Regulations on Battery Thermal Runaway in Aviation Safety Standards

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aviation Battery Safety Evolution and Objectives

The evolution of aviation battery safety standards has been significantly influenced by the increasing adoption of lithium-ion batteries in aircraft systems. In the early 2000s, aviation safety regulations primarily focused on traditional lead-acid and nickel-cadmium batteries, with minimal specific provisions for lithium-based technologies. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) initially addressed battery safety through general electrical system requirements rather than dedicated battery thermal runaway prevention measures.

A pivotal shift occurred following several high-profile incidents between 2010-2013, most notably the Boeing 787 Dreamliner battery failures that led to fleet grounding in 2013. These events catalyzed comprehensive regulatory reforms, establishing thermal runaway as a critical safety concern requiring specific mitigation strategies. The FAA's subsequent Special Conditions for lithium battery installations marked the beginning of a more rigorous approach to battery thermal management in aviation.

By 2016, RTCA DO-311A and DO-347 standards emerged as cornerstone documents establishing testing protocols and performance criteria specifically addressing thermal runaway risks. These standards introduced crucial requirements for containment, venting, and monitoring systems designed to prevent cascading thermal events. The International Civil Aviation Organization (ICAO) further strengthened this regulatory framework by implementing global dangerous goods regulations for battery transport.

The current regulatory landscape reflects a multi-layered approach combining airworthiness directives, technical standard orders (TSOs), and certification specifications. Modern standards emphasize a systems-based perspective that considers battery integration within aircraft electrical architectures rather than viewing batteries as isolated components. This holistic approach acknowledges the complex interactions between battery management systems, thermal control mechanisms, and aircraft emergency procedures.

The primary objective of contemporary aviation battery safety standards is to establish a comprehensive safety framework that enables the benefits of advanced battery technologies while maintaining the aviation industry's exceptional safety record. Specific goals include preventing thermal runaway initiation, containing thermal events when they occur, eliminating toxic gas release into aircraft environments, and ensuring continued safe operation of critical systems during battery failure scenarios.

Looking forward, regulatory bodies aim to develop performance-based standards that can adapt to rapidly evolving battery chemistries and configurations without requiring continuous regulatory revisions. This approach seeks to balance innovation enablement with rigorous safety assurance, recognizing that next-generation electric aircraft will demand even greater energy density from their battery systems.

A pivotal shift occurred following several high-profile incidents between 2010-2013, most notably the Boeing 787 Dreamliner battery failures that led to fleet grounding in 2013. These events catalyzed comprehensive regulatory reforms, establishing thermal runaway as a critical safety concern requiring specific mitigation strategies. The FAA's subsequent Special Conditions for lithium battery installations marked the beginning of a more rigorous approach to battery thermal management in aviation.

By 2016, RTCA DO-311A and DO-347 standards emerged as cornerstone documents establishing testing protocols and performance criteria specifically addressing thermal runaway risks. These standards introduced crucial requirements for containment, venting, and monitoring systems designed to prevent cascading thermal events. The International Civil Aviation Organization (ICAO) further strengthened this regulatory framework by implementing global dangerous goods regulations for battery transport.

The current regulatory landscape reflects a multi-layered approach combining airworthiness directives, technical standard orders (TSOs), and certification specifications. Modern standards emphasize a systems-based perspective that considers battery integration within aircraft electrical architectures rather than viewing batteries as isolated components. This holistic approach acknowledges the complex interactions between battery management systems, thermal control mechanisms, and aircraft emergency procedures.

The primary objective of contemporary aviation battery safety standards is to establish a comprehensive safety framework that enables the benefits of advanced battery technologies while maintaining the aviation industry's exceptional safety record. Specific goals include preventing thermal runaway initiation, containing thermal events when they occur, eliminating toxic gas release into aircraft environments, and ensuring continued safe operation of critical systems during battery failure scenarios.

Looking forward, regulatory bodies aim to develop performance-based standards that can adapt to rapidly evolving battery chemistries and configurations without requiring continuous regulatory revisions. This approach seeks to balance innovation enablement with rigorous safety assurance, recognizing that next-generation electric aircraft will demand even greater energy density from their battery systems.

Market Analysis of Aviation Battery Systems

The aviation battery systems market is experiencing robust growth, driven primarily by the increasing adoption of electric and hybrid-electric propulsion systems in aircraft. As of 2023, the global aviation battery market is valued at approximately 7.8 billion USD, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030. This significant growth trajectory is underpinned by the aviation industry's intensifying focus on sustainability and the reduction of carbon emissions.

The market segmentation reveals distinct categories based on battery chemistry, with lithium-ion batteries dominating the landscape due to their superior energy density and relatively lighter weight. These batteries currently account for over 65% of the aviation battery market share. Other chemistries, including nickel-cadmium and lead-acid, continue to serve specific applications but are gradually losing market share to more advanced technologies.

From an application perspective, the market can be divided into three primary segments: auxiliary power units (APUs), emergency systems, and propulsion systems. The propulsion segment is witnessing the fastest growth rate at 23.5% annually, reflecting the accelerating development of electric vertical takeoff and landing (eVTOL) aircraft and urban air mobility solutions.

Regional analysis indicates that North America currently leads the market with approximately 38% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in aviation infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Key market drivers include stringent environmental regulations, technological advancements in battery energy density, and increasing investments in electric aircraft development. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has been particularly influential in accelerating the adoption of electric and hybrid-electric systems.

Market challenges predominantly revolve around safety concerns, particularly regarding thermal runaway risks. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented increasingly stringent certification requirements for battery systems, directly impacting market dynamics and product development cycles. These regulations have created both barriers to entry and opportunities for companies with advanced battery management and thermal control technologies.

Consumer demand patterns indicate growing preference for aircraft with reduced environmental impact, creating pull factors for airlines to adopt more efficient battery systems. This trend is particularly pronounced in the commercial aviation sector, where fuel costs and environmental considerations significantly influence purchasing decisions.

The market segmentation reveals distinct categories based on battery chemistry, with lithium-ion batteries dominating the landscape due to their superior energy density and relatively lighter weight. These batteries currently account for over 65% of the aviation battery market share. Other chemistries, including nickel-cadmium and lead-acid, continue to serve specific applications but are gradually losing market share to more advanced technologies.

From an application perspective, the market can be divided into three primary segments: auxiliary power units (APUs), emergency systems, and propulsion systems. The propulsion segment is witnessing the fastest growth rate at 23.5% annually, reflecting the accelerating development of electric vertical takeoff and landing (eVTOL) aircraft and urban air mobility solutions.

Regional analysis indicates that North America currently leads the market with approximately 38% share, followed closely by Europe at 32%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in aviation infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Key market drivers include stringent environmental regulations, technological advancements in battery energy density, and increasing investments in electric aircraft development. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has been particularly influential in accelerating the adoption of electric and hybrid-electric systems.

Market challenges predominantly revolve around safety concerns, particularly regarding thermal runaway risks. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented increasingly stringent certification requirements for battery systems, directly impacting market dynamics and product development cycles. These regulations have created both barriers to entry and opportunities for companies with advanced battery management and thermal control technologies.

Consumer demand patterns indicate growing preference for aircraft with reduced environmental impact, creating pull factors for airlines to adopt more efficient battery systems. This trend is particularly pronounced in the commercial aviation sector, where fuel costs and environmental considerations significantly influence purchasing decisions.

Current Thermal Runaway Prevention Challenges

Despite significant advancements in battery technology for aviation applications, thermal runaway prevention remains a critical challenge with several persistent obstacles. Current lithium-ion battery systems face inherent limitations in their ability to contain thermal events once initiated. The high energy density that makes these batteries attractive for aviation simultaneously creates significant safety risks when thermal stability is compromised.

Material science constraints present a fundamental challenge, as existing separator materials cannot reliably prevent internal short circuits at extreme temperatures. When cells reach critical temperatures (typically 130-150°C), separator integrity deteriorates rapidly, allowing direct contact between electrodes and triggering cascading thermal failures. Current flame-retardant additives and modified electrolytes show promise but often compromise battery performance and longevity.

Detection systems face significant limitations in early identification of precursor events. The time window between detectable thermal anomalies and catastrophic failure can be extremely short—sometimes less than 60 seconds—making effective intervention challenging. Current sensing technologies struggle with the balance between sensitivity and false alarm rates, particularly in the variable environmental conditions experienced during flight operations.

Containment strategies present another major hurdle. Aviation's strict weight constraints limit the implementation of robust physical containment systems that could otherwise mitigate propagation risks. Current venting mechanisms designed to release pressure during thermal events can inadvertently introduce oxygen to the reaction, potentially exacerbating the situation in certain scenarios.

Regulatory fragmentation compounds these technical challenges. Different jurisdictions maintain varying requirements for battery safety certification, creating compliance complexities for manufacturers and operators. The FAA, EASA, and other regulatory bodies have established interim guidelines, but comprehensive standardized testing protocols specific to aviation battery thermal runaway prevention remain under development.

The integration of battery management systems (BMS) with aircraft systems presents additional challenges. Current BMS technologies can monitor cell parameters but have limited predictive capabilities for identifying cells at risk of thermal runaway before measurable symptoms appear. The computational demands of more sophisticated predictive algorithms conflict with the certification requirements for flight-critical systems.

Environmental factors further complicate prevention efforts. Aviation batteries must operate reliably across extreme temperature ranges, pressure variations, and vibration conditions that can accelerate degradation mechanisms leading to thermal events. Current testing regimes struggle to accurately simulate the combined effects of these stressors over the operational lifetime of battery systems.

Material science constraints present a fundamental challenge, as existing separator materials cannot reliably prevent internal short circuits at extreme temperatures. When cells reach critical temperatures (typically 130-150°C), separator integrity deteriorates rapidly, allowing direct contact between electrodes and triggering cascading thermal failures. Current flame-retardant additives and modified electrolytes show promise but often compromise battery performance and longevity.

Detection systems face significant limitations in early identification of precursor events. The time window between detectable thermal anomalies and catastrophic failure can be extremely short—sometimes less than 60 seconds—making effective intervention challenging. Current sensing technologies struggle with the balance between sensitivity and false alarm rates, particularly in the variable environmental conditions experienced during flight operations.

Containment strategies present another major hurdle. Aviation's strict weight constraints limit the implementation of robust physical containment systems that could otherwise mitigate propagation risks. Current venting mechanisms designed to release pressure during thermal events can inadvertently introduce oxygen to the reaction, potentially exacerbating the situation in certain scenarios.

Regulatory fragmentation compounds these technical challenges. Different jurisdictions maintain varying requirements for battery safety certification, creating compliance complexities for manufacturers and operators. The FAA, EASA, and other regulatory bodies have established interim guidelines, but comprehensive standardized testing protocols specific to aviation battery thermal runaway prevention remain under development.

The integration of battery management systems (BMS) with aircraft systems presents additional challenges. Current BMS technologies can monitor cell parameters but have limited predictive capabilities for identifying cells at risk of thermal runaway before measurable symptoms appear. The computational demands of more sophisticated predictive algorithms conflict with the certification requirements for flight-critical systems.

Environmental factors further complicate prevention efforts. Aviation batteries must operate reliably across extreme temperature ranges, pressure variations, and vibration conditions that can accelerate degradation mechanisms leading to thermal events. Current testing regimes struggle to accurately simulate the combined effects of these stressors over the operational lifetime of battery systems.

Existing Thermal Runaway Mitigation Solutions

01 Thermal management systems for battery safety

Various thermal management systems are designed to prevent thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, and intelligent control systems that can detect temperature anomalies and take preventive actions before thermal runaway occurs.- Thermal management systems for battery safety: Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature ranges. Advanced designs incorporate phase change materials, liquid cooling circuits, and thermal barriers to isolate cells during thermal events, effectively preventing propagation of thermal runaway between battery cells.

- Battery cell design and materials for thermal stability: Innovations in battery cell design and materials focus on enhancing thermal stability and preventing thermal runaway. These include specialized electrode compositions, separator materials with thermal shutdown properties, and flame-retardant electrolytes. Advanced cell designs incorporate safety features such as pressure relief mechanisms, internal thermal fuses, and structural reinforcements that can withstand thermal stress while maintaining electrical isolation during failure events.

- Detection and early warning systems for thermal events: Early detection systems for thermal runaway employ various sensors and monitoring technologies to identify precursors to thermal events. These systems utilize temperature sensors, gas detectors, voltage monitoring, and impedance tracking to detect abnormal battery behavior. Advanced systems incorporate machine learning algorithms to analyze battery parameters and predict potential failures before they occur, enabling preventive measures and emergency responses to be activated promptly.

- Battery management systems (BMS) for thermal safety: Battery management systems play a crucial role in preventing thermal runaway by continuously monitoring and controlling battery parameters. These systems regulate charging and discharging rates, cell balancing, and thermal conditions to ensure operation within safe limits. Advanced BMS implementations include adaptive algorithms that adjust battery usage based on environmental conditions, state of health, and operational demands, with fail-safe protocols that can isolate problematic cells or modules.

- Regulatory frameworks and testing standards for battery safety: Comprehensive regulatory frameworks and testing standards have been developed to ensure battery safety across various applications. These include protocols for thermal abuse testing, mechanical integrity verification, and electrical safety validation. Standards specify requirements for thermal runaway containment, propagation resistance, and emergency response procedures. Certification processes require batteries to undergo rigorous testing under extreme conditions to demonstrate compliance with safety thresholds before market approval.

02 Battery cell design and materials for preventing thermal runaway

Innovations in battery cell design and materials focus on inherently safer battery compositions that resist thermal runaway. These include modified electrode materials, separator technologies with thermal shutdown capabilities, and flame-retardant electrolytes. Some designs incorporate physical barriers between cells to prevent propagation of thermal events, while others use novel cathode and anode materials that remain stable at higher temperatures, reducing the risk of exothermic reactions that lead to thermal runaway.Expand Specific Solutions03 Battery management systems (BMS) for early detection and prevention

Advanced battery management systems employ sophisticated algorithms and sensors to monitor battery health and detect early signs of potential thermal runaway. These systems track parameters such as voltage, current, temperature gradients, and internal resistance across individual cells and the entire battery pack. When abnormal patterns are detected, the BMS can implement protective measures such as load reduction, circuit isolation, or emergency shutdown procedures to prevent thermal runaway from developing or spreading.Expand Specific Solutions04 Safety standards and testing protocols for battery certification

Comprehensive safety standards and testing protocols have been developed to evaluate battery resistance to thermal runaway under various conditions. These include abuse tests such as nail penetration, crush tests, overcharging, external short circuit, and extreme temperature exposure. Certification requirements mandate that batteries demonstrate containment of thermal events, minimal propagation between cells, and safe venting of gases. Standards organizations like UL, IEC, and UN have established specific requirements for different battery applications, from consumer electronics to electric vehicles and grid storage.Expand Specific Solutions05 Containment and suppression systems for thermal runaway events

When thermal runaway cannot be prevented, containment and suppression systems are designed to minimize damage and protect surrounding components and users. These systems include fire-resistant battery enclosures, pressure relief mechanisms, gas venting channels, and automatic fire suppression technologies. Some designs incorporate intumescent materials that expand when heated to create barriers against flame spread, while others use specialized extinguishing agents that can penetrate between battery cells to suppress fires at their source.Expand Specific Solutions

Key Aviation Battery Safety Stakeholders

The aviation battery thermal runaway regulatory landscape is evolving rapidly as the industry transitions from early-stage safety protocols to comprehensive standards. The market is expanding significantly due to increasing electrification in aviation, though still relatively small compared to automotive applications. Technologically, established aerospace players like Safran, Airbus Defence & Space, and Rolls-Royce lead with mature safety systems, while battery specialists including Microvast, Tesla, Samsung SDI, and Huawei Digital Power are advancing thermal management innovations. Research institutions such as Southwest Research Institute and Industrial Technology Research Institute contribute significantly to safety testing methodologies. The regulatory framework remains in development, with aviation authorities collaborating with industry leaders to establish standardized certification requirements for battery thermal runaway prevention and containment systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an advanced aviation battery safety system that addresses thermal runaway risks through a comprehensive approach aligned with FAA and EASA requirements. Their solution combines predictive analytics with physical protection measures to create a multi-layered defense system. The technology utilizes proprietary algorithms that analyze battery performance parameters to detect precursors to thermal events up to 30 minutes before they become critical. Honeywell's system incorporates specialized ceramic-based thermal barriers between cells that can withstand temperatures exceeding 1200°C while preventing propagation to adjacent cells. Their design includes a patented pressure-relief system that manages gas venting while maintaining aircraft structural integrity. The technology also features an intelligent power management system that can isolate individual cells or modules when anomalies are detected. Honeywell has integrated this solution with their broader aircraft management systems to provide pilots with actionable information and automated emergency response protocols in the event of battery thermal events.

Strengths: Strong integration with aircraft avionics and control systems; advanced predictive capabilities; extensive aviation certification experience; comprehensive approach combining software and hardware protection. Weaknesses: Higher system complexity requiring specialized maintenance; premium cost position; requires more frequent calibration and monitoring compared to simpler systems.

Airbus Defence & Space SAS

Technical Solution: Airbus has engineered a multi-layered thermal runaway protection system specifically for aviation applications that meets EASA and FAA certification requirements. Their solution features a sophisticated early detection system using differential thermal analysis to identify potential cell failures before thermal runaway occurs. The technology incorporates specialized battery enclosures with aeronautical-grade fire containment capabilities that can withstand extreme thermal events while maintaining structural integrity. Airbus's system includes automated isolation circuits that can disconnect compromised battery modules within milliseconds of detecting abnormal behavior. Their approach also features a patented active cooling system that uses aircraft environmental control system integration to rapidly remove heat from battery assemblies. The design incorporates dedicated venting channels that safely direct thermal runaway byproducts outside the pressure vessel while maintaining cabin pressurization. Airbus has validated this technology through extensive testing including simulated flight conditions and extreme abuse testing protocols.

Strengths: Comprehensive aviation-specific design with full regulatory compliance; integration with aircraft systems; extensive testing under actual flight conditions; proven containment capabilities. Weaknesses: Higher weight penalty compared to some competitors; complex integration requirements with aircraft systems; significant cost premium for the aviation-certified components.

Critical Patents in Battery Thermal Management

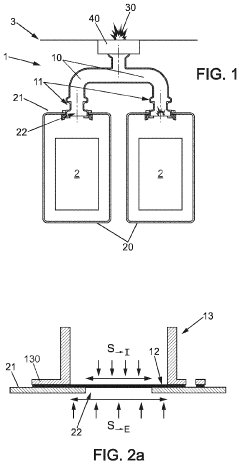

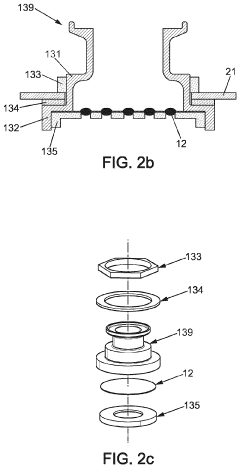

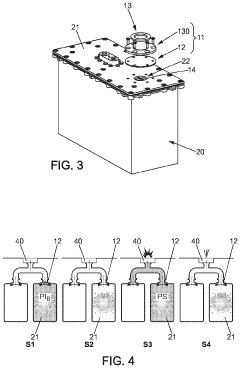

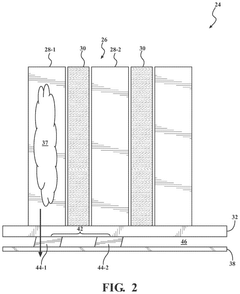

Anti-propagation exhaust device for aircraft lithium-ion batteries

PatentActiveUS11962032B2

Innovation

- A shared exhaust device with check valves and a pressure relief system connects multiple battery housings to a common discharge port, using membranes that burst at lower internal pressure to prevent thermal runaway contamination and ensure high reliability, allowing gases to escape without risking other batteries.

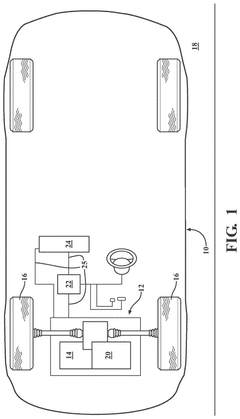

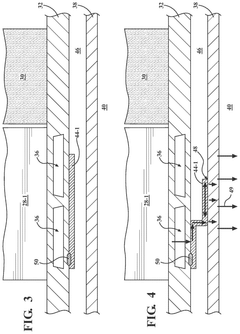

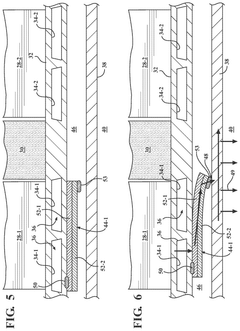

Mitigation of thermal runaway in a battery module

PatentActiveUS12308404B2

Innovation

- The battery module incorporates a heat sink in contact with each battery cell to absorb thermal energy, along with a heat transfer mechanism featuring a switch that detects temperature exceeding a predetermined value, bridging an air gap to direct thermal energy from the overheated cell to the module enclosure, thereby controlling the propagation of thermal runaway.

Regulatory Compliance Framework

The aviation industry operates under a complex web of international, regional, and national regulatory frameworks that govern battery safety standards. The International Civil Aviation Organization (ICAO) establishes the foundational requirements through its Technical Instructions for the Safe Transport of Dangerous Goods by Air, which specifically addresses lithium battery thermal runaway risks. These instructions are legally binding for all 193 member states and serve as the baseline for regional and national regulations.

At the regional level, the European Union Aviation Safety Agency (EASA) has implemented comprehensive certification specifications (CS-25) that include specific requirements for lithium battery installations in aircraft. These specifications mandate robust containment systems, thermal management solutions, and failure mode detection capabilities. Similarly, the Federal Aviation Administration (FAA) in the United States has established Federal Aviation Regulations (FARs) that incorporate Special Conditions for lithium battery installations, particularly focusing on thermal runaway prevention and containment.

The regulatory landscape is further shaped by industry standards developed by organizations such as RTCA and SAE International. RTCA DO-311A provides detailed performance standards for rechargeable lithium batteries in airborne applications, while SAE AS6413 establishes test methods for evaluating thermal runaway containment and venting systems. These standards are often incorporated by reference into regulatory requirements, creating a cohesive compliance framework.

Certification processes require manufacturers to demonstrate compliance through rigorous testing protocols. These typically include abuse testing under various environmental conditions, propagation testing to verify containment capabilities, and system-level integration testing. Documentation requirements are extensive, necessitating detailed safety analyses, test reports, and continued airworthiness instructions.

Recent regulatory developments have focused on enhancing thermal runaway detection capabilities, improving containment technologies, and establishing more stringent testing protocols. The FAA's 2020 update to Advisory Circular AC 20-184A reflects this trend, providing more detailed guidance on lithium battery installation safety. Similarly, EASA's 2021 revision to CS-25 incorporated additional requirements for thermal runaway protection systems.

Compliance challenges remain significant, particularly for smaller manufacturers navigating the complex regulatory landscape. Harmonization efforts between regulatory bodies aim to streamline requirements while maintaining rigorous safety standards. The International Coordinating Council of Aerospace Industries Associations (ICCAIA) plays a crucial role in facilitating these harmonization initiatives, working to align technical requirements across different jurisdictions.

At the regional level, the European Union Aviation Safety Agency (EASA) has implemented comprehensive certification specifications (CS-25) that include specific requirements for lithium battery installations in aircraft. These specifications mandate robust containment systems, thermal management solutions, and failure mode detection capabilities. Similarly, the Federal Aviation Administration (FAA) in the United States has established Federal Aviation Regulations (FARs) that incorporate Special Conditions for lithium battery installations, particularly focusing on thermal runaway prevention and containment.

The regulatory landscape is further shaped by industry standards developed by organizations such as RTCA and SAE International. RTCA DO-311A provides detailed performance standards for rechargeable lithium batteries in airborne applications, while SAE AS6413 establishes test methods for evaluating thermal runaway containment and venting systems. These standards are often incorporated by reference into regulatory requirements, creating a cohesive compliance framework.

Certification processes require manufacturers to demonstrate compliance through rigorous testing protocols. These typically include abuse testing under various environmental conditions, propagation testing to verify containment capabilities, and system-level integration testing. Documentation requirements are extensive, necessitating detailed safety analyses, test reports, and continued airworthiness instructions.

Recent regulatory developments have focused on enhancing thermal runaway detection capabilities, improving containment technologies, and establishing more stringent testing protocols. The FAA's 2020 update to Advisory Circular AC 20-184A reflects this trend, providing more detailed guidance on lithium battery installation safety. Similarly, EASA's 2021 revision to CS-25 incorporated additional requirements for thermal runaway protection systems.

Compliance challenges remain significant, particularly for smaller manufacturers navigating the complex regulatory landscape. Harmonization efforts between regulatory bodies aim to streamline requirements while maintaining rigorous safety standards. The International Coordinating Council of Aerospace Industries Associations (ICCAIA) plays a crucial role in facilitating these harmonization initiatives, working to align technical requirements across different jurisdictions.

Environmental Impact Assessment

The environmental implications of battery thermal runaway incidents in aviation extend far beyond immediate safety concerns. When lithium-ion batteries experience thermal runaway in aircraft environments, they release a complex mixture of toxic gases, particulate matter, and potentially harmful compounds into the atmosphere. These emissions include carbon monoxide, hydrogen fluoride, and various volatile organic compounds that can contribute to air pollution and pose respiratory hazards.

Aviation regulatory bodies increasingly recognize that environmental impact assessments must be integrated into safety standards addressing battery thermal runaway. The FAA and EASA have begun incorporating environmental considerations into their certification requirements, mandating that manufacturers evaluate not only the immediate safety risks but also the potential environmental consequences of battery failures.

Water contamination represents another significant environmental concern. Fire suppression systems used to control thermal runaway events typically employ chemicals that, when mixed with water runoff, can contaminate groundwater and aquatic ecosystems. Recent studies indicate that perfluoroalkyl substances (PFAS) from aviation fire suppression systems can persist in the environment for decades, earning them the designation "forever chemicals."

The disposal of damaged batteries following thermal runaway incidents presents additional environmental challenges. These batteries contain heavy metals and toxic materials that require specialized handling and disposal protocols. Current aviation regulations are evolving to address this post-incident environmental management, with requirements for proper containment, transportation, and disposal of compromised battery systems.

Carbon footprint considerations have also entered the regulatory conversation. The energy-intensive manufacturing processes for replacement batteries and aircraft components following thermal runaway incidents contribute to greenhouse gas emissions. Forward-thinking regulations now encourage lifecycle assessments that account for these indirect environmental impacts.

Noise pollution, while often overlooked, constitutes another environmental factor in battery thermal runaway regulations. Emergency response procedures following battery incidents can create significant noise disturbances, particularly at airports near residential areas. Emerging standards are beginning to address noise mitigation strategies during emergency responses to battery failures.

As aviation transitions toward more electric propulsion systems, the environmental aspects of battery safety regulations will likely become increasingly prominent, balancing immediate safety needs with long-term environmental sustainability goals.

Aviation regulatory bodies increasingly recognize that environmental impact assessments must be integrated into safety standards addressing battery thermal runaway. The FAA and EASA have begun incorporating environmental considerations into their certification requirements, mandating that manufacturers evaluate not only the immediate safety risks but also the potential environmental consequences of battery failures.

Water contamination represents another significant environmental concern. Fire suppression systems used to control thermal runaway events typically employ chemicals that, when mixed with water runoff, can contaminate groundwater and aquatic ecosystems. Recent studies indicate that perfluoroalkyl substances (PFAS) from aviation fire suppression systems can persist in the environment for decades, earning them the designation "forever chemicals."

The disposal of damaged batteries following thermal runaway incidents presents additional environmental challenges. These batteries contain heavy metals and toxic materials that require specialized handling and disposal protocols. Current aviation regulations are evolving to address this post-incident environmental management, with requirements for proper containment, transportation, and disposal of compromised battery systems.

Carbon footprint considerations have also entered the regulatory conversation. The energy-intensive manufacturing processes for replacement batteries and aircraft components following thermal runaway incidents contribute to greenhouse gas emissions. Forward-thinking regulations now encourage lifecycle assessments that account for these indirect environmental impacts.

Noise pollution, while often overlooked, constitutes another environmental factor in battery thermal runaway regulations. Emergency response procedures following battery incidents can create significant noise disturbances, particularly at airports near residential areas. Emerging standards are beginning to address noise mitigation strategies during emergency responses to battery failures.

As aviation transitions toward more electric propulsion systems, the environmental aspects of battery safety regulations will likely become increasingly prominent, balancing immediate safety needs with long-term environmental sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!