Machine learning algorithms enhance BMS capabilities by predicting potential failure modes based on historical data and usage patterns, enabling preemptive interventions to maintain safe operation.

02 Battery cell design and materials for thermal stability

Innovative battery cell designs and materials are developed to enhance thermal stability and reduce the risk of thermal runaway. These include specialized electrode materials, separator technologies with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. The cell architecture may incorporate safety features such as pressure relief mechanisms, current interrupt devices, and thermally resistant components that prevent the propagation of thermal events between cells.Expand Specific Solutions03 Detection and early warning systems

Advanced detection systems are implemented to identify early signs of thermal runaway and provide warnings before catastrophic failure occurs. These systems utilize sensors to monitor parameters such as temperature, voltage, gas emissions, and internal pressure of battery cells. Machine learning algorithms and predictive analytics are employed to process sensor data and identify patterns indicative of impending thermal events, allowing for preventive measures to be taken before a full thermal runaway develops.Expand Specific Solutions04 Battery pack architecture and isolation strategies

Battery pack designs incorporate isolation strategies to prevent thermal runaway propagation between cells. These architectures include physical barriers, thermal fuses, and compartmentalization techniques that contain thermal events within affected cells or modules. Strategic placement of heat-resistant materials, fire-resistant dividers, and thermal breaks within the battery pack structure helps limit the spread of heat and fire, reducing the severity of thermal runaway incidents and protecting adjacent components.Expand Specific Solutions05 Emergency response and containment systems

Emergency response systems are designed to activate when thermal runaway is detected, minimizing damage and safety risks. These systems include automatic shutdown mechanisms, venting systems to release pressure and gases safely, and fire suppression technologies specifically formulated for battery fires. Some solutions incorporate encapsulation materials that activate during thermal events to contain heat and flames, while others feature rapid discharge circuits to safely deplete the battery's energy when critical temperature thresholds are exceeded.Expand Specific Solutions

Leading Battery Manufacturers and Safety Solution Providers

Battery thermal runaway presents a significant challenge in the energy storage landscape, with the market currently in a growth phase driven by EV adoption and renewable energy integration. The global thermal management solutions market is expanding rapidly, expected to reach substantial scale by 2030. Leading companies like Tesla, Samsung SDI, and CATL (Ningde Amperex) are investing heavily in advanced thermal management technologies, while specialized firms such as Aspen Aerogels develop innovative insulation materials. Research institutions like Jilin University and companies including ProLogium are advancing solid-state battery technology to fundamentally address thermal runaway issues. The competitive landscape features both established automotive manufacturers and emerging technology providers working on various approaches from improved cell design to advanced cooling systems and fire suppression technologies.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive thermal management system to prevent battery thermal runaway. Their approach includes multi-layered safety mechanisms with thermal separation technology that physically isolates cells to prevent propagation of thermal events. The company utilizes advanced ceramic-coated separators that maintain structural integrity at high temperatures (up to 180°C) compared to conventional polyolefin separators that shrink at 130°C. Samsung's thermal management system incorporates phase change materials (PCMs) that absorb excess heat during operation, effectively regulating battery temperature. Their Battery Management System (BMS) employs predictive algorithms to detect early signs of thermal abnormalities through continuous monitoring of voltage, current, and temperature parameters across multiple points in the battery pack. Additionally, Samsung has implemented pressure-sensitive current interrupt devices that physically disconnect cells when internal pressure exceeds safety thresholds due to gas generation during thermal events.

Strengths: Samsung's multi-layered approach provides redundant safety mechanisms, significantly reducing single-point failure risks. Their ceramic-coated separators offer superior thermal stability compared to industry standards. Weaknesses: The complex thermal management systems add weight, cost, and manufacturing complexity to battery packs, potentially reducing energy density compared to simpler designs.

Tesla, Inc.

Technical Solution: Tesla has pioneered an integrated approach to mitigating battery thermal runaway through their proprietary thermal management architecture. Their system utilizes a serpentine cooling system with a glycol-based coolant that flows through channels between cells, maintaining optimal temperature distribution across the entire battery pack. Tesla's thermal management strategy incorporates sophisticated cell-to-pack design that minimizes thermal gradients and hotspot formation. Their battery packs feature intumescent materials between cells that expand when exposed to heat, creating physical barriers to prevent thermal propagation between adjacent cells. Tesla's Battery Management System employs machine learning algorithms trained on millions of miles of real-world data to predict and prevent thermal anomalies before they escalate to critical levels. The company has also developed proprietary cell chemistry modifications that increase the thermal runaway onset temperature by approximately 20-30°C compared to standard lithium-ion formulations. Additionally, Tesla implements rapid fuse-triggered isolation of damaged cells, containing thermal events to minimal sections of the battery pack while maintaining overall functionality.

Strengths: Tesla's liquid cooling system provides superior heat dissipation compared to air-cooled alternatives, enabling faster charging rates while maintaining thermal stability. Their data-driven approach to thermal management leverages vast real-world operational data for continuous improvement. Weaknesses: The complex liquid cooling infrastructure adds weight and potential points of failure through coolant leaks or pump malfunctions, requiring additional maintenance considerations.

Critical Thermodynamic Mechanisms Analysis

Lithium-ion battery cooling system

PatentPendingIN202221067889A

Innovation

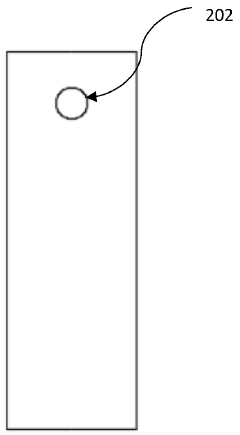

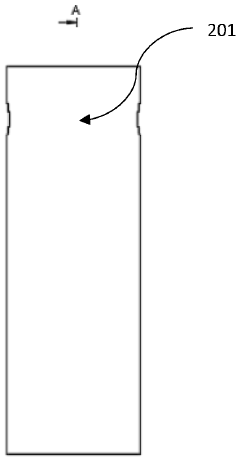

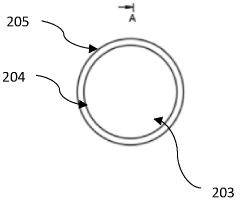

- A cooling manifold assembly with a shell-like cooling jacket made of dissimilar metals, where the inner surface is highly conductive (aluminium or copper) and the outer surface is robust (steel or stainless steel), ensuring uniform cooling and high thermal conductivity, connected in a way that coolant flows through without contacting the cells, and sealed with rubber rings for efficient heat transfer.

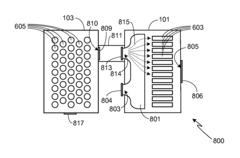

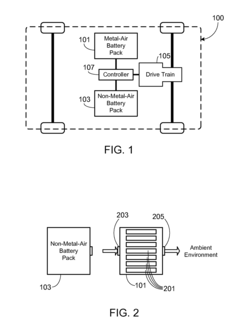

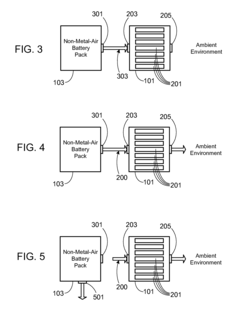

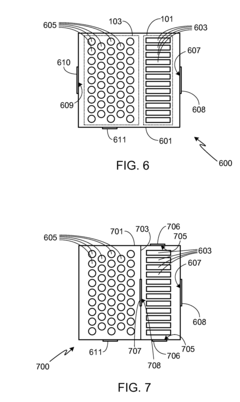

Hazard Mitigation Through Gas Flow Communication Between Battery Packs

PatentActiveUS20120040255A1

Innovation

- A system and method that directs hot gas from a non-metal-air battery pack through metal-air cells, utilizing valves and sensors to control airflow and temperature, thereby absorbing thermal energy and delaying gas release, incorporating a metal-air battery pack with specific air passageways and valves to manage thermal events.

Regulatory Standards for Battery Safety

The regulatory landscape for battery safety has evolved significantly in response to increasing incidents of thermal runaway. International standards such as IEC 62133 and UL 1642 establish comprehensive safety requirements for lithium-ion batteries, including specific thermal stability tests designed to evaluate resistance to thermal runaway conditions. These standards mandate rigorous testing protocols including short circuit, overcharge, forced discharge, and thermal abuse tests to simulate extreme conditions that might trigger thermal events.

The UN Transportation Testing (UN 38.3) specifically addresses the safety concerns related to battery transportation, requiring batteries to undergo altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests before being approved for shipping. This multi-faceted approach ensures batteries can withstand various stressors without experiencing thermal runaway during transit.

Regional regulations add another layer of complexity to battery safety standards. In the United States, the Consumer Product Safety Commission (CPSC) enforces safety standards for consumer products containing batteries, while the Federal Aviation Administration (FAA) has implemented strict regulations regarding the transportation of lithium batteries on aircraft due to thermal runaway concerns. The European Union's Battery Directive (2006/66/EC) and the more recent Regulation 2019/1020 establish safety requirements for batteries marketed within the EU.

Industry-specific standards further refine safety requirements based on application contexts. For electric vehicles, standards such as SAE J2464 and ISO 6469 address battery safety concerns specific to automotive applications, including thermal management requirements designed to prevent propagation of thermal events. For consumer electronics, IEEE 1625 and IEEE 1725 provide guidelines for rechargeable batteries in portable computing and cellular telephone applications respectively.

Emerging regulatory trends are increasingly focusing on battery management systems (BMS) as critical safety components. Standards are evolving to require sophisticated thermal monitoring and management capabilities, with requirements for redundant safety mechanisms and fail-safe designs. Additionally, there is growing emphasis on end-of-life considerations, with regulations beginning to address the potential thermal risks associated with aging batteries and proper disposal protocols to prevent thermal incidents during recycling processes.

The UN Transportation Testing (UN 38.3) specifically addresses the safety concerns related to battery transportation, requiring batteries to undergo altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge tests before being approved for shipping. This multi-faceted approach ensures batteries can withstand various stressors without experiencing thermal runaway during transit.

Regional regulations add another layer of complexity to battery safety standards. In the United States, the Consumer Product Safety Commission (CPSC) enforces safety standards for consumer products containing batteries, while the Federal Aviation Administration (FAA) has implemented strict regulations regarding the transportation of lithium batteries on aircraft due to thermal runaway concerns. The European Union's Battery Directive (2006/66/EC) and the more recent Regulation 2019/1020 establish safety requirements for batteries marketed within the EU.

Industry-specific standards further refine safety requirements based on application contexts. For electric vehicles, standards such as SAE J2464 and ISO 6469 address battery safety concerns specific to automotive applications, including thermal management requirements designed to prevent propagation of thermal events. For consumer electronics, IEEE 1625 and IEEE 1725 provide guidelines for rechargeable batteries in portable computing and cellular telephone applications respectively.

Emerging regulatory trends are increasingly focusing on battery management systems (BMS) as critical safety components. Standards are evolving to require sophisticated thermal monitoring and management capabilities, with requirements for redundant safety mechanisms and fail-safe designs. Additionally, there is growing emphasis on end-of-life considerations, with regulations beginning to address the potential thermal risks associated with aging batteries and proper disposal protocols to prevent thermal incidents during recycling processes.

Environmental Impact of Battery Thermal Events

Battery thermal events pose significant environmental challenges that extend far beyond the immediate safety concerns. When thermal runaway occurs, batteries release a complex mixture of toxic substances including heavy metals (lithium, cobalt, nickel), fluorinated compounds, and volatile organic compounds. These contaminants can persist in soil and water systems for extended periods, potentially entering food chains and causing bioaccumulation in various organisms.

Air pollution resulting from battery fires presents another serious environmental concern. The combustion of battery materials generates particulate matter, carbon monoxide, hydrogen fluoride, and other hazardous air pollutants that can travel considerable distances depending on atmospheric conditions. Studies have documented elevated levels of these pollutants in areas surrounding major battery thermal events, with potential impacts on local air quality lasting days or even weeks.

Water systems are particularly vulnerable to contamination from battery thermal events. Firefighting efforts often involve large quantities of water that, when mixed with battery materials, create toxic runoff. This contaminated water can infiltrate groundwater supplies or flow into surface water bodies, threatening aquatic ecosystems. Research has shown that even small concentrations of lithium and other battery metals can disrupt reproductive cycles and development in aquatic organisms.

The carbon footprint associated with battery thermal events compounds their environmental impact. Beyond the direct emissions from combustion, there are secondary environmental costs related to emergency response, site remediation, and replacement of damaged infrastructure. The premature end-of-life for damaged batteries also represents a significant loss of embodied energy and resources that went into their production.

Waste management challenges emerge in the aftermath of thermal events, as partially damaged batteries require specialized handling procedures. These batteries often cannot be processed through conventional recycling streams, creating additional waste streams that may end up in landfills. The contaminated materials from cleanup operations further contribute to hazardous waste volumes requiring specialized disposal.

Long-term ecosystem effects remain an area of ongoing research, with preliminary studies suggesting potential for chronic environmental impacts in areas affected by major battery thermal events. The combination of persistent pollutants and habitat disruption can alter ecosystem dynamics, potentially reducing biodiversity and ecological resilience in affected areas.

Air pollution resulting from battery fires presents another serious environmental concern. The combustion of battery materials generates particulate matter, carbon monoxide, hydrogen fluoride, and other hazardous air pollutants that can travel considerable distances depending on atmospheric conditions. Studies have documented elevated levels of these pollutants in areas surrounding major battery thermal events, with potential impacts on local air quality lasting days or even weeks.

Water systems are particularly vulnerable to contamination from battery thermal events. Firefighting efforts often involve large quantities of water that, when mixed with battery materials, create toxic runoff. This contaminated water can infiltrate groundwater supplies or flow into surface water bodies, threatening aquatic ecosystems. Research has shown that even small concentrations of lithium and other battery metals can disrupt reproductive cycles and development in aquatic organisms.

The carbon footprint associated with battery thermal events compounds their environmental impact. Beyond the direct emissions from combustion, there are secondary environmental costs related to emergency response, site remediation, and replacement of damaged infrastructure. The premature end-of-life for damaged batteries also represents a significant loss of embodied energy and resources that went into their production.

Waste management challenges emerge in the aftermath of thermal events, as partially damaged batteries require specialized handling procedures. These batteries often cannot be processed through conventional recycling streams, creating additional waste streams that may end up in landfills. The contaminated materials from cleanup operations further contribute to hazardous waste volumes requiring specialized disposal.

Long-term ecosystem effects remain an area of ongoing research, with preliminary studies suggesting potential for chronic environmental impacts in areas affected by major battery thermal events. The combination of persistent pollutants and habitat disruption can alter ecosystem dynamics, potentially reducing biodiversity and ecological resilience in affected areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!