Role of Temperature Sensors in Detecting Battery Thermal Runaway

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Detection Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in the rapidly expanding lithium-ion battery industry. This phenomenon, characterized by an uncontrolled increase in battery temperature that can lead to fire or explosion, has been documented across various applications from consumer electronics to electric vehicles and grid-scale energy storage systems. The evolution of thermal runaway detection technologies has progressed significantly over the past decade, transitioning from basic temperature monitoring to sophisticated multi-sensor systems capable of early detection and prevention.

Temperature sensors have emerged as fundamental components in battery management systems (BMS), serving as the first line of defense against thermal events. The technological trajectory shows a clear trend toward more precise, miniaturized, and cost-effective sensing solutions that can be integrated directly into battery cells or modules. This evolution aligns with the industry's growing recognition that early detection is crucial for preventing catastrophic failures.

The primary objective of temperature sensor implementation in BTR detection is to identify abnormal thermal behaviors before they escalate to critical levels. This requires not only accurate temperature measurement but also intelligent algorithms capable of distinguishing between normal operational heating and the onset of runaway conditions. Current research indicates that detection windows of less than 60 seconds between initial thermal anomaly and full runaway are necessary for effective intervention.

Market demands have driven significant innovation in this field, particularly as electric vehicle adoption accelerates globally. The technical goals include developing sensors that can operate reliably in harsh environments, withstand electromagnetic interference, and maintain accuracy over the battery's lifetime. Additionally, there is a push toward sensors that can be manufactured at scale without significantly increasing battery production costs.

Recent thermal runaway incidents in consumer electronics and electric vehicles have heightened regulatory scrutiny, creating additional technical imperatives for improved detection systems. Standards organizations including UL, IEC, and ISO have begun establishing specific requirements for thermal management in battery systems, further driving technical development in this area.

The convergence of advanced materials science, miniaturized electronics, and machine learning algorithms represents the frontier of temperature sensor technology for BTR detection. Research objectives now extend beyond simple temperature monitoring to include predictive capabilities that can forecast potential thermal events based on subtle precursor signals, potentially minutes or hours before traditional detection methods would identify a problem.

Temperature sensors have emerged as fundamental components in battery management systems (BMS), serving as the first line of defense against thermal events. The technological trajectory shows a clear trend toward more precise, miniaturized, and cost-effective sensing solutions that can be integrated directly into battery cells or modules. This evolution aligns with the industry's growing recognition that early detection is crucial for preventing catastrophic failures.

The primary objective of temperature sensor implementation in BTR detection is to identify abnormal thermal behaviors before they escalate to critical levels. This requires not only accurate temperature measurement but also intelligent algorithms capable of distinguishing between normal operational heating and the onset of runaway conditions. Current research indicates that detection windows of less than 60 seconds between initial thermal anomaly and full runaway are necessary for effective intervention.

Market demands have driven significant innovation in this field, particularly as electric vehicle adoption accelerates globally. The technical goals include developing sensors that can operate reliably in harsh environments, withstand electromagnetic interference, and maintain accuracy over the battery's lifetime. Additionally, there is a push toward sensors that can be manufactured at scale without significantly increasing battery production costs.

Recent thermal runaway incidents in consumer electronics and electric vehicles have heightened regulatory scrutiny, creating additional technical imperatives for improved detection systems. Standards organizations including UL, IEC, and ISO have begun establishing specific requirements for thermal management in battery systems, further driving technical development in this area.

The convergence of advanced materials science, miniaturized electronics, and machine learning algorithms represents the frontier of temperature sensor technology for BTR detection. Research objectives now extend beyond simple temperature monitoring to include predictive capabilities that can forecast potential thermal events based on subtle precursor signals, potentially minutes or hours before traditional detection methods would identify a problem.

Market Demand Analysis for Battery Safety Solutions

The global market for battery safety solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current market valuations indicate that the battery safety technology sector reached approximately $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 15-18% through 2030. This acceleration is particularly evident in regions with aggressive electrification targets such as Europe, North America, and East Asia.

Consumer demand for battery safety solutions stems from several critical factors. First, high-profile incidents involving thermal runaway in consumer electronics and EVs have heightened public awareness and regulatory scrutiny. Second, as battery energy densities continue to increase to meet performance demands, the associated thermal management challenges become more pronounced. Third, insurance companies and fleet operators are increasingly requiring advanced safety systems as prerequisites for coverage and deployment.

The automotive sector represents the largest market segment, accounting for approximately 45% of demand for battery thermal monitoring systems. This is followed by grid-scale energy storage (22%), consumer electronics (18%), and industrial applications (15%). Within these segments, real-time temperature monitoring solutions that can predict and prevent thermal runaway events command premium pricing and are experiencing the fastest growth rates.

Regulatory frameworks are significantly shaping market demand. The UN Global Technical Regulation No. 20 for EV safety, European Union Battery Directive, and similar regulations in China and the United States are mandating increasingly sophisticated battery management systems with enhanced thermal monitoring capabilities. These regulations are expected to become more stringent, with proposed standards requiring multiple redundant temperature sensing systems by 2025.

Customer requirements are evolving toward integrated solutions that combine temperature sensing with predictive analytics. End users are demanding systems that not only detect temperature anomalies but can predict potential failures hours or even days in advance. This has created a market shift from simple thermistor-based solutions toward distributed fiber optic sensors, infrared imaging systems, and electrochemical impedance spectroscopy techniques that offer earlier detection capabilities.

Cost sensitivity varies significantly by application segment. While automotive OEMs demonstrate willingness to invest in premium safety systems, consumer electronics manufacturers face intense pressure to minimize costs while maintaining safety standards. This dichotomy is creating a bifurcated market with high-end and value-oriented solution tracks developing in parallel.

Consumer demand for battery safety solutions stems from several critical factors. First, high-profile incidents involving thermal runaway in consumer electronics and EVs have heightened public awareness and regulatory scrutiny. Second, as battery energy densities continue to increase to meet performance demands, the associated thermal management challenges become more pronounced. Third, insurance companies and fleet operators are increasingly requiring advanced safety systems as prerequisites for coverage and deployment.

The automotive sector represents the largest market segment, accounting for approximately 45% of demand for battery thermal monitoring systems. This is followed by grid-scale energy storage (22%), consumer electronics (18%), and industrial applications (15%). Within these segments, real-time temperature monitoring solutions that can predict and prevent thermal runaway events command premium pricing and are experiencing the fastest growth rates.

Regulatory frameworks are significantly shaping market demand. The UN Global Technical Regulation No. 20 for EV safety, European Union Battery Directive, and similar regulations in China and the United States are mandating increasingly sophisticated battery management systems with enhanced thermal monitoring capabilities. These regulations are expected to become more stringent, with proposed standards requiring multiple redundant temperature sensing systems by 2025.

Customer requirements are evolving toward integrated solutions that combine temperature sensing with predictive analytics. End users are demanding systems that not only detect temperature anomalies but can predict potential failures hours or even days in advance. This has created a market shift from simple thermistor-based solutions toward distributed fiber optic sensors, infrared imaging systems, and electrochemical impedance spectroscopy techniques that offer earlier detection capabilities.

Cost sensitivity varies significantly by application segment. While automotive OEMs demonstrate willingness to invest in premium safety systems, consumer electronics manufacturers face intense pressure to minimize costs while maintaining safety standards. This dichotomy is creating a bifurcated market with high-end and value-oriented solution tracks developing in parallel.

Temperature Sensor Technology Status and Challenges

Temperature sensing technology for battery thermal runaway detection has evolved significantly over the past decade, yet still faces substantial challenges. Current state-of-the-art temperature sensors employed in battery management systems include thermistors, thermocouples, resistance temperature detectors (RTDs), and more recently, fiber optic sensors and infrared thermal imaging systems. These technologies vary considerably in accuracy, response time, form factor, and cost-effectiveness.

Globally, temperature sensor development for battery applications shows geographic concentration in East Asia (particularly Japan, South Korea, and China), North America, and Europe. This distribution aligns with regions leading battery manufacturing and electric vehicle production. Research institutions in these regions have established collaborative networks with industry partners to accelerate sensor technology advancement.

The primary technical challenges facing temperature sensors in thermal runaway detection include insufficient spatial resolution, delayed response times, and reliability issues under extreme conditions. Conventional point sensors can only monitor discrete locations, creating blind spots where thermal events may initiate undetected. Even advanced systems typically exhibit response latencies of 1-3 seconds—potentially insufficient for early-stage thermal runaway detection, which can progress exponentially within milliseconds.

Integration complexity presents another significant hurdle. Embedding sensors within battery cells improves detection capability but introduces manufacturing complications and potential failure points. Surface-mounted sensors are easier to implement but sacrifice detection speed and accuracy. This fundamental trade-off between integration depth and practicality remains unresolved.

Durability under harsh operating conditions poses additional challenges. Temperature sensors must maintain accuracy and reliability despite exposure to corrosive electrolytes, mechanical stress from cell expansion/contraction, and electromagnetic interference from nearby power electronics. Current sensor technologies often demonstrate performance degradation over time, compromising long-term monitoring capabilities.

Cost constraints further complicate widespread adoption of advanced sensing technologies. While fiber optic and distributed sensing systems offer superior performance, their implementation costs remain prohibitively high for mass-market applications. The industry continues to seek cost-effective solutions that don't compromise safety margins.

Data processing and interpretation represent emerging challenges as sensor networks grow more complex. Converting massive temperature data streams into actionable safety protocols requires sophisticated algorithms and computing resources. False positives must be minimized while ensuring no genuine thermal events go undetected—a delicate balance that current systems struggle to maintain consistently.

Globally, temperature sensor development for battery applications shows geographic concentration in East Asia (particularly Japan, South Korea, and China), North America, and Europe. This distribution aligns with regions leading battery manufacturing and electric vehicle production. Research institutions in these regions have established collaborative networks with industry partners to accelerate sensor technology advancement.

The primary technical challenges facing temperature sensors in thermal runaway detection include insufficient spatial resolution, delayed response times, and reliability issues under extreme conditions. Conventional point sensors can only monitor discrete locations, creating blind spots where thermal events may initiate undetected. Even advanced systems typically exhibit response latencies of 1-3 seconds—potentially insufficient for early-stage thermal runaway detection, which can progress exponentially within milliseconds.

Integration complexity presents another significant hurdle. Embedding sensors within battery cells improves detection capability but introduces manufacturing complications and potential failure points. Surface-mounted sensors are easier to implement but sacrifice detection speed and accuracy. This fundamental trade-off between integration depth and practicality remains unresolved.

Durability under harsh operating conditions poses additional challenges. Temperature sensors must maintain accuracy and reliability despite exposure to corrosive electrolytes, mechanical stress from cell expansion/contraction, and electromagnetic interference from nearby power electronics. Current sensor technologies often demonstrate performance degradation over time, compromising long-term monitoring capabilities.

Cost constraints further complicate widespread adoption of advanced sensing technologies. While fiber optic and distributed sensing systems offer superior performance, their implementation costs remain prohibitively high for mass-market applications. The industry continues to seek cost-effective solutions that don't compromise safety margins.

Data processing and interpretation represent emerging challenges as sensor networks grow more complex. Converting massive temperature data streams into actionable safety protocols requires sophisticated algorithms and computing resources. False positives must be minimized while ensuring no genuine thermal events go undetected—a delicate balance that current systems struggle to maintain consistently.

Current Temperature Sensing Solutions for Thermal Runaway

01 Battery thermal management systems with temperature sensors

Battery thermal management systems utilize temperature sensors to monitor and detect thermal runaway conditions in battery cells. These systems employ various sensor configurations to measure temperature distributions across battery packs, enabling early detection of abnormal temperature rises that could indicate potential thermal runaway. The sensors provide real-time temperature data to control units that can trigger protective measures such as cooling activation or system shutdown when temperatures exceed predetermined thresholds.- Temperature sensor configurations for battery thermal runaway detection: Various temperature sensor configurations can be implemented to detect thermal runaway in battery systems. These include distributed sensor arrays placed at strategic locations within battery packs, integrated temperature sensing elements embedded directly in battery cells, and multi-point temperature monitoring systems that can detect temperature gradients. These configurations enable early detection of abnormal temperature rises that may indicate the onset of thermal runaway conditions.

- Differential temperature measurement techniques: Differential temperature measurement techniques involve comparing readings from multiple sensors to identify unusual temperature patterns. These methods can detect localized heating that precedes thermal runaway by establishing normal temperature differentials during standard operation and triggering alerts when these patterns deviate. Advanced algorithms analyze temperature rate changes and gradients across battery modules to provide early warning of potential thermal events.

- Integration with battery management systems: Temperature sensors can be integrated with battery management systems (BMS) to create comprehensive thermal runaway protection. These integrated systems combine real-time temperature monitoring with voltage and current measurements to identify potential failure modes. The BMS can implement protective measures such as load disconnection, cooling system activation, or emergency shutdown when thermal anomalies are detected, preventing cascade failures across battery packs.

- Advanced sensor technologies for thermal event prediction: Advanced sensor technologies employ specialized materials and designs to improve thermal runaway detection capabilities. These include fiber optic temperature sensors for distributed sensing, infrared thermal imaging for surface temperature mapping, and thin-film sensors with fast response times. Some systems incorporate predictive algorithms that can forecast thermal events based on historical data patterns and real-time measurements, enabling preventive actions before critical temperatures are reached.

- Redundant safety systems with multi-parameter monitoring: Redundant safety systems employ multiple sensor types and monitoring parameters to ensure reliable thermal runaway detection. These systems combine temperature sensing with gas detection, pressure monitoring, and electrical parameter analysis to create multi-layered protection. By cross-validating different physical indicators of battery degradation, these systems can distinguish between normal temperature fluctuations and dangerous thermal events, reducing false alarms while maintaining high detection sensitivity.

02 Multi-sensor arrays for enhanced thermal runaway detection

Advanced thermal runaway detection systems employ multiple temperature sensors arranged in strategic patterns to create comprehensive thermal monitoring networks. These multi-sensor arrays provide improved spatial resolution of temperature measurements across battery modules or other heat-sensitive components. By comparing readings from different sensor locations, the systems can identify temperature gradients and hotspots that may indicate the early stages of thermal runaway, allowing for faster and more reliable detection than single-sensor approaches.Expand Specific Solutions03 Predictive algorithms for early thermal runaway detection

Sophisticated thermal runaway detection systems incorporate predictive algorithms that analyze temperature sensor data to identify patterns indicative of impending thermal events. These algorithms process temperature readings along with other parameters such as voltage, current, and internal resistance to predict potential thermal runaway conditions before they reach critical levels. Machine learning techniques may be employed to improve detection accuracy over time by recognizing subtle temperature signature changes that precede thermal runaway events.Expand Specific Solutions04 Integration of temperature sensors with battery management systems

Temperature sensors for thermal runaway detection are integrated with comprehensive battery management systems (BMS) to provide coordinated protection. These integrated systems combine temperature monitoring with voltage and current management to create multi-layered safety protocols. When temperature sensors detect abnormal conditions, the BMS can implement graduated response strategies including load reduction, cooling system activation, or emergency disconnection. This integration enables more nuanced and effective responses to potential thermal events based on multiple data inputs.Expand Specific Solutions05 Novel temperature sensor designs for improved thermal runaway detection

Innovative temperature sensor designs are being developed specifically for enhanced thermal runaway detection capabilities. These include flexible thin-film sensors that can be placed directly on battery surfaces, fiber optic temperature sensors for environments with electromagnetic interference, and phase-change materials that provide visual indicators of critical temperature thresholds. Some designs incorporate redundant sensing elements or self-diagnostic features to ensure reliability in safety-critical applications. These specialized sensors offer advantages such as faster response times, higher accuracy, or improved durability compared to conventional temperature sensors.Expand Specific Solutions

Key Players in Battery Safety and Sensor Manufacturing

The thermal runaway detection market is in a growth phase, driven by increasing electric vehicle adoption and energy storage systems. The market size is expanding rapidly, with projections showing significant growth due to safety concerns in battery applications. Technologically, temperature sensing solutions are evolving from basic thermistors to advanced integrated systems. Leading companies like Tesla, CATL, BYD, and LG Energy Solution are developing sophisticated thermal management systems, while automotive giants including Volkswagen, BMW, and Mercedes-Benz are integrating these technologies into their vehicles. Samsung SDI and EVE Energy are advancing sensor miniaturization and precision, while companies like Bosch and Renesas are focusing on semiconductor-based temperature sensing solutions for early thermal event detection.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced multi-layered thermal management system for detecting battery thermal runaway. Their approach integrates multiple temperature sensors strategically placed at critical points within battery modules to create a comprehensive thermal monitoring network. The system employs both NTC (Negative Temperature Coefficient) thermistors and specialized semiconductor-based temperature sensors with high precision (±0.5°C accuracy). Samsung's solution includes proprietary algorithms that analyze temperature gradients and rates of change rather than just absolute values, enabling earlier detection of potential thermal events before they escalate. Their Battery Management System (BMS) incorporates machine learning capabilities that adapt to usage patterns and environmental conditions, improving detection accuracy over time. Samsung has also implemented redundant sensing pathways to ensure system reliability even if individual sensors fail.

Strengths: Samsung's multi-layered approach provides exceptional reliability through redundancy and advanced predictive algorithms. Their integration of machine learning enables continuous improvement in detection accuracy. Weaknesses: The complex sensor network increases manufacturing costs and requires sophisticated calibration procedures. The system may be overly sensitive in certain conditions, potentially triggering false alarms.

Tesla, Inc.

Technical Solution: Tesla has pioneered a comprehensive thermal runaway detection system that combines multiple sensing technologies with advanced predictive analytics. Their approach utilizes a distributed network of temperature sensors throughout the battery pack, with particular concentration at cell boundaries and high-risk zones. Tesla's system employs proprietary NTC thermistors with rapid response times (<2 seconds) and high accuracy (±0.3°C). A key innovation is their implementation of differential temperature monitoring, which tracks temperature differences between adjacent cells and modules rather than just absolute values. This allows for earlier detection of anomalies before they manifest as significant temperature increases. Tesla's Battery Management System processes this thermal data through machine learning algorithms that continuously adapt to vehicle usage patterns and environmental conditions. The system also incorporates voltage and current monitoring as complementary indicators, creating a multi-parameter approach to thermal event prediction.

Strengths: Tesla's integrated approach combining thermal sensing with electrical parameters provides comprehensive protection. Their machine learning algorithms enable predictive capabilities that can identify potential issues before traditional threshold-based systems. Weaknesses: The system's complexity requires significant computational resources and sophisticated calibration. High sensor density increases manufacturing costs and potential points of failure.

Critical Patents and Research in Thermal Sensing Technology

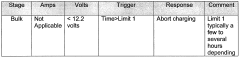

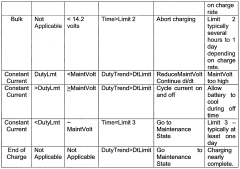

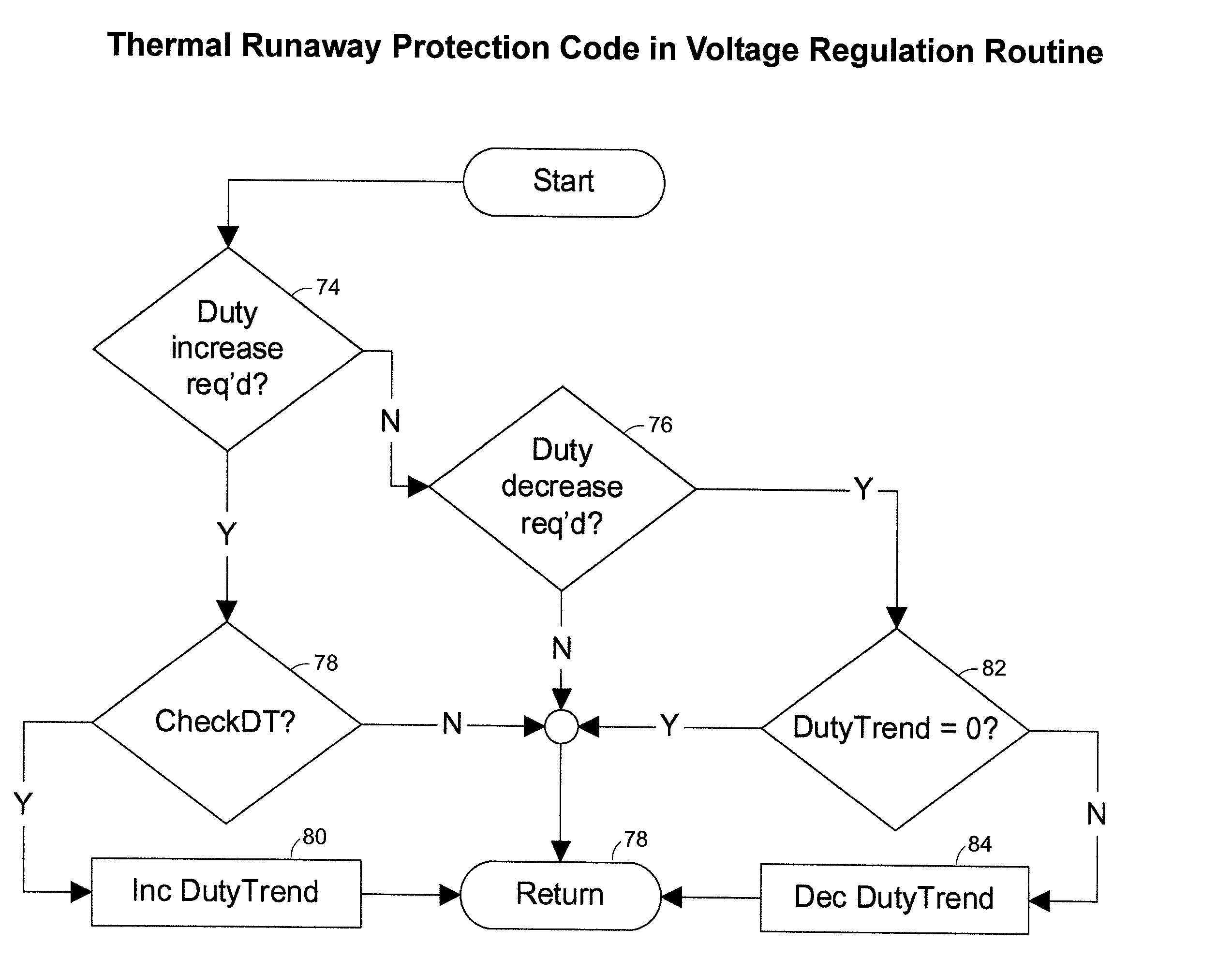

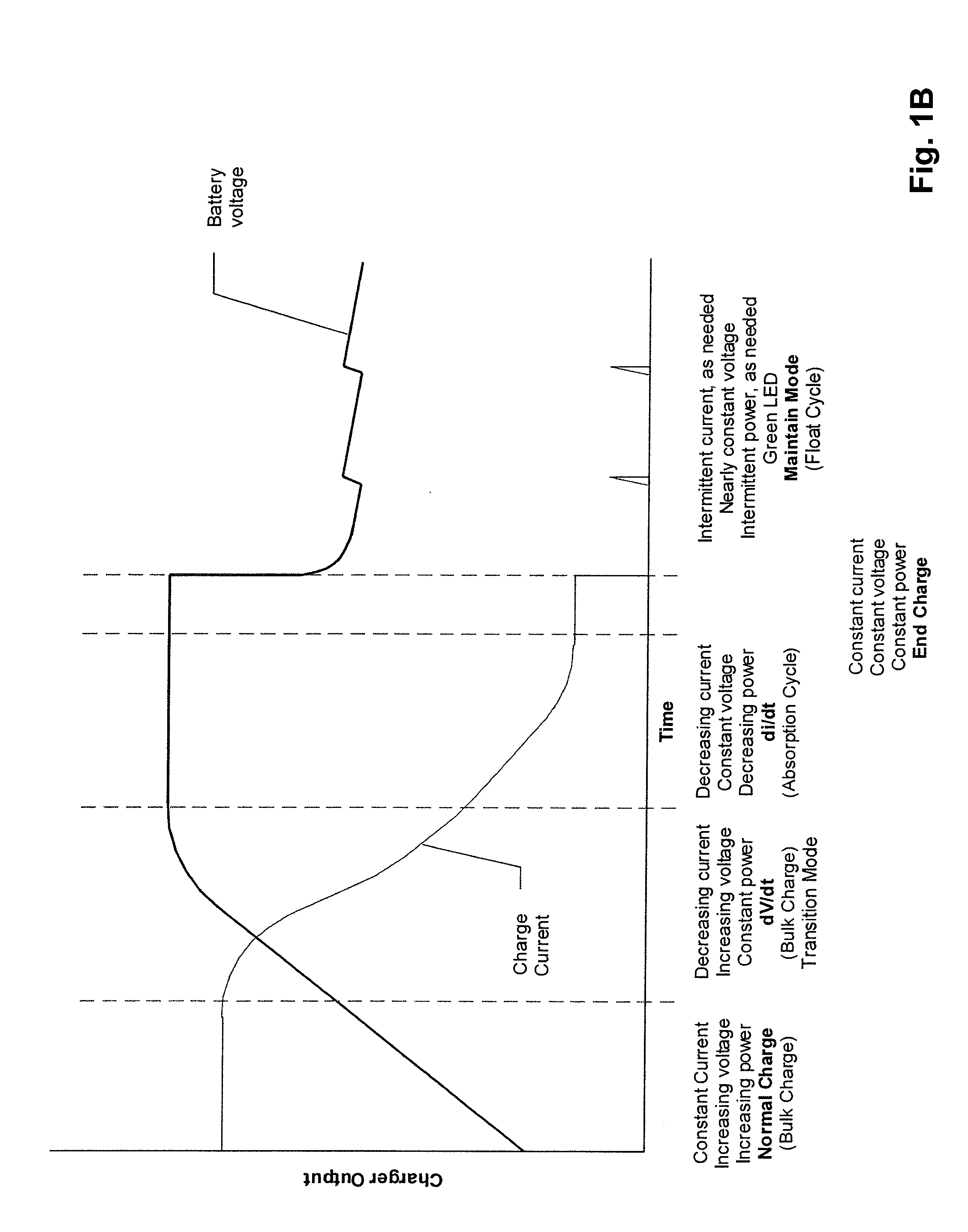

Thermal runaway protection system for a battery charger

PatentWO2009108613A1

Innovation

- A software-based protection system that monitors electrical parameters such as voltage and current during charging cycles to detect anomalies indicative of thermal runaway, eliminating the need for external temperature sensors and user intervention.

Thermal runaway protection system for a battery charger

PatentActiveUS7834593B2

Innovation

- A software-based protection system that monitors electrical parameters during charging, such as voltage and current trends, to detect anomalies indicative of thermal runaway conditions, eliminating the need for external sensors and user intervention.

Safety Standards and Regulatory Requirements

The regulatory landscape for battery thermal runaway detection systems has evolved significantly in response to high-profile battery failure incidents across various industries. International standards organizations have established comprehensive frameworks that specifically address temperature monitoring requirements for battery systems. The UN Transportation Testing standards (UN 38.3) mandate rigorous thermal testing for lithium batteries in transport, requiring manufacturers to demonstrate that their battery management systems can effectively detect and mitigate thermal events before catastrophic failure.

IEC 62133 and UL 1642 standards have become cornerstone regulations for consumer electronics, specifying temperature thresholds and sensor placement requirements for early thermal runaway detection. These standards typically require temperature monitoring systems capable of detecting temperature rises of 10°C/minute or greater, with response times under 500 milliseconds to trigger protective measures.

For electric vehicles, SAE J2464 and ISO 6469 outline critical safety requirements for battery thermal management systems. These standards mandate redundant temperature sensing networks with minimum sensor density requirements—typically one sensor per 3-5 cells in high-capacity battery packs. The regulations also specify performance criteria under extreme environmental conditions, ensuring sensors maintain accuracy between -40°C and 85°C.

The aerospace industry faces even more stringent requirements under DO-311A and RTCA standards, which demand fault-tolerant temperature monitoring systems with 99.999% reliability ratings. These regulations require sensors to withstand vibration profiles specific to aircraft operations while maintaining temperature measurement accuracy within ±1°C across the operational range.

Emerging regulations are increasingly focusing on predictive capabilities rather than just reactive measures. The latest updates to IEC 62619 and UL 2580 now include requirements for temperature gradient monitoring across cell arrays, recognizing that thermal runaway often manifests as temperature differentials before absolute temperature spikes occur.

Compliance with these regulations presents significant engineering challenges, particularly in balancing sensor density with system cost and complexity. Manufacturers must navigate a complex matrix of sometimes conflicting international standards, with different regions emphasizing different aspects of thermal safety. The trend toward harmonization of these standards is ongoing but remains incomplete, creating compliance challenges for global battery manufacturers.

IEC 62133 and UL 1642 standards have become cornerstone regulations for consumer electronics, specifying temperature thresholds and sensor placement requirements for early thermal runaway detection. These standards typically require temperature monitoring systems capable of detecting temperature rises of 10°C/minute or greater, with response times under 500 milliseconds to trigger protective measures.

For electric vehicles, SAE J2464 and ISO 6469 outline critical safety requirements for battery thermal management systems. These standards mandate redundant temperature sensing networks with minimum sensor density requirements—typically one sensor per 3-5 cells in high-capacity battery packs. The regulations also specify performance criteria under extreme environmental conditions, ensuring sensors maintain accuracy between -40°C and 85°C.

The aerospace industry faces even more stringent requirements under DO-311A and RTCA standards, which demand fault-tolerant temperature monitoring systems with 99.999% reliability ratings. These regulations require sensors to withstand vibration profiles specific to aircraft operations while maintaining temperature measurement accuracy within ±1°C across the operational range.

Emerging regulations are increasingly focusing on predictive capabilities rather than just reactive measures. The latest updates to IEC 62619 and UL 2580 now include requirements for temperature gradient monitoring across cell arrays, recognizing that thermal runaway often manifests as temperature differentials before absolute temperature spikes occur.

Compliance with these regulations presents significant engineering challenges, particularly in balancing sensor density with system cost and complexity. Manufacturers must navigate a complex matrix of sometimes conflicting international standards, with different regions emphasizing different aspects of thermal safety. The trend toward harmonization of these standards is ongoing but remains incomplete, creating compliance challenges for global battery manufacturers.

Integration Strategies with Battery Management Systems

Effective integration of temperature sensors with Battery Management Systems (BMS) is crucial for early detection and prevention of thermal runaway events. The BMS serves as the central nervous system of battery operations, and temperature sensors function as critical sensory inputs that enable comprehensive thermal monitoring and management.

Primary integration approaches include distributed sensor networks, where multiple temperature sensors are strategically positioned throughout battery packs to create thermal mapping capabilities. This configuration allows for real-time temperature gradient analysis across cells, enabling the detection of localized heating that often precedes thermal runaway. The optimal sensor density depends on battery size, configuration, and application requirements, with high-risk applications warranting higher sensor density.

Communication protocols between temperature sensors and the BMS must prioritize speed and reliability. Industry standards like CAN (Controller Area Network) and I²C (Inter-Integrated Circuit) are commonly employed, with sampling rates typically ranging from 1-10 Hz for normal operation, automatically increasing to 50-100 Hz when temperature anomalies are detected. This adaptive sampling approach balances system resources with safety requirements.

Data fusion algorithms represent another critical integration component, combining temperature data with other parameters such as voltage, current, and impedance measurements. Machine learning techniques increasingly enhance these algorithms, enabling pattern recognition that can identify thermal runaway precursors before traditional threshold-based systems. These algorithms typically employ Kalman filters or Bayesian networks to process multi-sensor inputs and reduce false alarms.

Redundancy and fail-safe mechanisms must be incorporated into the integration architecture. This includes sensor redundancy (multiple sensors monitoring critical areas), communication pathway redundancy, and algorithmic redundancy through diverse detection methods. System health monitoring capabilities that continuously verify sensor functionality and calibration status further enhance reliability.

Integration challenges include managing the trade-offs between sensor coverage, system complexity, and cost considerations. Miniaturization of sensor technology has enabled more comprehensive coverage without significant weight or space penalties, but integration designers must still optimize placement for maximum effectiveness. Additionally, electromagnetic interference from high-current battery operations can affect sensor accuracy, requiring appropriate shielding and signal filtering techniques.

Future integration trends point toward wireless sensor networks that reduce wiring complexity and improve installation flexibility, though these must address power consumption and communication reliability concerns. Increasingly, BMS architectures are evolving toward hierarchical designs with local processing nodes that perform preliminary analysis before transmitting summarized data to central controllers, reducing communication bandwidth requirements while maintaining rapid response capabilities.

Primary integration approaches include distributed sensor networks, where multiple temperature sensors are strategically positioned throughout battery packs to create thermal mapping capabilities. This configuration allows for real-time temperature gradient analysis across cells, enabling the detection of localized heating that often precedes thermal runaway. The optimal sensor density depends on battery size, configuration, and application requirements, with high-risk applications warranting higher sensor density.

Communication protocols between temperature sensors and the BMS must prioritize speed and reliability. Industry standards like CAN (Controller Area Network) and I²C (Inter-Integrated Circuit) are commonly employed, with sampling rates typically ranging from 1-10 Hz for normal operation, automatically increasing to 50-100 Hz when temperature anomalies are detected. This adaptive sampling approach balances system resources with safety requirements.

Data fusion algorithms represent another critical integration component, combining temperature data with other parameters such as voltage, current, and impedance measurements. Machine learning techniques increasingly enhance these algorithms, enabling pattern recognition that can identify thermal runaway precursors before traditional threshold-based systems. These algorithms typically employ Kalman filters or Bayesian networks to process multi-sensor inputs and reduce false alarms.

Redundancy and fail-safe mechanisms must be incorporated into the integration architecture. This includes sensor redundancy (multiple sensors monitoring critical areas), communication pathway redundancy, and algorithmic redundancy through diverse detection methods. System health monitoring capabilities that continuously verify sensor functionality and calibration status further enhance reliability.

Integration challenges include managing the trade-offs between sensor coverage, system complexity, and cost considerations. Miniaturization of sensor technology has enabled more comprehensive coverage without significant weight or space penalties, but integration designers must still optimize placement for maximum effectiveness. Additionally, electromagnetic interference from high-current battery operations can affect sensor accuracy, requiring appropriate shielding and signal filtering techniques.

Future integration trends point toward wireless sensor networks that reduce wiring complexity and improve installation flexibility, though these must address power consumption and communication reliability concerns. Increasingly, BMS architectures are evolving toward hierarchical designs with local processing nodes that perform preliminary analysis before transmitting summarized data to central controllers, reducing communication bandwidth requirements while maintaining rapid response capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!