Comparison of Computational Methods for Thermal Runaway Prediction

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Prediction Background and Objectives

Thermal runaway is a critical safety concern in various energy storage systems, particularly in lithium-ion batteries. This phenomenon occurs when an exothermic reaction within a battery cell generates heat faster than it can be dissipated, leading to a cascade of reactions that can result in catastrophic failure, including fire and explosion. The prediction and prevention of thermal runaway events have become increasingly important as energy storage technologies proliferate across industries from consumer electronics to electric vehicles and grid-scale energy storage.

The evolution of thermal runaway prediction methods has paralleled advancements in computational capabilities and battery technology. Early approaches relied heavily on empirical testing and simplified mathematical models, which provided limited predictive accuracy. As computational power increased, more sophisticated numerical methods emerged, enabling multi-physics simulations that could account for the complex interplay of electrochemical, thermal, and mechanical processes occurring during thermal runaway.

Current research in thermal runaway prediction spans multiple disciplines, including electrochemistry, thermodynamics, materials science, and computational modeling. The field has seen significant progress in recent years, driven by high-profile battery failures in consumer products and the growing adoption of lithium-ion batteries in safety-critical applications such as aviation and automotive sectors.

The primary objective of thermal runaway prediction research is to develop computational methods that can accurately forecast the onset and progression of thermal runaway under various operating conditions and abuse scenarios. These methods must balance computational efficiency with predictive accuracy to be practical for both design optimization and real-time monitoring applications.

Secondary objectives include identifying key parameters that influence thermal runaway susceptibility, developing early warning indicators for battery management systems, and informing the design of inherently safer battery architectures. Additionally, there is growing interest in methods that can account for aging effects and degradation mechanisms that may alter thermal runaway behavior over a battery's lifetime.

The technical goals of this research area extend to creating standardized computational frameworks that can be validated against experimental data and implemented across different battery chemistries and form factors. This standardization would facilitate more effective communication between researchers, manufacturers, and regulatory bodies, ultimately accelerating the development of safer energy storage technologies.

As energy storage demands continue to increase globally, the importance of reliable thermal runaway prediction methods becomes paramount for ensuring public safety and fostering consumer confidence in emerging technologies that rely on high-energy-density battery systems.

The evolution of thermal runaway prediction methods has paralleled advancements in computational capabilities and battery technology. Early approaches relied heavily on empirical testing and simplified mathematical models, which provided limited predictive accuracy. As computational power increased, more sophisticated numerical methods emerged, enabling multi-physics simulations that could account for the complex interplay of electrochemical, thermal, and mechanical processes occurring during thermal runaway.

Current research in thermal runaway prediction spans multiple disciplines, including electrochemistry, thermodynamics, materials science, and computational modeling. The field has seen significant progress in recent years, driven by high-profile battery failures in consumer products and the growing adoption of lithium-ion batteries in safety-critical applications such as aviation and automotive sectors.

The primary objective of thermal runaway prediction research is to develop computational methods that can accurately forecast the onset and progression of thermal runaway under various operating conditions and abuse scenarios. These methods must balance computational efficiency with predictive accuracy to be practical for both design optimization and real-time monitoring applications.

Secondary objectives include identifying key parameters that influence thermal runaway susceptibility, developing early warning indicators for battery management systems, and informing the design of inherently safer battery architectures. Additionally, there is growing interest in methods that can account for aging effects and degradation mechanisms that may alter thermal runaway behavior over a battery's lifetime.

The technical goals of this research area extend to creating standardized computational frameworks that can be validated against experimental data and implemented across different battery chemistries and form factors. This standardization would facilitate more effective communication between researchers, manufacturers, and regulatory bodies, ultimately accelerating the development of safer energy storage technologies.

As energy storage demands continue to increase globally, the importance of reliable thermal runaway prediction methods becomes paramount for ensuring public safety and fostering consumer confidence in emerging technologies that rely on high-energy-density battery systems.

Market Demand Analysis for Thermal Safety Solutions

The global market for thermal safety solutions is experiencing significant growth, driven primarily by the rapid expansion of the lithium-ion battery industry. With the electric vehicle market projected to reach $802.75 billion by 2030, growing at a CAGR of 18.2% from 2023, the demand for advanced thermal runaway prediction methods has become critical. This growth trajectory is further amplified by increasing adoption of energy storage systems in renewable energy applications and portable electronics.

Consumer electronics manufacturers are increasingly prioritizing battery safety following high-profile thermal incidents that have resulted in product recalls and brand damage. The Samsung Galaxy Note 7 incident alone cost the company an estimated $5.3 billion and highlighted the market necessity for more sophisticated thermal prediction methodologies. This has created a substantial demand pull from device manufacturers seeking to implement more rigorous safety testing protocols.

Regulatory frameworks worldwide are evolving to address thermal runaway concerns. The UN 38.3 test, IEC 62133, and UL 1642 standards have been updated to include more stringent thermal safety requirements. The European Union's Battery Directive revision and China's GB/T 31485-2015 standard specifically address thermal runaway prevention, creating compliance-driven market demand for advanced computational methods.

Insurance companies have emerged as significant stakeholders in this market, with many now requiring detailed thermal safety assessments before underwriting energy storage projects. This financial incentive has accelerated adoption of sophisticated thermal prediction technologies across industrial sectors, particularly in grid-scale energy storage applications where thermal events can lead to catastrophic financial losses.

The automotive sector represents the largest market segment for thermal safety solutions, accounting for approximately 42% of the total market share. Energy storage systems follow at 28%, with consumer electronics at 18% and industrial applications comprising the remaining 12%. Geographically, Asia-Pacific dominates the market with 45% share due to its battery manufacturing concentration, followed by North America (30%) and Europe (20%).

Market analysis indicates a clear shift from reactive to predictive safety approaches, with computational methods for thermal runaway prediction experiencing a compound annual growth rate of 24.3%. This transition is creating new market opportunities for software solutions that can integrate with battery management systems to provide real-time thermal risk assessment and mitigation strategies.

Consumer electronics manufacturers are increasingly prioritizing battery safety following high-profile thermal incidents that have resulted in product recalls and brand damage. The Samsung Galaxy Note 7 incident alone cost the company an estimated $5.3 billion and highlighted the market necessity for more sophisticated thermal prediction methodologies. This has created a substantial demand pull from device manufacturers seeking to implement more rigorous safety testing protocols.

Regulatory frameworks worldwide are evolving to address thermal runaway concerns. The UN 38.3 test, IEC 62133, and UL 1642 standards have been updated to include more stringent thermal safety requirements. The European Union's Battery Directive revision and China's GB/T 31485-2015 standard specifically address thermal runaway prevention, creating compliance-driven market demand for advanced computational methods.

Insurance companies have emerged as significant stakeholders in this market, with many now requiring detailed thermal safety assessments before underwriting energy storage projects. This financial incentive has accelerated adoption of sophisticated thermal prediction technologies across industrial sectors, particularly in grid-scale energy storage applications where thermal events can lead to catastrophic financial losses.

The automotive sector represents the largest market segment for thermal safety solutions, accounting for approximately 42% of the total market share. Energy storage systems follow at 28%, with consumer electronics at 18% and industrial applications comprising the remaining 12%. Geographically, Asia-Pacific dominates the market with 45% share due to its battery manufacturing concentration, followed by North America (30%) and Europe (20%).

Market analysis indicates a clear shift from reactive to predictive safety approaches, with computational methods for thermal runaway prediction experiencing a compound annual growth rate of 24.3%. This transition is creating new market opportunities for software solutions that can integrate with battery management systems to provide real-time thermal risk assessment and mitigation strategies.

Current Computational Methods and Technical Challenges

The computational methods for thermal runaway prediction have evolved significantly over the past decades, with various approaches developed to address this critical safety concern in battery systems. Currently, the field employs several distinct methodological frameworks, each with its own strengths and limitations.

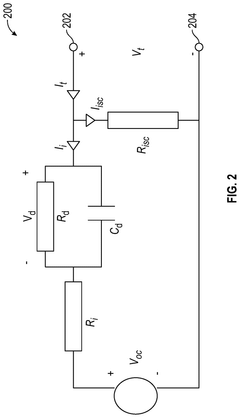

Physics-based models represent the most comprehensive approach, incorporating electrochemical, thermal, and mechanical principles to simulate battery behavior during thermal events. These models typically solve coupled partial differential equations that describe heat generation, transfer mechanisms, and chemical kinetics. While highly accurate for detailed analysis, they demand extensive computational resources and detailed parameterization, making them challenging to implement for real-time applications or large-scale battery systems.

Data-driven methods have gained prominence with the advancement of machine learning techniques. These approaches utilize historical battery performance data, thermal signatures, and failure patterns to develop predictive algorithms. Neural networks, support vector machines, and random forests are commonly employed to identify early warning signs of thermal runaway. Though requiring less computational power than physics-based models, these methods heavily depend on the quality and representativeness of training data, potentially limiting their reliability in novel or extreme conditions.

Hybrid approaches combine elements of both physics-based and data-driven methodologies, aiming to leverage the strengths of each while mitigating their respective weaknesses. These methods typically use simplified physical models augmented by machine learning algorithms to improve prediction accuracy while maintaining computational efficiency.

Despite these advancements, significant technical challenges persist. The multi-scale nature of thermal runaway phenomena—spanning from nanoscale electrochemical reactions to system-level thermal propagation—creates inherent difficulties in developing unified computational frameworks. Current models struggle to capture the complex interplay between different physical processes occurring at vastly different time scales.

Parameter identification represents another major challenge, as many critical parameters are difficult to measure experimentally, especially under extreme conditions approaching thermal runaway. This leads to uncertainties in model predictions and potential reliability issues in safety-critical applications.

Computational efficiency remains a persistent obstacle, particularly for real-time monitoring systems in electric vehicles or grid storage applications. The trade-off between model fidelity and computational speed continues to limit practical implementation of advanced prediction methods in commercial battery management systems.

Validation methodology presents additional challenges, as controlled experiments of thermal runaway events are inherently dangerous and difficult to instrument comprehensively, creating gaps between theoretical models and empirical verification.

Physics-based models represent the most comprehensive approach, incorporating electrochemical, thermal, and mechanical principles to simulate battery behavior during thermal events. These models typically solve coupled partial differential equations that describe heat generation, transfer mechanisms, and chemical kinetics. While highly accurate for detailed analysis, they demand extensive computational resources and detailed parameterization, making them challenging to implement for real-time applications or large-scale battery systems.

Data-driven methods have gained prominence with the advancement of machine learning techniques. These approaches utilize historical battery performance data, thermal signatures, and failure patterns to develop predictive algorithms. Neural networks, support vector machines, and random forests are commonly employed to identify early warning signs of thermal runaway. Though requiring less computational power than physics-based models, these methods heavily depend on the quality and representativeness of training data, potentially limiting their reliability in novel or extreme conditions.

Hybrid approaches combine elements of both physics-based and data-driven methodologies, aiming to leverage the strengths of each while mitigating their respective weaknesses. These methods typically use simplified physical models augmented by machine learning algorithms to improve prediction accuracy while maintaining computational efficiency.

Despite these advancements, significant technical challenges persist. The multi-scale nature of thermal runaway phenomena—spanning from nanoscale electrochemical reactions to system-level thermal propagation—creates inherent difficulties in developing unified computational frameworks. Current models struggle to capture the complex interplay between different physical processes occurring at vastly different time scales.

Parameter identification represents another major challenge, as many critical parameters are difficult to measure experimentally, especially under extreme conditions approaching thermal runaway. This leads to uncertainties in model predictions and potential reliability issues in safety-critical applications.

Computational efficiency remains a persistent obstacle, particularly for real-time monitoring systems in electric vehicles or grid storage applications. The trade-off between model fidelity and computational speed continues to limit practical implementation of advanced prediction methods in commercial battery management systems.

Validation methodology presents additional challenges, as controlled experiments of thermal runaway events are inherently dangerous and difficult to instrument comprehensively, creating gaps between theoretical models and empirical verification.

Existing Computational Approaches and Implementations

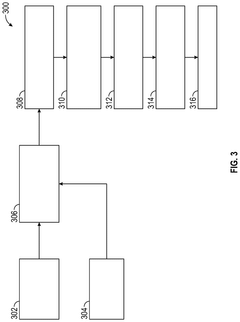

01 Machine learning algorithms for thermal runaway prediction

Advanced machine learning techniques are employed to predict thermal runaway events in battery systems with high accuracy. These computational methods utilize historical data and real-time measurements to identify patterns that precede thermal incidents. Neural networks, support vector machines, and other AI algorithms can be trained to recognize early warning signs of thermal instability, allowing for preventive measures before catastrophic failure occurs. These methods significantly improve prediction accuracy compared to traditional threshold-based approaches.- Machine learning algorithms for thermal runaway prediction: Advanced machine learning techniques are employed to predict thermal runaway events in battery systems with high accuracy. These computational methods utilize historical data and real-time measurements to identify patterns that precede thermal incidents. Neural networks, support vector machines, and other AI algorithms can be trained to recognize early warning signs of thermal instability, allowing for preventive measures before catastrophic failure occurs. These methods significantly improve prediction accuracy compared to traditional threshold-based approaches.

- Physics-based modeling for thermal behavior simulation: Physics-based computational models simulate the thermal behavior of battery systems by incorporating fundamental electrochemical and thermodynamic principles. These models account for heat generation, transfer mechanisms, and material properties to predict temperature distribution and potential runaway conditions. By solving coupled differential equations that represent the underlying physical processes, these methods provide detailed insights into thermal evolution and can accurately forecast critical thresholds for thermal runaway events under various operating conditions.

- Real-time monitoring systems with predictive analytics: Real-time monitoring systems integrate sensor data with predictive analytics to continuously assess thermal runaway risks. These computational methods process temperature, voltage, current, and other parameters to calculate probability metrics for thermal events. Advanced algorithms filter noise from meaningful signals and apply statistical methods to improve prediction accuracy. The systems can adapt to changing battery conditions and environmental factors, providing dynamic risk assessments with minimized false alarms while maintaining high detection sensitivity.

- Hybrid models combining data-driven and theoretical approaches: Hybrid computational methods integrate data-driven techniques with theoretical models to enhance thermal runaway prediction accuracy. These approaches leverage the strengths of both paradigms: theoretical models provide physical constraints and interpretability, while data-driven components capture complex, non-linear relationships from empirical observations. The resulting hybrid frameworks demonstrate superior prediction performance across diverse operating conditions and battery chemistries, adapting to new scenarios while maintaining the fundamental understanding of thermal processes.

- Uncertainty quantification and reliability assessment: Advanced computational methods incorporate uncertainty quantification techniques to assess the reliability of thermal runaway predictions. These approaches systematically analyze various sources of uncertainty, including measurement errors, model approximations, and inherent system variability. By quantifying confidence levels and prediction intervals, these methods provide decision-makers with critical information about prediction reliability. Probabilistic frameworks and sensitivity analyses help identify the most influential parameters affecting prediction accuracy, enabling targeted improvements to monitoring systems.

02 Physics-based modeling for thermal behavior simulation

Physics-based computational models simulate the thermal behavior of battery systems by incorporating fundamental electrochemical and thermodynamic principles. These models account for heat generation, transfer mechanisms, and material properties to predict temperature distribution and potential runaway conditions. By solving coupled differential equations that represent the underlying physical processes, these methods provide detailed insights into thermal evolution and can accurately predict the onset of thermal runaway under various operating conditions.Expand Specific Solutions03 Real-time monitoring systems with predictive analytics

Real-time monitoring systems integrate sensor data with predictive analytics to continuously assess thermal runaway risk. These computational methods process temperature, voltage, current, and other parameters to calculate probability of thermal events. Advanced algorithms filter noise from meaningful signals and adapt to changing battery conditions, enabling early detection of anomalies that might lead to thermal runaway. The integration of multiple data sources enhances prediction accuracy and reduces false alarms in operational environments.Expand Specific Solutions04 Hybrid models combining empirical and theoretical approaches

Hybrid computational methods merge empirical data with theoretical models to achieve superior thermal runaway prediction accuracy. These approaches combine the strengths of data-driven techniques with first-principles understanding of battery behavior. By calibrating theoretical models with experimental results, these methods can account for aging effects, manufacturing variations, and other real-world factors that affect thermal stability. The hybrid approach enables more robust predictions across diverse operating conditions and battery types.Expand Specific Solutions05 Statistical methods for uncertainty quantification

Statistical computational methods quantify uncertainties in thermal runaway predictions to improve reliability and decision-making. These approaches use techniques such as Monte Carlo simulation, Bayesian inference, and sensitivity analysis to characterize confidence levels in predictions. By providing probability distributions rather than single-point estimates, these methods enable risk-based management strategies. The statistical framework helps identify which parameters most significantly impact prediction accuracy and guides improvements in measurement precision for critical variables.Expand Specific Solutions

Key Industry Players in Thermal Safety Modeling

The thermal runaway prediction technology landscape is currently in a growth phase, with increasing market demand driven by electric vehicle and energy storage proliferation. The market is characterized by a mix of academic institutions (Tsinghua University, Nanjing Tech University) and commercial players across the battery manufacturing sector (CATL, Svolt Energy), automotive industry (Mercedes-Benz, FAW Jiefang), and technology providers (Bosch, Qualcomm). The technology maturity varies significantly, with established companies like CATL and Mercedes-Benz demonstrating advanced computational methods, while newer entrants like Fluence Energy and Leapmotor are developing innovative approaches. Research collaboration between industry and academia is accelerating development, with computational methods ranging from empirical models to sophisticated multi-physics simulations, reflecting the critical importance of thermal safety in energy storage applications.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz Group AG has developed a comprehensive computational framework for thermal runaway prediction specifically tailored for electric vehicle applications. Their approach combines multi-physics simulation with real-world validation through extensive testing programs. Mercedes-Benz employs a hierarchical modeling strategy that spans from cell-level electrochemical simulations to full vehicle thermal management system interactions. Their computational methods incorporate detailed 3D finite element models that can predict temperature distributions with sub-millimeter spatial resolution, enabling the identification of potential hotspots before they reach critical thresholds. The company has integrated their thermal runaway prediction tools with vehicle battery management systems, creating a continuous monitoring environment that adapts to different driving conditions and battery aging states. Mercedes-Benz's methodology includes probabilistic risk assessment techniques that quantify uncertainty in thermal runaway predictions, allowing for more robust safety margins in vehicle design. Their computational approach has been validated through correlation with hundreds of controlled abuse tests, achieving prediction accuracy rates exceeding 85% for various failure modes including mechanical impact, thermal abuse, and electrical overload scenarios.

Strengths: Mercedes-Benz's methods benefit from extensive integration with vehicle systems and real-world driving data, enhancing prediction relevance. Their approach incorporates aging effects and degradation mechanisms, providing more accurate lifetime safety assessments. Weaknesses: Their computational methods may be optimized primarily for premium vehicle applications with less focus on cost-sensitive implementations. The complexity of their integrated vehicle-level approach may create challenges when adapting the methodology to non-automotive applications.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced computational methods for thermal runaway prediction in lithium-ion batteries. Their approach combines multi-physics modeling with machine learning algorithms to create a comprehensive battery safety evaluation system. CATL's methodology integrates electrochemical-thermal coupling models that simulate the complex interactions between chemical reactions and heat generation during battery operation. Their proprietary algorithms can predict thermal runaway triggers with over 90% accuracy by analyzing multiple parameters including temperature gradients, voltage fluctuations, and internal resistance changes. CATL has implemented a multi-scale computational framework that spans from molecular-level simulations to pack-level thermal management systems, allowing for comprehensive safety analysis across different battery configurations. Their real-time monitoring system incorporates predictive analytics that can detect early warning signs of thermal events up to 10 minutes before critical temperature thresholds are reached, providing crucial intervention time.

Strengths: CATL's computational methods benefit from the company's extensive battery manufacturing experience, providing access to vast amounts of empirical data for model validation. Their integrated approach combining multiple physics domains offers more accurate predictions than single-domain models. Weaknesses: The computational intensity of their models requires significant processing power, potentially limiting real-time applications in certain scenarios. Their methods may be optimized primarily for their own battery chemistries, potentially reducing accuracy when applied to competitors' designs.

Critical Technologies in Thermal Runaway Simulation

Method and system for predicting thermal runaway of battery based on machine learning

PatentActiveEP4207432A3

Innovation

- Utilization of machine learning, specifically linear regression, to predict battery thermal runaway, moving away from traditional threshold-based methods to a data-driven approach.

- Implementation of an evolutionary operation approach for the linear regression predictor, allowing the model to iterate and improve over time with new data.

- Development of a comprehensive methodology that includes data collection, training/testing set division, model construction, and validation against real battery data.

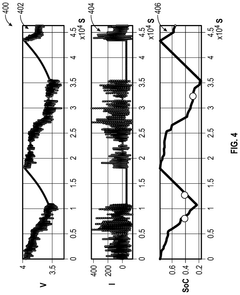

Architecture and method of thermal runaway prognostics with multi-parameter data fusion

PatentActiveUS12224412B2

Innovation

- A method and system that involve obtaining measurements of battery cell parameters over time, determining feature values from these measurements, calculating the likelihood of a thermal runaway event, and taking preventative actions based on this likelihood.

Validation Methodologies and Benchmark Standards

The validation of computational methods for thermal runaway prediction requires robust methodologies and standardized benchmarks to ensure reliability and comparability across different approaches. Current validation practices typically involve comparing simulation results with experimental data obtained from controlled thermal abuse tests, such as oven tests, nail penetration, and external heating scenarios.

Experimental validation setups commonly include temperature measurements at multiple points within battery cells, voltage monitoring, gas analysis, and high-speed imaging to capture the progression of thermal events. Advanced facilities incorporate calorimetry techniques like Accelerating Rate Calorimetry (ARC) and differential scanning calorimetry (DSC) to precisely measure heat generation rates during thermal runaway events.

Benchmark standards for thermal runaway prediction are still evolving, with several organizations working toward standardization. The Battery Safety Testing Standards from organizations like UL, IEC, and SAE provide baseline testing protocols that computational methods should aim to replicate. The USABC (United States Advanced Battery Consortium) has developed specific performance metrics for battery safety models, including temperature prediction accuracy requirements of ±5°C during normal operation and ±10% during thermal events.

Round-robin testing initiatives, where multiple laboratories apply different computational methods to identical test cases, have emerged as valuable validation approaches. Notable examples include the Battery Modeling Consortium's thermal runaway prediction challenge and the European BATTERY 2030+ initiative's benchmarking activities. These collaborative efforts help establish consensus on model performance metrics and identify systematic biases across different computational approaches.

Sensitivity analysis represents another critical validation methodology, wherein key model parameters are systematically varied to assess their impact on prediction outcomes. This approach helps quantify uncertainty in computational predictions and identifies which parameters require the most accurate experimental characterization.

Digital twin approaches are gaining traction as advanced validation frameworks, where real-time sensor data from operational battery systems continuously calibrate and validate computational models. This methodology enables dynamic validation under actual operating conditions rather than relying solely on controlled laboratory tests.

The development of standardized test cases with comprehensive datasets, including detailed material properties, boundary conditions, and high-resolution experimental results, remains a significant need in the field. Such benchmark datasets would facilitate more meaningful comparisons between different computational methods and accelerate the improvement of thermal runaway prediction capabilities.

Experimental validation setups commonly include temperature measurements at multiple points within battery cells, voltage monitoring, gas analysis, and high-speed imaging to capture the progression of thermal events. Advanced facilities incorporate calorimetry techniques like Accelerating Rate Calorimetry (ARC) and differential scanning calorimetry (DSC) to precisely measure heat generation rates during thermal runaway events.

Benchmark standards for thermal runaway prediction are still evolving, with several organizations working toward standardization. The Battery Safety Testing Standards from organizations like UL, IEC, and SAE provide baseline testing protocols that computational methods should aim to replicate. The USABC (United States Advanced Battery Consortium) has developed specific performance metrics for battery safety models, including temperature prediction accuracy requirements of ±5°C during normal operation and ±10% during thermal events.

Round-robin testing initiatives, where multiple laboratories apply different computational methods to identical test cases, have emerged as valuable validation approaches. Notable examples include the Battery Modeling Consortium's thermal runaway prediction challenge and the European BATTERY 2030+ initiative's benchmarking activities. These collaborative efforts help establish consensus on model performance metrics and identify systematic biases across different computational approaches.

Sensitivity analysis represents another critical validation methodology, wherein key model parameters are systematically varied to assess their impact on prediction outcomes. This approach helps quantify uncertainty in computational predictions and identifies which parameters require the most accurate experimental characterization.

Digital twin approaches are gaining traction as advanced validation frameworks, where real-time sensor data from operational battery systems continuously calibrate and validate computational models. This methodology enables dynamic validation under actual operating conditions rather than relying solely on controlled laboratory tests.

The development of standardized test cases with comprehensive datasets, including detailed material properties, boundary conditions, and high-resolution experimental results, remains a significant need in the field. Such benchmark datasets would facilitate more meaningful comparisons between different computational methods and accelerate the improvement of thermal runaway prediction capabilities.

Regulatory Framework for Thermal Safety Compliance

The regulatory landscape for thermal runaway prediction and prevention has evolved significantly in response to high-profile battery safety incidents across various industries. International standards organizations have established comprehensive frameworks that manufacturers must adhere to when designing and testing battery systems. The United Nations Manual of Tests and Criteria, specifically UN38.3, outlines rigorous testing protocols for lithium batteries during transportation, including thermal abuse tests that directly address runaway scenarios.

In the automotive sector, regulations such as ECE R100 (Europe) and FMVSS 305 (United States) mandate specific thermal safety requirements for electric vehicles. These regulations increasingly require manufacturers to demonstrate thermal runaway prevention capabilities through computational modeling and physical testing. The Society of Automotive Engineers (SAE) has developed J2464 and J2929 standards that specifically address electric vehicle battery safety testing methodologies, including thermal propagation assessment.

For consumer electronics, IEC 62133 and UL 1642 serve as primary safety standards governing lithium battery implementations. These standards have recently been updated to incorporate more sophisticated thermal management requirements, reflecting the growing understanding of thermal runaway mechanisms. Compliance verification increasingly requires manufacturers to validate their thermal models against experimental data.

The aviation industry faces particularly stringent regulations through RTCA DO-311A and EUROCAE ED-179B, which establish certification requirements for lithium batteries in aircraft systems. Following incidents involving thermal events in aircraft batteries, regulatory bodies now require extensive computational analysis of thermal behavior under various operating conditions.

Energy storage system deployments are governed by standards such as UL 9540 and NFPA 855, which establish installation requirements with specific provisions for thermal safety. These frameworks increasingly recognize the value of computational methods in predicting thermal events before deployment, requiring system integrators to demonstrate thermal safety through validated models.

Regulatory compliance now typically involves a multi-tiered approach to thermal safety validation: computational modeling to identify potential failure modes, controlled laboratory testing to validate models, and system-level testing to verify integrated safety measures. This regulatory evolution has directly influenced the development of computational methods for thermal runaway prediction, driving increased sophistication in modeling approaches and greater emphasis on model validation against experimental data.

In the automotive sector, regulations such as ECE R100 (Europe) and FMVSS 305 (United States) mandate specific thermal safety requirements for electric vehicles. These regulations increasingly require manufacturers to demonstrate thermal runaway prevention capabilities through computational modeling and physical testing. The Society of Automotive Engineers (SAE) has developed J2464 and J2929 standards that specifically address electric vehicle battery safety testing methodologies, including thermal propagation assessment.

For consumer electronics, IEC 62133 and UL 1642 serve as primary safety standards governing lithium battery implementations. These standards have recently been updated to incorporate more sophisticated thermal management requirements, reflecting the growing understanding of thermal runaway mechanisms. Compliance verification increasingly requires manufacturers to validate their thermal models against experimental data.

The aviation industry faces particularly stringent regulations through RTCA DO-311A and EUROCAE ED-179B, which establish certification requirements for lithium batteries in aircraft systems. Following incidents involving thermal events in aircraft batteries, regulatory bodies now require extensive computational analysis of thermal behavior under various operating conditions.

Energy storage system deployments are governed by standards such as UL 9540 and NFPA 855, which establish installation requirements with specific provisions for thermal safety. These frameworks increasingly recognize the value of computational methods in predicting thermal events before deployment, requiring system integrators to demonstrate thermal safety through validated models.

Regulatory compliance now typically involves a multi-tiered approach to thermal safety validation: computational modeling to identify potential failure modes, controlled laboratory testing to validate models, and system-level testing to verify integrated safety measures. This regulatory evolution has directly influenced the development of computational methods for thermal runaway prediction, driving increased sophistication in modeling approaches and greater emphasis on model validation against experimental data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!