Research into Cross-linkable Polymers for Battery Thermal Runaway Protection

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Safety Evolution and Protection Goals

Battery safety has evolved significantly over the past decades, driven by the increasing energy density of lithium-ion batteries and their widespread adoption in consumer electronics, electric vehicles, and energy storage systems. In the 1990s, early lithium-ion batteries faced numerous safety incidents, prompting initial safety measures focused primarily on mechanical protection and basic thermal management. By the early 2000s, safety mechanisms expanded to include positive temperature coefficient (PTC) devices, current interrupt devices (CIDs), and rudimentary battery management systems.

The mid-2000s to early 2010s saw a dramatic increase in battery energy density, accompanied by high-profile thermal runaway incidents in consumer electronics and electric vehicles. These events catalyzed more sophisticated safety approaches, including advanced battery management systems, improved cell design, and the introduction of flame-retardant electrolytes. However, these measures often addressed symptoms rather than the fundamental thermal runaway mechanism.

Current protection goals have shifted toward proactive prevention rather than reactive containment. The primary objective is to prevent thermal runaway initiation by addressing the root causes: internal short circuits, overcharging, mechanical damage, and thermal abuse. When prevention fails, secondary goals focus on containing thermal events within individual cells, preventing propagation to adjacent cells, and providing adequate time for system shutdown or evacuation.

Specifically for cross-linkable polymers in battery protection, the goals include developing materials that maintain mechanical integrity at elevated temperatures (>200°C), provide effective thermal insulation to neighboring cells, and exhibit minimal degradation during normal battery operation cycles. These polymers must activate precisely at predetermined temperature thresholds, rapidly forming cross-linked networks that physically contain cell components and absorb thermal energy.

Additional protection goals include ensuring these materials are compatible with existing battery manufacturing processes, cost-effective at scale, and environmentally sustainable. The polymers must maintain effectiveness throughout the battery's operational lifetime (8-15 years for automotive applications) without degradation or performance loss. They should also function across wide temperature ranges (-40°C to +85°C) and withstand hundreds to thousands of normal charge-discharge cycles without premature activation.

The ultimate protection goal is to develop a comprehensive safety system where cross-linkable polymers serve as a critical component in a multi-layered approach, working in conjunction with electronic safety systems, advanced thermal management, and improved cell chemistry to virtually eliminate catastrophic failure scenarios in next-generation energy storage systems.

The mid-2000s to early 2010s saw a dramatic increase in battery energy density, accompanied by high-profile thermal runaway incidents in consumer electronics and electric vehicles. These events catalyzed more sophisticated safety approaches, including advanced battery management systems, improved cell design, and the introduction of flame-retardant electrolytes. However, these measures often addressed symptoms rather than the fundamental thermal runaway mechanism.

Current protection goals have shifted toward proactive prevention rather than reactive containment. The primary objective is to prevent thermal runaway initiation by addressing the root causes: internal short circuits, overcharging, mechanical damage, and thermal abuse. When prevention fails, secondary goals focus on containing thermal events within individual cells, preventing propagation to adjacent cells, and providing adequate time for system shutdown or evacuation.

Specifically for cross-linkable polymers in battery protection, the goals include developing materials that maintain mechanical integrity at elevated temperatures (>200°C), provide effective thermal insulation to neighboring cells, and exhibit minimal degradation during normal battery operation cycles. These polymers must activate precisely at predetermined temperature thresholds, rapidly forming cross-linked networks that physically contain cell components and absorb thermal energy.

Additional protection goals include ensuring these materials are compatible with existing battery manufacturing processes, cost-effective at scale, and environmentally sustainable. The polymers must maintain effectiveness throughout the battery's operational lifetime (8-15 years for automotive applications) without degradation or performance loss. They should also function across wide temperature ranges (-40°C to +85°C) and withstand hundreds to thousands of normal charge-discharge cycles without premature activation.

The ultimate protection goal is to develop a comprehensive safety system where cross-linkable polymers serve as a critical component in a multi-layered approach, working in conjunction with electronic safety systems, advanced thermal management, and improved cell chemistry to virtually eliminate catastrophic failure scenarios in next-generation energy storage systems.

Market Analysis for Thermal Runaway Prevention Solutions

The global market for thermal runaway prevention solutions in lithium-ion batteries has experienced significant growth, driven by increasing safety concerns across multiple industries. The market value reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 15.8% through 2030, potentially reaching $6.7 billion by the end of the forecast period.

Electric vehicles represent the largest market segment, accounting for nearly 45% of the total demand for thermal runaway prevention technologies. This dominance stems from the high-profile nature of EV battery failures and stringent safety regulations being implemented worldwide. Consumer electronics follows as the second-largest segment at 28%, while energy storage systems represent a rapidly growing segment at 18%.

Regionally, Asia Pacific leads the market with approximately 42% share, primarily due to the concentration of battery manufacturing in China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with both regions showing accelerated adoption rates driven by safety regulations and consumer awareness.

Cross-linkable polymer solutions specifically are gaining significant traction within this broader market. These materials currently represent about 15% of the thermal runaway prevention market but are expected to grow at a faster rate (19.2% CAGR) than the overall market due to their superior performance characteristics and increasing cost-effectiveness as production scales.

Key market drivers include increasingly stringent safety regulations across major markets, growing consumer awareness of battery safety issues, and the expanding application of high-energy-density batteries in critical systems. The insurance industry has also become a significant market influencer, with several major insurers now offering premium reductions for systems employing advanced thermal runaway protection.

Market barriers include the additional cost burden on battery manufacturers, technical challenges in implementing solutions without compromising battery performance, and the fragmented regulatory landscape across different regions. The cost sensitivity is particularly acute in consumer electronics, where profit margins are already thin.

Emerging market opportunities include the development of retrofit solutions for existing battery systems, integration with battery management systems for active protection, and specialized solutions for extreme environment applications such as aerospace and military. The aftermarket segment is projected to grow particularly rapidly as fleet operators seek to extend the safe operational life of existing battery systems.

Electric vehicles represent the largest market segment, accounting for nearly 45% of the total demand for thermal runaway prevention technologies. This dominance stems from the high-profile nature of EV battery failures and stringent safety regulations being implemented worldwide. Consumer electronics follows as the second-largest segment at 28%, while energy storage systems represent a rapidly growing segment at 18%.

Regionally, Asia Pacific leads the market with approximately 42% share, primarily due to the concentration of battery manufacturing in China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with both regions showing accelerated adoption rates driven by safety regulations and consumer awareness.

Cross-linkable polymer solutions specifically are gaining significant traction within this broader market. These materials currently represent about 15% of the thermal runaway prevention market but are expected to grow at a faster rate (19.2% CAGR) than the overall market due to their superior performance characteristics and increasing cost-effectiveness as production scales.

Key market drivers include increasingly stringent safety regulations across major markets, growing consumer awareness of battery safety issues, and the expanding application of high-energy-density batteries in critical systems. The insurance industry has also become a significant market influencer, with several major insurers now offering premium reductions for systems employing advanced thermal runaway protection.

Market barriers include the additional cost burden on battery manufacturers, technical challenges in implementing solutions without compromising battery performance, and the fragmented regulatory landscape across different regions. The cost sensitivity is particularly acute in consumer electronics, where profit margins are already thin.

Emerging market opportunities include the development of retrofit solutions for existing battery systems, integration with battery management systems for active protection, and specialized solutions for extreme environment applications such as aerospace and military. The aftermarket segment is projected to grow particularly rapidly as fleet operators seek to extend the safe operational life of existing battery systems.

Cross-linkable Polymers: Current State and Challenges

Cross-linkable polymers represent a significant advancement in materials science with promising applications in battery thermal runaway protection. Currently, these polymers are being extensively researched globally, with notable progress in developing materials that can withstand extreme temperature conditions while maintaining structural integrity. The state-of-the-art cross-linkable polymers include modified polyethylene, fluoropolymers, silicones, and various copolymer systems specifically engineered for thermal stability.

Despite significant advancements, several critical challenges persist in the development and implementation of cross-linkable polymers for battery safety applications. The primary technical hurdle involves achieving the optimal balance between thermal responsiveness and mechanical durability. Many current formulations exhibit excellent thermal resistance but suffer from brittleness or inadequate adhesion to battery components, limiting their practical application in commercial battery systems.

Another significant challenge is the scalability of production processes. Laboratory-scale synthesis methods often prove difficult to translate to industrial manufacturing settings without compromising the polymer's performance characteristics. This manufacturing gap has slowed the widespread adoption of these materials in commercial battery systems, despite their proven efficacy in controlled environments.

The activation temperature precision presents another technical obstacle. Ideal cross-linkable polymers should activate within a narrow temperature window—high enough to avoid false triggering during normal operation but low enough to respond before thermal runaway becomes catastrophic. Current materials often exhibit too broad an activation range or inconsistent cross-linking behavior under variable conditions.

Compatibility issues with existing battery components and electrolytes further complicate implementation. Some cross-linkable polymers can react adversely with electrolyte solutions or electrode materials, potentially introducing new failure modes or reducing battery performance metrics such as energy density and cycle life.

From a geographical perspective, research leadership in this field is distributed across several regions. Japan and South Korea lead in commercial applications, while China has rapidly expanded its research output in recent years. North American and European institutions maintain strong positions in fundamental research and novel material development, particularly in academic settings.

The regulatory landscape adds another layer of complexity, as safety standards for battery materials vary significantly across global markets. This regulatory fragmentation creates additional barriers to the universal adoption of new polymer technologies, requiring extensive validation testing across different jurisdictions.

Despite significant advancements, several critical challenges persist in the development and implementation of cross-linkable polymers for battery safety applications. The primary technical hurdle involves achieving the optimal balance between thermal responsiveness and mechanical durability. Many current formulations exhibit excellent thermal resistance but suffer from brittleness or inadequate adhesion to battery components, limiting their practical application in commercial battery systems.

Another significant challenge is the scalability of production processes. Laboratory-scale synthesis methods often prove difficult to translate to industrial manufacturing settings without compromising the polymer's performance characteristics. This manufacturing gap has slowed the widespread adoption of these materials in commercial battery systems, despite their proven efficacy in controlled environments.

The activation temperature precision presents another technical obstacle. Ideal cross-linkable polymers should activate within a narrow temperature window—high enough to avoid false triggering during normal operation but low enough to respond before thermal runaway becomes catastrophic. Current materials often exhibit too broad an activation range or inconsistent cross-linking behavior under variable conditions.

Compatibility issues with existing battery components and electrolytes further complicate implementation. Some cross-linkable polymers can react adversely with electrolyte solutions or electrode materials, potentially introducing new failure modes or reducing battery performance metrics such as energy density and cycle life.

From a geographical perspective, research leadership in this field is distributed across several regions. Japan and South Korea lead in commercial applications, while China has rapidly expanded its research output in recent years. North American and European institutions maintain strong positions in fundamental research and novel material development, particularly in academic settings.

The regulatory landscape adds another layer of complexity, as safety standards for battery materials vary significantly across global markets. This regulatory fragmentation creates additional barriers to the universal adoption of new polymer technologies, requiring extensive validation testing across different jurisdictions.

Current Cross-linkable Polymer Protection Mechanisms

01 Cross-linkable polymers for battery thermal protection

Cross-linkable polymers can be incorporated into battery systems to provide thermal runaway protection. These polymers can form a protective layer that prevents thermal propagation between cells when activated by heat. The cross-linking mechanism creates a barrier that limits heat transfer and contains potential fires, enhancing the overall safety of battery packs in electric vehicles and energy storage systems.- Cross-linkable polymers for battery thermal protection: Cross-linkable polymers can be incorporated into battery systems to provide thermal runaway protection. These polymers can form a protective layer that activates when temperatures rise above critical thresholds, preventing thermal propagation between cells. The cross-linking mechanism creates a barrier that limits heat transfer and contains potential fires, enhancing overall battery safety in high-energy storage applications.

- Temperature-responsive polymer networks for safety devices: Temperature-responsive polymer networks can be designed to undergo structural changes at specific temperature thresholds, providing protection against thermal runaway events. These materials can be formulated to expand, contract, or change physical properties when exposed to excessive heat, effectively acting as passive safety mechanisms. The networks can be tailored to respond at precise temperature ranges relevant to different applications requiring thermal protection.

- Flame-retardant cross-linkable polymer compositions: Specialized cross-linkable polymer compositions can be formulated with flame-retardant properties to prevent or mitigate thermal runaway events. These compositions often incorporate halogenated compounds, phosphorus-based additives, or inorganic fillers that enhance fire resistance. When exposed to high temperatures, these materials form a carbonaceous char layer that limits oxygen access and heat transfer, providing critical protection in high-risk thermal environments.

- Self-healing cross-linkable polymers for thermal management: Self-healing cross-linkable polymers offer advanced thermal runaway protection through their ability to repair damage caused by thermal stress. These materials contain dynamic bonds that can reform after being broken by excessive heat, maintaining structural integrity during thermal events. The self-healing mechanism provides continuous protection even after initial thermal damage, extending the effective lifetime of thermal protection systems in critical applications.

- Nanocomposite cross-linkable polymers for enhanced thermal stability: Nanocomposite cross-linkable polymers incorporate nanoscale materials such as clay, graphene, or metal oxides to significantly enhance thermal stability and runaway protection. These nanofillers create tortuous paths for heat transfer and gas diffusion, improving the material's resistance to thermal degradation. The synergistic effect between the cross-linked polymer matrix and nanofillers results in superior thermal protection properties compared to conventional materials, making them ideal for high-temperature applications.

02 Heat-activated cross-linking mechanisms

Certain polymer formulations are designed to undergo cross-linking reactions when exposed to elevated temperatures. This temperature-triggered mechanism allows the polymers to remain in a normal state during regular operation but rapidly form a protective barrier when thermal events begin. The cross-linking reaction absorbs heat energy while creating a more thermally resistant structure, effectively providing a dual mechanism of protection against thermal runaway.Expand Specific Solutions03 Flame retardant cross-linkable polymer composites

Specialized polymer composites incorporate both cross-linkable elements and flame retardant additives to enhance thermal runaway protection. These composites can simultaneously form a physical barrier through cross-linking while releasing flame-suppressing compounds when exposed to high temperatures. The synergistic effect provides superior protection against thermal events compared to conventional materials, making them particularly valuable for high-energy density applications.Expand Specific Solutions04 Cross-linkable polymer coatings and separators

Cross-linkable polymers can be applied as coatings on battery components or used to create advanced separator materials. These specialized coatings and separators maintain normal ion transport during regular operation but activate their protective properties during thermal events. The cross-linking reaction creates a more tortuous path for heat propagation and can physically separate battery components to prevent cascading failures in energy storage systems.Expand Specific Solutions05 Self-healing cross-linkable polymer systems

Advanced cross-linkable polymer systems incorporate self-healing capabilities to provide ongoing thermal protection. These innovative materials can repair minor damage through reversible cross-linking mechanisms, maintaining their protective properties over extended periods. The self-healing aspect ensures that the thermal runaway protection remains effective throughout the lifecycle of the device, even after exposure to mechanical stress or minor thermal events.Expand Specific Solutions

Key Industry Players in Battery Safety Materials

The cross-linkable polymers for battery thermal runaway protection market is in an early growth stage, with increasing adoption driven by rising EV safety concerns. The market is projected to expand significantly as battery technologies evolve, with an estimated value reaching several hundred million dollars by 2025. Tesla, LG Energy Solution, and Samsung SDI lead commercial implementation, while research institutions like Huazhong University and Shanghai Jiao Tong University advance fundamental technologies. Companies like Aspen Aerogels and BASF are developing specialized polymer solutions, while automotive manufacturers including Ford and GM are integrating these technologies into vehicle designs. The competitive landscape features collaboration between material suppliers, battery manufacturers, and OEMs, with varying levels of technological maturity from research-stage concepts to commercially deployed solutions.

Aspen Aerogels, Inc.

Technical Solution: Aspen Aerogels has developed PyroThin™, an advanced cross-linkable polymer-based thermal barrier technology specifically designed for battery thermal runaway protection. Their solution utilizes silica aerogel technology combined with cross-linked polymers to create ultra-thin, lightweight thermal barriers that can withstand extreme temperatures up to 1200°C. The PyroThin™ technology incorporates a proprietary cross-linking mechanism that activates during thermal events, creating an expanded char layer that significantly reduces heat transfer between cells. This technology has been engineered to be just 2mm thick while providing thermal protection equivalent to much thicker conventional materials. Aspen has demonstrated that their solution can delay thermal propagation by up to 10 minutes in EV battery packs, giving critical time for occupant evacuation. The material maintains its integrity even after repeated thermal cycling and mechanical stress, making it suitable for the demanding environment of EV batteries.

Strengths: Extremely thin and lightweight design minimizes impact on battery energy density; exceptional thermal insulation properties; proven effectiveness in delaying thermal runaway propagation; maintains performance over battery lifetime. Weaknesses: Higher cost compared to conventional materials; requires specialized manufacturing processes; potential challenges in scaling production to meet growing EV market demands.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a comprehensive approach to battery thermal runaway protection through their Safety Reinforced Separator (SRS) technology, which incorporates cross-linkable polymers. Their solution features a multi-layer separator with ceramic-coated polyethylene base and proprietary cross-linkable polymer coating that forms a three-dimensional network structure when activated by heat. This cross-linked structure maintains mechanical integrity at high temperatures (>200°C), preventing separator shrinkage and subsequent short circuits. LG Chem's technology includes thermally-triggered cross-linking agents that activate at specific temperature thresholds, creating additional thermal barriers before full thermal runaway occurs. The company has also developed flame-retardant electrolyte additives that work synergistically with their cross-linkable polymer separators to suppress thermal propagation. Testing has shown that this integrated approach can prevent cell-to-cell thermal propagation in over 90% of test cases, significantly improving overall battery pack safety.

Strengths: Comprehensive safety approach that addresses multiple failure modes; technology already implemented in commercial batteries; maintains separator integrity at high temperatures; minimal impact on battery performance metrics. Weaknesses: Adds complexity to manufacturing process; slightly increases internal resistance; potential long-term aging effects of cross-linkable additives require further study.

Critical Patents in Thermal Runaway Prevention

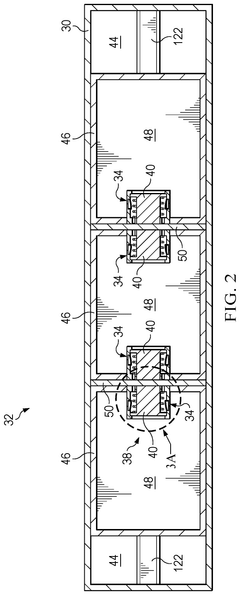

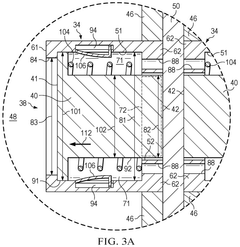

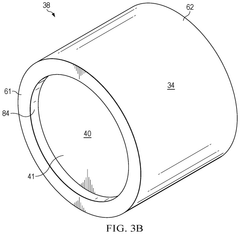

Thermal runaway detection and cotainment mechanism

PatentPendingUS20250286210A1

Innovation

- A thermal runaway protection system incorporating a battery module enclosure, divider wall, protection structure, and piston mechanism that separates overheated modules to create a thermal barrier by converting pressure into a separation air gap, using a piston to move and separate the overheated module when pressure exceeds a threshold, with a spring and lock pawl system to maintain separation.

Protection structure forthermal dissipation and preventing thermal runaway diffusion in battery system

PatentActiveUS8785026B2

Innovation

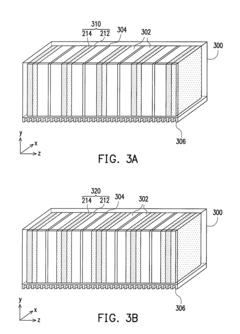

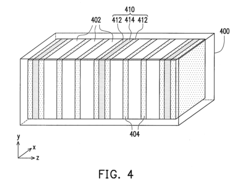

- A multilayer anisotropic heat conduction structure with composite heat conduction plates, consisting of heat conduction and insulation layers, is introduced between battery cells and modules to control heat transmission and dissipation, preventing thermal runaway diffusion and enhancing safety.

Regulatory Framework for Battery Safety Materials

The regulatory landscape for battery safety materials has evolved significantly in response to increasing concerns about battery thermal runaway incidents. International standards such as IEC 62133, UL 1642, and UN 38.3 have established baseline requirements for battery safety, with specific provisions addressing thermal management and fire prevention. These standards mandate rigorous testing protocols including thermal abuse tests, short circuit tests, and overcharge protection evaluations that directly impact the development of cross-linkable polymer solutions.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent guidelines for battery-powered consumer products, while the Department of Transportation (DOT) regulates the transportation of lithium batteries with specific requirements for thermal protection systems. The National Fire Protection Association (NFPA) has also developed standards specifically addressing battery fire risks in various applications, creating additional compliance requirements for thermal runaway protection materials.

The European Union's regulatory framework includes the Battery Directive (2006/66/EC) and its recent updates, which are progressively incorporating more specific requirements for thermal safety systems. The EU's REACH regulation additionally impacts the chemical composition of cross-linkable polymers, requiring manufacturers to verify that all components meet toxicity and environmental persistence standards. The upcoming EU Battery Regulation will further strengthen safety requirements with explicit provisions for thermal runaway prevention.

In Asia, China's GB/T 31241 standard specifically addresses the safety requirements of lithium-ion batteries with detailed specifications for thermal management systems. Japan's JIS C8714 and South Korea's KC certification also include comprehensive safety requirements that influence the development and implementation of cross-linkable polymer solutions for thermal protection.

Industry-specific regulations present another layer of compliance requirements. The automotive sector, through standards like ISO 6469 and SAE J2929, has established particularly rigorous thermal safety requirements for electric vehicle batteries. Aerospace applications follow even stricter guidelines under FAA and EASA regulations, while consumer electronics must adhere to IEC 62368-1, which includes specific provisions for preventing thermal hazards.

These regulatory frameworks are continuously evolving, with a clear trend toward more stringent thermal runaway protection requirements. Recent regulatory updates have increasingly focused on the performance of protective materials under extreme conditions, creating both challenges and opportunities for cross-linkable polymer technologies that can demonstrate superior thermal stability and fire resistance properties.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent guidelines for battery-powered consumer products, while the Department of Transportation (DOT) regulates the transportation of lithium batteries with specific requirements for thermal protection systems. The National Fire Protection Association (NFPA) has also developed standards specifically addressing battery fire risks in various applications, creating additional compliance requirements for thermal runaway protection materials.

The European Union's regulatory framework includes the Battery Directive (2006/66/EC) and its recent updates, which are progressively incorporating more specific requirements for thermal safety systems. The EU's REACH regulation additionally impacts the chemical composition of cross-linkable polymers, requiring manufacturers to verify that all components meet toxicity and environmental persistence standards. The upcoming EU Battery Regulation will further strengthen safety requirements with explicit provisions for thermal runaway prevention.

In Asia, China's GB/T 31241 standard specifically addresses the safety requirements of lithium-ion batteries with detailed specifications for thermal management systems. Japan's JIS C8714 and South Korea's KC certification also include comprehensive safety requirements that influence the development and implementation of cross-linkable polymer solutions for thermal protection.

Industry-specific regulations present another layer of compliance requirements. The automotive sector, through standards like ISO 6469 and SAE J2929, has established particularly rigorous thermal safety requirements for electric vehicle batteries. Aerospace applications follow even stricter guidelines under FAA and EASA regulations, while consumer electronics must adhere to IEC 62368-1, which includes specific provisions for preventing thermal hazards.

These regulatory frameworks are continuously evolving, with a clear trend toward more stringent thermal runaway protection requirements. Recent regulatory updates have increasingly focused on the performance of protective materials under extreme conditions, creating both challenges and opportunities for cross-linkable polymer technologies that can demonstrate superior thermal stability and fire resistance properties.

Environmental Impact of Polymer-Based Safety Solutions

The environmental implications of polymer-based battery safety solutions represent a critical dimension in the overall assessment of cross-linkable polymers for thermal runaway protection. These materials, while offering significant safety benefits, introduce complex environmental considerations throughout their lifecycle.

When evaluating the environmental footprint of cross-linkable polymers, production processes emerge as a primary concern. Many conventional polymer manufacturing methods involve petroleum-derived feedstocks and energy-intensive processes that generate substantial carbon emissions. However, recent advancements have yielded bio-based alternatives and greener synthesis routes that significantly reduce environmental impact while maintaining thermal protection properties.

Disposal and end-of-life management present another environmental challenge. Traditional polymer materials may persist in the environment for decades or centuries when improperly disposed of. Cross-linkable polymers used in battery applications often contain flame retardants and other additives that could potentially leach into soil and water systems. The development of biodegradable cross-linkable polymers represents a promising frontier, though balancing degradability with the long service life required for battery applications remains technically challenging.

Recyclability considerations are particularly relevant as the electric vehicle and energy storage markets expand. The cross-linked structure that provides excellent thermal stability also complicates recycling efforts, as these materials typically cannot be melted and reformed like thermoplastics. Advanced chemical recycling methods are emerging that can break down cross-linked networks into reusable monomers or other valuable chemical feedstocks, though these processes are still being optimized for commercial scale.

The environmental benefits of these materials must also be acknowledged. By preventing catastrophic thermal runaway events, these polymers help avoid the release of toxic gases and materials from damaged batteries. This protective function reduces the risk of fires that could release significant pollutants and greenhouse gases. Additionally, by extending battery lifespans through enhanced safety, these materials contribute to resource conservation and reduced waste generation.

Life cycle assessment (LCA) studies comparing different polymer-based safety solutions reveal varying environmental profiles. Silicone-based cross-linkable polymers generally demonstrate lower aquatic toxicity but higher energy requirements in production compared to some fluoropolymer alternatives. Meanwhile, emerging bio-based cross-linkable polymers show promise in reducing carbon footprint but may present land-use concerns if widely adopted.

When evaluating the environmental footprint of cross-linkable polymers, production processes emerge as a primary concern. Many conventional polymer manufacturing methods involve petroleum-derived feedstocks and energy-intensive processes that generate substantial carbon emissions. However, recent advancements have yielded bio-based alternatives and greener synthesis routes that significantly reduce environmental impact while maintaining thermal protection properties.

Disposal and end-of-life management present another environmental challenge. Traditional polymer materials may persist in the environment for decades or centuries when improperly disposed of. Cross-linkable polymers used in battery applications often contain flame retardants and other additives that could potentially leach into soil and water systems. The development of biodegradable cross-linkable polymers represents a promising frontier, though balancing degradability with the long service life required for battery applications remains technically challenging.

Recyclability considerations are particularly relevant as the electric vehicle and energy storage markets expand. The cross-linked structure that provides excellent thermal stability also complicates recycling efforts, as these materials typically cannot be melted and reformed like thermoplastics. Advanced chemical recycling methods are emerging that can break down cross-linked networks into reusable monomers or other valuable chemical feedstocks, though these processes are still being optimized for commercial scale.

The environmental benefits of these materials must also be acknowledged. By preventing catastrophic thermal runaway events, these polymers help avoid the release of toxic gases and materials from damaged batteries. This protective function reduces the risk of fires that could release significant pollutants and greenhouse gases. Additionally, by extending battery lifespans through enhanced safety, these materials contribute to resource conservation and reduced waste generation.

Life cycle assessment (LCA) studies comparing different polymer-based safety solutions reveal varying environmental profiles. Silicone-based cross-linkable polymers generally demonstrate lower aquatic toxicity but higher energy requirements in production compared to some fluoropolymer alternatives. Meanwhile, emerging bio-based cross-linkable polymers show promise in reducing carbon footprint but may present land-use concerns if widely adopted.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!