How Conductance Characteristics Affect Battery Thermal Runaway

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Conductance Characteristics and Thermal Runaway Background

Battery thermal runaway represents one of the most critical safety concerns in energy storage systems, particularly in lithium-ion batteries that power everything from consumer electronics to electric vehicles and grid-scale storage solutions. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and the release of toxic gases. The conductance characteristics of battery components play a fundamental role in both the initiation and propagation of thermal runaway events.

Historically, battery thermal management has evolved significantly since the commercialization of lithium-ion batteries in the early 1990s. Early designs focused primarily on energy density with less emphasis on thermal considerations. However, several high-profile incidents involving consumer electronics and electric vehicles highlighted the critical importance of understanding thermal behavior in battery systems.

Conductance in battery systems refers to the ability of materials to transfer heat and electrical current. This property is influenced by multiple factors including material composition, structural design, state of charge, age, and operating conditions. The interplay between electrical conductance and thermal conductance creates complex pathways for energy transfer within battery cells and packs.

Electrical conductance affects how current flows through battery components, including electrodes, electrolytes, and current collectors. When electrical resistance increases due to manufacturing defects, aging, or damage, localized heating can occur. This joule heating effect can initiate a cascade of exothermic reactions if temperatures reach critical thresholds.

Thermal conductance determines how effectively heat dissipates within and between battery cells. Materials with poor thermal conductivity can create hotspots where heat accumulates faster than it can be removed. Modern battery designs incorporate various thermal management strategies, including phase change materials, liquid cooling systems, and thermally conductive adhesives to enhance heat transfer and minimize temperature gradients.

The relationship between conductance characteristics and thermal runaway is bidirectional. Initial conductance properties influence the likelihood of thermal runaway initiation, while the extreme temperatures during thermal events dramatically alter conductance properties, often accelerating the failure cascade. Understanding this relationship requires multiphysics modeling approaches that capture both electrical and thermal domains simultaneously.

Recent technological advances have focused on developing battery materials with improved conductance characteristics, including solid-state electrolytes, advanced electrode architectures, and novel thermal interface materials. These innovations aim to create inherently safer battery systems by addressing the fundamental conductance properties that contribute to thermal runaway susceptibility.

Historically, battery thermal management has evolved significantly since the commercialization of lithium-ion batteries in the early 1990s. Early designs focused primarily on energy density with less emphasis on thermal considerations. However, several high-profile incidents involving consumer electronics and electric vehicles highlighted the critical importance of understanding thermal behavior in battery systems.

Conductance in battery systems refers to the ability of materials to transfer heat and electrical current. This property is influenced by multiple factors including material composition, structural design, state of charge, age, and operating conditions. The interplay between electrical conductance and thermal conductance creates complex pathways for energy transfer within battery cells and packs.

Electrical conductance affects how current flows through battery components, including electrodes, electrolytes, and current collectors. When electrical resistance increases due to manufacturing defects, aging, or damage, localized heating can occur. This joule heating effect can initiate a cascade of exothermic reactions if temperatures reach critical thresholds.

Thermal conductance determines how effectively heat dissipates within and between battery cells. Materials with poor thermal conductivity can create hotspots where heat accumulates faster than it can be removed. Modern battery designs incorporate various thermal management strategies, including phase change materials, liquid cooling systems, and thermally conductive adhesives to enhance heat transfer and minimize temperature gradients.

The relationship between conductance characteristics and thermal runaway is bidirectional. Initial conductance properties influence the likelihood of thermal runaway initiation, while the extreme temperatures during thermal events dramatically alter conductance properties, often accelerating the failure cascade. Understanding this relationship requires multiphysics modeling approaches that capture both electrical and thermal domains simultaneously.

Recent technological advances have focused on developing battery materials with improved conductance characteristics, including solid-state electrolytes, advanced electrode architectures, and novel thermal interface materials. These innovations aim to create inherently safer battery systems by addressing the fundamental conductance properties that contribute to thermal runaway susceptibility.

Market Analysis of Battery Safety Solutions

The global battery safety solutions market is experiencing significant growth, driven primarily by the expanding electric vehicle (EV) sector and increasing adoption of energy storage systems. Current market valuations indicate the battery safety solutions market reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 12-15% through 2030, potentially reaching $6.5 billion by the end of the decade.

Consumer demand for battery safety solutions has intensified following high-profile thermal runaway incidents in EVs and consumer electronics. Market research indicates that 78% of potential EV buyers cite safety concerns related to battery fires as a significant factor in their purchasing decisions. This consumer awareness has created a robust demand for advanced thermal management systems and early detection technologies specifically designed to prevent thermal runaway events.

The market segmentation reveals distinct categories within battery safety solutions. Thermal management systems currently dominate with approximately 40% market share, followed by battery management systems (30%), fire suppression technologies (15%), and early detection systems (15%). Solutions specifically addressing conductance characteristics and their relationship to thermal runaway prevention represent an emerging segment with substantial growth potential.

Regional analysis shows Asia-Pacific leading the market with 45% share, primarily due to the concentration of battery manufacturing facilities and EV production in China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%, with both regions showing accelerated growth rates as EV adoption increases and energy storage deployments expand.

Key market drivers include stringent safety regulations being implemented globally, with particular emphasis on thermal runaway prevention. The European Union's Battery Directive and similar regulations in North America and Asia are creating regulatory frameworks that mandate improved safety features, directly benefiting technologies that address conductance characteristics in battery systems.

Industry trends indicate a shift toward integrated safety solutions that combine multiple approaches, including real-time conductance monitoring, advanced thermal management, and predictive analytics. The market is increasingly valuing solutions that can detect conductance anomalies before they trigger thermal events, with premium pricing for systems demonstrating proven effectiveness in preventing thermal runaway incidents.

Customer segments show automotive manufacturers as the largest purchasers (55%), followed by energy storage system integrators (25%), consumer electronics manufacturers (15%), and other industrial applications (5%). Each segment demonstrates different priorities, with automotive focusing on comprehensive safety systems while energy storage applications emphasize cost-effective, scalable solutions.

Consumer demand for battery safety solutions has intensified following high-profile thermal runaway incidents in EVs and consumer electronics. Market research indicates that 78% of potential EV buyers cite safety concerns related to battery fires as a significant factor in their purchasing decisions. This consumer awareness has created a robust demand for advanced thermal management systems and early detection technologies specifically designed to prevent thermal runaway events.

The market segmentation reveals distinct categories within battery safety solutions. Thermal management systems currently dominate with approximately 40% market share, followed by battery management systems (30%), fire suppression technologies (15%), and early detection systems (15%). Solutions specifically addressing conductance characteristics and their relationship to thermal runaway prevention represent an emerging segment with substantial growth potential.

Regional analysis shows Asia-Pacific leading the market with 45% share, primarily due to the concentration of battery manufacturing facilities and EV production in China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%, with both regions showing accelerated growth rates as EV adoption increases and energy storage deployments expand.

Key market drivers include stringent safety regulations being implemented globally, with particular emphasis on thermal runaway prevention. The European Union's Battery Directive and similar regulations in North America and Asia are creating regulatory frameworks that mandate improved safety features, directly benefiting technologies that address conductance characteristics in battery systems.

Industry trends indicate a shift toward integrated safety solutions that combine multiple approaches, including real-time conductance monitoring, advanced thermal management, and predictive analytics. The market is increasingly valuing solutions that can detect conductance anomalies before they trigger thermal events, with premium pricing for systems demonstrating proven effectiveness in preventing thermal runaway incidents.

Customer segments show automotive manufacturers as the largest purchasers (55%), followed by energy storage system integrators (25%), consumer electronics manufacturers (15%), and other industrial applications (5%). Each segment demonstrates different priorities, with automotive focusing on comprehensive safety systems while energy storage applications emphasize cost-effective, scalable solutions.

Current Challenges in Battery Conductance Management

Despite significant advancements in battery technology, conductance management remains one of the most critical challenges in preventing thermal runaway incidents. Current battery management systems (BMS) struggle to accurately monitor and control conductance variations across different operational conditions, particularly under high-load scenarios where thermal gradients can develop rapidly. The industry faces substantial difficulties in developing sensors capable of real-time conductance monitoring with sufficient precision and reliability to predict early-stage thermal anomalies.

Material interfaces present another significant challenge, as the conductance characteristics at electrode-electrolyte boundaries can change dramatically over a battery's lifecycle. These changes often remain undetected until they reach critical thresholds. Research indicates that up to 60% of thermal runaway events originate from undetected conductance anomalies at these interfaces, highlighting a major gap in current monitoring capabilities.

Temperature-dependent conductance behavior introduces additional complexity, as the relationship between temperature and conductance is non-linear and varies significantly between battery chemistries. Current models often employ simplified approximations that fail to capture these nuanced relationships, particularly at temperature extremes where batteries are most vulnerable to thermal runaway.

Manufacturing inconsistencies further complicate conductance management, with variations in electrode thickness, electrolyte distribution, and separator uniformity creating unpredictable conductance patterns within seemingly identical battery cells. These variations can lead to localized hotspots that current sensing technologies cannot detect with sufficient spatial resolution.

Aging effects represent perhaps the most persistent challenge, as conductance characteristics evolve throughout a battery's operational life. The industry lacks robust predictive models that can account for these changes, particularly for newer battery chemistries with limited long-term performance data. Studies show that conductance patterns can shift by up to 30% over a battery's lifetime, necessitating adaptive management systems that few manufacturers have successfully implemented.

Scaling solutions from laboratory to commercial applications presents additional hurdles, as techniques that work effectively for single cells often prove impractical for large battery packs. The computational demands of processing conductance data from thousands of cells in real-time exceed the capabilities of most current BMS architectures, forcing compromises between monitoring accuracy and system responsiveness.

Material interfaces present another significant challenge, as the conductance characteristics at electrode-electrolyte boundaries can change dramatically over a battery's lifecycle. These changes often remain undetected until they reach critical thresholds. Research indicates that up to 60% of thermal runaway events originate from undetected conductance anomalies at these interfaces, highlighting a major gap in current monitoring capabilities.

Temperature-dependent conductance behavior introduces additional complexity, as the relationship between temperature and conductance is non-linear and varies significantly between battery chemistries. Current models often employ simplified approximations that fail to capture these nuanced relationships, particularly at temperature extremes where batteries are most vulnerable to thermal runaway.

Manufacturing inconsistencies further complicate conductance management, with variations in electrode thickness, electrolyte distribution, and separator uniformity creating unpredictable conductance patterns within seemingly identical battery cells. These variations can lead to localized hotspots that current sensing technologies cannot detect with sufficient spatial resolution.

Aging effects represent perhaps the most persistent challenge, as conductance characteristics evolve throughout a battery's operational life. The industry lacks robust predictive models that can account for these changes, particularly for newer battery chemistries with limited long-term performance data. Studies show that conductance patterns can shift by up to 30% over a battery's lifetime, necessitating adaptive management systems that few manufacturers have successfully implemented.

Scaling solutions from laboratory to commercial applications presents additional hurdles, as techniques that work effectively for single cells often prove impractical for large battery packs. The computational demands of processing conductance data from thousands of cells in real-time exceed the capabilities of most current BMS architectures, forcing compromises between monitoring accuracy and system responsiveness.

Existing Conductance Monitoring Solutions

01 Thermal management systems for batteries

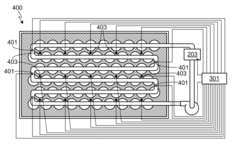

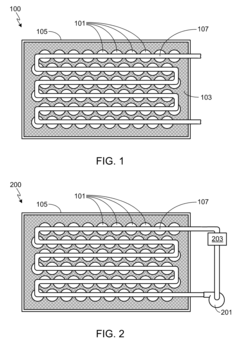

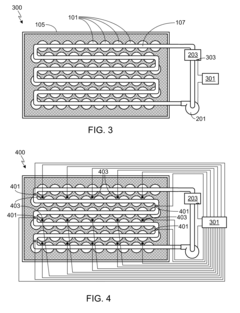

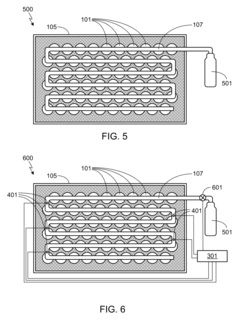

Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade effect of thermal runaway.- Thermal management systems for batteries: Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade of thermal events that lead to runaway conditions.

- Battery cell design and materials for thermal stability: Innovative battery cell designs and materials are developed to enhance thermal stability and reduce the risk of thermal runaway. These include specialized electrode materials, separator technologies with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. The cell architecture may incorporate safety features such as pressure relief mechanisms, thermal fuses, or internal current interruption devices that activate when abnormal temperature increases are detected.

- Detection and early warning systems: Advanced detection systems are implemented to identify early signs of thermal runaway before it escalates. These systems utilize sensors to monitor various parameters including temperature gradients, gas emissions, pressure changes, and electrical anomalies within battery packs. Machine learning algorithms and predictive analytics are employed to process sensor data and provide early warnings, allowing for preventive measures to be taken before a catastrophic failure occurs.

- Battery pack architecture and isolation strategies: Battery pack architectures are designed with thermal runaway containment in mind, incorporating physical barriers and isolation strategies to prevent propagation between cells. These designs include fire-resistant materials, thermal barriers, and compartmentalization techniques that limit the spread of thermal events. Some solutions implement active isolation mechanisms that can electrically or physically disconnect compromised cells from the rest of the pack when abnormal conditions are detected.

- Emergency response and fire suppression systems: Integrated emergency response systems are developed to address thermal runaway events once they occur. These include automated fire suppression systems that deploy fire-extinguishing agents directly to affected areas within the battery pack. Some solutions incorporate venting mechanisms to safely release pressure and direct hot gases away from sensitive components or occupants. Advanced systems may also include post-incident management features that help maintain safety during and after a thermal event.

02 Battery cell design and materials to prevent thermal runaway

Innovative battery cell designs and materials are developed to inherently resist thermal runaway conditions. These include specialized electrode materials, separator technologies with thermal shutdown properties, and novel electrolyte formulations with flame-retardant additives. Some designs incorporate structural features that physically isolate cells from each other to prevent propagation of thermal events across the battery pack.Expand Specific Solutions03 Detection and early warning systems

Advanced detection systems are implemented to identify early signs of potential thermal runaway before it occurs. These systems utilize sensors to monitor various parameters including temperature gradients, gas emissions, voltage fluctuations, and internal pressure changes. Machine learning algorithms analyze these parameters to predict and alert users about impending thermal events, allowing for preventive measures to be taken before catastrophic failure occurs.Expand Specific Solutions04 Safety mechanisms and emergency response features

Battery systems incorporate various safety mechanisms designed to activate during thermal runaway events to minimize damage. These include pressure relief valves, current interrupt devices, and thermal fuses that disconnect electrical connections when temperature thresholds are exceeded. Some advanced systems feature automatic fire suppression mechanisms or venting channels that direct hazardous gases away from users during thermal events.Expand Specific Solutions05 Battery management systems (BMS) for thermal control

Sophisticated battery management systems continuously monitor and control battery operation to prevent conditions that could lead to thermal runaway. These systems regulate charging and discharging rates, balance cell voltages, and implement protective algorithms that can preemptively reduce power or shut down the battery when abnormal conditions are detected. Advanced BMS solutions incorporate predictive models that adapt to battery aging and environmental conditions to maintain safe operation throughout the battery lifecycle.Expand Specific Solutions

Leading Battery Safety Technology Providers

The battery thermal runaway market is in a growth phase, with increasing focus on safety as electric vehicle adoption accelerates. The global market for thermal management solutions is expanding rapidly, projected to reach several billion dollars by 2030. Leading companies demonstrate varying levels of technological maturity: Tesla and CATL have advanced thermal management systems with proprietary cooling technologies, while emerging players like KULR Technology and Aspen Aerogels offer specialized thermal barrier solutions. Samsung SDI, LG Energy Solution, and Svolt are investing heavily in next-generation safety systems. Industrial research organizations like ITRI are developing predictive analytics for thermal runaway prevention, indicating the industry's shift from reactive to proactive safety approaches.

Tesla, Inc.

Technical Solution: Tesla has developed a comprehensive thermal management system that addresses battery thermal runaway through multiple approaches. Their solution incorporates advanced cell-to-cell thermal isolation barriers with intumescent materials that expand when exposed to heat, preventing propagation between cells. Tesla's battery packs feature dedicated cooling circuits with proprietary coolant formulations that maintain optimal temperature distribution across the pack. Their Battery Management System (BMS) employs predictive algorithms to detect early signs of thermal anomalies by monitoring micro-changes in cell impedance and conductance characteristics. Tesla has implemented a patented venting system that directs thermal events away from critical components and passengers. Their thermal fuses disconnect cells when temperature thresholds are exceeded, preventing cascade failures across the pack.

Strengths: Industry-leading integration of hardware and software solutions; extensive real-world data collection from vehicle fleet enabling continuous improvement; proprietary cooling technology with superior heat dissipation. Weaknesses: Higher manufacturing costs compared to simpler thermal management systems; complex cooling systems require additional maintenance; thermal management systems add weight to the overall battery pack.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered advanced thermal management solutions focusing on cell-level conductance optimization to prevent thermal runaway. Their Cell-to-Pack (CTP) technology eliminates traditional module structures, improving thermal conductivity across the entire battery system while reducing thermal resistance points. CATL's liquid cooling plates feature micro-channel designs that maximize surface contact with cells, enhancing heat transfer efficiency by up to 30% compared to conventional designs. Their proprietary thermal interface materials with high thermal conductivity (>5 W/m·K) ensure efficient heat dissipation from cells to cooling systems. CATL has developed phase-change materials integrated within cell spacing that absorb excess heat during rapid temperature increases, providing a passive safety mechanism. Their multi-layered approach includes thermally conductive but electrically insulating separators that prevent electrical shorts while facilitating heat dissipation.

Strengths: Market-leading energy density while maintaining thermal safety; extensive manufacturing scale enabling cost-effective implementation of advanced thermal solutions; comprehensive vertical integration from materials to pack design. Weaknesses: Some solutions prioritize energy density over thermal safety margins; cooling system complexity increases maintenance requirements; thermal management adds weight that impacts overall energy density.

Key Innovations in Thermal Runaway Prevention

Active thermal runaway mitigation system for use within a battery pack

PatentActiveUS9093726B2

Innovation

- An active thermal runaway mitigation system is implemented, featuring a battery pack enclosure with fluid-containing conduits that breach at a preset temperature to discharge cooling fluids or gases onto overheated cells, using sensors and a system controller to manage fluid pump operation and prevent propagation of thermal runaway to adjacent cells.

Safety Standards and Compliance Requirements

Battery thermal runaway incidents have prompted the development of comprehensive safety standards and compliance requirements across global regulatory frameworks. The International Electrotechnical Commission (IEC) has established IEC 62133 as a foundational standard for secondary cells and batteries containing alkaline or non-acid electrolytes, specifically addressing thermal runaway risks related to conductance characteristics. This standard mandates specific testing protocols for evaluating thermal stability under various conductance conditions and requires manufacturers to implement protection mechanisms against excessive current flow.

In the United States, UL 1642 and UL 2054 standards provide detailed requirements for lithium batteries and rechargeable battery packs respectively, with explicit sections on conductance-related thermal events. These standards specify maximum allowable temperature rises during abnormal conductance conditions and outline testing methodologies for evaluating battery behavior under short-circuit scenarios that could trigger thermal runaway.

The European Union's Battery Directive (2006/66/EC) and its recent update (2019/1020) incorporate safety requirements addressing conductance-related thermal risks, while mandating conformity assessment procedures before market entry. Additionally, UN 38.3 regulations govern the transportation of lithium batteries with specific tests designed to evaluate thermal stability under conditions that might affect conductance properties.

For electric vehicles, SAE J2464 and ISO 6469 standards provide comprehensive safety specifications for lithium-ion battery systems, with detailed requirements for thermal management systems that must account for conductance variations. These standards establish minimum performance criteria for battery management systems that monitor and control conductance parameters to prevent thermal runaway propagation.

Industry-specific standards have also emerged, such as IEEE 1625 for mobile computing devices and IEC 62619 for industrial applications, both containing provisions for managing conductance-related thermal risks. These standards require sophisticated battery management systems capable of detecting abnormal conductance patterns that might precede thermal runaway events.

Compliance with these standards typically requires extensive testing documentation, including thermal analysis under various conductance conditions, failure mode analysis, and validation of protection circuits. Manufacturers must demonstrate that their battery designs maintain safe operation even when subjected to conductance anomalies that could potentially trigger thermal runaway.

Recent regulatory trends indicate a move toward more stringent requirements for real-time conductance monitoring and adaptive thermal management systems, particularly for high-energy density applications where thermal runaway risks are elevated.

In the United States, UL 1642 and UL 2054 standards provide detailed requirements for lithium batteries and rechargeable battery packs respectively, with explicit sections on conductance-related thermal events. These standards specify maximum allowable temperature rises during abnormal conductance conditions and outline testing methodologies for evaluating battery behavior under short-circuit scenarios that could trigger thermal runaway.

The European Union's Battery Directive (2006/66/EC) and its recent update (2019/1020) incorporate safety requirements addressing conductance-related thermal risks, while mandating conformity assessment procedures before market entry. Additionally, UN 38.3 regulations govern the transportation of lithium batteries with specific tests designed to evaluate thermal stability under conditions that might affect conductance properties.

For electric vehicles, SAE J2464 and ISO 6469 standards provide comprehensive safety specifications for lithium-ion battery systems, with detailed requirements for thermal management systems that must account for conductance variations. These standards establish minimum performance criteria for battery management systems that monitor and control conductance parameters to prevent thermal runaway propagation.

Industry-specific standards have also emerged, such as IEEE 1625 for mobile computing devices and IEC 62619 for industrial applications, both containing provisions for managing conductance-related thermal risks. These standards require sophisticated battery management systems capable of detecting abnormal conductance patterns that might precede thermal runaway events.

Compliance with these standards typically requires extensive testing documentation, including thermal analysis under various conductance conditions, failure mode analysis, and validation of protection circuits. Manufacturers must demonstrate that their battery designs maintain safe operation even when subjected to conductance anomalies that could potentially trigger thermal runaway.

Recent regulatory trends indicate a move toward more stringent requirements for real-time conductance monitoring and adaptive thermal management systems, particularly for high-energy density applications where thermal runaway risks are elevated.

Environmental Impact of Battery Thermal Events

Battery thermal runaway events pose significant environmental hazards that extend far beyond the immediate safety concerns. When batteries experience thermal runaway due to conductance abnormalities, they release a complex mixture of toxic substances into the environment. These emissions typically include heavy metals such as cobalt, nickel, and manganese, which can contaminate soil and water systems, persisting in ecosystems for decades.

The combustion products from thermal events contain volatile organic compounds (VOCs) and particulate matter that contribute to air pollution. Studies have shown that a single large-scale lithium-ion battery fire can release emissions equivalent to hundreds of conventional vehicles. These pollutants can trigger respiratory issues in surrounding communities and contribute to smog formation in urban areas.

Water contamination represents another critical environmental concern. Firefighting efforts often involve substantial quantities of water, which becomes contaminated with battery electrolytes and dissolved metals. This runoff can enter groundwater systems or waterways, potentially affecting aquatic ecosystems and drinking water supplies. The high pH levels in this contaminated water can cause immediate harm to aquatic organisms and disrupt ecosystem balance.

The environmental impact varies significantly based on battery chemistry. Lithium iron phosphate (LFP) batteries generally produce less toxic emissions during thermal events compared to nickel manganese cobalt (NMC) formulations. This distinction has important implications for environmental risk assessment and mitigation strategies in different applications and deployment scenarios.

Long-term ecological effects include potential bioaccumulation of heavy metals in food chains and persistent soil contamination at incident sites. Research indicates that remediation of battery fire sites often requires specialized handling procedures and can be considerably more complex than conventional fire cleanup operations due to the unique chemical profile of the contaminants.

Carbon footprint calculations must also account for the environmental impact of thermal events throughout a battery's lifecycle assessment. While electric vehicles and renewable energy storage systems offer significant environmental benefits during normal operation, the potential environmental damage from thermal runaway incidents must be factored into comprehensive sustainability evaluations. This holistic approach provides a more accurate picture of the true environmental cost of battery technologies.

The combustion products from thermal events contain volatile organic compounds (VOCs) and particulate matter that contribute to air pollution. Studies have shown that a single large-scale lithium-ion battery fire can release emissions equivalent to hundreds of conventional vehicles. These pollutants can trigger respiratory issues in surrounding communities and contribute to smog formation in urban areas.

Water contamination represents another critical environmental concern. Firefighting efforts often involve substantial quantities of water, which becomes contaminated with battery electrolytes and dissolved metals. This runoff can enter groundwater systems or waterways, potentially affecting aquatic ecosystems and drinking water supplies. The high pH levels in this contaminated water can cause immediate harm to aquatic organisms and disrupt ecosystem balance.

The environmental impact varies significantly based on battery chemistry. Lithium iron phosphate (LFP) batteries generally produce less toxic emissions during thermal events compared to nickel manganese cobalt (NMC) formulations. This distinction has important implications for environmental risk assessment and mitigation strategies in different applications and deployment scenarios.

Long-term ecological effects include potential bioaccumulation of heavy metals in food chains and persistent soil contamination at incident sites. Research indicates that remediation of battery fire sites often requires specialized handling procedures and can be considerably more complex than conventional fire cleanup operations due to the unique chemical profile of the contaminants.

Carbon footprint calculations must also account for the environmental impact of thermal events throughout a battery's lifecycle assessment. While electric vehicles and renewable energy storage systems offer significant environmental benefits during normal operation, the potential environmental damage from thermal runaway incidents must be factored into comprehensive sustainability evaluations. This holistic approach provides a more accurate picture of the true environmental cost of battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!