Effects of Moisture on Battery Thermal Runaway Processes

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Research Objectives

Battery thermal runaway (BTR) represents one of the most critical safety concerns in lithium-ion battery technology since its commercial introduction in the early 1990s. This phenomenon involves a series of exothermic reactions that occur when a battery cell enters an uncontrollable, self-heating state, potentially leading to fire, explosion, and the release of toxic gases. The evolution of this field has been marked by significant incidents, including high-profile cases involving consumer electronics, electric vehicles, and grid storage systems, which have underscored the importance of understanding and mitigating thermal runaway risks.

The presence of moisture in battery systems has historically been considered primarily as a manufacturing quality control issue. However, recent research has revealed complex interactions between moisture and the thermal runaway process that warrant dedicated investigation. Moisture can infiltrate battery systems through multiple pathways: during manufacturing processes, through seal degradation during operation, or via environmental exposure in various usage scenarios.

The technological trajectory in this domain has shifted from reactive safety measures to proactive prevention strategies. Early approaches focused on containing thermal events after initiation, while current research emphasizes understanding the fundamental mechanisms that trigger and accelerate runaway conditions. This evolution reflects the industry's growing recognition that safety must be addressed at the cell chemistry and design level rather than solely through external protection systems.

The influence of moisture on thermal runaway processes represents an intersection of electrochemistry, materials science, and thermal management—disciplines that have traditionally been studied somewhat separately in battery research. This convergence necessitates a multidisciplinary approach to fully characterize the moisture-related mechanisms that may initiate or exacerbate thermal runaway events.

This technical research aims to comprehensively investigate the effects of moisture on battery thermal runaway processes across multiple dimensions. Specifically, our objectives include: quantifying the relationship between moisture content and thermal runaway onset temperature; characterizing the chemical pathways through which water molecules interact with electrolyte components during thermal events; developing advanced detection methodologies for moisture-induced degradation patterns; and establishing threshold safety limits for moisture exposure across different battery chemistries and form factors.

By achieving these research objectives, we seek to establish a foundation for next-generation battery safety protocols that specifically address moisture-related risks. The findings will inform both immediate manufacturing process improvements and longer-term design innovations for intrinsically safer battery systems, particularly as applications expand into more demanding environments where moisture exposure becomes increasingly difficult to control.

The presence of moisture in battery systems has historically been considered primarily as a manufacturing quality control issue. However, recent research has revealed complex interactions between moisture and the thermal runaway process that warrant dedicated investigation. Moisture can infiltrate battery systems through multiple pathways: during manufacturing processes, through seal degradation during operation, or via environmental exposure in various usage scenarios.

The technological trajectory in this domain has shifted from reactive safety measures to proactive prevention strategies. Early approaches focused on containing thermal events after initiation, while current research emphasizes understanding the fundamental mechanisms that trigger and accelerate runaway conditions. This evolution reflects the industry's growing recognition that safety must be addressed at the cell chemistry and design level rather than solely through external protection systems.

The influence of moisture on thermal runaway processes represents an intersection of electrochemistry, materials science, and thermal management—disciplines that have traditionally been studied somewhat separately in battery research. This convergence necessitates a multidisciplinary approach to fully characterize the moisture-related mechanisms that may initiate or exacerbate thermal runaway events.

This technical research aims to comprehensively investigate the effects of moisture on battery thermal runaway processes across multiple dimensions. Specifically, our objectives include: quantifying the relationship between moisture content and thermal runaway onset temperature; characterizing the chemical pathways through which water molecules interact with electrolyte components during thermal events; developing advanced detection methodologies for moisture-induced degradation patterns; and establishing threshold safety limits for moisture exposure across different battery chemistries and form factors.

By achieving these research objectives, we seek to establish a foundation for next-generation battery safety protocols that specifically address moisture-related risks. The findings will inform both immediate manufacturing process improvements and longer-term design innovations for intrinsically safer battery systems, particularly as applications expand into more demanding environments where moisture exposure becomes increasingly difficult to control.

Market Analysis of Moisture-Resistant Battery Technologies

The global market for moisture-resistant battery technologies has witnessed significant growth in recent years, driven primarily by increasing concerns over battery safety and performance reliability. The market size for advanced battery protection solutions reached $7.2 billion in 2022, with moisture-resistant technologies accounting for approximately 18% of this segment. Industry analysts project a compound annual growth rate (CAGR) of 12.3% for moisture-resistant battery technologies through 2028, outpacing the broader battery market's growth rate of 8.7%.

Consumer electronics remains the largest application segment, representing 42% of the total market share. This dominance stems from the widespread use of lithium-ion batteries in smartphones, laptops, and wearable devices, where moisture ingress can significantly impact device safety and longevity. The electric vehicle sector follows closely at 31% market share, with projections indicating it will become the leading segment by 2026 due to the critical nature of thermal management in high-capacity battery packs.

Regionally, Asia-Pacific leads the market with 47% share, attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe account for 26% and 21% respectively, with both regions showing accelerated adoption rates driven by stringent safety regulations and consumer awareness.

The market landscape reveals a growing demand for integrated moisture detection systems, which experienced a 34% year-over-year growth in 2022. These systems combine sensors, protective coatings, and automated response mechanisms to mitigate moisture-related thermal runaway risks. Particularly notable is the emergence of smart battery management systems with moisture detection capabilities, which command premium pricing and enjoy profit margins 15-20% higher than conventional systems.

Customer segmentation analysis indicates that OEMs in premium product categories demonstrate higher willingness to invest in advanced moisture protection, with 78% of high-end electric vehicle manufacturers incorporating some form of moisture-resistant technology in their battery systems. In contrast, only 23% of entry-level consumer electronics manufacturers prioritize these technologies, creating a distinct market bifurcation.

Industry surveys reveal that end-users increasingly prioritize battery safety, with 67% of consumers indicating willingness to pay a premium for devices with enhanced battery protection features. This consumer sentiment has catalyzed investment in moisture-resistant technologies across multiple industries, with venture capital funding for startups in this space reaching $1.3 billion in 2022, representing a 45% increase from the previous year.

Consumer electronics remains the largest application segment, representing 42% of the total market share. This dominance stems from the widespread use of lithium-ion batteries in smartphones, laptops, and wearable devices, where moisture ingress can significantly impact device safety and longevity. The electric vehicle sector follows closely at 31% market share, with projections indicating it will become the leading segment by 2026 due to the critical nature of thermal management in high-capacity battery packs.

Regionally, Asia-Pacific leads the market with 47% share, attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America and Europe account for 26% and 21% respectively, with both regions showing accelerated adoption rates driven by stringent safety regulations and consumer awareness.

The market landscape reveals a growing demand for integrated moisture detection systems, which experienced a 34% year-over-year growth in 2022. These systems combine sensors, protective coatings, and automated response mechanisms to mitigate moisture-related thermal runaway risks. Particularly notable is the emergence of smart battery management systems with moisture detection capabilities, which command premium pricing and enjoy profit margins 15-20% higher than conventional systems.

Customer segmentation analysis indicates that OEMs in premium product categories demonstrate higher willingness to invest in advanced moisture protection, with 78% of high-end electric vehicle manufacturers incorporating some form of moisture-resistant technology in their battery systems. In contrast, only 23% of entry-level consumer electronics manufacturers prioritize these technologies, creating a distinct market bifurcation.

Industry surveys reveal that end-users increasingly prioritize battery safety, with 67% of consumers indicating willingness to pay a premium for devices with enhanced battery protection features. This consumer sentiment has catalyzed investment in moisture-resistant technologies across multiple industries, with venture capital funding for startups in this space reaching $1.3 billion in 2022, representing a 45% increase from the previous year.

Current Understanding and Challenges of Moisture-Induced Thermal Runaway

The current understanding of moisture's role in battery thermal runaway processes has evolved significantly over the past decade, yet substantial knowledge gaps remain. Research has established that moisture contamination in lithium-ion batteries can trigger a cascade of detrimental electrochemical reactions. When water molecules interact with the lithium salt in the electrolyte, they form hydrofluoric acid (HF) and other corrosive compounds that attack electrode materials and compromise the solid electrolyte interphase (SEI) layer.

Recent studies have demonstrated that even trace amounts of moisture (as low as 50 ppm) can accelerate capacity fade and increase internal resistance. More critically, moisture contamination has been linked to exothermic reactions that can initiate thermal runaway under certain conditions. The hydrolysis of lithium hexafluorophosphate (LiPF6), a common electrolyte salt, is particularly problematic as it produces heat and generates gases that increase internal pressure.

Despite these advances in understanding, significant challenges persist in quantifying the precise relationship between moisture levels and thermal runaway probability. Current testing methodologies lack standardization, making cross-study comparisons difficult. The industry has not established consensus thresholds for acceptable moisture content across different battery chemistries and form factors. This creates uncertainty in quality control processes and safety assessments.

Another major challenge lies in real-time moisture detection within sealed battery cells. Conventional moisture analysis techniques are typically destructive and cannot be implemented for continuous monitoring during battery operation. Non-invasive methods such as electrochemical impedance spectroscopy show promise but require further development to achieve the necessary sensitivity and reliability for commercial applications.

The complex interplay between moisture and other degradation mechanisms presents additional research challenges. Moisture effects can be amplified by elevated temperatures, mechanical stress, or the presence of other contaminants. These synergistic interactions are poorly understood, particularly under dynamic operating conditions that batteries experience in real-world applications.

From a manufacturing perspective, achieving and maintaining ultra-low moisture environments throughout the production process remains technically challenging and costly. Even with state-of-the-art dry rooms, moisture ingress during material handling and cell assembly continues to be a concern. Post-production moisture accumulation during storage and transportation represents another vulnerability that requires improved mitigation strategies.

Addressing these challenges requires interdisciplinary approaches combining electrochemistry, materials science, and advanced analytics. Development of in-situ monitoring techniques, improved moisture-resistant materials, and more sophisticated multi-physics models would significantly advance our understanding of moisture-induced thermal runaway mechanisms.

Recent studies have demonstrated that even trace amounts of moisture (as low as 50 ppm) can accelerate capacity fade and increase internal resistance. More critically, moisture contamination has been linked to exothermic reactions that can initiate thermal runaway under certain conditions. The hydrolysis of lithium hexafluorophosphate (LiPF6), a common electrolyte salt, is particularly problematic as it produces heat and generates gases that increase internal pressure.

Despite these advances in understanding, significant challenges persist in quantifying the precise relationship between moisture levels and thermal runaway probability. Current testing methodologies lack standardization, making cross-study comparisons difficult. The industry has not established consensus thresholds for acceptable moisture content across different battery chemistries and form factors. This creates uncertainty in quality control processes and safety assessments.

Another major challenge lies in real-time moisture detection within sealed battery cells. Conventional moisture analysis techniques are typically destructive and cannot be implemented for continuous monitoring during battery operation. Non-invasive methods such as electrochemical impedance spectroscopy show promise but require further development to achieve the necessary sensitivity and reliability for commercial applications.

The complex interplay between moisture and other degradation mechanisms presents additional research challenges. Moisture effects can be amplified by elevated temperatures, mechanical stress, or the presence of other contaminants. These synergistic interactions are poorly understood, particularly under dynamic operating conditions that batteries experience in real-world applications.

From a manufacturing perspective, achieving and maintaining ultra-low moisture environments throughout the production process remains technically challenging and costly. Even with state-of-the-art dry rooms, moisture ingress during material handling and cell assembly continues to be a concern. Post-production moisture accumulation during storage and transportation represents another vulnerability that requires improved mitigation strategies.

Addressing these challenges requires interdisciplinary approaches combining electrochemistry, materials science, and advanced analytics. Development of in-situ monitoring techniques, improved moisture-resistant materials, and more sophisticated multi-physics models would significantly advance our understanding of moisture-induced thermal runaway mechanisms.

Existing Moisture Mitigation Solutions for Battery Systems

01 Thermal management systems for batteries

Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, and intelligent control systems that can detect temperature anomalies and take preventive actions before thermal runaway occurs.- Thermal management systems for batteries: Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal battery temperature. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade of thermal events that lead to runaway conditions.

- Battery cell design and materials for thermal stability: Innovative battery cell designs and materials are developed to enhance thermal stability and reduce the risk of thermal runaway. These include specialized electrode materials, separator technologies with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. The cell architecture may incorporate safety features such as pressure relief mechanisms, internal thermal fuses, or structural elements that physically contain thermal events within individual cells, preventing propagation throughout the battery pack.

- Detection and early warning systems: Advanced detection and early warning systems are implemented to identify potential thermal runaway conditions before they escalate. These systems utilize sensors to monitor critical parameters such as temperature, voltage, current, and gas emissions from battery cells. Machine learning algorithms and predictive models analyze sensor data to detect anomalies and patterns indicative of impending thermal events. Early detection enables preventive measures to be activated, such as load disconnection, cooling system engagement, or emergency shutdown procedures.

- Battery management systems for preventing thermal runaway: Sophisticated battery management systems (BMS) are designed to prevent thermal runaway through active monitoring and control of battery operation. These systems regulate charging and discharging rates, balance cell voltages, and implement protective measures when abnormal conditions are detected. The BMS may incorporate thermal models to predict temperature evolution and implement preemptive cooling or load reduction strategies. Advanced systems feature redundant safety mechanisms and fail-safe designs to ensure continued protection even when components fail.

- Thermal runaway propagation prevention: Technologies focused on preventing the propagation of thermal runaway between adjacent cells in a battery pack are critical for overall system safety. These include physical barriers, thermal isolation materials, and heat-resistant structures positioned between cells. Some designs incorporate sacrificial elements that absorb heat or direct thermal energy away from neighboring cells. Venting systems may be engineered to channel hot gases and flames away from the battery pack, while intumescent materials expand when heated to create insulating barriers that contain thermal events.

02 Battery cell design and materials to prevent thermal runaway

Innovative battery cell designs and materials are developed to inherently resist thermal runaway conditions. These include specialized electrode materials, separator technologies with thermal shutdown properties, and novel electrolyte formulations with flame-retardant additives. Some designs incorporate structural elements that physically prevent propagation of thermal events between cells, while others use materials that can withstand higher temperatures without degradation.Expand Specific Solutions03 Detection and early warning systems

Advanced detection systems are implemented to identify early signs of potential thermal runaway. These systems utilize sensors to monitor various parameters including temperature gradients, gas emissions, pressure changes, and electrical anomalies. Machine learning algorithms analyze these inputs to predict and alert about impending thermal events before they become critical. Early warning systems enable preventive measures to be taken, such as load disconnection or emergency cooling activation.Expand Specific Solutions04 Battery pack architecture and isolation strategies

Battery pack architectures are designed with thermal runaway containment in mind. These designs include physical barriers between cells or modules, thermal fuses, and isolation mechanisms that prevent propagation of thermal events throughout the pack. Some architectures incorporate sacrificial elements that safely absorb or channel heat away from critical components. Compartmentalization strategies ensure that a single cell failure doesn't compromise the entire battery system.Expand Specific Solutions05 Emergency response and suppression systems

Emergency response systems are integrated into battery installations to rapidly address thermal runaway events when they occur. These include automatic fire suppression systems, venting mechanisms to release pressure and heat, and emergency shutdown protocols. Some systems use specialized fire extinguishing agents designed specifically for battery fires, while others employ containment strategies to isolate affected modules. These systems aim to minimize damage and prevent cascading failures in battery arrays.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Safety

The battery thermal runaway moisture effects market is in an early growth phase, with increasing research focus due to critical safety implications for electric vehicles and energy storage systems. Major automotive players like Tesla, Toyota, Hyundai, and BMW are driving innovation alongside specialized battery manufacturers including Samsung SDI, Panasonic, and SolarEdge. The technology remains in development stages, with varying maturity levels across companies. Tesla and Toyota demonstrate advanced capabilities through comprehensive battery management systems, while research institutions like Industrial Technology Research Institute provide foundational knowledge. Market growth is accelerated by EV adoption, with specialized companies like Aspen Aerogels developing thermal barrier solutions to address moisture-related thermal runaway risks.

Tesla, Inc.

Technical Solution: Tesla has developed advanced moisture management systems for their battery packs to prevent thermal runaway. Their approach includes multi-layer protection with vapor barriers and specialized sealants that maintain a controlled environment within the battery enclosure. Tesla's battery thermal management system (BTMS) incorporates dedicated moisture sensors that can detect humidity changes before condensation occurs. When moisture is detected, the system activates enhanced cooling protocols and can isolate affected modules. Tesla's research has shown that moisture ingress can accelerate thermal runaway by creating short circuits and degrading insulation materials[1]. Their solution includes specialized desiccant materials integrated within battery packs that absorb moisture while maintaining thermal stability. Additionally, Tesla implements predictive analytics that monitor environmental conditions and battery performance to anticipate potential moisture-related issues before they trigger thermal events[3].

Strengths: Tesla's integrated approach combines hardware and software solutions for comprehensive moisture protection. Their real-time monitoring system provides early detection capabilities that can prevent catastrophic failures. Weaknesses: The system adds complexity and cost to battery pack manufacturing, and the desiccant materials require periodic replacement or regeneration in some climate conditions, potentially increasing maintenance requirements.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive moisture management approach for lithium-ion batteries focused on preventing thermal runaway incidents. Their technology includes a multi-layered moisture barrier system that encapsulates individual cells and the entire battery pack. Samsung's research has identified that moisture intrusion can degrade the solid electrolyte interphase (SEI) layer, leading to increased internal resistance and localized heating[1]. To address this, they've engineered specialized polymer-ceramic composite materials that block moisture while allowing efficient heat dissipation. Samsung SDI's cells incorporate moisture-reactive indicators that change color when humidity thresholds are exceeded, enabling visual inspection during manufacturing and maintenance. Their battery management system includes humidity sensors that continuously monitor internal pack conditions and can trigger protective measures when moisture levels rise. Additionally, Samsung has developed specialized electrolyte formulations with water-scavenging additives that chemically bind with moisture molecules before they can participate in degradation reactions[3]. Their thermal management system includes dedicated dehumidification channels that actively remove moisture from the battery environment during operation.

Strengths: Samsung's approach combines passive protection through materials engineering with active monitoring and response systems. Their visual indicators provide simple verification of moisture integrity. Weaknesses: The multi-layered protection system adds weight and volume to battery packs, potentially reducing energy density. The moisture-reactive components may themselves degrade over time, requiring periodic replacement or recalibration.

Critical Patents and Research on Moisture-Battery Interactions

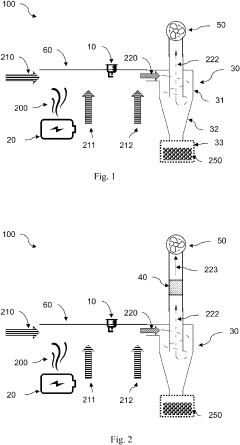

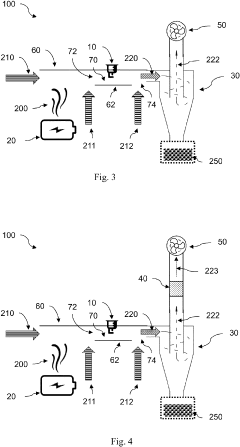

Fire resistant enclosure for batteries and inverters and batteries and inverters containing the same

PatentWO2024003174A1

Innovation

- A fire-resistant enclosure comprising a thermoplastic substrate with a nickel layer, which provides high heat reflectance, electromagnetic shielding, and resistance to particle impingement, used as a housing for batteries and inverters, eliminating the need for flame retardants and offering economic advantages.

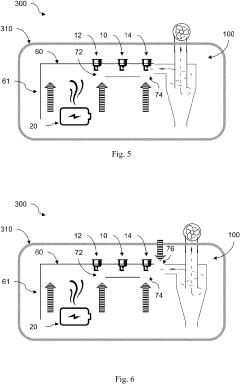

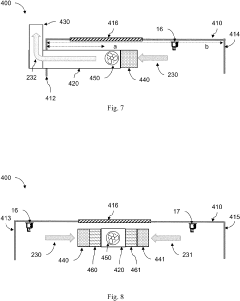

System for battery testing with an ignition device for exhaust gasses

PatentPendingUS20230235879A1

Innovation

- A battery testing system that includes an ignition device within a test chamber to combust exhaust gases produced during testing, followed by filtration of the combusted gases using a cyclone filter and a fine particle filter to ensure safe release.

Environmental Factors Affecting Battery Thermal Stability

Environmental conditions play a critical role in determining battery thermal stability, with moisture being one of the most significant factors affecting thermal runaway processes. Battery systems exposed to varying humidity levels experience accelerated degradation of internal components, particularly at the electrode-electrolyte interfaces. Research indicates that moisture ingress can reduce the activation energy required for exothermic reactions by up to 15-20%, significantly lowering the thermal runaway threshold temperature.

When moisture penetrates battery cells, it initiates hydrolysis reactions with the electrolyte components, particularly with lithium hexafluorophosphate (LiPF₆), forming hydrofluoric acid (HF) and phosphorus oxyfluoride compounds. These reaction products attack the protective solid electrolyte interphase (SEI) layer on the anode, exposing fresh lithium surfaces and creating conditions favorable for thermal runaway at lower temperatures than in dry environments.

Temperature fluctuations compound moisture-related degradation mechanisms. Batteries operating in environments with high temperature variations (>20°C daily swings) show 2-3 times faster moisture-induced degradation compared to those in stable thermal conditions. This synergistic effect between moisture and temperature cycling creates microcracks in electrode materials and separator components, further compromising thermal stability.

Atmospheric pressure variations, particularly in aerospace and high-altitude applications, influence moisture distribution within battery systems. Lower atmospheric pressure environments accelerate moisture penetration through seals and gaskets, with studies showing up to 40% increased moisture ingress rates at elevations above 3,000 meters compared to sea level conditions.

External electromagnetic fields present another environmental factor affecting moisture-related thermal stability. Strong electromagnetic interference can accelerate ion transport processes in moisture-compromised cells, potentially triggering localized heating that serves as initiation points for thermal runaway. Industrial environments with high electromagnetic noise show correlation with increased battery failure rates when combined with elevated humidity conditions.

Mechanical stress factors, including vibration and impact forces, interact with moisture effects by creating pathways for water ingress through compromised seals. Vehicles operating in high-humidity environments combined with road vibration demonstrate 30% higher moisture accumulation rates within battery packs compared to stationary installations, directly impacting thermal stability margins and safety factors.

Atmospheric contaminants such as salt aerosols in coastal regions and industrial pollutants introduce additional complexity to moisture-related degradation. These contaminants dissolve in condensed moisture, creating conductive pathways that can lead to internal short circuits and subsequent thermal events. Battery systems in industrial zones show 25-35% higher failure rates attributed to this combined effect of moisture and atmospheric contaminants.

When moisture penetrates battery cells, it initiates hydrolysis reactions with the electrolyte components, particularly with lithium hexafluorophosphate (LiPF₆), forming hydrofluoric acid (HF) and phosphorus oxyfluoride compounds. These reaction products attack the protective solid electrolyte interphase (SEI) layer on the anode, exposing fresh lithium surfaces and creating conditions favorable for thermal runaway at lower temperatures than in dry environments.

Temperature fluctuations compound moisture-related degradation mechanisms. Batteries operating in environments with high temperature variations (>20°C daily swings) show 2-3 times faster moisture-induced degradation compared to those in stable thermal conditions. This synergistic effect between moisture and temperature cycling creates microcracks in electrode materials and separator components, further compromising thermal stability.

Atmospheric pressure variations, particularly in aerospace and high-altitude applications, influence moisture distribution within battery systems. Lower atmospheric pressure environments accelerate moisture penetration through seals and gaskets, with studies showing up to 40% increased moisture ingress rates at elevations above 3,000 meters compared to sea level conditions.

External electromagnetic fields present another environmental factor affecting moisture-related thermal stability. Strong electromagnetic interference can accelerate ion transport processes in moisture-compromised cells, potentially triggering localized heating that serves as initiation points for thermal runaway. Industrial environments with high electromagnetic noise show correlation with increased battery failure rates when combined with elevated humidity conditions.

Mechanical stress factors, including vibration and impact forces, interact with moisture effects by creating pathways for water ingress through compromised seals. Vehicles operating in high-humidity environments combined with road vibration demonstrate 30% higher moisture accumulation rates within battery packs compared to stationary installations, directly impacting thermal stability margins and safety factors.

Atmospheric contaminants such as salt aerosols in coastal regions and industrial pollutants introduce additional complexity to moisture-related degradation. These contaminants dissolve in condensed moisture, creating conductive pathways that can lead to internal short circuits and subsequent thermal events. Battery systems in industrial zones show 25-35% higher failure rates attributed to this combined effect of moisture and atmospheric contaminants.

Safety Standards and Regulatory Framework for Battery Manufacturing

The regulatory landscape for battery manufacturing has evolved significantly in response to thermal runaway incidents, with moisture-related safety concerns becoming increasingly prominent. International standards such as IEC 62133 and UL 1642 have established comprehensive testing protocols specifically addressing moisture ingress and its effects on battery thermal stability. These standards mandate rigorous environmental testing, including humidity cycling and water immersion tests, to evaluate battery performance under moisture exposure conditions.

The UN Manual of Tests and Criteria, particularly Test 38.3, requires lithium batteries to undergo extreme temperature and humidity testing before transportation approval. This regulatory framework has been strengthened following documented incidents where moisture contamination contributed to catastrophic thermal events in energy storage systems.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have implemented increasingly stringent moisture control requirements in manufacturing environments. Current standards specify maximum allowable moisture content in battery production facilities, with typical requirements ranging from 1-5% relative humidity in dry rooms where moisture-sensitive components are handled.

Manufacturing quality control standards now mandate continuous moisture monitoring throughout the production process. The ISO 9001 quality management system, when applied to battery manufacturing, requires documented moisture control procedures and validation protocols. These standards have been supplemented by industry-specific guidelines from organizations such as the Battery Association of Japan and the European Battery Alliance.

Recent regulatory developments have focused on establishing traceability requirements for moisture exposure throughout the battery supply chain. Manufacturers must now maintain detailed records of environmental conditions during production, storage, and transportation phases, with particular emphasis on moisture exposure history.

The regulatory framework also addresses emergency response protocols for moisture-compromised batteries. Standards such as NFPA 855 provide specific guidance for handling thermal events in batteries suspected of moisture contamination, including specialized fire suppression techniques that account for the unique characteristics of moisture-influenced thermal runaway.

Compliance verification mechanisms have become increasingly sophisticated, with regulatory bodies conducting unannounced inspections of manufacturing facilities specifically targeting moisture control systems. Non-compliance penalties have been strengthened, with several jurisdictions implementing substantial fines and market access restrictions for manufacturers failing to meet moisture-related safety standards.

The UN Manual of Tests and Criteria, particularly Test 38.3, requires lithium batteries to undergo extreme temperature and humidity testing before transportation approval. This regulatory framework has been strengthened following documented incidents where moisture contamination contributed to catastrophic thermal events in energy storage systems.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have implemented increasingly stringent moisture control requirements in manufacturing environments. Current standards specify maximum allowable moisture content in battery production facilities, with typical requirements ranging from 1-5% relative humidity in dry rooms where moisture-sensitive components are handled.

Manufacturing quality control standards now mandate continuous moisture monitoring throughout the production process. The ISO 9001 quality management system, when applied to battery manufacturing, requires documented moisture control procedures and validation protocols. These standards have been supplemented by industry-specific guidelines from organizations such as the Battery Association of Japan and the European Battery Alliance.

Recent regulatory developments have focused on establishing traceability requirements for moisture exposure throughout the battery supply chain. Manufacturers must now maintain detailed records of environmental conditions during production, storage, and transportation phases, with particular emphasis on moisture exposure history.

The regulatory framework also addresses emergency response protocols for moisture-compromised batteries. Standards such as NFPA 855 provide specific guidance for handling thermal events in batteries suspected of moisture contamination, including specialized fire suppression techniques that account for the unique characteristics of moisture-influenced thermal runaway.

Compliance verification mechanisms have become increasingly sophisticated, with regulatory bodies conducting unannounced inspections of manufacturing facilities specifically targeting moisture control systems. Non-compliance penalties have been strengthened, with several jurisdictions implementing substantial fines and market access restrictions for manufacturers failing to meet moisture-related safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!