Influence of Voltage Regulation on Battery Thermal Runaway Prevention

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Prevention Goals

Battery thermal runaway (BTR) represents one of the most critical safety challenges in lithium-ion battery technology. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to catastrophic failure, including fire and explosion. The evolution of BTR typically begins with internal short circuits, overcharging, mechanical damage, or exposure to extreme temperatures, which trigger exothermic reactions within the cell. These reactions generate heat faster than it can be dissipated, creating a dangerous positive feedback loop.

The historical development of battery thermal runaway understanding dates back to the early commercialization of lithium-ion batteries in the 1990s. Several high-profile incidents, including laptop fires in the early 2000s and more recent electric vehicle combustion events, have highlighted the persistent nature of this challenge despite technological advancements. The increasing energy density of modern batteries has paradoxically elevated the risk profile, as higher energy storage capacity correlates with greater potential thermal energy release during failure events.

Voltage regulation has emerged as a critical factor in BTR prevention. Battery management systems (BMS) that precisely control cell voltage can significantly reduce the risk of thermal events by preventing overcharging conditions that initiate decomposition of the electrolyte and cathode materials. Research indicates that maintaining cell voltages below specific thresholds—typically 4.2V for most commercial lithium-ion chemistries—substantially reduces the probability of thermal runaway initiation.

The technical goals for thermal runaway prevention through voltage regulation are multifaceted. Primary objectives include developing more precise voltage monitoring systems capable of detecting minute variations across individual cells within milliseconds, implementing adaptive voltage thresholds based on real-time temperature and aging conditions, and creating predictive algorithms that can anticipate potential thermal events before traditional warning signs appear.

Industry standards and regulatory frameworks have evolved to address these challenges, with organizations such as UL, IEC, and ISO establishing increasingly stringent safety requirements for voltage management in battery systems. The UN 38.3 test and IEC 62133 standard specifically address voltage-related safety parameters that manufacturers must meet before market approval.

The ultimate prevention goal involves creating inherently safe battery systems where thermal runaway becomes virtually impossible even under extreme conditions. This requires a holistic approach combining advanced voltage regulation with complementary technologies such as thermal management systems, safer electrolyte formulations, and physical cell separation barriers. The ideal solution would maintain optimal performance characteristics while eliminating the possibility of cascading thermal failures across battery packs.

The historical development of battery thermal runaway understanding dates back to the early commercialization of lithium-ion batteries in the 1990s. Several high-profile incidents, including laptop fires in the early 2000s and more recent electric vehicle combustion events, have highlighted the persistent nature of this challenge despite technological advancements. The increasing energy density of modern batteries has paradoxically elevated the risk profile, as higher energy storage capacity correlates with greater potential thermal energy release during failure events.

Voltage regulation has emerged as a critical factor in BTR prevention. Battery management systems (BMS) that precisely control cell voltage can significantly reduce the risk of thermal events by preventing overcharging conditions that initiate decomposition of the electrolyte and cathode materials. Research indicates that maintaining cell voltages below specific thresholds—typically 4.2V for most commercial lithium-ion chemistries—substantially reduces the probability of thermal runaway initiation.

The technical goals for thermal runaway prevention through voltage regulation are multifaceted. Primary objectives include developing more precise voltage monitoring systems capable of detecting minute variations across individual cells within milliseconds, implementing adaptive voltage thresholds based on real-time temperature and aging conditions, and creating predictive algorithms that can anticipate potential thermal events before traditional warning signs appear.

Industry standards and regulatory frameworks have evolved to address these challenges, with organizations such as UL, IEC, and ISO establishing increasingly stringent safety requirements for voltage management in battery systems. The UN 38.3 test and IEC 62133 standard specifically address voltage-related safety parameters that manufacturers must meet before market approval.

The ultimate prevention goal involves creating inherently safe battery systems where thermal runaway becomes virtually impossible even under extreme conditions. This requires a holistic approach combining advanced voltage regulation with complementary technologies such as thermal management systems, safer electrolyte formulations, and physical cell separation barriers. The ideal solution would maintain optimal performance characteristics while eliminating the possibility of cascading thermal failures across battery packs.

Market Demand for Advanced Battery Safety Solutions

The global market for advanced battery safety solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Current market valuations indicate that the battery safety technology sector is projected to reach $8.5 billion by 2027, with a compound annual growth rate of 12.3% from 2022. This substantial growth reflects the increasing awareness and concern regarding battery thermal runaway incidents across various industries.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This consumer sentiment has created significant market pull for advanced voltage regulation systems that can effectively prevent thermal runaway events.

The regulatory landscape is simultaneously evolving to address these safety concerns. In North America, Europe, and Asia, regulatory bodies are implementing increasingly stringent safety standards for lithium-ion batteries, particularly focusing on thermal management and voltage control mechanisms. These regulations are compelling manufacturers to invest in advanced voltage regulation technologies as compliance becomes mandatory rather than optional.

Commercial sectors demonstrate varying degrees of demand intensity. The automotive industry represents the largest market segment, accounting for approximately 42% of the total demand for advanced battery safety solutions. Energy storage systems follow at 28%, with consumer electronics comprising 21% of market demand. The remaining 9% is distributed across industrial applications, aerospace, and medical devices.

Geographic distribution of market demand shows significant regional variations. Asia-Pacific leads with 45% of global demand, driven by its dominant position in battery manufacturing and electric vehicle production. North America follows with 30%, while Europe accounts for 22% of the market. The remaining 3% comes from other regions where adoption is gradually increasing.

The economic implications of battery thermal incidents further amplify market demand. Insurance companies report that claims related to battery fires have increased by 35% annually since 2019, creating financial incentives for implementing preventive technologies. Additionally, manufacturers are recognizing that the cost of implementing advanced voltage regulation systems is significantly lower than the potential financial impact of product recalls, liability claims, and brand damage resulting from thermal runaway incidents.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. A recent industry survey revealed that 78% of potential EV buyers consider battery safety features as "extremely important" in their purchasing decisions, ranking it above range and charging speed. This consumer sentiment has created significant market pull for advanced voltage regulation systems that can effectively prevent thermal runaway events.

The regulatory landscape is simultaneously evolving to address these safety concerns. In North America, Europe, and Asia, regulatory bodies are implementing increasingly stringent safety standards for lithium-ion batteries, particularly focusing on thermal management and voltage control mechanisms. These regulations are compelling manufacturers to invest in advanced voltage regulation technologies as compliance becomes mandatory rather than optional.

Commercial sectors demonstrate varying degrees of demand intensity. The automotive industry represents the largest market segment, accounting for approximately 42% of the total demand for advanced battery safety solutions. Energy storage systems follow at 28%, with consumer electronics comprising 21% of market demand. The remaining 9% is distributed across industrial applications, aerospace, and medical devices.

Geographic distribution of market demand shows significant regional variations. Asia-Pacific leads with 45% of global demand, driven by its dominant position in battery manufacturing and electric vehicle production. North America follows with 30%, while Europe accounts for 22% of the market. The remaining 3% comes from other regions where adoption is gradually increasing.

The economic implications of battery thermal incidents further amplify market demand. Insurance companies report that claims related to battery fires have increased by 35% annually since 2019, creating financial incentives for implementing preventive technologies. Additionally, manufacturers are recognizing that the cost of implementing advanced voltage regulation systems is significantly lower than the potential financial impact of product recalls, liability claims, and brand damage resulting from thermal runaway incidents.

Current Voltage Regulation Technologies and Challenges

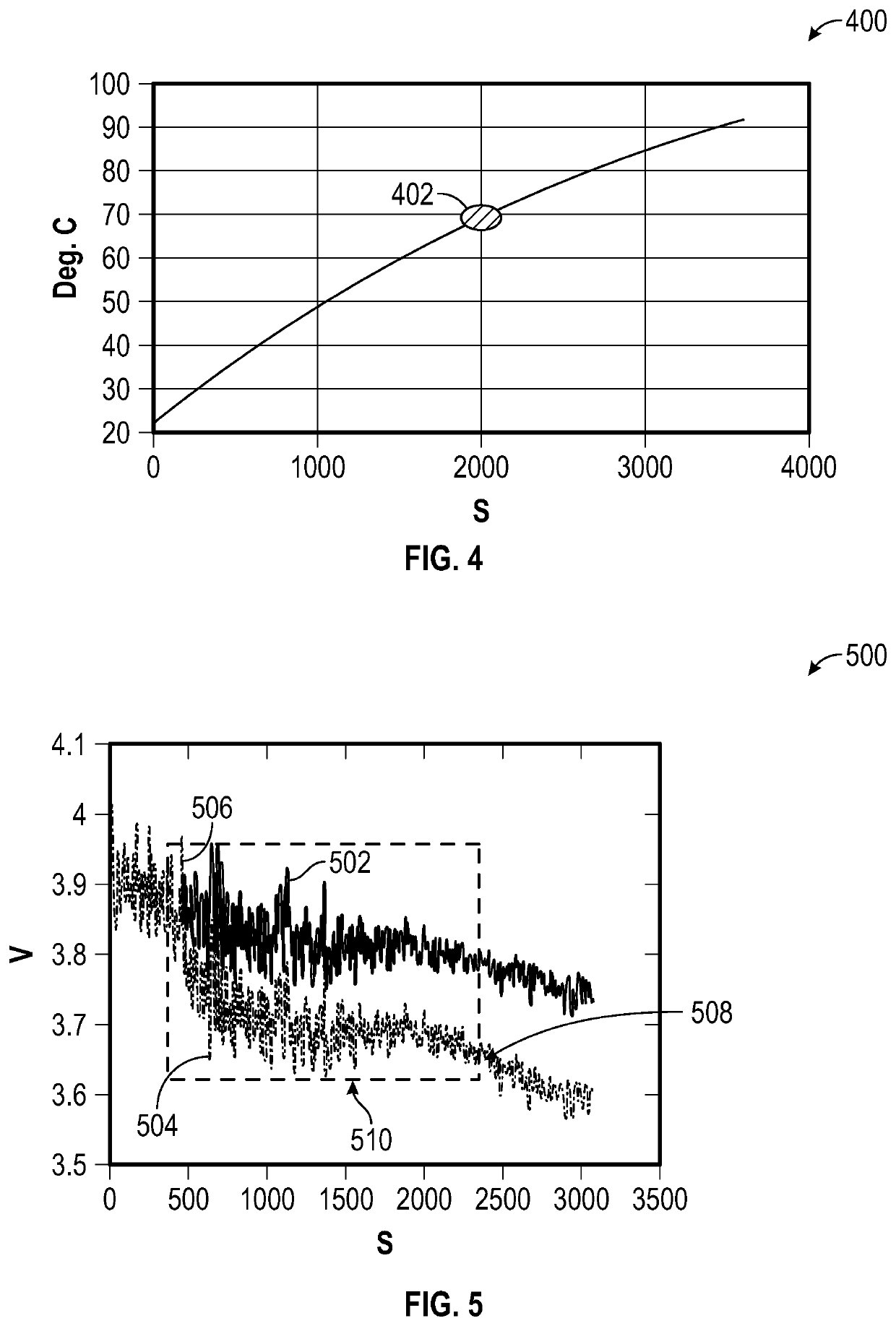

Voltage regulation technologies for battery systems have evolved significantly over the past decade, with contemporary approaches focusing on both hardware and software solutions. Current hardware-based voltage regulation primarily employs Battery Management Systems (BMS) that utilize precision voltage sensors coupled with advanced microcontrollers to monitor cell voltages in real-time. These systems typically achieve voltage measurement accuracies of ±2mV, enabling precise control over individual cell states.

Advanced BMS architectures implement multi-level protection mechanisms, including primary voltage monitoring circuits, secondary verification systems, and tertiary failsafe protocols. This redundancy significantly reduces the probability of undetected voltage anomalies that could lead to thermal events. Industry leaders have developed proprietary algorithms that can detect voltage fluctuations as small as 0.5mV, providing early warning indicators of potential cell degradation.

Despite these advancements, current voltage regulation technologies face several critical challenges. The first major challenge involves balancing speed and accuracy in voltage measurements. High-precision measurements typically require longer sampling times, creating a fundamental tradeoff between measurement accuracy and response time. This becomes particularly problematic during rapid charge/discharge cycles where thermal runaway conditions can develop quickly.

Another significant challenge is the management of parasitic impedance variations across large battery packs. These variations can cause uneven voltage distributions that are difficult to detect with conventional sensing methods. Research indicates that up to 15% of early-stage thermal events begin in cells experiencing localized voltage irregularities that remain undetected by standard monitoring systems.

Temperature dependency of voltage measurements presents an additional complication. Most voltage sensing components exhibit thermal drift characteristics that can introduce measurement errors of up to 5mV per 10°C temperature change. This creates particular difficulties in environments with significant temperature gradients across the battery pack, such as in electric vehicles operating in extreme climates.

The integration of voltage regulation with thermal management systems remains suboptimal in many current implementations. While these systems often operate independently, research demonstrates that coordinated regulation strategies that simultaneously address voltage and thermal parameters can reduce thermal runaway incidents by up to 60% compared to decoupled approaches.

Scalability presents another challenge as battery systems grow larger and more complex. Current centralized BMS architectures struggle to maintain real-time monitoring capabilities when managing thousands of cells simultaneously. This has led to emerging distributed architectures, though these introduce new challenges related to communication latency and system synchronization.

Advanced BMS architectures implement multi-level protection mechanisms, including primary voltage monitoring circuits, secondary verification systems, and tertiary failsafe protocols. This redundancy significantly reduces the probability of undetected voltage anomalies that could lead to thermal events. Industry leaders have developed proprietary algorithms that can detect voltage fluctuations as small as 0.5mV, providing early warning indicators of potential cell degradation.

Despite these advancements, current voltage regulation technologies face several critical challenges. The first major challenge involves balancing speed and accuracy in voltage measurements. High-precision measurements typically require longer sampling times, creating a fundamental tradeoff between measurement accuracy and response time. This becomes particularly problematic during rapid charge/discharge cycles where thermal runaway conditions can develop quickly.

Another significant challenge is the management of parasitic impedance variations across large battery packs. These variations can cause uneven voltage distributions that are difficult to detect with conventional sensing methods. Research indicates that up to 15% of early-stage thermal events begin in cells experiencing localized voltage irregularities that remain undetected by standard monitoring systems.

Temperature dependency of voltage measurements presents an additional complication. Most voltage sensing components exhibit thermal drift characteristics that can introduce measurement errors of up to 5mV per 10°C temperature change. This creates particular difficulties in environments with significant temperature gradients across the battery pack, such as in electric vehicles operating in extreme climates.

The integration of voltage regulation with thermal management systems remains suboptimal in many current implementations. While these systems often operate independently, research demonstrates that coordinated regulation strategies that simultaneously address voltage and thermal parameters can reduce thermal runaway incidents by up to 60% compared to decoupled approaches.

Scalability presents another challenge as battery systems grow larger and more complex. Current centralized BMS architectures struggle to maintain real-time monitoring capabilities when managing thousands of cells simultaneously. This has led to emerging distributed architectures, though these introduce new challenges related to communication latency and system synchronization.

Existing Voltage Regulation Solutions for Thermal Runaway Prevention

01 Advanced battery management systems for thermal control

Battery management systems that incorporate temperature monitoring and control mechanisms to prevent thermal runaway. These systems use sensors to detect abnormal temperature rises and implement cooling strategies or power reduction to maintain safe operating conditions. The systems can include intelligent algorithms that predict potential thermal issues before they become critical, allowing for preventive measures.- Advanced voltage regulation systems: Modern battery management systems employ sophisticated voltage regulation techniques to maintain optimal battery performance and prevent thermal runaway. These systems continuously monitor battery voltage levels and adjust charging parameters accordingly. Advanced voltage regulators can detect abnormal voltage fluctuations that might indicate potential thermal issues and implement protective measures such as reducing charging current or activating cooling systems. These regulation systems often incorporate microcontrollers that can make real-time adjustments based on battery conditions.

- Thermal management solutions: Effective thermal management is crucial for preventing battery thermal runaway. Solutions include active cooling systems that use air or liquid circulation to dissipate heat, passive cooling through heat sinks or thermally conductive materials, and thermal isolation techniques to prevent heat propagation between cells. Advanced thermal management systems incorporate temperature sensors at multiple points to detect hotspots and trigger protective responses before thermal runaway can occur. These systems work in conjunction with voltage regulation to maintain safe operating conditions.

- Battery cell monitoring and protection circuits: Protection circuits monitor individual battery cells for signs of overcharging, over-discharging, or abnormal temperature increases. These circuits can automatically disconnect problematic cells or reduce current flow when dangerous conditions are detected. Cell balancing techniques ensure uniform voltage distribution across battery packs, preventing individual cells from experiencing stress that could lead to thermal events. Advanced monitoring systems use algorithms to predict potential failures before they occur based on voltage patterns and temperature trends.

- Intelligent charging control systems: Smart charging systems regulate voltage and current during the charging process to prevent conditions that could lead to thermal runaway. These systems implement multi-stage charging protocols that adjust parameters based on battery state of charge and temperature. Adaptive charging algorithms can learn from battery behavior over time to optimize charging profiles for specific battery chemistries and usage patterns. Some advanced systems incorporate predictive models that anticipate how charging decisions will affect battery temperature and adjust accordingly to maintain safe operating conditions.

- Emergency response and failsafe mechanisms: Failsafe systems provide last-resort protection against thermal runaway when primary prevention methods are insufficient. These include physical disconnection mechanisms that isolate battery cells or modules when dangerous conditions are detected, pressure relief valves that safely vent gases before they can cause explosions, and fire suppression systems integrated into battery enclosures. Some designs incorporate thermal fuses that permanently disconnect the circuit when temperature exceeds safe thresholds. These emergency systems work alongside voltage regulation to provide comprehensive protection against thermal runaway events.

02 Voltage regulation techniques for battery safety

Methods for regulating battery voltage to prevent overcharging and thermal runaway. These techniques include precision voltage control circuits, adaptive charging algorithms, and voltage limiting mechanisms that maintain cell voltages within safe operating ranges. By preventing excessive voltage across battery cells, these methods significantly reduce the risk of thermal events and extend battery life.Expand Specific Solutions03 Thermal dissipation and cooling solutions

Physical design solutions that enhance heat dissipation from battery packs to prevent thermal runaway. These include innovative cooling structures, heat-conductive materials, and active cooling systems such as liquid cooling or forced air circulation. The designs focus on efficiently removing heat from critical battery components, maintaining optimal operating temperatures even under high load conditions.Expand Specific Solutions04 Cell-level protection and monitoring systems

Systems that monitor and protect individual battery cells from conditions that could lead to thermal runaway. These include cell balancing circuits, individual cell voltage monitoring, and cell-level thermal sensors. By focusing protection at the cell level, these systems can identify and isolate problematic cells before they affect the entire battery pack, preventing cascading thermal failures.Expand Specific Solutions05 Emergency response and failsafe mechanisms

Safety systems designed to respond to detected thermal events and prevent progression to catastrophic failure. These include emergency disconnection circuits, venting mechanisms, fire suppression systems, and isolation strategies. These failsafe mechanisms activate when abnormal conditions are detected, containing potential thermal runaway events and protecting surrounding components and users from harm.Expand Specific Solutions

Key Industry Players in Battery Management Systems

The voltage regulation technology for battery thermal runaway prevention is evolving rapidly in a market transitioning from early adoption to growth phase. The global lithium-ion battery safety market is expanding significantly, projected to reach $25-30 billion by 2030. Leading companies demonstrate varying levels of technical maturity: CATL, LG Energy Solution, and Tesla have advanced voltage regulation systems integrated into their battery management systems, while Samsung SDI and SK On are developing sophisticated thermal monitoring technologies. Automotive manufacturers like BMW, Volkswagen, and GM are incorporating these systems into their EV designs. Research institutions such as Southwest Research Institute and Industrial Technology Research Institute are pioneering next-generation solutions, focusing on predictive analytics and AI-driven voltage control mechanisms to prevent thermal incidents before they occur.

Contemporary Amperex Technology Co., Ltd.

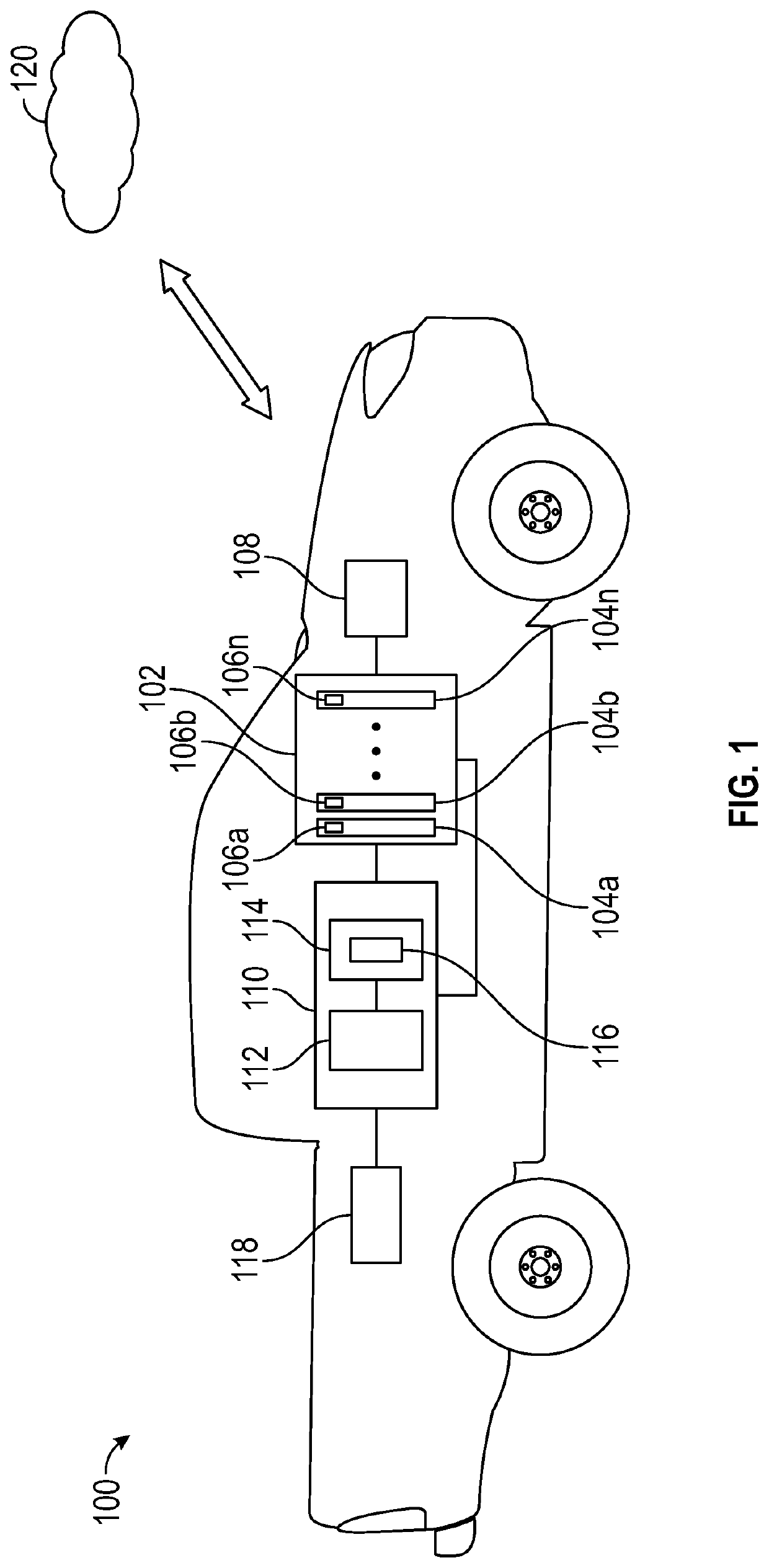

Technical Solution: CATL has developed an advanced Battery Management System (BMS) that implements multi-level voltage regulation strategies to prevent thermal runaway. Their solution incorporates real-time cell voltage monitoring with microsecond-level response times and adaptive control algorithms that can detect voltage abnormalities before they lead to thermal issues. The system employs cell balancing techniques that maintain uniform voltage distribution across battery packs, reducing hotspot formation. CATL's voltage regulation technology includes predictive modeling that anticipates thermal behavior based on voltage patterns, allowing preemptive intervention. Their latest generation BMS can detect voltage fluctuations as small as 3mV, providing early warning of potential thermal events. The system also features isolation mechanisms that can electrically disconnect compromised cells when voltage parameters indicate imminent thermal risk.

Strengths: Industry-leading precision in voltage monitoring with microsecond response times; sophisticated predictive algorithms that can anticipate thermal events before they occur; seamless integration with various cooling systems. Weaknesses: Higher implementation cost compared to conventional systems; requires significant computational resources; system complexity may increase maintenance challenges.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a comprehensive voltage regulation framework specifically designed to mitigate thermal runaway risks. Their approach combines hardware and software solutions, featuring proprietary voltage monitoring ICs that can detect micro-fluctuations in cell voltage with precision up to 1mV. The system implements dynamic voltage thresholds that adjust based on battery state, ambient conditions, and usage patterns. LG's voltage regulation technology incorporates machine learning algorithms that continuously analyze the correlation between voltage behaviors and thermal signatures, building predictive models that improve over time. Their Safety Reinforced Separator (SRS) technology works in conjunction with voltage regulation systems to provide multiple layers of protection. When voltage anomalies are detected, the system can implement graduated response protocols, from reducing charging current to complete electrical isolation of affected modules.

Strengths: Highly integrated approach combining hardware and software solutions; self-learning capability that improves thermal prediction accuracy over time; proven effectiveness in high-energy density applications. Weaknesses: System complexity requires specialized maintenance expertise; higher initial implementation costs; potential for false positives in certain operating conditions.

Critical Technologies in Battery Thermal Management

Method for monitoring a battery

PatentWO2020127752A1

Innovation

- A method using a control unit with a sensor unit to detect abnormal temperature and voltage changes in the battery, setting threshold values based on normal operation data, to proactively detect impending thermal runaway and initiate safety measures such as shutdown, warnings, and enhanced cooling.

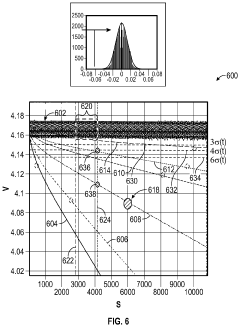

Thermal runaway prognosis by detecting abnormal cell voltage and SOC degeneration

PatentActiveUS20220352737A1

Innovation

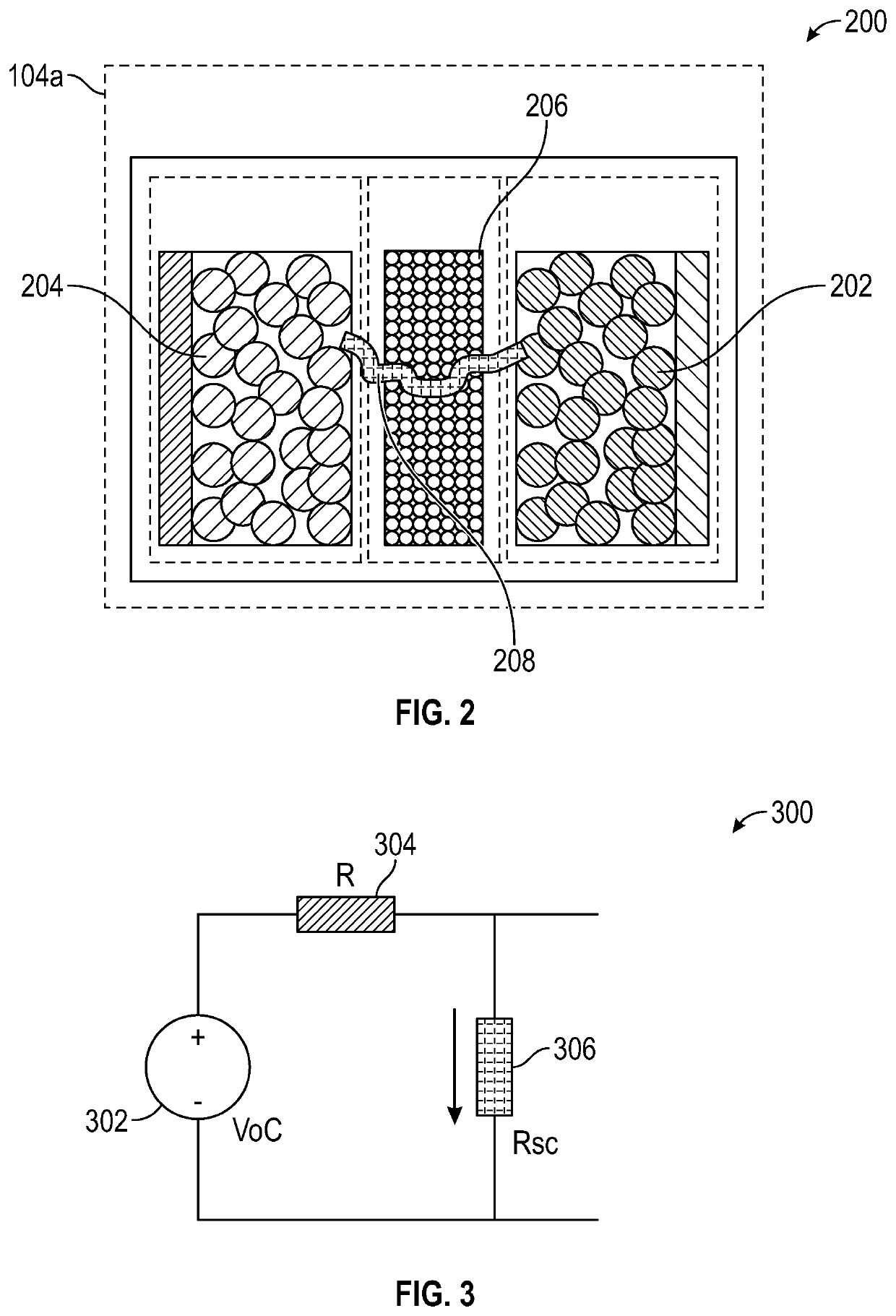

- A system and method that involve obtaining voltage measurements from multiple battery cells, calculating a mean value and standard deviation, and generating a notification signal when a selected cell's voltage exceeds a prognostic threshold, allowing for the detection of internal short circuits and potential thermal runaway, using voltage sensors and a processor to determine voltage parameters and resistance within the battery cells.

Regulatory Standards for Battery Safety Systems

Regulatory standards for battery safety systems have evolved significantly in response to the growing concerns about battery thermal runaway incidents. The International Electrotechnical Commission (IEC) has established several standards, including IEC 62133 for portable batteries and IEC 62619 for larger industrial applications, which specifically address voltage regulation parameters as critical safety factors. These standards mandate specific voltage thresholds and monitoring requirements to prevent overcharging scenarios that often precede thermal events.

The Underwriters Laboratories (UL) has developed UL 1642 for lithium batteries and UL 2054 for household and commercial batteries, both incorporating stringent requirements for voltage management systems. These standards require manufacturers to implement robust voltage regulation mechanisms that can maintain cell voltages within safe operating windows even under abnormal conditions. Recent updates to these standards have placed increased emphasis on the integration of redundant voltage monitoring systems.

In the automotive sector, ISO 26262 and UN ECE R100 regulations have established comprehensive frameworks for electric vehicle battery safety, with specific provisions for voltage regulation systems. These standards require multi-layered protection mechanisms that can detect and respond to voltage anomalies before they trigger thermal cascades. The regulations mandate real-time voltage monitoring at both cell and pack levels, with automated cutoff systems that activate when predefined voltage thresholds are exceeded.

The European Union's Battery Directive (2006/66/EC) and its recent amendments have expanded regulatory requirements beyond performance to include safety considerations, particularly emphasizing voltage management as a preventive measure against thermal incidents. Similarly, China's GB/T 31485 standard for electric vehicle batteries includes detailed specifications for voltage regulation systems, requiring manufacturers to implement sophisticated battery management systems with precise voltage control capabilities.

Regulatory compliance testing protocols have also evolved to specifically evaluate the effectiveness of voltage regulation systems under various stress conditions. These tests typically include overcharge resistance, external short circuit response, and thermal stability under voltage fluctuations. The IEC 61960 standard, for example, outlines specific test procedures to verify that voltage regulation systems can effectively prevent thermal runaway even when subjected to electrical abnormalities.

Recent regulatory trends indicate a move toward more dynamic standards that account for the relationship between voltage regulation and thermal management. The next generation of safety standards is expected to incorporate requirements for adaptive voltage regulation systems that can adjust their parameters based on real-time thermal feedback, creating a more integrated approach to preventing thermal runaway incidents.

The Underwriters Laboratories (UL) has developed UL 1642 for lithium batteries and UL 2054 for household and commercial batteries, both incorporating stringent requirements for voltage management systems. These standards require manufacturers to implement robust voltage regulation mechanisms that can maintain cell voltages within safe operating windows even under abnormal conditions. Recent updates to these standards have placed increased emphasis on the integration of redundant voltage monitoring systems.

In the automotive sector, ISO 26262 and UN ECE R100 regulations have established comprehensive frameworks for electric vehicle battery safety, with specific provisions for voltage regulation systems. These standards require multi-layered protection mechanisms that can detect and respond to voltage anomalies before they trigger thermal cascades. The regulations mandate real-time voltage monitoring at both cell and pack levels, with automated cutoff systems that activate when predefined voltage thresholds are exceeded.

The European Union's Battery Directive (2006/66/EC) and its recent amendments have expanded regulatory requirements beyond performance to include safety considerations, particularly emphasizing voltage management as a preventive measure against thermal incidents. Similarly, China's GB/T 31485 standard for electric vehicle batteries includes detailed specifications for voltage regulation systems, requiring manufacturers to implement sophisticated battery management systems with precise voltage control capabilities.

Regulatory compliance testing protocols have also evolved to specifically evaluate the effectiveness of voltage regulation systems under various stress conditions. These tests typically include overcharge resistance, external short circuit response, and thermal stability under voltage fluctuations. The IEC 61960 standard, for example, outlines specific test procedures to verify that voltage regulation systems can effectively prevent thermal runaway even when subjected to electrical abnormalities.

Recent regulatory trends indicate a move toward more dynamic standards that account for the relationship between voltage regulation and thermal management. The next generation of safety standards is expected to incorporate requirements for adaptive voltage regulation systems that can adjust their parameters based on real-time thermal feedback, creating a more integrated approach to preventing thermal runaway incidents.

Economic Impact of Battery Thermal Runaway Incidents

Battery thermal runaway incidents have significant economic implications across multiple sectors. The direct financial impact of these incidents includes property damage, which can range from localized damage to complete destruction of facilities. For electric vehicle manufacturers, a single thermal runaway incident can cost between $1.8 million to $7.5 million when accounting for vehicle replacement, liability claims, and immediate response measures.

Insurance companies face increasing challenges in accurately pricing policies for lithium-ion battery applications due to the evolving risk profile. Premium increases of 30-50% have been observed for facilities with large-scale battery installations following high-profile thermal runaway incidents. This trend affects the total cost of ownership for battery systems and potentially slows market adoption rates.

Supply chain disruptions represent another substantial economic consequence. When thermal runaway incidents occur at battery manufacturing facilities, production delays can cascade throughout the supply chain. For automotive manufacturers, a week-long disruption in battery supply can result in production losses exceeding $25 million for high-volume models.

The reputational damage following thermal runaway incidents often translates into measurable market capitalization losses. Analysis of public companies that experienced significant battery safety incidents shows an average 4-7% drop in share value in the immediate aftermath, with recovery periods extending from three months to over a year depending on incident severity and response effectiveness.

Regulatory responses to thermal runaway incidents create compliance costs that affect entire industries. Following clusters of incidents, regulatory bodies typically implement more stringent safety requirements, increasing compliance costs by an estimated 15-20% for manufacturers. These costs are eventually distributed across the value chain, affecting end-product pricing and market competitiveness.

Voltage regulation technologies that effectively prevent thermal runaway can deliver substantial economic benefits. Cost-benefit analyses indicate that implementing advanced voltage regulation systems adds approximately 2-5% to battery system costs but can reduce insurance premiums by up to 15% and virtually eliminate the catastrophic costs associated with thermal events. The return on investment for these preventive technologies typically ranges from 300-700% when calculated over a five-year operational period.

Insurance companies face increasing challenges in accurately pricing policies for lithium-ion battery applications due to the evolving risk profile. Premium increases of 30-50% have been observed for facilities with large-scale battery installations following high-profile thermal runaway incidents. This trend affects the total cost of ownership for battery systems and potentially slows market adoption rates.

Supply chain disruptions represent another substantial economic consequence. When thermal runaway incidents occur at battery manufacturing facilities, production delays can cascade throughout the supply chain. For automotive manufacturers, a week-long disruption in battery supply can result in production losses exceeding $25 million for high-volume models.

The reputational damage following thermal runaway incidents often translates into measurable market capitalization losses. Analysis of public companies that experienced significant battery safety incidents shows an average 4-7% drop in share value in the immediate aftermath, with recovery periods extending from three months to over a year depending on incident severity and response effectiveness.

Regulatory responses to thermal runaway incidents create compliance costs that affect entire industries. Following clusters of incidents, regulatory bodies typically implement more stringent safety requirements, increasing compliance costs by an estimated 15-20% for manufacturers. These costs are eventually distributed across the value chain, affecting end-product pricing and market competitiveness.

Voltage regulation technologies that effectively prevent thermal runaway can deliver substantial economic benefits. Cost-benefit analyses indicate that implementing advanced voltage regulation systems adds approximately 2-5% to battery system costs but can reduce insurance premiums by up to 15% and virtually eliminate the catastrophic costs associated with thermal events. The return on investment for these preventive technologies typically ranges from 300-700% when calculated over a five-year operational period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!