Role of Heat Dissipation Techniques in Battery Thermal Runaway Prevention

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple passive cooling systems to sophisticated active thermal management solutions. The evolution has been primarily driven by the increasing energy density of modern batteries, particularly lithium-ion batteries, which has intensified thermal challenges. Initially, thermal management focused on maintaining optimal operating temperatures for performance and longevity. However, as high-energy-density batteries became prevalent in electric vehicles, consumer electronics, and grid storage systems, preventing thermal runaway events emerged as a critical safety concern.

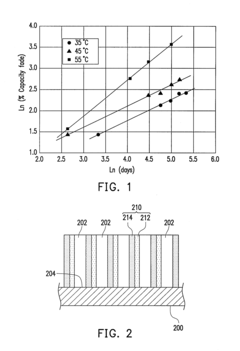

Thermal runaway, a self-accelerating heat-generating process that can lead to catastrophic battery failure, fire, and explosion, represents one of the most significant safety challenges in battery technology. This phenomenon occurs when exothermic reactions within the battery generate heat faster than it can be dissipated to the environment, creating a dangerous positive feedback loop. The risk is particularly pronounced in lithium-ion batteries due to their high energy density and the flammable organic electrolytes they contain.

The technical objective of heat dissipation techniques in this context is multifaceted. Primary goals include: maintaining battery temperature within safe operating ranges (typically 15-35°C); minimizing temperature gradients across battery packs to prevent localized hotspots; rapidly removing heat during high-power charging and discharging events; and critically, preventing the initiation and propagation of thermal runaway. These objectives must be achieved while meeting constraints of weight, volume, cost, and reliability appropriate to the application.

Recent high-profile battery failures in consumer electronics and electric vehicles have heightened regulatory scrutiny and consumer awareness regarding battery safety. This has accelerated research into advanced thermal management solutions that can effectively prevent thermal runaway or, at minimum, contain its effects. The technical community has responded with innovations spanning material science, mechanical engineering, and control systems.

The evolution of battery thermal management systems reflects a growing understanding of the complex interplay between electrochemistry, heat transfer, and material properties. Early approaches relied primarily on passive cooling through natural convection and conduction. Modern systems employ sophisticated active cooling methods including forced air, liquid cooling circuits, phase change materials, and even refrigeration cycles. The frontier of research now extends to predictive thermal management using real-time sensors and algorithms to anticipate and prevent thermal events before they occur.

Thermal runaway, a self-accelerating heat-generating process that can lead to catastrophic battery failure, fire, and explosion, represents one of the most significant safety challenges in battery technology. This phenomenon occurs when exothermic reactions within the battery generate heat faster than it can be dissipated to the environment, creating a dangerous positive feedback loop. The risk is particularly pronounced in lithium-ion batteries due to their high energy density and the flammable organic electrolytes they contain.

The technical objective of heat dissipation techniques in this context is multifaceted. Primary goals include: maintaining battery temperature within safe operating ranges (typically 15-35°C); minimizing temperature gradients across battery packs to prevent localized hotspots; rapidly removing heat during high-power charging and discharging events; and critically, preventing the initiation and propagation of thermal runaway. These objectives must be achieved while meeting constraints of weight, volume, cost, and reliability appropriate to the application.

Recent high-profile battery failures in consumer electronics and electric vehicles have heightened regulatory scrutiny and consumer awareness regarding battery safety. This has accelerated research into advanced thermal management solutions that can effectively prevent thermal runaway or, at minimum, contain its effects. The technical community has responded with innovations spanning material science, mechanical engineering, and control systems.

The evolution of battery thermal management systems reflects a growing understanding of the complex interplay between electrochemistry, heat transfer, and material properties. Early approaches relied primarily on passive cooling through natural convection and conduction. Modern systems employ sophisticated active cooling methods including forced air, liquid cooling circuits, phase change materials, and even refrigeration cycles. The frontier of research now extends to predictive thermal management using real-time sensors and algorithms to anticipate and prevent thermal events before they occur.

Market Demand for Advanced Battery Safety Solutions

The global market for advanced battery safety solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Current market valuations indicate that the battery thermal management system market reached approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 16-18% through 2030, highlighting the critical importance of heat dissipation technologies in preventing thermal runaway incidents.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. These incidents have not only damaged brand reputations but have also resulted in costly recalls and regulatory scrutiny. For instance, the automotive sector alone has witnessed recalls affecting hundreds of thousands of vehicles due to battery safety concerns, with associated costs reaching billions of dollars.

Regulatory frameworks worldwide are evolving to address these safety concerns. The UN Transportation Testing Requirements (UN 38.3), IEC 62133, and UL 1642 standards have all been updated to include more stringent thermal management requirements. Additionally, the European Union's Battery Directive revision and China's GB/T 31485 standard now place greater emphasis on thermal safety, creating market pressure for advanced heat dissipation solutions.

Insurance companies have also become significant market drivers, with many now offering premium reductions for energy storage systems and electric vehicles that incorporate advanced thermal management technologies. This financial incentive has accelerated adoption across commercial and industrial sectors, particularly in grid-scale energy storage applications where the consequences of thermal events can be catastrophic.

The market shows distinct segmentation based on application needs. The EV sector demands solutions that balance weight, space constraints, and performance, while stationary energy storage systems prioritize longevity and reliability. Consumer electronics manufacturers seek increasingly compact yet effective thermal management solutions that don't compromise device aesthetics or functionality.

Emerging markets in Southeast Asia, India, and parts of Africa represent significant growth opportunities, as these regions rapidly expand their renewable energy infrastructure and electric mobility adoption. These markets are particularly sensitive to cost-effective solutions that can function reliably in diverse and often challenging climatic conditions.

Industry forecasts suggest that the demand for passive cooling systems will grow at 13% annually, while active cooling technologies will see even higher growth rates of approximately 20% annually through 2028, reflecting the market's recognition that effective heat dissipation is fundamental to preventing catastrophic battery failures.

Consumer demand for safer battery technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. These incidents have not only damaged brand reputations but have also resulted in costly recalls and regulatory scrutiny. For instance, the automotive sector alone has witnessed recalls affecting hundreds of thousands of vehicles due to battery safety concerns, with associated costs reaching billions of dollars.

Regulatory frameworks worldwide are evolving to address these safety concerns. The UN Transportation Testing Requirements (UN 38.3), IEC 62133, and UL 1642 standards have all been updated to include more stringent thermal management requirements. Additionally, the European Union's Battery Directive revision and China's GB/T 31485 standard now place greater emphasis on thermal safety, creating market pressure for advanced heat dissipation solutions.

Insurance companies have also become significant market drivers, with many now offering premium reductions for energy storage systems and electric vehicles that incorporate advanced thermal management technologies. This financial incentive has accelerated adoption across commercial and industrial sectors, particularly in grid-scale energy storage applications where the consequences of thermal events can be catastrophic.

The market shows distinct segmentation based on application needs. The EV sector demands solutions that balance weight, space constraints, and performance, while stationary energy storage systems prioritize longevity and reliability. Consumer electronics manufacturers seek increasingly compact yet effective thermal management solutions that don't compromise device aesthetics or functionality.

Emerging markets in Southeast Asia, India, and parts of Africa represent significant growth opportunities, as these regions rapidly expand their renewable energy infrastructure and electric mobility adoption. These markets are particularly sensitive to cost-effective solutions that can function reliably in diverse and often challenging climatic conditions.

Industry forecasts suggest that the demand for passive cooling systems will grow at 13% annually, while active cooling technologies will see even higher growth rates of approximately 20% annually through 2028, reflecting the market's recognition that effective heat dissipation is fundamental to preventing catastrophic battery failures.

Current Heat Dissipation Technologies and Challenges

Current heat dissipation technologies for battery thermal management can be broadly categorized into passive and active cooling systems. Passive systems include phase change materials (PCMs), which absorb heat through phase transitions, providing effective thermal buffering without energy input. These materials can absorb significant amounts of heat while maintaining relatively constant temperatures, making them particularly valuable for electric vehicle applications. However, PCMs face challenges in thermal conductivity limitations and potential leakage issues during long-term operation.

Air cooling represents the simplest active cooling approach, utilizing forced convection to remove heat from battery surfaces. While cost-effective and lightweight, air cooling systems struggle to maintain uniform temperature distribution across battery packs, especially in high-power applications or extreme ambient conditions. This non-uniformity can accelerate battery degradation and increase thermal runaway risks.

Liquid cooling systems have emerged as the dominant solution for high-performance applications, offering superior heat transfer coefficients compared to air cooling. Direct liquid cooling, where coolant directly contacts battery cells, provides excellent thermal performance but introduces sealing and electrical isolation challenges. Indirect liquid cooling using cooling plates or jackets offers a balance between performance and safety, though with slightly reduced thermal efficiency.

Immersion cooling, where batteries are completely submerged in dielectric fluids, represents an emerging technology with exceptional cooling performance. However, its widespread adoption faces barriers including high costs, increased system complexity, and concerns about long-term compatibility between battery materials and cooling fluids.

A significant challenge across all cooling technologies is the trade-off between cooling performance and system complexity/cost. High-performance cooling solutions typically demand greater space, weight, and energy consumption, directly impacting vehicle range and cost metrics. Additionally, the integration of cooling systems with battery management systems remains technically challenging, requiring sophisticated control algorithms to balance thermal management with battery performance and longevity.

The industry also faces challenges in developing cooling solutions that can respond effectively to thermal runaway events once initiated. Current technologies excel at preventing thermal events during normal operation but have limited capability to contain cascading thermal failures. This gap represents a critical area for technological advancement, particularly as battery energy densities continue to increase.

Standardization issues further complicate technology development, with varying cell formats and pack designs requiring customized thermal solutions rather than universal approaches. This fragmentation increases development costs and slows industry-wide implementation of optimal thermal management strategies.

Air cooling represents the simplest active cooling approach, utilizing forced convection to remove heat from battery surfaces. While cost-effective and lightweight, air cooling systems struggle to maintain uniform temperature distribution across battery packs, especially in high-power applications or extreme ambient conditions. This non-uniformity can accelerate battery degradation and increase thermal runaway risks.

Liquid cooling systems have emerged as the dominant solution for high-performance applications, offering superior heat transfer coefficients compared to air cooling. Direct liquid cooling, where coolant directly contacts battery cells, provides excellent thermal performance but introduces sealing and electrical isolation challenges. Indirect liquid cooling using cooling plates or jackets offers a balance between performance and safety, though with slightly reduced thermal efficiency.

Immersion cooling, where batteries are completely submerged in dielectric fluids, represents an emerging technology with exceptional cooling performance. However, its widespread adoption faces barriers including high costs, increased system complexity, and concerns about long-term compatibility between battery materials and cooling fluids.

A significant challenge across all cooling technologies is the trade-off between cooling performance and system complexity/cost. High-performance cooling solutions typically demand greater space, weight, and energy consumption, directly impacting vehicle range and cost metrics. Additionally, the integration of cooling systems with battery management systems remains technically challenging, requiring sophisticated control algorithms to balance thermal management with battery performance and longevity.

The industry also faces challenges in developing cooling solutions that can respond effectively to thermal runaway events once initiated. Current technologies excel at preventing thermal events during normal operation but have limited capability to contain cascading thermal failures. This gap represents a critical area for technological advancement, particularly as battery energy densities continue to increase.

Standardization issues further complicate technology development, with varying cell formats and pack designs requiring customized thermal solutions rather than universal approaches. This fragmentation increases development costs and slows industry-wide implementation of optimal thermal management strategies.

Existing Heat Dissipation Solutions for Thermal Runaway

01 Thermal management systems for battery packs

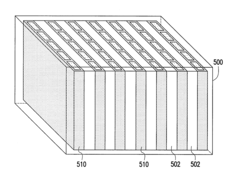

Advanced thermal management systems are designed to prevent thermal runaway in battery packs by efficiently dissipating heat. These systems incorporate cooling plates, heat sinks, and thermal interface materials to maintain optimal operating temperatures. Some designs feature liquid cooling channels that circulate coolant through the battery pack to remove excess heat. These systems often include temperature sensors and controllers that monitor battery conditions and adjust cooling intensity accordingly.- Thermal management systems for battery packs: Advanced thermal management systems are designed to prevent thermal runaway in battery packs by efficiently dissipating heat. These systems include liquid cooling channels, heat pipes, and phase change materials that absorb excess heat. By maintaining optimal operating temperatures throughout the battery pack, these systems prevent hotspots that could trigger thermal runaway events, thereby enhancing overall safety and extending battery life.

- Heat dissipation structures in electronic devices: Specialized heat dissipation structures are implemented in electronic devices to prevent thermal runaway. These include heat sinks, thermal interface materials, and strategically placed ventilation channels that facilitate airflow. The structures are designed to quickly transfer heat away from critical components, reducing the risk of overheating and subsequent thermal events that could lead to device failure or safety hazards.

- Temperature monitoring and control systems: Sophisticated temperature monitoring and control systems are employed to detect early signs of thermal runaway and take preventive actions. These systems utilize temperature sensors, thermal imaging cameras, and predictive algorithms to continuously monitor device temperatures. When abnormal temperature patterns are detected, the systems can automatically adjust power levels, activate additional cooling mechanisms, or safely shut down the device to prevent thermal runaway progression.

- Thermal insulation and isolation techniques: Thermal insulation and isolation techniques are implemented to contain potential thermal runaway events and prevent their propagation. These techniques include fire-resistant barriers, thermal insulation layers, and compartmentalization designs that physically separate critical components. By isolating heat sources and creating thermal boundaries, these approaches limit the spread of thermal events and provide additional time for safety systems to respond.

- Advanced materials for heat management: Novel materials with superior thermal properties are utilized for effective heat management and thermal runaway prevention. These include high thermal conductivity materials, aerogels, ceramic composites, and graphene-based solutions that efficiently conduct or insulate heat as needed. The strategic implementation of these materials in device design enhances heat dissipation capabilities, reduces thermal resistance, and improves overall thermal stability under various operating conditions.

02 Phase change materials for heat absorption

Phase change materials (PCMs) are incorporated into battery systems to absorb excess heat during operation. These materials change from solid to liquid state when temperatures rise, absorbing large amounts of thermal energy without significant temperature increase. PCMs can be strategically placed between battery cells or integrated into cooling systems to provide passive thermal management. This approach helps prevent thermal runaway by maintaining stable temperatures during peak load conditions and absorbing heat during abnormal operating conditions.Expand Specific Solutions03 Structural heat dissipation designs

Innovative structural designs enhance heat dissipation in battery systems through optimized airflow paths and increased surface area for heat exchange. These designs include specialized housing structures with integrated cooling fins, ventilation channels, and thermally conductive materials. Some approaches incorporate honeycomb structures or heat pipes embedded within battery modules to facilitate heat transfer away from critical components. These structural solutions provide passive cooling mechanisms that work alongside active systems to prevent thermal runaway conditions.Expand Specific Solutions04 Smart thermal monitoring and control systems

Advanced monitoring systems use temperature sensors, thermal imaging, and predictive algorithms to detect potential thermal issues before they escalate to thermal runaway. These systems continuously monitor battery temperature distributions and can identify hotspots or abnormal temperature gradients. When concerning thermal conditions are detected, automated control systems can activate enhanced cooling, reduce power output, or initiate safety protocols. Some systems incorporate machine learning algorithms to improve prediction accuracy and response effectiveness based on historical thermal behavior patterns.Expand Specific Solutions05 Thermal isolation and compartmentalization techniques

Thermal isolation strategies prevent heat propagation between battery cells or modules by incorporating fire-resistant barriers, thermal insulators, and compartmentalized designs. These techniques limit the spread of thermal events by containing heat within affected areas and preventing chain reactions that could lead to system-wide thermal runaway. Some designs include heat-resistant separators between cells, thermally insulated compartments, and sacrificial materials that absorb heat during thermal events. These approaches work to localize thermal incidents and protect the overall battery system integrity.Expand Specific Solutions

Key Industry Players in Battery Thermal Management

The battery thermal runaway prevention market is in a growth phase, with increasing demand driven by electric vehicle proliferation and energy storage applications. The global market size is expanding rapidly as safety concerns become paramount in battery technologies. Leading companies like CATL, LG Energy Solution, Samsung SDI, and BYD are advancing sophisticated heat dissipation techniques, with varying levels of technological maturity. Tesla and SK On are pushing innovation in integrated cooling systems, while research institutions like Tsinghua University and Southwest Research Institute contribute fundamental advancements. The competitive landscape features both established battery manufacturers and specialized thermal management solution providers, with Asian companies currently dominating the technological frontier in phase change materials and advanced cooling architectures.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a multi-layered approach to battery thermal runaway prevention focusing on both active and passive systems. Their primary technology utilizes a direct liquid cooling system with a specialized coolant that flows through micro-channels integrated directly into the battery module structure. This design enables rapid heat dissipation with minimal thermal gradients across cells[1]. Samsung has also developed an advanced ceramic-coated separator technology that maintains structural integrity at high temperatures (up to 180°C), preventing internal short circuits even under extreme thermal conditions[2]. Their latest innovation includes a phase change material (PCM) composite that absorbs excess heat during high-load operations and gradually releases it during rest periods, effectively dampening temperature fluctuations. Samsung's system is complemented by a thermal propagation prevention design that incorporates fire-resistant barriers between cells and modules to isolate potential thermal events[3].

Strengths: Excellent thermal stability under extreme conditions; innovative separator technology provides additional safety layer; comprehensive approach combining active cooling with passive safety features. Weaknesses: Complex manufacturing process increases production costs; liquid cooling systems require additional maintenance and introduce potential leak points; slightly lower energy density compared to some competitors due to safety features.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive heat dissipation strategy centered around their cell-to-pack (CTP) technology, which eliminates module housings to improve thermal efficiency. Their system incorporates a liquid cooling plate design with optimized flow channels that maximize contact area with cells while minimizing coolant volume[1]. CATL's latest innovation is their "cooling in a healing way" technology that embeds cooling elements directly into the battery's structural components, creating a more uniform temperature distribution. They've also pioneered the use of thermally conductive adhesives between cells that facilitate heat transfer while providing structural support[2]. For extreme conditions, CATL has developed a rapid temperature rise detection system that can identify potential thermal runaway events up to 4 minutes before they occur, allowing for preventative measures to be implemented[3]. Their newest battery generations incorporate flame-retardant electrolytes and high-temperature resistant separators as additional safety measures against thermal propagation.

Strengths: Industry-leading energy density while maintaining thermal safety; innovative CTP design reduces thermal barriers; early detection systems provide critical response time for preventative actions. Weaknesses: Highly integrated design makes repairs and cell replacement more difficult; system optimization requires extensive testing across various use conditions; cooling efficiency can be compromised in extremely high ambient temperatures.

Critical Patents in Battery Cooling Technologies

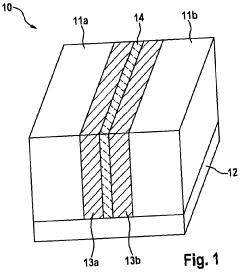

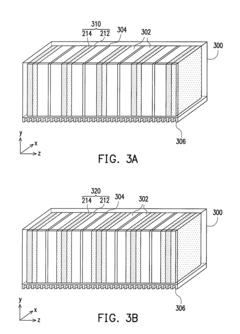

Thermal decoupling of adjacent cells in a battery system

PatentWO2011035990A1

Innovation

- Incorporating a thermal insulation layer between adjacent battery cells to prevent direct thermal energy transfer, while using heat conduction means connected to both the cell and a heat sink for efficient heat dissipation along a primary path, thereby reducing the risk of thermal runaway spread.

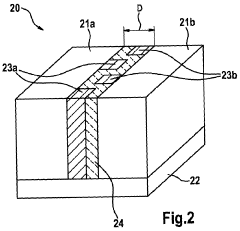

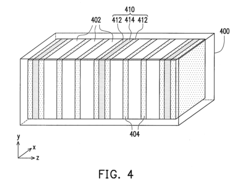

Protection structure forthermal dissipation and preventing thermal runaway diffusion in battery system

PatentActiveUS8785026B2

Innovation

- A multilayer anisotropic heat conduction structure with composite heat conduction plates, consisting of heat conduction and insulation layers, is introduced between battery cells and modules to control heat transmission and dissipation, preventing thermal runaway diffusion and enhancing safety.

Safety Standards and Regulatory Requirements

The regulatory landscape for battery thermal management systems has evolved significantly in response to high-profile thermal runaway incidents. International standards such as IEC 62133, UL 1642, and UN 38.3 establish comprehensive safety requirements for lithium-ion batteries, with specific provisions addressing thermal management and heat dissipation techniques. These standards mandate rigorous testing protocols including thermal abuse tests, short circuit tests, and overcharge tests to verify a battery's ability to withstand thermal stress without cascading into thermal runaway.

The automotive sector has developed particularly stringent regulations, with standards like SAE J2464 and ISO 6469 specifically addressing thermal runaway prevention in electric vehicle batteries. These standards require manufacturers to implement effective heat dissipation systems and thermal barriers between cells to prevent propagation of thermal events. Compliance with these standards often necessitates advanced cooling technologies such as liquid cooling systems or phase change materials.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. While the European Union enforces EN 62133 and the upcoming Battery Directive amendments focus heavily on thermal safety, the United States relies on UL standards and NFPA guidelines. Meanwhile, China has implemented GB/T 31485, which contains some of the most demanding thermal management requirements globally.

Regulatory bodies are increasingly adopting performance-based approaches rather than prescriptive requirements, allowing manufacturers flexibility in heat dissipation technology selection while maintaining strict safety outcomes. This shift has accelerated innovation in thermal management solutions while ensuring baseline safety standards are met across different applications.

Recent regulatory trends indicate movement toward real-time thermal monitoring requirements, with standards beginning to specify temperature gradient limits and response times for cooling systems. The integration of Battery Management Systems (BMS) with thermal management is becoming a regulatory focus, with requirements for automated thermal protection mechanisms that can detect and mitigate potential thermal events before they escalate.

Compliance documentation for heat dissipation systems has become increasingly comprehensive, requiring detailed thermal modeling, simulation results, and physical test data. Manufacturers must demonstrate through both analysis and testing that their thermal management solutions can effectively prevent thermal runaway under various abuse conditions and operational scenarios specified in applicable standards.

The automotive sector has developed particularly stringent regulations, with standards like SAE J2464 and ISO 6469 specifically addressing thermal runaway prevention in electric vehicle batteries. These standards require manufacturers to implement effective heat dissipation systems and thermal barriers between cells to prevent propagation of thermal events. Compliance with these standards often necessitates advanced cooling technologies such as liquid cooling systems or phase change materials.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. While the European Union enforces EN 62133 and the upcoming Battery Directive amendments focus heavily on thermal safety, the United States relies on UL standards and NFPA guidelines. Meanwhile, China has implemented GB/T 31485, which contains some of the most demanding thermal management requirements globally.

Regulatory bodies are increasingly adopting performance-based approaches rather than prescriptive requirements, allowing manufacturers flexibility in heat dissipation technology selection while maintaining strict safety outcomes. This shift has accelerated innovation in thermal management solutions while ensuring baseline safety standards are met across different applications.

Recent regulatory trends indicate movement toward real-time thermal monitoring requirements, with standards beginning to specify temperature gradient limits and response times for cooling systems. The integration of Battery Management Systems (BMS) with thermal management is becoming a regulatory focus, with requirements for automated thermal protection mechanisms that can detect and mitigate potential thermal events before they escalate.

Compliance documentation for heat dissipation systems has become increasingly comprehensive, requiring detailed thermal modeling, simulation results, and physical test data. Manufacturers must demonstrate through both analysis and testing that their thermal management solutions can effectively prevent thermal runaway under various abuse conditions and operational scenarios specified in applicable standards.

Environmental Impact of Cooling Materials

The environmental impact of cooling materials used in battery thermal management systems represents a critical consideration in the sustainable development of energy storage technologies. Traditional cooling materials such as phase change materials (PCMs), thermal interface materials (TIMs), and liquid coolants often contain compounds that pose significant environmental challenges throughout their lifecycle.

PCMs, while effective for thermal regulation, frequently incorporate paraffins and salt hydrates that derive from petroleum sources, contributing to carbon footprint concerns. Additionally, some specialized PCMs contain potentially toxic compounds that require careful handling during manufacturing and disposal phases. The environmental persistence of these materials varies significantly, with some synthetic variants demonstrating poor biodegradability profiles.

Liquid coolants present particular environmental challenges, especially those containing ethylene glycol or propylene glycol, which can contaminate soil and water systems if improperly disposed. Dielectric fluids used in immersion cooling systems often contain perfluorocarbons (PFCs) or hydrofluoroethers (HFEs) with high global warming potentials, sometimes thousands of times more potent than CO2 as greenhouse gases.

The manufacturing processes for advanced thermal interface materials frequently involve energy-intensive production methods and the use of rare earth elements. The extraction of these elements generates substantial environmental disruption through habitat destruction, water pollution, and the generation of radioactive waste byproducts in certain mining operations.

End-of-life considerations reveal additional environmental concerns. Many cooling materials cannot be easily separated from battery components during recycling processes, complicating material recovery efforts. The cross-contamination between cooling materials and battery components often necessitates specialized recycling protocols that are not widely available in current waste management infrastructure.

Recent innovations are addressing these environmental challenges through the development of bio-based PCMs derived from sustainable sources such as fatty acids and vegetable oils. These alternatives demonstrate comparable thermal performance while offering improved biodegradability and reduced toxicity profiles. Similarly, water-based coolants enhanced with environmentally benign additives are emerging as alternatives to traditional glycol-based solutions.

The regulatory landscape is evolving rapidly, with initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly influencing material selection in thermal management systems. These frameworks are driving manufacturers toward more environmentally responsible cooling solutions that maintain thermal performance while minimizing ecological impact.

PCMs, while effective for thermal regulation, frequently incorporate paraffins and salt hydrates that derive from petroleum sources, contributing to carbon footprint concerns. Additionally, some specialized PCMs contain potentially toxic compounds that require careful handling during manufacturing and disposal phases. The environmental persistence of these materials varies significantly, with some synthetic variants demonstrating poor biodegradability profiles.

Liquid coolants present particular environmental challenges, especially those containing ethylene glycol or propylene glycol, which can contaminate soil and water systems if improperly disposed. Dielectric fluids used in immersion cooling systems often contain perfluorocarbons (PFCs) or hydrofluoroethers (HFEs) with high global warming potentials, sometimes thousands of times more potent than CO2 as greenhouse gases.

The manufacturing processes for advanced thermal interface materials frequently involve energy-intensive production methods and the use of rare earth elements. The extraction of these elements generates substantial environmental disruption through habitat destruction, water pollution, and the generation of radioactive waste byproducts in certain mining operations.

End-of-life considerations reveal additional environmental concerns. Many cooling materials cannot be easily separated from battery components during recycling processes, complicating material recovery efforts. The cross-contamination between cooling materials and battery components often necessitates specialized recycling protocols that are not widely available in current waste management infrastructure.

Recent innovations are addressing these environmental challenges through the development of bio-based PCMs derived from sustainable sources such as fatty acids and vegetable oils. These alternatives demonstrate comparable thermal performance while offering improved biodegradability and reduced toxicity profiles. Similarly, water-based coolants enhanced with environmentally benign additives are emerging as alternatives to traditional glycol-based solutions.

The regulatory landscape is evolving rapidly, with initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly influencing material selection in thermal management systems. These frameworks are driving manufacturers toward more environmentally responsible cooling solutions that maintain thermal performance while minimizing ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!