Battery Thermal Runaway Solutions for Extreme Environmental Conditions

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway has emerged as a critical safety concern in the energy storage industry, particularly as lithium-ion batteries have become ubiquitous in applications ranging from consumer electronics to electric vehicles and grid-scale energy storage systems. The phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and the release of toxic gases. This chain reaction typically begins when internal temperature exceeds a critical threshold of approximately 80-100°C, depending on the specific battery chemistry.

The evolution of battery thermal runaway management has progressed through several distinct phases. Initially, focus was placed on basic cell-level safety mechanisms such as positive temperature coefficient (PTC) devices and current interrupt devices (CIDs). As battery applications expanded into more demanding environments, research shifted toward advanced battery management systems (BMS) capable of early detection and prevention. Recent developments have centered on innovative materials and structural designs that can inherently suppress thermal propagation.

Extreme environmental conditions present unique challenges for battery thermal management. High ambient temperatures (above 45°C) significantly reduce the thermal headroom before runaway conditions are reached. Conversely, extremely low temperatures (below -20°C) can lead to lithium plating during charging, creating internal shorts that may trigger thermal events. Additionally, rapid temperature fluctuations can cause mechanical stress on battery components, potentially compromising structural integrity.

The primary technical objectives for addressing thermal runaway in extreme conditions include developing solutions that maintain safety across temperature ranges from -40°C to +60°C, preventing cell-to-cell propagation even under severe external thermal loads, and ensuring system resilience against thermal events without catastrophic failure. These solutions must maintain battery performance while adding minimal weight, volume, and cost to the overall system.

Industry standards and regulatory frameworks have evolved significantly, with UN 38.3, IEC 62133, and UL 1642 establishing baseline safety requirements. More recently, standards specific to electric vehicles (SAE J2464, ISO 6469) and energy storage systems (UL 9540A) have emerged, driving more rigorous thermal safety testing protocols. The technical goal is to exceed these standards, particularly for applications in aerospace, military, and extreme climate deployments where conventional approaches prove insufficient.

The evolution of battery thermal runaway management has progressed through several distinct phases. Initially, focus was placed on basic cell-level safety mechanisms such as positive temperature coefficient (PTC) devices and current interrupt devices (CIDs). As battery applications expanded into more demanding environments, research shifted toward advanced battery management systems (BMS) capable of early detection and prevention. Recent developments have centered on innovative materials and structural designs that can inherently suppress thermal propagation.

Extreme environmental conditions present unique challenges for battery thermal management. High ambient temperatures (above 45°C) significantly reduce the thermal headroom before runaway conditions are reached. Conversely, extremely low temperatures (below -20°C) can lead to lithium plating during charging, creating internal shorts that may trigger thermal events. Additionally, rapid temperature fluctuations can cause mechanical stress on battery components, potentially compromising structural integrity.

The primary technical objectives for addressing thermal runaway in extreme conditions include developing solutions that maintain safety across temperature ranges from -40°C to +60°C, preventing cell-to-cell propagation even under severe external thermal loads, and ensuring system resilience against thermal events without catastrophic failure. These solutions must maintain battery performance while adding minimal weight, volume, and cost to the overall system.

Industry standards and regulatory frameworks have evolved significantly, with UN 38.3, IEC 62133, and UL 1642 establishing baseline safety requirements. More recently, standards specific to electric vehicles (SAE J2464, ISO 6469) and energy storage systems (UL 9540A) have emerged, driving more rigorous thermal safety testing protocols. The technical goal is to exceed these standards, particularly for applications in aerospace, military, and extreme climate deployments where conventional approaches prove insufficient.

Market Analysis for Extreme Environment Battery Solutions

The global market for extreme environment battery solutions is experiencing significant growth, driven by expanding applications in aerospace, deep-sea exploration, polar research, and industrial operations in harsh conditions. Current market valuation stands at approximately 5.2 billion USD, with projections indicating a compound annual growth rate of 8.7% through 2028. This acceleration is primarily fueled by increasing demand for reliable power sources in environments where conventional batteries fail due to temperature extremes, pressure variations, or other challenging conditions.

The aerospace and defense sectors currently dominate market share, accounting for roughly 38% of total demand. These industries require batteries capable of functioning reliably at both extremely low temperatures encountered at high altitudes and the high temperatures generated during operation. The deep-sea exploration segment follows with 22% market share, where batteries must withstand enormous pressure differentials and consistently cold temperatures.

Regional analysis reveals North America leads the market with 41% share, attributed to substantial aerospace and defense investments, followed by Europe at 28% and Asia-Pacific at 23%. The latter region demonstrates the fastest growth trajectory, with China and South Korea making significant advancements in extreme environment battery technology development.

Customer requirements in this specialized market emphasize safety above all other considerations. Thermal runaway prevention capabilities command premium pricing, with customers willing to pay 30-40% more for solutions with proven safety records in extreme conditions. Secondary priorities include energy density, operational lifespan, and weight considerations, though these factors vary by application sector.

Market barriers include high development costs, stringent regulatory requirements particularly for aerospace applications, and the technical complexity of creating solutions that address multiple environmental challenges simultaneously. The average R&D timeline for bringing new extreme environment battery solutions to market exceeds four years, significantly longer than conventional battery development cycles.

Emerging market opportunities exist in renewable energy installations in extreme climates, electric vehicles designed for polar or desert environments, and remote industrial operations. The Arctic region represents a particularly promising growth area, with increasing commercial activities creating demand for cold-resistant energy storage solutions.

Competition remains concentrated among specialized manufacturers rather than mainstream battery producers, with most market leaders focusing on application-specific solutions rather than universal extreme environment products. This specialization trend is expected to continue, with thermal runaway prevention technology becoming a key differentiator in competitive positioning.

The aerospace and defense sectors currently dominate market share, accounting for roughly 38% of total demand. These industries require batteries capable of functioning reliably at both extremely low temperatures encountered at high altitudes and the high temperatures generated during operation. The deep-sea exploration segment follows with 22% market share, where batteries must withstand enormous pressure differentials and consistently cold temperatures.

Regional analysis reveals North America leads the market with 41% share, attributed to substantial aerospace and defense investments, followed by Europe at 28% and Asia-Pacific at 23%. The latter region demonstrates the fastest growth trajectory, with China and South Korea making significant advancements in extreme environment battery technology development.

Customer requirements in this specialized market emphasize safety above all other considerations. Thermal runaway prevention capabilities command premium pricing, with customers willing to pay 30-40% more for solutions with proven safety records in extreme conditions. Secondary priorities include energy density, operational lifespan, and weight considerations, though these factors vary by application sector.

Market barriers include high development costs, stringent regulatory requirements particularly for aerospace applications, and the technical complexity of creating solutions that address multiple environmental challenges simultaneously. The average R&D timeline for bringing new extreme environment battery solutions to market exceeds four years, significantly longer than conventional battery development cycles.

Emerging market opportunities exist in renewable energy installations in extreme climates, electric vehicles designed for polar or desert environments, and remote industrial operations. The Arctic region represents a particularly promising growth area, with increasing commercial activities creating demand for cold-resistant energy storage solutions.

Competition remains concentrated among specialized manufacturers rather than mainstream battery producers, with most market leaders focusing on application-specific solutions rather than universal extreme environment products. This specialization trend is expected to continue, with thermal runaway prevention technology becoming a key differentiator in competitive positioning.

Current Challenges in Thermal Runaway Prevention

Despite significant advancements in battery technology, thermal runaway prevention remains a critical challenge, particularly in extreme environmental conditions. Current battery management systems (BMS) struggle to accurately predict and prevent thermal events when operating in temperature ranges beyond -40°C to 60°C. This limitation becomes especially problematic in aerospace, deep-sea exploration, and polar applications where batteries may experience rapid temperature fluctuations and extreme conditions.

Material degradation under extreme conditions presents another significant challenge. Conventional separator materials show accelerated deterioration when repeatedly exposed to temperature extremes, reducing their effectiveness as physical barriers between electrodes. Additionally, electrolyte stability becomes compromised, with standard formulations exhibiting increased volatility and reduced thermal stability at high temperatures, while suffering from poor ionic conductivity at extremely low temperatures.

Sensing technologies for early detection face substantial reliability issues in extreme environments. Current temperature sensors often exhibit drift or complete failure when operating beyond their designed parameters. The industry lacks robust, multi-parameter sensing systems capable of functioning reliably across extreme temperature ranges while providing the necessary precision for early thermal event detection.

Heat dissipation mechanisms demonstrate inadequate performance in challenging environments. Passive cooling systems become ineffective in high-ambient temperature conditions, while active cooling systems consume significant power and add considerable weight. For applications in remote or weight-sensitive contexts, this creates an unresolved engineering dilemma between safety and operational efficiency.

The integration of safety systems presents compatibility challenges with existing battery architectures. Many proposed solutions require fundamental redesigns of battery packs, making retrofitting existing systems prohibitively expensive or technically unfeasible. This creates significant barriers to adoption, particularly in industries with established infrastructure.

Computational models for predicting thermal runaway events show reduced accuracy in extreme conditions. Current algorithms struggle to account for the complex interplay of factors that occur at temperature extremes, resulting in either excessive false alarms or dangerous missed detection events. The development of more sophisticated predictive models is hampered by insufficient real-world data from extreme environmental operations.

Regulatory frameworks and testing protocols have not kept pace with the deployment of batteries in extreme environments, creating uncertainty regarding certification and compliance. This regulatory gap complicates the development and commercialization of specialized thermal runaway prevention solutions for niche but critical applications.

Material degradation under extreme conditions presents another significant challenge. Conventional separator materials show accelerated deterioration when repeatedly exposed to temperature extremes, reducing their effectiveness as physical barriers between electrodes. Additionally, electrolyte stability becomes compromised, with standard formulations exhibiting increased volatility and reduced thermal stability at high temperatures, while suffering from poor ionic conductivity at extremely low temperatures.

Sensing technologies for early detection face substantial reliability issues in extreme environments. Current temperature sensors often exhibit drift or complete failure when operating beyond their designed parameters. The industry lacks robust, multi-parameter sensing systems capable of functioning reliably across extreme temperature ranges while providing the necessary precision for early thermal event detection.

Heat dissipation mechanisms demonstrate inadequate performance in challenging environments. Passive cooling systems become ineffective in high-ambient temperature conditions, while active cooling systems consume significant power and add considerable weight. For applications in remote or weight-sensitive contexts, this creates an unresolved engineering dilemma between safety and operational efficiency.

The integration of safety systems presents compatibility challenges with existing battery architectures. Many proposed solutions require fundamental redesigns of battery packs, making retrofitting existing systems prohibitively expensive or technically unfeasible. This creates significant barriers to adoption, particularly in industries with established infrastructure.

Computational models for predicting thermal runaway events show reduced accuracy in extreme conditions. Current algorithms struggle to account for the complex interplay of factors that occur at temperature extremes, resulting in either excessive false alarms or dangerous missed detection events. The development of more sophisticated predictive models is hampered by insufficient real-world data from extreme environmental operations.

Regulatory frameworks and testing protocols have not kept pace with the deployment of batteries in extreme environments, creating uncertainty regarding certification and compliance. This regulatory gap complicates the development and commercialization of specialized thermal runaway prevention solutions for niche but critical applications.

Existing Thermal Runaway Mitigation Strategies

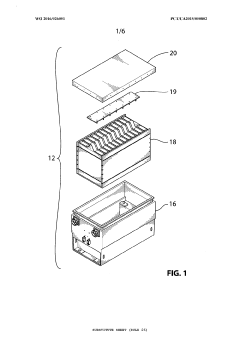

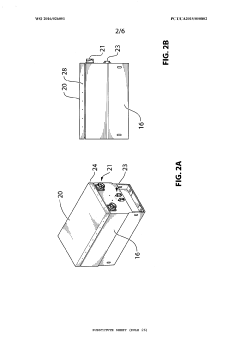

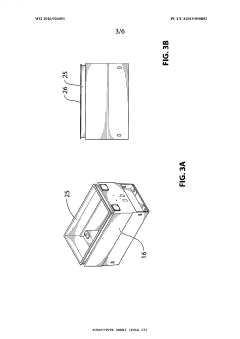

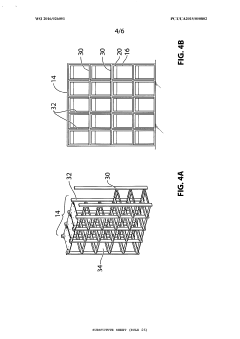

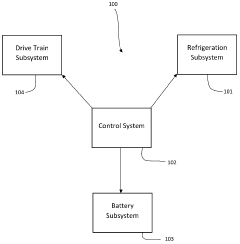

01 Thermal management systems for battery safety

Advanced thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring technologies that work together to maintain optimal battery temperature ranges. By effectively managing heat distribution and dissipation, these systems can significantly reduce the risk of thermal runaway events and enhance overall battery safety.- Thermal management systems for battery packs: Advanced thermal management systems are designed to prevent thermal runaway in battery packs by efficiently dissipating heat. These systems include liquid cooling circuits, heat sinks, and thermal interface materials that help maintain optimal operating temperatures. By controlling the temperature distribution within battery packs, these systems can prevent the initiation and propagation of thermal runaway events, enhancing overall battery safety and performance.

- Fire-resistant materials and thermal barriers: Incorporating fire-resistant materials and thermal barriers between battery cells can significantly reduce the risk of thermal runaway propagation. These materials include ceramic separators, intumescent coatings, and phase change materials that absorb heat during temperature spikes. When a single cell experiences thermal runaway, these barriers prevent the heat from spreading to adjacent cells, containing the failure to a localized area and preventing catastrophic battery pack failure.

- Early detection and monitoring systems: Advanced sensor networks and monitoring systems can detect early signs of thermal runaway before it becomes critical. These systems monitor parameters such as temperature gradients, voltage fluctuations, and gas emissions to identify potential failure modes. When abnormal conditions are detected, the system can trigger preventive measures such as load disconnection, cooling activation, or emergency shutdown protocols, providing critical time for intervention before thermal runaway occurs.

- Battery cell design and chemistry modifications: Innovations in battery cell design and chemistry can inherently reduce thermal runaway risks. These include modified electrode materials, improved separator designs, and electrolyte additives that enhance thermal stability. Some approaches involve using solid-state electrolytes or flame-retardant additives that significantly raise the temperature threshold required for thermal runaway initiation, making batteries intrinsically safer under extreme conditions.

- Safety venting and pressure management: Safety venting mechanisms and pressure management systems help prevent explosive failures during thermal events. These systems include controlled rupture discs, pressure relief valves, and specialized venting channels that allow gases to escape safely during a thermal event. By managing internal pressure buildup, these solutions prevent catastrophic cell rupture and explosive disassembly, redirecting hazardous gases away from users and other battery components.

02 Fire-resistant materials and barrier technologies

Specialized fire-resistant materials and barrier technologies are incorporated into battery designs to contain thermal runaway events. These materials include flame-retardant separators, intumescent coatings, and thermal insulation layers that can withstand high temperatures and prevent fire propagation between cells. When thermal runaway occurs in one cell, these barriers help isolate the affected cell and prevent the spread of heat and fire to adjacent cells.Expand Specific Solutions03 Early detection and warning systems

Advanced sensor technologies and monitoring systems are employed to detect early signs of thermal runaway conditions. These systems continuously monitor parameters such as temperature, voltage, and gas emissions to identify abnormal battery behavior before a critical situation develops. Early detection allows for preventive measures to be activated, such as load disconnection or emergency cooling, significantly reducing the risk of catastrophic failure.Expand Specific Solutions04 Novel battery chemistries and structural designs

Innovative battery chemistries and structural designs are being developed to inherently reduce thermal runaway risks. These include solid-state electrolytes, advanced electrode materials, and novel cell architectures that are more stable under extreme conditions. By addressing the fundamental causes of thermal instability at the material and design level, these innovations significantly improve battery safety while maintaining or enhancing performance characteristics.Expand Specific Solutions05 Venting and pressure management solutions

Specialized venting mechanisms and pressure management systems are integrated into battery designs to safely release pressure and gases during thermal events. These systems include controlled rupture points, pressure relief valves, and gas channeling structures that direct hazardous emissions away from sensitive components and users. By managing internal pressure buildup, these solutions help prevent explosive failures and provide controlled pathways for heat and gas dissipation during thermal runaway incidents.Expand Specific Solutions

Leading Battery Safety Solution Providers

The battery thermal runaway solutions market for extreme environments is in a growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. Market size is projected to grow significantly as safety concerns become paramount in battery applications. Technologically, the field is evolving rapidly with varying maturity levels across solutions. Leading players like Tesla, Samsung SDI, and CATL are advancing proprietary thermal management systems, while specialized companies such as Aspen Aerogels focus on innovative insulation materials. Traditional automotive manufacturers including BMW, Hyundai Mobis, and Geely are investing heavily in thermal safety technologies. The competitive landscape features collaboration between battery manufacturers, automotive OEMs, and specialized material science companies, creating a dynamic ecosystem of innovation.

Aspen Aerogels, Inc.

Technical Solution: Aspen Aerogels has developed a specialized thermal barrier solution for battery systems called "PyroThin™" specifically designed to prevent thermal runaway propagation in extreme environments. Their technology features: 1) Ultra-lightweight aerogel-based materials with thermal conductivity as low as 0.02 W/m·K, providing exceptional insulation with minimal weight penalty; 2) Fire-resistant formulations that maintain structural integrity at temperatures exceeding 1200°C; 3) Flexible, compressible designs that can be integrated between cells, modules, or as pack-level protection; 4) Hydrophobic properties that prevent moisture ingress and subsequent performance degradation in humid environments; and 5) Customizable thickness and density profiles to address specific thermal management requirements across different battery architectures. Aspen's PyroThin™ technology has been validated through extensive testing including direct flame exposure, demonstrating the ability to contain thermal events and provide critical time for emergency response by slowing thermal propagation by up to 400% compared to conventional materials.

Strengths: Exceptional thermal insulation properties with minimal weight and space requirements; compatibility with various battery chemistries and form factors; passive protection requiring no power or control systems. Weaknesses: Primarily focused on containment rather than prevention of initial thermal events; requires integration with active thermal management systems for comprehensive protection; higher material costs compared to conventional insulators.

Tesla, Inc.

Technical Solution: Tesla has pioneered a multi-faceted approach to battery thermal runaway prevention and containment for extreme environments. Their solution integrates: 1) A patented intumescent material system that expands when exposed to heat, creating physical barriers between cells; 2) A sophisticated serpentine cooling system using a proprietary coolant formula that maintains optimal operating temperatures between -40°C and 60°C; 3) Advanced cell-level fusing that electrically isolates compromised cells within milliseconds; 4) Dedicated venting channels that direct thermal events away from critical components and passenger compartments; and 5) A predictive thermal management algorithm that continuously monitors individual cell impedance and temperature patterns to identify potential failure points before thermal runaway occurs. Tesla's system has been extensively tested in extreme conditions including desert heat (55°C+), arctic cold (-40°C), and high-altitude operations, demonstrating the ability to prevent propagation of thermal events across the battery pack.

Strengths: Highly integrated approach combining hardware and software solutions; extensive real-world data from global fleet operations in extreme environments; rapid detection and isolation capabilities. Weaknesses: Proprietary nature of technology limits industry-wide adoption; system complexity requires specialized manufacturing and maintenance; additional weight from thermal management systems impacts overall vehicle efficiency.

Key Patents in Battery Thermal Protection Systems

Thermal runaway containment apparatus for a battery

PatentWO2016026051A1

Innovation

- A thermal runaway containment apparatus featuring an enclosure base and lid with a releasable coupling that allows venting of pressurized gases while preventing oxygen ingress, using a tortuous flow path and lid constraining structure to control pressure release and minimize combustion, ensuring the lid remains closed during normal operation but separates during thermal events.

Lithium-ion battery cooling system

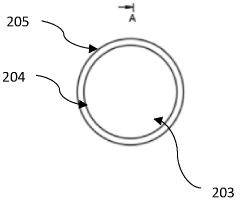

PatentPendingIN202221067889A

Innovation

- A cooling manifold assembly with a shell-like cooling jacket made of dissimilar metals, where the inner surface is highly conductive (aluminium or copper) and the outer surface is robust (steel or stainless steel), ensuring uniform cooling and high thermal conductivity, connected in a way that coolant flows through without contacting the cells, and sealed with rubber rings for efficient heat transfer.

Safety Standards and Compliance Requirements

The regulatory landscape for battery thermal runaway protection in extreme environments is governed by a comprehensive framework of international, regional, and industry-specific standards. Key international standards include IEC 62133 and UN 38.3, which establish baseline requirements for battery safety testing, including thermal abuse tests that simulate extreme conditions.

For automotive applications, standards such as ISO 6469-1 and SAE J2464 specifically address battery safety in electric vehicles, with particular emphasis on thermal management systems that must function in temperature extremes ranging from -40°C to +85°C. These standards mandate specific performance criteria for thermal runaway prevention and containment systems.

The aerospace industry follows more stringent requirements outlined in RTCA DO-311A and SAE AS8049, which demand battery systems capable of withstanding extreme altitude, pressure, and temperature variations while maintaining thermal stability. These standards require extensive testing under simulated environmental extremes.

Maritime applications are governed by IEC 62281 and IMO regulations, which address the unique challenges of saltwater environments and extended exposure to high humidity conditions that can accelerate thermal degradation in battery systems.

Compliance certification processes typically involve third-party testing by organizations such as UL, TÜV, and SGS. These certification bodies conduct rigorous testing protocols including thermal shock cycling, extreme temperature operation, and accelerated aging tests to verify system performance under worst-case environmental scenarios.

Recent regulatory developments have introduced more stringent requirements for thermal runaway prevention, particularly following high-profile battery failure incidents. The 2023 updates to UL 9540A and NFPA 855 have established more comprehensive testing protocols specifically addressing thermal propagation in extreme environmental conditions.

Regional variations in compliance requirements present significant challenges for global deployment of battery systems. While North American standards emphasize fire prevention and containment, European regulations focus more on environmental impact and end-of-life management. Asian markets, particularly China with GB/T 31485, have implemented some of the most rigorous thermal safety requirements.

Emerging standards are increasingly addressing the intersection of thermal runaway prevention and environmental extremes, with particular attention to climate resilience in battery systems deployed in regions experiencing increasing frequency of extreme weather events.

For automotive applications, standards such as ISO 6469-1 and SAE J2464 specifically address battery safety in electric vehicles, with particular emphasis on thermal management systems that must function in temperature extremes ranging from -40°C to +85°C. These standards mandate specific performance criteria for thermal runaway prevention and containment systems.

The aerospace industry follows more stringent requirements outlined in RTCA DO-311A and SAE AS8049, which demand battery systems capable of withstanding extreme altitude, pressure, and temperature variations while maintaining thermal stability. These standards require extensive testing under simulated environmental extremes.

Maritime applications are governed by IEC 62281 and IMO regulations, which address the unique challenges of saltwater environments and extended exposure to high humidity conditions that can accelerate thermal degradation in battery systems.

Compliance certification processes typically involve third-party testing by organizations such as UL, TÜV, and SGS. These certification bodies conduct rigorous testing protocols including thermal shock cycling, extreme temperature operation, and accelerated aging tests to verify system performance under worst-case environmental scenarios.

Recent regulatory developments have introduced more stringent requirements for thermal runaway prevention, particularly following high-profile battery failure incidents. The 2023 updates to UL 9540A and NFPA 855 have established more comprehensive testing protocols specifically addressing thermal propagation in extreme environmental conditions.

Regional variations in compliance requirements present significant challenges for global deployment of battery systems. While North American standards emphasize fire prevention and containment, European regulations focus more on environmental impact and end-of-life management. Asian markets, particularly China with GB/T 31485, have implemented some of the most rigorous thermal safety requirements.

Emerging standards are increasingly addressing the intersection of thermal runaway prevention and environmental extremes, with particular attention to climate resilience in battery systems deployed in regions experiencing increasing frequency of extreme weather events.

Environmental Impact of Battery Safety Technologies

The environmental implications of battery safety technologies, particularly those addressing thermal runaway in extreme conditions, extend far beyond immediate safety concerns. Battery thermal management systems (BTMS) designed for extreme environments often incorporate materials and chemicals that pose significant environmental challenges throughout their lifecycle.

Cooling systems utilizing traditional refrigerants contribute to greenhouse gas emissions when leaked or improperly disposed of. Particularly concerning are hydrofluorocarbon (HFC) refrigerants, which have global warming potentials thousands of times greater than CO2. Phase change materials (PCMs), while effective for thermal management, often contain paraffins derived from fossil fuels, raising sustainability concerns regarding resource depletion and end-of-life disposal.

Fire suppression systems in battery installations frequently employ halogenated compounds that, despite their effectiveness, can deplete atmospheric ozone when released. The environmental cost of these systems must be weighed against their safety benefits, particularly as battery deployments scale globally. Additionally, the mining of rare earth elements for advanced thermal management materials creates substantial ecological disruption, including habitat destruction, water pollution, and energy-intensive processing.

Water-based cooling solutions present their own environmental trade-offs. While generally considered more environmentally friendly than chemical alternatives, they require significant water resources in potentially water-stressed regions and may introduce thermal pollution when discharged into natural water bodies after use in cooling systems.

The manufacturing processes for advanced ceramic thermal barriers and aerogel insulation materials are typically energy-intensive, contributing to indirect carbon emissions. However, these materials can significantly extend battery lifespans, potentially offsetting their production footprint through reduced replacement frequency and associated manufacturing impacts.

End-of-life considerations reveal further environmental challenges. Many specialized thermal management components contain composite materials that are difficult to separate and recycle effectively. This complexity often results in these components being landfilled rather than recovered, representing both resource loss and potential contamination risks.

Progressive battery safety technologies are increasingly incorporating environmental considerations into their design parameters. Biodegradable phase change materials, natural refrigerants with minimal global warming potential, and water-based systems with closed-loop recycling are emerging as environmentally responsible alternatives. These innovations demonstrate the industry's growing recognition that environmental sustainability must be integrated with safety performance rather than sacrificed for it.

Cooling systems utilizing traditional refrigerants contribute to greenhouse gas emissions when leaked or improperly disposed of. Particularly concerning are hydrofluorocarbon (HFC) refrigerants, which have global warming potentials thousands of times greater than CO2. Phase change materials (PCMs), while effective for thermal management, often contain paraffins derived from fossil fuels, raising sustainability concerns regarding resource depletion and end-of-life disposal.

Fire suppression systems in battery installations frequently employ halogenated compounds that, despite their effectiveness, can deplete atmospheric ozone when released. The environmental cost of these systems must be weighed against their safety benefits, particularly as battery deployments scale globally. Additionally, the mining of rare earth elements for advanced thermal management materials creates substantial ecological disruption, including habitat destruction, water pollution, and energy-intensive processing.

Water-based cooling solutions present their own environmental trade-offs. While generally considered more environmentally friendly than chemical alternatives, they require significant water resources in potentially water-stressed regions and may introduce thermal pollution when discharged into natural water bodies after use in cooling systems.

The manufacturing processes for advanced ceramic thermal barriers and aerogel insulation materials are typically energy-intensive, contributing to indirect carbon emissions. However, these materials can significantly extend battery lifespans, potentially offsetting their production footprint through reduced replacement frequency and associated manufacturing impacts.

End-of-life considerations reveal further environmental challenges. Many specialized thermal management components contain composite materials that are difficult to separate and recycle effectively. This complexity often results in these components being landfilled rather than recovered, representing both resource loss and potential contamination risks.

Progressive battery safety technologies are increasingly incorporating environmental considerations into their design parameters. Biodegradable phase change materials, natural refrigerants with minimal global warming potential, and water-based systems with closed-loop recycling are emerging as environmentally responsible alternatives. These innovations demonstrate the industry's growing recognition that environmental sustainability must be integrated with safety performance rather than sacrificed for it.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!