What Causes Enhanced Thermal Runaway in High-Performance Batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Research Objectives

Thermal runaway in high-performance batteries represents one of the most critical safety challenges in modern energy storage systems. This phenomenon, characterized by an uncontrollable, self-accelerating exothermic reaction, has been documented since the early development of lithium-ion technology in the 1990s. The evolution of battery technology has consistently prioritized energy density improvements, with contemporary high-performance cells achieving energy densities exceeding 250 Wh/kg—a remarkable five-fold increase compared to early commercial versions.

The trajectory of thermal runaway research has evolved from reactive investigation following safety incidents to proactive prevention strategies. Initially focused on consumer electronics, research emphasis has shifted toward electric vehicles and grid-scale storage applications where the consequences of thermal events are significantly magnified due to larger battery arrays and higher energy capacities.

Current technical objectives in this field center on understanding the complex interplay of electrochemical, thermal, and mechanical factors that contribute to enhanced thermal runaway susceptibility in high-performance batteries. Specifically, researchers aim to identify critical temperature thresholds, characterize reaction kinetics, and quantify heat generation rates across various battery chemistries and form factors.

A key research goal involves developing comprehensive models that can accurately predict thermal runaway propagation within battery packs—addressing the transition from single-cell failure to system-level cascading effects. This includes understanding how cell-to-cell thermal and electrical interactions influence propagation dynamics in densely packed configurations typical of high-performance applications.

The industry seeks to establish standardized testing protocols that can reliably evaluate thermal stability under realistic operating conditions, including fast charging, extreme temperatures, and mechanical abuse scenarios. These protocols must balance practical implementation with scientific rigor to enable meaningful comparisons across different battery technologies.

From a materials science perspective, research objectives include identifying inherently safer electrode materials, electrolyte formulations, and separator designs that maintain high energy density while introducing thermal runaway resistance. This includes exploration of solid-state electrolytes, flame-retardant additives, and thermally triggered shutdown mechanisms.

Ultimately, the overarching goal is to develop next-generation battery systems that maintain the performance advantages of high-energy-density chemistries while eliminating or substantially mitigating thermal runaway risks through fundamental materials innovations and advanced system-level safety architectures.

The trajectory of thermal runaway research has evolved from reactive investigation following safety incidents to proactive prevention strategies. Initially focused on consumer electronics, research emphasis has shifted toward electric vehicles and grid-scale storage applications where the consequences of thermal events are significantly magnified due to larger battery arrays and higher energy capacities.

Current technical objectives in this field center on understanding the complex interplay of electrochemical, thermal, and mechanical factors that contribute to enhanced thermal runaway susceptibility in high-performance batteries. Specifically, researchers aim to identify critical temperature thresholds, characterize reaction kinetics, and quantify heat generation rates across various battery chemistries and form factors.

A key research goal involves developing comprehensive models that can accurately predict thermal runaway propagation within battery packs—addressing the transition from single-cell failure to system-level cascading effects. This includes understanding how cell-to-cell thermal and electrical interactions influence propagation dynamics in densely packed configurations typical of high-performance applications.

The industry seeks to establish standardized testing protocols that can reliably evaluate thermal stability under realistic operating conditions, including fast charging, extreme temperatures, and mechanical abuse scenarios. These protocols must balance practical implementation with scientific rigor to enable meaningful comparisons across different battery technologies.

From a materials science perspective, research objectives include identifying inherently safer electrode materials, electrolyte formulations, and separator designs that maintain high energy density while introducing thermal runaway resistance. This includes exploration of solid-state electrolytes, flame-retardant additives, and thermally triggered shutdown mechanisms.

Ultimately, the overarching goal is to develop next-generation battery systems that maintain the performance advantages of high-energy-density chemistries while eliminating or substantially mitigating thermal runaway risks through fundamental materials innovations and advanced system-level safety architectures.

Market Analysis of High-Performance Battery Demand

The high-performance battery market has experienced unprecedented growth over the past decade, primarily driven by the rapid expansion of electric vehicles (EVs), consumer electronics, and renewable energy storage systems. The global market for high-performance batteries reached approximately $112 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching $498 billion by the end of the decade.

Electric vehicle applications represent the largest segment of this market, accounting for nearly 60% of high-performance battery demand. This dominance is expected to continue as automotive manufacturers worldwide commit to electrification strategies, with many planning to phase out internal combustion engines entirely within the next 10-15 years. The consumer electronics sector constitutes roughly 25% of market demand, while grid-scale energy storage systems represent an emerging segment with the highest growth potential at 24.3% CAGR.

Geographically, Asia-Pacific dominates high-performance battery production and consumption, with China alone accounting for 42% of global manufacturing capacity. North America and Europe are rapidly expanding their domestic production capabilities through significant public and private investments to reduce dependency on Asian supply chains.

The demand for batteries with enhanced thermal stability has become particularly critical as applications require increasingly higher energy densities. Market research indicates that 78% of commercial battery users rank safety as their primary concern, specifically highlighting thermal runaway risks. This concern has created a premium market segment for thermally stable high-performance batteries, estimated at $28 billion in 2023.

Industry surveys reveal that customers are willing to pay 15-20% price premiums for batteries with proven enhanced thermal safety features, even at the cost of slightly reduced energy density. This trend is most pronounced in aerospace, medical device, and premium automotive segments where safety considerations outweigh marginal performance advantages.

The regulatory landscape is simultaneously evolving, with new safety standards being implemented across major markets. The UN 38.3 test, IEC 62133, and UL 1642 standards have been updated to include more stringent thermal stability requirements, directly influencing market demand for batteries with superior thermal management capabilities. These regulatory developments are expected to accelerate innovation in thermal runaway prevention technologies and reshape competitive dynamics within the industry.

Electric vehicle applications represent the largest segment of this market, accounting for nearly 60% of high-performance battery demand. This dominance is expected to continue as automotive manufacturers worldwide commit to electrification strategies, with many planning to phase out internal combustion engines entirely within the next 10-15 years. The consumer electronics sector constitutes roughly 25% of market demand, while grid-scale energy storage systems represent an emerging segment with the highest growth potential at 24.3% CAGR.

Geographically, Asia-Pacific dominates high-performance battery production and consumption, with China alone accounting for 42% of global manufacturing capacity. North America and Europe are rapidly expanding their domestic production capabilities through significant public and private investments to reduce dependency on Asian supply chains.

The demand for batteries with enhanced thermal stability has become particularly critical as applications require increasingly higher energy densities. Market research indicates that 78% of commercial battery users rank safety as their primary concern, specifically highlighting thermal runaway risks. This concern has created a premium market segment for thermally stable high-performance batteries, estimated at $28 billion in 2023.

Industry surveys reveal that customers are willing to pay 15-20% price premiums for batteries with proven enhanced thermal safety features, even at the cost of slightly reduced energy density. This trend is most pronounced in aerospace, medical device, and premium automotive segments where safety considerations outweigh marginal performance advantages.

The regulatory landscape is simultaneously evolving, with new safety standards being implemented across major markets. The UN 38.3 test, IEC 62133, and UL 1642 standards have been updated to include more stringent thermal stability requirements, directly influencing market demand for batteries with superior thermal management capabilities. These regulatory developments are expected to accelerate innovation in thermal runaway prevention technologies and reshape competitive dynamics within the industry.

Current Challenges in Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains one of the most critical challenges in high-performance battery development. Current prevention strategies face substantial limitations when confronted with the increasing energy densities and charging rates demanded by modern applications. The fundamental issue lies in the complex interplay between thermal, electrical, and chemical processes that accelerate exponentially once triggered.

Conventional battery management systems (BMS) struggle with real-time detection capabilities, particularly in distinguishing between normal temperature fluctuations and early indicators of thermal runaway. The detection-to-response time window is often too narrow, with current systems requiring 2-5 seconds to identify anomalies and implement countermeasures, while thermal propagation can accelerate beyond control in less than 1 second under certain conditions.

Material degradation presents another significant challenge. Current separator materials, typically polyolefin-based, begin to lose structural integrity at temperatures above 130°C, well below the thermal runaway trigger point of approximately 150-180°C. This narrow safety margin provides insufficient time for intervention once critical temperatures are approached.

Heat dissipation mechanisms remain inadequate for high-energy-density cells. Traditional passive cooling systems cannot effectively manage heat generation during fast charging or high-discharge scenarios, while active cooling systems add significant weight, volume, and complexity to battery packs, compromising energy density advantages.

The industry also faces standardization challenges across testing protocols. Current safety standards (IEC 62133, UL 1642) do not fully address the unique thermal characteristics of newer battery chemistries like silicon-rich anodes or high-nickel cathodes. This regulatory gap complicates the development of universally effective prevention strategies.

Mechanical abuse tolerance represents another critical vulnerability. Despite improvements in cell casing designs, internal short circuits caused by mechanical deformation remain difficult to predict and prevent. Current crush-resistant designs add weight without proportionally increasing safety margins under extreme conditions.

Aging effects further complicate prevention strategies. Batteries naturally develop increased internal resistance and reduced thermal stability over their lifecycle. Current predictive models inadequately account for these aging-related changes, leading to potentially dangerous miscalculations in thermal management parameters for batteries beyond 500-800 cycles.

The economic constraints of implementing comprehensive thermal safety systems present additional barriers. Advanced thermal management solutions can increase battery pack costs by 15-25%, creating market resistance despite their safety benefits. This cost-safety tradeoff continues to limit widespread adoption of the most effective prevention technologies.

Conventional battery management systems (BMS) struggle with real-time detection capabilities, particularly in distinguishing between normal temperature fluctuations and early indicators of thermal runaway. The detection-to-response time window is often too narrow, with current systems requiring 2-5 seconds to identify anomalies and implement countermeasures, while thermal propagation can accelerate beyond control in less than 1 second under certain conditions.

Material degradation presents another significant challenge. Current separator materials, typically polyolefin-based, begin to lose structural integrity at temperatures above 130°C, well below the thermal runaway trigger point of approximately 150-180°C. This narrow safety margin provides insufficient time for intervention once critical temperatures are approached.

Heat dissipation mechanisms remain inadequate for high-energy-density cells. Traditional passive cooling systems cannot effectively manage heat generation during fast charging or high-discharge scenarios, while active cooling systems add significant weight, volume, and complexity to battery packs, compromising energy density advantages.

The industry also faces standardization challenges across testing protocols. Current safety standards (IEC 62133, UL 1642) do not fully address the unique thermal characteristics of newer battery chemistries like silicon-rich anodes or high-nickel cathodes. This regulatory gap complicates the development of universally effective prevention strategies.

Mechanical abuse tolerance represents another critical vulnerability. Despite improvements in cell casing designs, internal short circuits caused by mechanical deformation remain difficult to predict and prevent. Current crush-resistant designs add weight without proportionally increasing safety margins under extreme conditions.

Aging effects further complicate prevention strategies. Batteries naturally develop increased internal resistance and reduced thermal stability over their lifecycle. Current predictive models inadequately account for these aging-related changes, leading to potentially dangerous miscalculations in thermal management parameters for batteries beyond 500-800 cycles.

The economic constraints of implementing comprehensive thermal safety systems present additional barriers. Advanced thermal management solutions can increase battery pack costs by 15-25%, creating market resistance despite their safety benefits. This cost-safety tradeoff continues to limit widespread adoption of the most effective prevention technologies.

Existing Thermal Management Solutions

01 Thermal management systems for high-performance batteries

Advanced thermal management systems are crucial for preventing thermal runaway in high-performance batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal operating temperatures. By effectively managing heat generation and dissipation, these systems can prevent the cascade of exothermic reactions that lead to thermal runaway, significantly improving battery safety and performance in high-demand applications.- Thermal management systems for preventing thermal runaway: Advanced thermal management systems are designed to prevent thermal runaway in high-performance batteries by efficiently dissipating heat and maintaining optimal operating temperatures. These systems may include cooling channels, heat sinks, phase change materials, or liquid cooling circuits integrated into battery packs. By controlling temperature distribution and preventing hotspots, these systems can significantly reduce the risk of thermal events and extend battery life while maintaining performance.

- Safety mechanisms and protective materials: Various safety mechanisms and protective materials are incorporated into high-performance batteries to mitigate thermal runaway risks. These include thermal fuses, current interrupt devices, pressure relief mechanisms, and flame-retardant separators. Advanced composite materials and coatings can be applied to battery components to enhance thermal stability and contain potential fires. These protective elements work together to isolate failures and prevent cascading thermal events across battery cells.

- Battery monitoring and early detection systems: Sophisticated monitoring systems are employed to detect early signs of thermal runaway in high-performance batteries. These systems utilize sensors to track parameters such as temperature, voltage, current, and internal pressure across battery cells. Advanced algorithms analyze this data in real-time to identify abnormal patterns that may indicate impending thermal issues. Early detection allows for preventive measures to be activated before a thermal runaway event can fully develop.

- Novel electrode and electrolyte formulations: Innovative electrode and electrolyte formulations are developed to enhance the intrinsic safety of high-performance batteries against thermal runaway. These include solid-state electrolytes, flame-retardant additives, and thermally stable cathode materials. Modified separator designs with shutdown capabilities can prevent ion transport at elevated temperatures. These material innovations aim to increase the thermal stability threshold of battery cells while maintaining or improving energy density and performance characteristics.

- Battery pack design and cell isolation strategies: Strategic battery pack designs incorporate physical barriers and isolation mechanisms to prevent thermal runaway propagation between cells. Compartmentalization techniques, thermal barriers, and spacing optimization help contain thermal events to individual cells. Some designs implement active isolation systems that can electrically or thermally disconnect compromised cells. These architectural approaches are crucial for large-scale battery systems where the consequences of thermal runaway can be particularly severe.

02 Battery cell design and materials for thermal stability

Innovative cell designs and advanced materials play a critical role in mitigating thermal runaway risks in high-performance batteries. These include specialized electrode materials, separator technologies with thermal shutdown capabilities, and novel electrolyte formulations with flame-retardant properties. The strategic selection and arrangement of these components can significantly increase the thermal stability threshold of battery cells, allowing them to withstand higher temperatures before entering thermal runaway conditions.Expand Specific Solutions03 Detection and early warning systems for thermal events

Advanced detection and early warning systems are being developed to identify precursors to thermal runaway events before they escalate. These systems utilize sensors, monitoring algorithms, and predictive analytics to detect abnormal temperature increases, voltage fluctuations, or gas emissions that may indicate an impending thermal event. Early detection allows for preventive measures to be implemented, such as load reduction or emergency shutdown procedures, significantly reducing the risk of catastrophic battery failure.Expand Specific Solutions04 Safety mechanisms and containment strategies

Safety mechanisms and containment strategies are essential components in high-performance battery systems to mitigate the consequences of thermal runaway events. These include pressure relief mechanisms, thermal fuses, current interrupt devices, and physical containment structures designed to prevent propagation of thermal events between cells. Additionally, advanced battery management systems can implement protective measures such as circuit isolation and controlled discharge when abnormal conditions are detected, limiting the severity of thermal incidents.Expand Specific Solutions05 Battery pack architecture and system-level thermal management

System-level approaches to thermal runaway prevention focus on optimizing battery pack architecture and implementing comprehensive thermal management strategies. These include strategic cell spacing, thermal barriers between modules, dedicated cooling channels, and intelligent heat distribution systems. By addressing thermal management at the pack and system level, these approaches can prevent localized heating from spreading throughout the battery system, effectively containing potential thermal runaway events and protecting the overall battery integrity.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The thermal runaway issue in high-performance batteries represents a critical challenge in an industry transitioning from early growth to maturity. The market for safer battery technologies is expanding rapidly, projected to reach $115 billion by 2030. Companies demonstrate varying levels of technical maturity in addressing this challenge: Tesla and Samsung SDI lead with extensive commercial implementations; Aspen Aerogels and ProLogium Technology are advancing innovative thermal management solutions; while newer entrants like Beijing WeLion and Arc Boat are developing specialized applications. Research institutions including Argonne National Laboratory and Industrial Technology Research Institute provide crucial scientific foundations. The competitive landscape is intensifying as automotive manufacturers (BMW, Geely, Hyundai Mobis) increasingly develop proprietary battery safety technologies to secure competitive advantages in the electric vehicle market.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive thermal management system for their high-performance batteries to mitigate thermal runaway risks. Their approach includes a patented cooling architecture with a serpentine cooling tube design that maintains uniform temperature distribution across battery packs. Tesla's system incorporates real-time temperature monitoring with thousands of sensors throughout the pack, allowing for predictive thermal management. Their battery management system (BMS) employs advanced algorithms to detect early signs of thermal anomalies before they cascade into thermal runaway events. Tesla has also implemented physical cell separation with flame-retardant barriers between cells and modules to prevent propagation of thermal events. Additionally, they've developed a specialized vent system that directs heat and gases away from the passenger compartment in case of thermal incidents. Tesla's research has identified that lithium plating during fast charging and mechanical deformation are primary triggers for thermal runaway, leading them to implement charging protocols that dynamically adjust based on battery temperature and state of charge.

Strengths: Tesla's integrated approach combining hardware (cooling systems, physical barriers) with sophisticated software (predictive algorithms, real-time monitoring) provides multiple layers of protection. Their extensive real-world data from millions of vehicles allows for continuous refinement of thermal management strategies. Weaknesses: The complex cooling system adds weight and manufacturing complexity to battery packs. Their approach requires significant computational resources for real-time monitoring and prediction, potentially increasing costs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered advanced safety mechanisms to address thermal runaway in high-performance batteries following their Galaxy Note 7 incident. Their multi-layered approach begins at the cell level with their "Safety Reinforced Separator" technology that includes a ceramic coating capable of withstanding higher temperatures before breakdown. Samsung has developed proprietary electrolyte additives that increase the thermal stability threshold of their batteries by approximately 30°C compared to standard formulations. Their research identified that internal short circuits from manufacturing defects were a primary cause of thermal runaway, leading to the implementation of X-ray and CT scanning for 100% of cells in critical applications. Samsung's battery packs incorporate thermal barriers between cells using aerogel-based materials that can withstand temperatures exceeding 500°C. Their Battery Management System employs machine learning algorithms trained on thermal failure data to detect abnormal temperature patterns before they reach critical thresholds. Additionally, Samsung has developed a "thermal fuse" technology that physically disconnects cells when temperatures approach dangerous levels, preventing cascade failures across the pack.

Strengths: Samsung's comprehensive approach addresses thermal runaway at multiple levels: materials engineering, manufacturing quality control, and active management systems. Their extensive experience with consumer electronics batteries has informed robust safety protocols for larger format cells. Weaknesses: Some of their safety mechanisms add cost and weight to battery systems, potentially reducing energy density. Their thermal management approach may be more conservative than competitors, potentially limiting performance in high-demand applications.

Critical Mechanisms of Enhanced Thermal Runaway

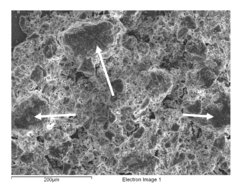

Materials for electrochemical device safety

PatentActiveUS20110281154A1

Innovation

- Incorporating a thermally or gas-triggered intumescent material in lithium batteries and supercapacitors, such as calcium gluconate monohydrate or shape memory polymers, which expand to disrupt short circuits and prevent further thermal events, thereby maintaining energy storage capacity while enhancing safety.

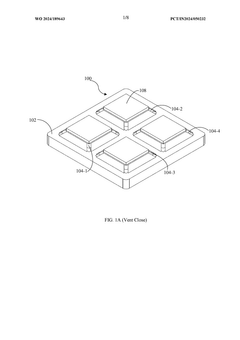

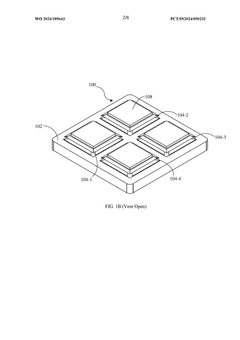

A valve

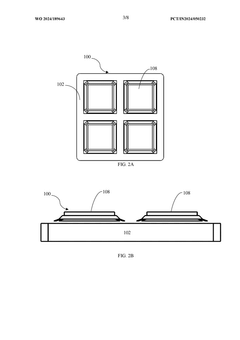

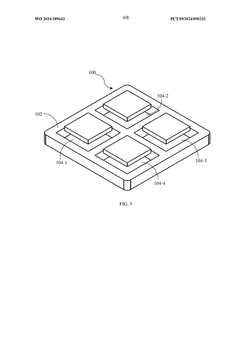

PatentWO2024189643A1

Innovation

- A valve with a base plate and vent structure featuring flaps that open at specific pressure thresholds to release gases externally, made from high-heat resistant materials like silicone, ensuring safe pressure regulation and gas ejection during thermal runaway, while maintaining the battery pack's sealing integrity.

Regulatory Framework for Battery Safety Standards

The global regulatory landscape for battery safety has evolved significantly in response to the increasing incidents of thermal runaway in high-performance batteries. International standards organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established comprehensive frameworks that address various aspects of battery safety, with specific focus on thermal management and runaway prevention.

IEC 62133 serves as a cornerstone standard for secondary cells and batteries containing alkaline or non-acid electrolytes, mandating rigorous testing protocols including forced internal short circuit tests, overcharge protection, and thermal abuse evaluations. This standard has been widely adopted across multiple jurisdictions and forms the basis for many regional certification requirements.

In the United States, UL 1642 for lithium batteries and UL 2054 for household and commercial batteries establish stringent safety requirements with particular emphasis on thermal stability. The U.S. Department of Transportation (DOT) has also implemented regulations under 49 CFR that specifically address the transportation of lithium batteries, recognizing their heightened risk of thermal runaway during shipping conditions.

The European Union has implemented battery safety regulations through EN 62133 (harmonized with IEC 62133) and additional requirements under the Battery Directive 2006/66/EC. More recently, the proposed Battery Regulation COM(2020) 798/3 introduces enhanced safety provisions specifically targeting thermal runaway risks in high-energy density systems.

In Asia, China's GB/T 31241 standard has established particularly rigorous requirements for lithium-ion battery safety, with Japan's JIS C8714 and South Korea's KC 62133 providing similar frameworks with regional adaptations. These standards have been continuously updated to address emerging concerns related to thermal runaway in high-performance battery technologies.

Industry-specific standards have also emerged, with SAE J2464 and ISO 12405 addressing automotive applications, and IEC 62619 focusing on industrial applications of lithium-ion batteries. These standards incorporate specialized testing protocols for thermal propagation and thermal runaway mitigation that reflect the unique operating conditions in these sectors.

Regulatory gaps remain evident in emerging battery chemistries and ultra-high-energy density systems, where existing test protocols may not adequately predict thermal runaway behavior. Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety thresholds.

The harmonization of global standards remains a significant challenge, with manufacturers often needing to navigate multiple certification processes across different markets. Efforts by organizations such as the Global Battery Alliance seek to establish more consistent international frameworks that specifically address thermal runaway risks while facilitating global trade and technology adoption.

IEC 62133 serves as a cornerstone standard for secondary cells and batteries containing alkaline or non-acid electrolytes, mandating rigorous testing protocols including forced internal short circuit tests, overcharge protection, and thermal abuse evaluations. This standard has been widely adopted across multiple jurisdictions and forms the basis for many regional certification requirements.

In the United States, UL 1642 for lithium batteries and UL 2054 for household and commercial batteries establish stringent safety requirements with particular emphasis on thermal stability. The U.S. Department of Transportation (DOT) has also implemented regulations under 49 CFR that specifically address the transportation of lithium batteries, recognizing their heightened risk of thermal runaway during shipping conditions.

The European Union has implemented battery safety regulations through EN 62133 (harmonized with IEC 62133) and additional requirements under the Battery Directive 2006/66/EC. More recently, the proposed Battery Regulation COM(2020) 798/3 introduces enhanced safety provisions specifically targeting thermal runaway risks in high-energy density systems.

In Asia, China's GB/T 31241 standard has established particularly rigorous requirements for lithium-ion battery safety, with Japan's JIS C8714 and South Korea's KC 62133 providing similar frameworks with regional adaptations. These standards have been continuously updated to address emerging concerns related to thermal runaway in high-performance battery technologies.

Industry-specific standards have also emerged, with SAE J2464 and ISO 12405 addressing automotive applications, and IEC 62619 focusing on industrial applications of lithium-ion batteries. These standards incorporate specialized testing protocols for thermal propagation and thermal runaway mitigation that reflect the unique operating conditions in these sectors.

Regulatory gaps remain evident in emerging battery chemistries and ultra-high-energy density systems, where existing test protocols may not adequately predict thermal runaway behavior. Regulatory bodies are increasingly moving toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety thresholds.

The harmonization of global standards remains a significant challenge, with manufacturers often needing to navigate multiple certification processes across different markets. Efforts by organizations such as the Global Battery Alliance seek to establish more consistent international frameworks that specifically address thermal runaway risks while facilitating global trade and technology adoption.

Environmental Impact of Battery Thermal Events

Battery thermal runaway events pose significant environmental challenges that extend far beyond the immediate safety concerns. When high-performance batteries experience thermal runaway, they release a complex mixture of toxic gases, particulate matter, and potentially harmful chemicals into the atmosphere. These emissions typically include carbon monoxide, hydrogen fluoride, phosphoryl fluoride, and various volatile organic compounds (VOCs), which can contribute to air pollution and pose respiratory risks to nearby populations.

The environmental impact is particularly concerning when thermal events occur at scale, such as in energy storage facilities or electric vehicle fleet fires. Studies have documented that a single large-scale lithium-ion battery fire can release emissions equivalent to thousands of conventional vehicles operating simultaneously, creating localized air quality emergencies that may require evacuation of surrounding areas.

Water contamination represents another critical environmental concern. Firefighting efforts often involve substantial quantities of water, which becomes contaminated with battery electrolytes, heavy metals including cobalt, nickel, and manganese, and other hazardous materials. This contaminated runoff can infiltrate soil and water systems, potentially affecting aquatic ecosystems and drinking water supplies if not properly contained and treated.

The long-term environmental persistence of certain battery components exacerbates these concerns. Many of the materials used in high-performance batteries degrade slowly in the environment, with some heavy metals and fluorinated compounds having environmental half-lives measured in decades or longer. This persistence increases the potential for bioaccumulation in food chains and prolonged ecosystem disruption.

Climate impacts must also be considered, as thermal runaway events release greenhouse gases directly and indirectly. Beyond the immediate CO2 emissions from combustion, the release of refrigerants and other high-GWP (Global Warming Potential) compounds from battery cooling systems can have climate impacts hundreds or thousands of times greater than equivalent amounts of carbon dioxide.

Mitigation strategies are increasingly focusing on environmental protection alongside safety considerations. These include advanced containment systems for battery installations, specialized firefighting protocols designed to minimize water usage and runoff, and the development of environmentally benign fire suppression agents specifically formulated for battery fires. Additionally, regulatory frameworks are evolving to require environmental impact assessments and mitigation plans for large-scale battery deployments.

The environmental impact is particularly concerning when thermal events occur at scale, such as in energy storage facilities or electric vehicle fleet fires. Studies have documented that a single large-scale lithium-ion battery fire can release emissions equivalent to thousands of conventional vehicles operating simultaneously, creating localized air quality emergencies that may require evacuation of surrounding areas.

Water contamination represents another critical environmental concern. Firefighting efforts often involve substantial quantities of water, which becomes contaminated with battery electrolytes, heavy metals including cobalt, nickel, and manganese, and other hazardous materials. This contaminated runoff can infiltrate soil and water systems, potentially affecting aquatic ecosystems and drinking water supplies if not properly contained and treated.

The long-term environmental persistence of certain battery components exacerbates these concerns. Many of the materials used in high-performance batteries degrade slowly in the environment, with some heavy metals and fluorinated compounds having environmental half-lives measured in decades or longer. This persistence increases the potential for bioaccumulation in food chains and prolonged ecosystem disruption.

Climate impacts must also be considered, as thermal runaway events release greenhouse gases directly and indirectly. Beyond the immediate CO2 emissions from combustion, the release of refrigerants and other high-GWP (Global Warming Potential) compounds from battery cooling systems can have climate impacts hundreds or thousands of times greater than equivalent amounts of carbon dioxide.

Mitigation strategies are increasingly focusing on environmental protection alongside safety considerations. These include advanced containment systems for battery installations, specialized firefighting protocols designed to minimize water usage and runoff, and the development of environmentally benign fire suppression agents specifically formulated for battery fires. Additionally, regulatory frameworks are evolving to require environmental impact assessments and mitigation plans for large-scale battery deployments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!