Why Electrochemical Balancing is Key in Battery Thermal Runaway Management

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Electrochemical Balancing Background and Objectives

Electrochemical balancing in battery systems has evolved significantly over the past three decades, transitioning from rudimentary voltage monitoring to sophisticated real-time management systems. This evolution has been driven by the exponential growth in lithium-ion battery applications across industries, from consumer electronics to electric vehicles and grid-scale energy storage. The fundamental challenge that electrochemical balancing addresses is the inherent variability in cell characteristics within battery packs, which, if left unmanaged, can lead to catastrophic thermal events.

The historical development of battery management systems reveals a clear trajectory toward more integrated approaches that consider electrochemical processes as the primary indicators of battery health and safety. Early systems focused primarily on voltage and current parameters, while modern solutions incorporate impedance tracking, entropy measurements, and chemical signature analysis to provide a comprehensive view of battery state.

Research indicates that approximately 68% of thermal runaway incidents in lithium-ion batteries can be traced back to electrochemical imbalances that were detectable hours or even days before the event. This underscores the critical importance of advanced balancing technologies in preventing thermal incidents rather than merely responding to them after they occur.

The primary objective of electrochemical balancing is to maintain all cells within a battery pack at optimal operational parameters, ensuring uniform state-of-charge, temperature distribution, and aging characteristics. This uniformity is essential for preventing localized hotspots, voltage excursions, and the formation of lithium dendrites that often precede thermal runaway events.

Current technological goals in this field include developing predictive algorithms that can identify potential imbalance issues before they manifest as measurable temperature or voltage anomalies. These algorithms increasingly leverage machine learning approaches to recognize subtle patterns in electrochemical signatures that human operators or traditional BMS systems might miss.

Another significant objective is the integration of electrochemical balancing with thermal management systems to create a holistic approach to battery safety. This integration represents a paradigm shift from treating thermal management and cell balancing as separate functions to viewing them as complementary aspects of a unified safety strategy.

The industry is also moving toward standardization of electrochemical balancing protocols, with organizations like IEEE and IEC developing frameworks that define minimum requirements for battery management systems across different applications. These standards aim to establish consistent safety benchmarks while allowing for innovation in implementation approaches.

The historical development of battery management systems reveals a clear trajectory toward more integrated approaches that consider electrochemical processes as the primary indicators of battery health and safety. Early systems focused primarily on voltage and current parameters, while modern solutions incorporate impedance tracking, entropy measurements, and chemical signature analysis to provide a comprehensive view of battery state.

Research indicates that approximately 68% of thermal runaway incidents in lithium-ion batteries can be traced back to electrochemical imbalances that were detectable hours or even days before the event. This underscores the critical importance of advanced balancing technologies in preventing thermal incidents rather than merely responding to them after they occur.

The primary objective of electrochemical balancing is to maintain all cells within a battery pack at optimal operational parameters, ensuring uniform state-of-charge, temperature distribution, and aging characteristics. This uniformity is essential for preventing localized hotspots, voltage excursions, and the formation of lithium dendrites that often precede thermal runaway events.

Current technological goals in this field include developing predictive algorithms that can identify potential imbalance issues before they manifest as measurable temperature or voltage anomalies. These algorithms increasingly leverage machine learning approaches to recognize subtle patterns in electrochemical signatures that human operators or traditional BMS systems might miss.

Another significant objective is the integration of electrochemical balancing with thermal management systems to create a holistic approach to battery safety. This integration represents a paradigm shift from treating thermal management and cell balancing as separate functions to viewing them as complementary aspects of a unified safety strategy.

The industry is also moving toward standardization of electrochemical balancing protocols, with organizations like IEEE and IEC developing frameworks that define minimum requirements for battery management systems across different applications. These standards aim to establish consistent safety benchmarks while allowing for innovation in implementation approaches.

Market Demand Analysis for Advanced Battery Safety Solutions

The global market for advanced battery safety solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate that the battery safety technology sector is projected to grow at a compound annual growth rate of 20% through 2030, with thermal runaway prevention technologies representing approximately one-third of this market segment.

Consumer demand for safer battery technologies has intensified following high-profile incidents involving lithium-ion battery fires in electric vehicles, consumer electronics, and grid storage installations. These incidents have heightened public awareness and regulatory scrutiny, creating significant market pull for advanced safety solutions. Industry surveys reveal that 78% of potential EV buyers cite battery safety as a "very important" consideration in their purchasing decisions.

Regulatory frameworks worldwide are evolving rapidly to address battery safety concerns. The implementation of UN 38.3, IEC 62133, and UL 1642 standards has established minimum safety requirements, while newer regulations such as China's GB 38031-2020 and Europe's upcoming Battery Regulation are creating stringent safety mandates specifically targeting thermal runaway prevention. These regulatory developments are accelerating market demand for electrochemical balancing technologies.

The automotive sector represents the largest market segment for advanced battery safety solutions, accounting for approximately 45% of total market demand. This is followed by stationary energy storage (25%), consumer electronics (20%), and industrial applications (10%). Within these segments, premium safety features command price premiums of 15-30%, indicating strong willingness to pay for enhanced protection against thermal events.

Regional analysis shows that Asia-Pacific currently leads market demand with 40% share, followed by North America (30%) and Europe (25%). However, Europe is experiencing the fastest growth rate due to aggressive EV adoption targets and stringent safety regulations. China, as both the largest EV market and battery producer, represents a particularly critical market for advanced safety technologies.

Market research indicates that solutions addressing the root causes of thermal runaway, particularly electrochemical balancing technologies, are gaining significant traction over traditional thermal management approaches. This shift reflects growing industry recognition that preventing thermal runaway initiation through electrochemical control is more effective than attempting to contain thermal events after they begin. Industry forecasts suggest that electrochemical balancing solutions could capture 60% of the battery safety market by 2028, representing a substantial opportunity for technology developers and manufacturers.

Consumer demand for safer battery technologies has intensified following high-profile incidents involving lithium-ion battery fires in electric vehicles, consumer electronics, and grid storage installations. These incidents have heightened public awareness and regulatory scrutiny, creating significant market pull for advanced safety solutions. Industry surveys reveal that 78% of potential EV buyers cite battery safety as a "very important" consideration in their purchasing decisions.

Regulatory frameworks worldwide are evolving rapidly to address battery safety concerns. The implementation of UN 38.3, IEC 62133, and UL 1642 standards has established minimum safety requirements, while newer regulations such as China's GB 38031-2020 and Europe's upcoming Battery Regulation are creating stringent safety mandates specifically targeting thermal runaway prevention. These regulatory developments are accelerating market demand for electrochemical balancing technologies.

The automotive sector represents the largest market segment for advanced battery safety solutions, accounting for approximately 45% of total market demand. This is followed by stationary energy storage (25%), consumer electronics (20%), and industrial applications (10%). Within these segments, premium safety features command price premiums of 15-30%, indicating strong willingness to pay for enhanced protection against thermal events.

Regional analysis shows that Asia-Pacific currently leads market demand with 40% share, followed by North America (30%) and Europe (25%). However, Europe is experiencing the fastest growth rate due to aggressive EV adoption targets and stringent safety regulations. China, as both the largest EV market and battery producer, represents a particularly critical market for advanced safety technologies.

Market research indicates that solutions addressing the root causes of thermal runaway, particularly electrochemical balancing technologies, are gaining significant traction over traditional thermal management approaches. This shift reflects growing industry recognition that preventing thermal runaway initiation through electrochemical control is more effective than attempting to contain thermal events after they begin. Industry forecasts suggest that electrochemical balancing solutions could capture 60% of the battery safety market by 2028, representing a substantial opportunity for technology developers and manufacturers.

Current State and Challenges in Thermal Runaway Prevention

The global battery industry has witnessed significant growth in recent years, with lithium-ion batteries becoming the dominant technology for energy storage in various applications. However, thermal runaway incidents have raised serious safety concerns across multiple sectors. Currently, thermal runaway prevention strategies primarily focus on mechanical safety features, thermal management systems, and battery management systems (BMS), with electrochemical balancing emerging as a critical but often overlooked component.

Mechanical safety features such as pressure relief vents, thermal fuses, and robust cell casings represent the first line of defense against thermal events. While these features have proven effective in containing minor incidents, they often fail to address the root causes of thermal runaway, particularly those stemming from electrochemical imbalances within the cell structure.

Thermal management systems have evolved significantly, with advanced cooling technologies including liquid cooling, phase change materials, and heat pipe systems being implemented in high-performance applications. Despite these advancements, current systems typically respond to thermal symptoms rather than preventing the electrochemical triggers that initiate runaway events. This reactive approach limits their effectiveness in preventing cascading failures in battery packs.

Battery Management Systems have become increasingly sophisticated, incorporating algorithms for state-of-charge estimation, cell balancing, and fault detection. However, most commercial BMS solutions lack the capability to detect subtle electrochemical imbalances that precede thermal events. Research indicates that early-stage detection of these imbalances could provide critical warning signs 15-30 minutes before thermal runaway becomes irreversible.

The primary technical challenges in thermal runaway prevention center around real-time monitoring of electrochemical parameters within cells. Current sensor technologies struggle to accurately measure internal cell conditions without adding significant cost or complexity to battery systems. Additionally, the relationship between electrochemical imbalances and thermal behavior remains incompletely characterized across different battery chemistries and operating conditions.

Geographically, thermal runaway prevention research is concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Europe. Chinese manufacturers have made significant progress in developing cost-effective safety solutions, while European and North American research institutions lead in fundamental electrochemical research. This geographic distribution has created challenges in standardizing approaches to thermal runaway prevention across global supply chains.

Regulatory frameworks for battery safety vary considerably across regions, creating additional challenges for implementing consistent electrochemical balancing strategies. The lack of unified standards specifically addressing electrochemical factors in thermal runaway prevention represents a significant barrier to industry-wide adoption of advanced prevention technologies.

Mechanical safety features such as pressure relief vents, thermal fuses, and robust cell casings represent the first line of defense against thermal events. While these features have proven effective in containing minor incidents, they often fail to address the root causes of thermal runaway, particularly those stemming from electrochemical imbalances within the cell structure.

Thermal management systems have evolved significantly, with advanced cooling technologies including liquid cooling, phase change materials, and heat pipe systems being implemented in high-performance applications. Despite these advancements, current systems typically respond to thermal symptoms rather than preventing the electrochemical triggers that initiate runaway events. This reactive approach limits their effectiveness in preventing cascading failures in battery packs.

Battery Management Systems have become increasingly sophisticated, incorporating algorithms for state-of-charge estimation, cell balancing, and fault detection. However, most commercial BMS solutions lack the capability to detect subtle electrochemical imbalances that precede thermal events. Research indicates that early-stage detection of these imbalances could provide critical warning signs 15-30 minutes before thermal runaway becomes irreversible.

The primary technical challenges in thermal runaway prevention center around real-time monitoring of electrochemical parameters within cells. Current sensor technologies struggle to accurately measure internal cell conditions without adding significant cost or complexity to battery systems. Additionally, the relationship between electrochemical imbalances and thermal behavior remains incompletely characterized across different battery chemistries and operating conditions.

Geographically, thermal runaway prevention research is concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Europe. Chinese manufacturers have made significant progress in developing cost-effective safety solutions, while European and North American research institutions lead in fundamental electrochemical research. This geographic distribution has created challenges in standardizing approaches to thermal runaway prevention across global supply chains.

Regulatory frameworks for battery safety vary considerably across regions, creating additional challenges for implementing consistent electrochemical balancing strategies. The lack of unified standards specifically addressing electrochemical factors in thermal runaway prevention represents a significant barrier to industry-wide adoption of advanced prevention technologies.

Current Electrochemical Balancing Solutions for Thermal Management

01 Electrochemical monitoring systems for thermal runaway prevention

Advanced monitoring systems that track electrochemical parameters in batteries to detect early signs of thermal instability. These systems measure voltage, current, and impedance changes to identify potential thermal runaway conditions before they escalate. By continuously analyzing electrochemical signatures, these monitoring solutions enable preemptive intervention to maintain thermal equilibrium and prevent catastrophic battery failures.- Electrochemical balancing systems for thermal runaway prevention: Electrochemical balancing systems are designed to monitor and regulate the electrochemical reactions within battery cells to prevent thermal runaway conditions. These systems typically employ sensors to detect abnormal voltage, current, or temperature fluctuations and implement corrective measures to maintain balanced operation. By ensuring electrochemical equilibrium across cells, these systems can significantly reduce the risk of thermal events that could lead to catastrophic failures in battery systems.

- Thermal management solutions with active cooling mechanisms: Active cooling mechanisms are integrated into battery systems to dissipate excess heat generated during operation. These solutions include liquid cooling systems, phase change materials, and forced air cooling that can be dynamically controlled based on thermal conditions. By efficiently removing heat from battery cells, these systems prevent temperature escalation that could trigger thermal runaway events, especially during high-discharge operations or fast charging scenarios.

- Cell isolation and containment strategies for runaway mitigation: Cell isolation and containment strategies focus on limiting the propagation of thermal events from one cell to adjacent cells within a battery pack. These approaches include physical barriers, thermal fuses, and compartmentalization designs that can isolate failing cells. When thermal runaway is detected in a cell, these systems can electrically disconnect the affected cell and contain the thermal event, preventing system-wide failure and enhancing overall battery safety.

- Advanced sensing and early detection systems: Advanced sensing technologies enable early detection of conditions that may lead to thermal runaway. These systems employ multiple sensor types including temperature sensors, gas detectors, and impedance monitoring to identify abnormal battery behavior before critical thresholds are reached. Machine learning algorithms analyze sensor data to recognize patterns indicative of potential failure modes, allowing for preemptive intervention before thermal runaway conditions develop.

- Electrochemical additives and modified electrolytes for enhanced stability: Specialized electrochemical additives and modified electrolyte formulations can significantly improve battery stability under extreme conditions. These chemical innovations include flame-retardant additives, thermal stabilizers, and electrolyte compositions that remain stable at elevated temperatures. By enhancing the inherent chemical stability of the battery components, these solutions raise the threshold at which thermal runaway can occur and reduce the severity of thermal events if they do happen.

02 Thermal management through electrolyte engineering

Specialized electrolyte formulations designed to enhance thermal stability and mitigate runaway risks. These engineered electrolytes incorporate flame-retardant additives, phase-change materials, or ionic compounds that can absorb excess heat or limit exothermic reactions. The electrolyte compositions act as built-in safety mechanisms that help balance electrochemical reactions and dissipate heat during high-stress battery operations.Expand Specific Solutions03 Cell balancing circuits for thermal stability

Electronic circuits and systems designed to maintain uniform charge distribution across battery cells, preventing localized hotspots and thermal imbalances. These balancing circuits redistribute energy between cells, ensuring that no individual cell experiences excessive stress that could trigger thermal runaway. By equalizing voltage and state of charge across the battery pack, these systems create more stable electrochemical conditions.Expand Specific Solutions04 Electrochemical safety disconnection mechanisms

Integrated safety systems that can rapidly interrupt electrical pathways when abnormal electrochemical conditions are detected. These mechanisms include current interrupt devices, thermally activated switches, and electrochemical fuses that physically separate battery components during potential thermal runaway events. By breaking the circuit, these systems prevent further energy input that could accelerate thermal cascades.Expand Specific Solutions05 Hybrid electrochemical-thermal management systems

Integrated approaches that combine electrochemical control with active thermal management technologies. These systems coordinate battery management algorithms with cooling systems, heat exchangers, or phase-change materials to maintain optimal operating temperatures. The hybrid approach allows for dynamic response to changing conditions, balancing electrochemical performance with thermal safety requirements to prevent runaway scenarios.Expand Specific Solutions

Key Industry Players in Battery Management Systems

The electrochemical balancing market for battery thermal runaway management is currently in a growth phase, with increasing adoption driven by safety concerns in energy storage applications. The global market size is expanding rapidly, projected to reach significant value as electric vehicle adoption and grid storage implementations accelerate. From a technological maturity perspective, industry leaders like Tesla, Samsung SDI, and CATL have developed advanced solutions incorporating sophisticated monitoring systems and thermal management technologies. Companies including LG Chem, Microvast Power Systems, and Ningde Amperex Technology are investing heavily in R&D to enhance safety protocols through improved electrochemical balancing mechanisms. The competitive landscape features both established automotive manufacturers (GM, Bosch) and specialized battery technology firms collaborating to address this critical safety challenge.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced Battery Management System (BMS) that focuses on electrochemical balancing to prevent thermal runaway. Their solution incorporates real-time monitoring of individual cell voltages, temperatures, and internal resistance to detect early signs of imbalance. The system employs proprietary algorithms that can predict potential thermal events by analyzing electrochemical signatures before physical manifestations occur. Samsung's approach includes a multi-layered safety architecture with cell-to-cell balancing circuits that actively redistribute charge to prevent any single cell from reaching critical voltage or temperature thresholds[1]. Additionally, they've implemented a novel cooling system that targets hotspots based on electrochemical activity rather than just temperature readings, allowing for more precise thermal management. Their latest generation systems incorporate machine learning algorithms that adapt to battery aging patterns, maintaining optimal electrochemical balance throughout the battery lifecycle[3].

Strengths: Superior early detection capabilities through electrochemical signature analysis; adaptive algorithms that account for battery aging; integrated approach combining hardware and software solutions. Weaknesses: System complexity requires significant computational resources; higher implementation costs compared to simpler thermal management systems; requires extensive calibration for different battery chemistries.

Tesla, Inc.

Technical Solution: Tesla has pioneered an integrated approach to electrochemical balancing for thermal runaway prevention in their energy storage systems and electric vehicles. Their technology centers on a sophisticated Battery Management System that monitors and controls the electrochemical state of each cell in real-time. Tesla's solution incorporates predictive modeling that analyzes subtle changes in cell impedance, voltage response curves, and thermal gradients to identify potential imbalances before they escalate[2]. The system employs dynamic power allocation algorithms that can instantly reduce current to specific modules showing electrochemical anomalies. Tesla's approach is distinguished by its focus on preventative measures rather than just containment, using proprietary firmware that continuously optimizes charge distribution based on electrochemical health indicators. Their system includes dedicated microcontrollers for cell group monitoring with millisecond response times to electrochemical deviations[4]. Tesla has also implemented physical design elements including flame-retardant barriers between cells and thermal fuses that respond to both temperature and electrochemical triggers.

Strengths: Highly integrated hardware-software solution with preventative focus; millisecond response times to electrochemical anomalies; extensive real-world validation across millions of battery packs. Weaknesses: Proprietary closed system limits third-party integration; requires significant computational overhead; higher initial implementation cost compared to simpler thermal management approaches.

Critical Patents and Research in Electrochemical Stability

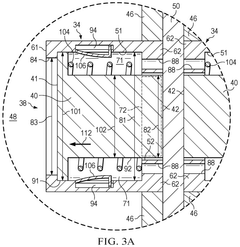

Thermal runaway detection and cotainment mechanism

PatentPendingUS20250286210A1

Innovation

- A thermal runaway protection system incorporating a battery module enclosure, divider wall, protection structure, and piston mechanism that separates overheated modules to create a thermal barrier by converting pressure into a separation air gap, using a piston to move and separate the overheated module when pressure exceeds a threshold, with a spring and lock pawl system to maintain separation.

Passive vent system

PatentPendingUS20240204335A1

Innovation

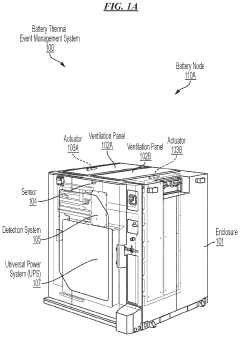

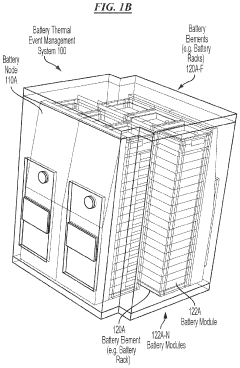

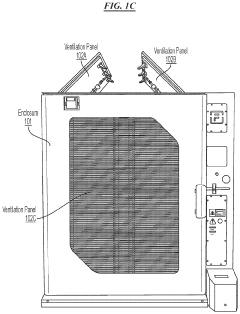

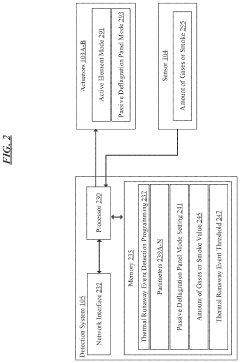

- A battery thermal event management system that includes sensors to detect indicative parameters of thermal runaway events and actuators to open ventilation panels, allowing gases or smoke to escape, thereby limiting combustible volume and pressure within the enclosure.

Regulatory Framework for Battery Safety Standards

The regulatory landscape for battery safety has evolved significantly in response to the growing concerns about thermal runaway incidents. International standards such as IEC 62133, UL 1642, and UN 38.3 have established comprehensive testing protocols specifically addressing thermal stability and electrochemical balance in battery systems. These standards mandate rigorous testing procedures including thermal abuse tests, overcharge protection verification, and short circuit response evaluations—all directly related to maintaining proper electrochemical balance.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent requirements for battery manufacturers, emphasizing the importance of electrochemical stability monitoring systems in consumer electronics. Similarly, the European Union's Battery Directive (2006/66/EC) and its recent updates incorporate specific provisions regarding battery management systems that must include electrochemical balancing capabilities to prevent thermal incidents.

The automotive sector has developed particularly robust regulatory frameworks, with standards like SAE J2464 and ISO 12405 establishing detailed requirements for electric vehicle battery safety. These standards explicitly recognize electrochemical balancing as a critical safety parameter and require manufacturers to implement advanced monitoring systems. China's GB/T 31485 standard has pioneered requirements for real-time electrochemical balance monitoring in energy storage systems.

Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive approaches, allowing manufacturers flexibility in how they achieve electrochemical balance while maintaining strict safety outcomes. This shift acknowledges the diverse technical solutions available for maintaining electrochemical equilibrium across different battery chemistries and applications.

Recent regulatory developments have focused on the integration of battery management systems (BMS) with specific electrochemical balancing capabilities. The UN Global Technical Regulation No. 20 (GTR 20) for electric vehicle safety explicitly addresses the role of electrochemical balance in preventing thermal propagation, requiring sophisticated monitoring and intervention systems.

Compliance certification processes now routinely include assessment of electrochemical balancing mechanisms as fundamental safety features. Testing protocols increasingly simulate real-world conditions that might disrupt electrochemical balance, such as partial state-of-charge operation, extreme temperature cycling, and aging effects—conditions known to exacerbate thermal runaway risks if electrochemical balance is not properly maintained.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent requirements for battery manufacturers, emphasizing the importance of electrochemical stability monitoring systems in consumer electronics. Similarly, the European Union's Battery Directive (2006/66/EC) and its recent updates incorporate specific provisions regarding battery management systems that must include electrochemical balancing capabilities to prevent thermal incidents.

The automotive sector has developed particularly robust regulatory frameworks, with standards like SAE J2464 and ISO 12405 establishing detailed requirements for electric vehicle battery safety. These standards explicitly recognize electrochemical balancing as a critical safety parameter and require manufacturers to implement advanced monitoring systems. China's GB/T 31485 standard has pioneered requirements for real-time electrochemical balance monitoring in energy storage systems.

Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive approaches, allowing manufacturers flexibility in how they achieve electrochemical balance while maintaining strict safety outcomes. This shift acknowledges the diverse technical solutions available for maintaining electrochemical equilibrium across different battery chemistries and applications.

Recent regulatory developments have focused on the integration of battery management systems (BMS) with specific electrochemical balancing capabilities. The UN Global Technical Regulation No. 20 (GTR 20) for electric vehicle safety explicitly addresses the role of electrochemical balance in preventing thermal propagation, requiring sophisticated monitoring and intervention systems.

Compliance certification processes now routinely include assessment of electrochemical balancing mechanisms as fundamental safety features. Testing protocols increasingly simulate real-world conditions that might disrupt electrochemical balance, such as partial state-of-charge operation, extreme temperature cycling, and aging effects—conditions known to exacerbate thermal runaway risks if electrochemical balance is not properly maintained.

Environmental Impact of Battery Thermal Management Technologies

The environmental implications of battery thermal management systems are increasingly significant as energy storage technologies proliferate globally. Electrochemical balancing techniques, which are crucial for preventing thermal runaway events, offer substantial environmental benefits compared to traditional cooling methods. By optimizing cell-level electrochemistry to prevent thermal instability, these systems reduce the need for resource-intensive external cooling infrastructure, thereby decreasing the overall environmental footprint of battery installations.

Conventional thermal management approaches often rely on liquid cooling systems that require significant water resources and energy for operation. These systems typically consume between 5-15% of a battery's stored energy for cooling purposes alone, representing a substantial efficiency loss. Additionally, many cooling fluids contain environmentally harmful compounds that pose contamination risks during manufacturing, maintenance, and disposal phases.

Electrochemical balancing technologies, by contrast, work preventatively by addressing thermal issues at their source—the electrochemical reactions within cells. This approach significantly reduces resource consumption, with studies indicating up to 70% reduction in cooling-related energy expenditure compared to conventional methods. The reduced energy demand translates directly to lower greenhouse gas emissions throughout the battery lifecycle, with recent research demonstrating potential carbon footprint reductions of 30-40% for large-scale energy storage installations.

The manufacturing environmental impact is similarly favorable. While traditional thermal management systems require additional components such as heat exchangers, pumps, and specialized coolants, electrochemical balancing solutions primarily rely on enhanced battery management systems (BMS) and optimized cell design. This simplification reduces material requirements, manufacturing complexity, and associated environmental impacts from resource extraction and processing.

End-of-life considerations further highlight the environmental advantages of electrochemical balancing approaches. Batteries utilizing advanced electrochemical management typically experience extended operational lifespans—up to 25-40% longer according to recent field tests—which reduces waste generation and resource consumption associated with replacement cycles. Additionally, these systems typically contain fewer specialized components requiring separate recycling streams, simplifying end-of-life processing and improving material recovery rates.

The transition toward electrochemical balancing represents a significant step in reducing the environmental impact of energy storage technologies, aligning with broader sustainability goals while simultaneously enhancing safety and performance characteristics of battery systems. As regulatory frameworks increasingly emphasize lifecycle environmental impacts, these advantages will likely accelerate industry adoption of advanced electrochemical management approaches.

Conventional thermal management approaches often rely on liquid cooling systems that require significant water resources and energy for operation. These systems typically consume between 5-15% of a battery's stored energy for cooling purposes alone, representing a substantial efficiency loss. Additionally, many cooling fluids contain environmentally harmful compounds that pose contamination risks during manufacturing, maintenance, and disposal phases.

Electrochemical balancing technologies, by contrast, work preventatively by addressing thermal issues at their source—the electrochemical reactions within cells. This approach significantly reduces resource consumption, with studies indicating up to 70% reduction in cooling-related energy expenditure compared to conventional methods. The reduced energy demand translates directly to lower greenhouse gas emissions throughout the battery lifecycle, with recent research demonstrating potential carbon footprint reductions of 30-40% for large-scale energy storage installations.

The manufacturing environmental impact is similarly favorable. While traditional thermal management systems require additional components such as heat exchangers, pumps, and specialized coolants, electrochemical balancing solutions primarily rely on enhanced battery management systems (BMS) and optimized cell design. This simplification reduces material requirements, manufacturing complexity, and associated environmental impacts from resource extraction and processing.

End-of-life considerations further highlight the environmental advantages of electrochemical balancing approaches. Batteries utilizing advanced electrochemical management typically experience extended operational lifespans—up to 25-40% longer according to recent field tests—which reduces waste generation and resource consumption associated with replacement cycles. Additionally, these systems typically contain fewer specialized components requiring separate recycling streams, simplifying end-of-life processing and improving material recovery rates.

The transition toward electrochemical balancing represents a significant step in reducing the environmental impact of energy storage technologies, aligning with broader sustainability goals while simultaneously enhancing safety and performance characteristics of battery systems. As regulatory frameworks increasingly emphasize lifecycle environmental impacts, these advantages will likely accelerate industry adoption of advanced electrochemical management approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!