Battery Thermal Runaway Evaluation in Smart Grid Integration

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Battery thermal runaway (BTR) represents one of the most critical safety challenges in energy storage systems, particularly as battery technologies become increasingly integrated into smart grid infrastructures. The phenomenon, characterized by an uncontrolled, self-accelerating exothermic reaction within battery cells, has evolved from a niche concern to a central focus in energy storage safety research over the past two decades. Initially observed primarily in early lithium-ion battery implementations, thermal runaway incidents have prompted significant research attention as energy storage deployments have scaled dramatically across utility, commercial, and residential applications.

The evolution of battery thermal runaway understanding has progressed through several distinct phases. Early research (2000-2010) focused primarily on identifying fundamental mechanisms and triggering conditions. The middle period (2010-2018) saw increased emphasis on prevention technologies and early detection systems. Most recently (2018-present), research has shifted toward integration of thermal management systems with smart grid communication protocols and predictive analytics capabilities.

Current technological trajectories indicate continued advancement in real-time monitoring systems, AI-driven predictive maintenance, and grid-responsive thermal management solutions. These developments align with broader industry trends toward distributed energy resources and vehicle-to-grid applications, where battery safety becomes increasingly critical to system reliability and public acceptance.

The primary technical objective of this research is to develop comprehensive evaluation methodologies for battery thermal runaway risks specifically within smart grid integration contexts. This includes establishing standardized testing protocols that account for the unique operational conditions of grid-connected storage systems, such as variable charging/discharging rates, frequency regulation services, and demand response applications.

Secondary objectives include identifying key early indicators of potential thermal events that can be monitored through existing grid communication infrastructure, developing risk assessment frameworks that incorporate both battery-level and grid-level factors, and establishing mitigation strategies that leverage grid flexibility to reduce thermal stress on battery systems during high-risk operational periods.

The ultimate goal is to enable safe, reliable integration of increasingly dense energy storage systems into smart grid architectures by providing robust evaluation tools that can be implemented across diverse battery chemistries, form factors, and application environments. This research aims to bridge the current gap between battery-focused safety research and grid integration requirements, creating a unified approach to thermal runaway risk assessment in interconnected energy systems.

The evolution of battery thermal runaway understanding has progressed through several distinct phases. Early research (2000-2010) focused primarily on identifying fundamental mechanisms and triggering conditions. The middle period (2010-2018) saw increased emphasis on prevention technologies and early detection systems. Most recently (2018-present), research has shifted toward integration of thermal management systems with smart grid communication protocols and predictive analytics capabilities.

Current technological trajectories indicate continued advancement in real-time monitoring systems, AI-driven predictive maintenance, and grid-responsive thermal management solutions. These developments align with broader industry trends toward distributed energy resources and vehicle-to-grid applications, where battery safety becomes increasingly critical to system reliability and public acceptance.

The primary technical objective of this research is to develop comprehensive evaluation methodologies for battery thermal runaway risks specifically within smart grid integration contexts. This includes establishing standardized testing protocols that account for the unique operational conditions of grid-connected storage systems, such as variable charging/discharging rates, frequency regulation services, and demand response applications.

Secondary objectives include identifying key early indicators of potential thermal events that can be monitored through existing grid communication infrastructure, developing risk assessment frameworks that incorporate both battery-level and grid-level factors, and establishing mitigation strategies that leverage grid flexibility to reduce thermal stress on battery systems during high-risk operational periods.

The ultimate goal is to enable safe, reliable integration of increasingly dense energy storage systems into smart grid architectures by providing robust evaluation tools that can be implemented across diverse battery chemistries, form factors, and application environments. This research aims to bridge the current gap between battery-focused safety research and grid integration requirements, creating a unified approach to thermal runaway risk assessment in interconnected energy systems.

Smart Grid Integration Market Analysis

The global smart grid market is experiencing robust growth, projected to reach $103.4 billion by 2026, with a compound annual growth rate of 17.4% from 2021. This growth is primarily driven by increasing energy demand, aging power infrastructure, and the global push toward renewable energy integration. The smart grid ecosystem encompasses various components including advanced metering infrastructure, distribution automation, substation automation, and energy storage systems, with battery storage becoming increasingly critical for grid stability and resilience.

Battery energy storage systems (BESS) represent one of the fastest-growing segments within the smart grid market, expected to reach $12.1 billion by 2025. This growth is fueled by declining battery costs, which have decreased by approximately 87% over the past decade, making grid-scale storage economically viable for utilities and energy providers. The integration of batteries into smart grids serves multiple functions including peak shaving, frequency regulation, renewable energy time-shifting, and emergency backup power.

Thermal runaway concerns in battery systems represent a significant market constraint, with safety incidents causing an estimated $300 million in damages annually across global energy storage installations. This has created a specialized market segment focused on battery safety systems, thermal management solutions, and advanced monitoring technologies, currently valued at approximately $1.8 billion and growing at 22% annually.

Regional analysis reveals varying adoption patterns, with North America leading in smart grid investments (34% of global market share), followed by Europe (28%) and Asia-Pacific (27%). China dominates the battery manufacturing landscape, controlling 73% of global lithium-ion battery production capacity, while European and North American markets focus more on advanced battery management systems and safety protocols.

Consumer and regulatory demands are reshaping market dynamics, with 76% of utility customers expressing concern about grid reliability and 82% of utilities reporting increased regulatory pressure regarding battery safety standards. This has accelerated the development of thermal runaway prevention technologies, with venture capital investments in this specific segment reaching $780 million in 2022, a 45% increase from the previous year.

Market forecasts indicate that battery thermal management systems specifically designed for grid applications will see particularly strong growth, with demand expected to triple by 2028 as utilities expand their energy storage portfolios. The economic impact of preventing thermal runaway events extends beyond direct damage prevention, with studies suggesting that effective thermal management systems can extend battery lifespan by 30-40%, significantly improving the return on investment for grid-scale storage projects.

Battery energy storage systems (BESS) represent one of the fastest-growing segments within the smart grid market, expected to reach $12.1 billion by 2025. This growth is fueled by declining battery costs, which have decreased by approximately 87% over the past decade, making grid-scale storage economically viable for utilities and energy providers. The integration of batteries into smart grids serves multiple functions including peak shaving, frequency regulation, renewable energy time-shifting, and emergency backup power.

Thermal runaway concerns in battery systems represent a significant market constraint, with safety incidents causing an estimated $300 million in damages annually across global energy storage installations. This has created a specialized market segment focused on battery safety systems, thermal management solutions, and advanced monitoring technologies, currently valued at approximately $1.8 billion and growing at 22% annually.

Regional analysis reveals varying adoption patterns, with North America leading in smart grid investments (34% of global market share), followed by Europe (28%) and Asia-Pacific (27%). China dominates the battery manufacturing landscape, controlling 73% of global lithium-ion battery production capacity, while European and North American markets focus more on advanced battery management systems and safety protocols.

Consumer and regulatory demands are reshaping market dynamics, with 76% of utility customers expressing concern about grid reliability and 82% of utilities reporting increased regulatory pressure regarding battery safety standards. This has accelerated the development of thermal runaway prevention technologies, with venture capital investments in this specific segment reaching $780 million in 2022, a 45% increase from the previous year.

Market forecasts indicate that battery thermal management systems specifically designed for grid applications will see particularly strong growth, with demand expected to triple by 2028 as utilities expand their energy storage portfolios. The economic impact of preventing thermal runaway events extends beyond direct damage prevention, with studies suggesting that effective thermal management systems can extend battery lifespan by 30-40%, significantly improving the return on investment for grid-scale storage projects.

Thermal Runaway Detection Challenges

Detecting thermal runaway in battery systems integrated with smart grids presents significant technical challenges that require innovative solutions. Current detection methods often struggle with the rapid progression of thermal events, which can escalate from initial stages to catastrophic failure within minutes or even seconds. This time constraint makes early detection crucial yet extremely difficult to achieve reliably.

The primary challenge lies in distinguishing between normal operational temperature fluctuations and early indicators of thermal runaway. Batteries naturally experience temperature variations during charging, discharging, and ambient condition changes. Detection systems must be sophisticated enough to differentiate these normal patterns from abnormal thermal behaviors without generating excessive false alarms that could undermine grid stability.

Sensor placement represents another substantial hurdle. The internal temperature distribution within battery cells is non-uniform, creating "hot spots" that may not be detected by external sensors. Embedding sensors directly within cells improves detection accuracy but introduces manufacturing complexities, increases costs, and may affect battery performance or lifespan. This creates a difficult trade-off between detection capability and practical implementation.

Data processing challenges are equally significant. Smart grid environments generate enormous volumes of data from numerous battery systems simultaneously. Processing this information in real-time requires substantial computational resources and sophisticated algorithms. The latency between data acquisition, processing, and response must be minimized to prevent thermal events from escalating beyond containment.

Environmental factors further complicate detection efforts. Ambient temperature variations, humidity levels, and air flow patterns can all influence battery thermal behavior and mask early warning signs. Detection systems must account for these external variables to maintain accuracy across diverse operating conditions.

The integration of battery systems with varying ages, chemistries, and manufacturers within the same smart grid infrastructure creates additional complexity. Different battery types exhibit distinct thermal signatures and failure modes, necessitating adaptive detection approaches that can accommodate this heterogeneity.

Cost considerations present practical limitations to implementing comprehensive detection systems. While advanced thermal imaging, gas sensors, and electrochemical impedance spectroscopy offer superior detection capabilities, their high cost prohibits widespread deployment across all battery installations in smart grid applications. This economic constraint forces difficult decisions about the appropriate level of monitoring for different system components based on their criticality.

Regulatory frameworks and standards for thermal runaway detection in grid-connected battery systems remain underdeveloped in many regions, creating uncertainty about minimum safety requirements and complicating technology development efforts. This regulatory gap slows the adoption of innovative detection technologies that could otherwise enhance system safety.

The primary challenge lies in distinguishing between normal operational temperature fluctuations and early indicators of thermal runaway. Batteries naturally experience temperature variations during charging, discharging, and ambient condition changes. Detection systems must be sophisticated enough to differentiate these normal patterns from abnormal thermal behaviors without generating excessive false alarms that could undermine grid stability.

Sensor placement represents another substantial hurdle. The internal temperature distribution within battery cells is non-uniform, creating "hot spots" that may not be detected by external sensors. Embedding sensors directly within cells improves detection accuracy but introduces manufacturing complexities, increases costs, and may affect battery performance or lifespan. This creates a difficult trade-off between detection capability and practical implementation.

Data processing challenges are equally significant. Smart grid environments generate enormous volumes of data from numerous battery systems simultaneously. Processing this information in real-time requires substantial computational resources and sophisticated algorithms. The latency between data acquisition, processing, and response must be minimized to prevent thermal events from escalating beyond containment.

Environmental factors further complicate detection efforts. Ambient temperature variations, humidity levels, and air flow patterns can all influence battery thermal behavior and mask early warning signs. Detection systems must account for these external variables to maintain accuracy across diverse operating conditions.

The integration of battery systems with varying ages, chemistries, and manufacturers within the same smart grid infrastructure creates additional complexity. Different battery types exhibit distinct thermal signatures and failure modes, necessitating adaptive detection approaches that can accommodate this heterogeneity.

Cost considerations present practical limitations to implementing comprehensive detection systems. While advanced thermal imaging, gas sensors, and electrochemical impedance spectroscopy offer superior detection capabilities, their high cost prohibits widespread deployment across all battery installations in smart grid applications. This economic constraint forces difficult decisions about the appropriate level of monitoring for different system components based on their criticality.

Regulatory frameworks and standards for thermal runaway detection in grid-connected battery systems remain underdeveloped in many regions, creating uncertainty about minimum safety requirements and complicating technology development efforts. This regulatory gap slows the adoption of innovative detection technologies that could otherwise enhance system safety.

Current Detection Methods

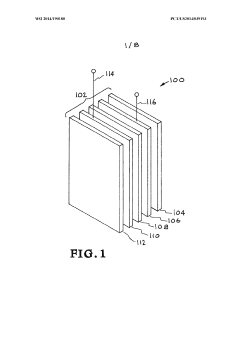

01 Thermal management systems for battery packs

Various thermal management systems are designed to prevent thermal runaway in battery packs. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to maintain optimal operating temperatures. Advanced designs incorporate phase change materials, liquid cooling circuits, and thermally conductive materials to efficiently remove heat from battery cells and prevent the propagation of thermal events.- Thermal management systems for batteries: Various thermal management systems are designed to prevent and mitigate thermal runaway in batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that help maintain optimal operating temperatures. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling channels to efficiently remove excess heat from battery cells, preventing the cascade effect that leads to thermal runaway.

- Battery cell design and materials for thermal stability: Innovations in battery cell design and materials focus on enhancing thermal stability to prevent thermal runaway. These include specialized electrode materials, separator designs with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. Novel cathode and anode materials with higher thermal decomposition temperatures and reduced exothermic reactions contribute to safer battery operation under extreme conditions.

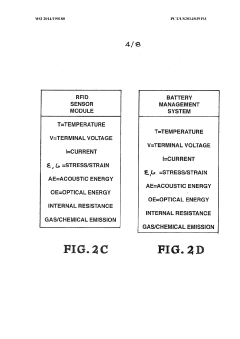

- Detection and early warning systems: Advanced detection systems are developed to identify early signs of thermal runaway before it escalates. These systems employ temperature sensors, gas detectors, voltage monitoring, and impedance tracking to detect abnormal battery behavior. Machine learning algorithms analyze battery parameters in real-time to predict potential thermal events, allowing for preventive measures to be taken before catastrophic failure occurs.

- Containment and isolation strategies: Containment strategies focus on limiting the spread of thermal runaway between cells in a battery pack. These include physical barriers between cells, thermal isolation materials, and compartmentalized designs that prevent propagation of thermal events. Some solutions incorporate pressure relief mechanisms, venting systems, and fire-resistant enclosures to safely manage gases and heat released during thermal runaway incidents.

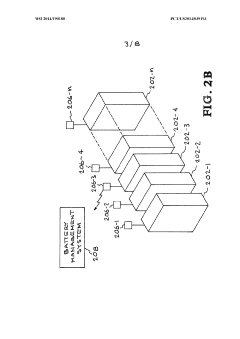

- Battery management systems (BMS) for thermal runaway prevention: Sophisticated battery management systems are designed to prevent thermal runaway through active monitoring and control. These systems regulate charging and discharging rates, implement protective cutoffs when abnormal conditions are detected, and balance cell voltages to prevent overcharging. Advanced BMS solutions incorporate predictive algorithms that adapt battery operation based on environmental conditions and usage patterns to maintain safe operating parameters.

02 Battery cell design and materials for thermal stability

Innovations in battery cell design and materials focus on enhancing thermal stability to prevent thermal runaway. These include specialized electrode materials, separator technologies with thermal shutdown properties, and electrolyte formulations with flame-retardant additives. Novel cell architectures incorporate safety features such as pressure relief mechanisms and internal thermal fuses that activate before thermal runaway conditions are reached.Expand Specific Solutions03 Detection and early warning systems

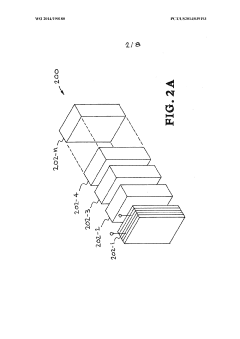

Advanced detection systems are developed to identify precursors to thermal runaway before catastrophic failure occurs. These systems utilize sensors to monitor parameters such as temperature gradients, gas emissions, internal pressure, and electrical anomalies. Machine learning algorithms analyze these inputs to predict potential thermal events, allowing for preventive measures to be taken. Early warning systems can trigger automated safety responses or alert operators to intervene.Expand Specific Solutions04 Thermal runaway propagation prevention

Methods and structures to prevent the propagation of thermal runaway from one cell to adjacent cells within a battery pack are critical for overall system safety. These include physical barriers, thermal isolation materials, heat-resistant cell casings, and strategic cell arrangement. Some designs incorporate sacrificial elements that absorb heat or fire-suppression materials that activate when thermal thresholds are exceeded, containing the failure to a single cell or limited area.Expand Specific Solutions05 Battery management systems for thermal runaway prevention

Sophisticated battery management systems (BMS) play a crucial role in preventing thermal runaway by continuously monitoring and controlling battery operation. These systems regulate charging and discharging rates, balance cell voltages, and implement protective measures when abnormal conditions are detected. Advanced BMS incorporate predictive algorithms that can identify potential failure modes based on battery usage patterns and aging characteristics, enabling preemptive action before thermal issues develop.Expand Specific Solutions

Key Industry Players

Battery thermal runaway evaluation in smart grid integration is currently in a growth phase, with the market expected to reach significant expansion due to increasing electric vehicle adoption and renewable energy storage systems. The global market for battery safety technologies is projected to grow substantially as grid-scale energy storage deployments accelerate. Leading companies like Tesla, CATL, and BYD are advancing thermal management technologies, while traditional players such as Honeywell International and Boeing are contributing aerospace-grade safety protocols. Automotive manufacturers including Mercedes-Benz, Volkswagen, and GM are investing heavily in battery safety research. The technology is approaching maturity in consumer electronics but remains in development for large-scale grid applications, with companies like Safran Electrical & Power and Lawrence Livermore National Security pushing innovations in thermal runaway prevention and early detection systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced Battery Thermal Runaway Evaluation (BTRE) system designed specifically for vehicle-to-grid (V2G) applications, leveraging their Ultium battery platform. Their approach focuses on bidirectional safety, protecting both vehicle batteries and grid infrastructure during energy exchange. The system employs a distributed sensor network with over 100 temperature monitoring points per battery pack, capable of detecting thermal anomalies with 0.3°C precision. GM's proprietary algorithms analyze thermal gradients and propagation patterns to identify potential runaway conditions before they reach critical thresholds. For grid integration, the system includes dedicated communication protocols that transmit battery health and thermal status data to grid operators in real-time, allowing for immediate load adjustment or disconnection if anomalous conditions are detected. The technology incorporates predictive modeling based on electrochemical impedance spectroscopy to identify internal short circuits or degradation patterns that might lead to thermal events. GM has also implemented a multi-stage intervention system that progressively restricts power flow, activates enhanced cooling, and ultimately isolates affected modules when thermal risk exceeds predetermined safety thresholds.

Strengths: Specifically optimized for V2G applications with bidirectional safety protocols; extensive integration with vehicle systems provides comprehensive monitoring capabilities; leverages GM's extensive battery testing and validation infrastructure. Weaknesses: Currently limited to GM's Ultium platform, reducing compatibility with other battery systems; requires specialized training for grid operators to interpret vehicle battery data; system adds complexity and cost to vehicle battery management systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced Battery Thermal Runaway Early Warning (BTREW) system specifically designed for smart grid integration. This system employs a multi-layered approach combining real-time monitoring with predictive analytics. At the cell level, CATL utilizes proprietary thermal gradient sensors that can detect temperature anomalies as small as 0.5°C within milliseconds. Their system incorporates machine learning algorithms trained on over 10,000 thermal runaway test scenarios to identify pre-failure patterns before catastrophic events occur. For grid integration, CATL's solution includes a hierarchical management architecture that enables individual battery packs to communicate thermal status data to central grid management systems, allowing for load balancing and emergency isolation protocols. The technology also features redundant monitoring pathways and self-diagnostic capabilities to ensure system reliability even during partial sensor failures. CATL's thermal runaway mitigation includes automated cooling systems that can target specific modules showing early warning signs, significantly reducing false alarms while maintaining high safety standards.

Strengths: Industry-leading early detection capabilities with extremely low false positive rates (under 0.01%); seamless integration with existing grid management systems; scalable from residential to utility-scale applications. Weaknesses: Higher implementation cost compared to basic thermal management systems; requires significant computational resources for real-time analytics; system effectiveness partially dependent on the quality of historical training data.

Critical Patents Analysis

Comprehensive evaluation method and system for power battery thermal runaway safety

PatentWO2020199415A1

Innovation

- Multi-scale thermal stability testing and comprehensive analysis methods are adopted, including battery material composition analysis, thermal characteristic analysis, adiabatic thermal runaway testing and side reaction temperature sequence diagram drawing, to quantitatively evaluate the thermal runaway safety of battery cells through characteristic values.

Li-ion battery thermal runaway suppression system using microchannel coolers and refrigerant injections

PatentWO2014190180A1

Innovation

- A battery management system with thermally integrated fire suppression that includes individual cells with cooling passages, sensors to detect thermal runaway, and a method to inject coolant into these passages to rapidly quench the event, using microchannels and refrigerant injections for direct heat transfer and prevention of cell-to-cell propagation.

Regulatory Framework

The regulatory landscape governing battery thermal runaway in smart grid integration has evolved significantly in response to increasing safety concerns and technological advancements. International standards such as IEC 62619 and UL 1973 establish comprehensive testing protocols specifically designed to evaluate thermal runaway risks in grid-scale battery systems. These standards mandate rigorous testing procedures including thermal abuse tests, overcharge protection verification, and short circuit response evaluations to ensure batteries can withstand abnormal operating conditions without catastrophic failure.

In the United States, the National Fire Protection Association (NFPA) has developed NFPA 855, which provides specific requirements for the installation of energy storage systems, including thermal runaway mitigation strategies. The standard requires thermal runaway propagation prevention between battery modules and mandates detection systems capable of early identification of thermal events. Similarly, the Institute of Electrical and Electronics Engineers (IEEE) has established IEEE 1547, which addresses the interconnection requirements for distributed energy resources, including battery storage systems integrated with smart grids.

European regulations have taken a more comprehensive approach through the Battery Directive (2006/66/EC) and its recent updates, which incorporate specific safety requirements for grid-connected battery systems. The European Committee for Electrotechnical Standardization (CENELEC) has developed EN 50272, which addresses safety aspects of stationary battery installations with particular attention to thermal management requirements.

Regulatory frameworks in Asia, particularly in Japan and South Korea, have implemented some of the most stringent requirements following high-profile battery thermal incidents. Japan's Industrial Standard (JIS) C8715-2 and South Korea's KC 62619 certification mandate extensive thermal runaway testing before grid integration approval. China's recent energy storage safety regulations (NEA 2020-19) specifically address thermal runaway prevention in grid-scale applications.

Compliance verification processes typically involve third-party certification by recognized testing laboratories. These certifications require manufacturers to demonstrate that their battery systems incorporate multiple layers of protection against thermal runaway, including battery management systems with advanced thermal monitoring capabilities, physical isolation between cells, and active cooling systems designed to prevent cascading thermal events.

The regulatory landscape continues to evolve, with increasing focus on real-time monitoring requirements and remote shutdown capabilities for grid-connected battery systems. Recent regulatory trends indicate movement toward harmonized global standards that incorporate lessons learned from thermal runaway incidents across different markets and applications.

In the United States, the National Fire Protection Association (NFPA) has developed NFPA 855, which provides specific requirements for the installation of energy storage systems, including thermal runaway mitigation strategies. The standard requires thermal runaway propagation prevention between battery modules and mandates detection systems capable of early identification of thermal events. Similarly, the Institute of Electrical and Electronics Engineers (IEEE) has established IEEE 1547, which addresses the interconnection requirements for distributed energy resources, including battery storage systems integrated with smart grids.

European regulations have taken a more comprehensive approach through the Battery Directive (2006/66/EC) and its recent updates, which incorporate specific safety requirements for grid-connected battery systems. The European Committee for Electrotechnical Standardization (CENELEC) has developed EN 50272, which addresses safety aspects of stationary battery installations with particular attention to thermal management requirements.

Regulatory frameworks in Asia, particularly in Japan and South Korea, have implemented some of the most stringent requirements following high-profile battery thermal incidents. Japan's Industrial Standard (JIS) C8715-2 and South Korea's KC 62619 certification mandate extensive thermal runaway testing before grid integration approval. China's recent energy storage safety regulations (NEA 2020-19) specifically address thermal runaway prevention in grid-scale applications.

Compliance verification processes typically involve third-party certification by recognized testing laboratories. These certifications require manufacturers to demonstrate that their battery systems incorporate multiple layers of protection against thermal runaway, including battery management systems with advanced thermal monitoring capabilities, physical isolation between cells, and active cooling systems designed to prevent cascading thermal events.

The regulatory landscape continues to evolve, with increasing focus on real-time monitoring requirements and remote shutdown capabilities for grid-connected battery systems. Recent regulatory trends indicate movement toward harmonized global standards that incorporate lessons learned from thermal runaway incidents across different markets and applications.

Environmental Impact

The environmental implications of battery thermal runaway events in smart grid integration extend far beyond immediate safety concerns. When thermal runaway occurs, batteries can release toxic gases including hydrogen fluoride, carbon monoxide, and various volatile organic compounds. These emissions pose significant health risks to nearby populations and contribute to air pollution, particularly in densely populated areas where grid-scale battery installations are becoming more common.

Water contamination represents another critical environmental concern. During thermal runaway incidents, firefighting efforts often utilize substantial water resources, which can become contaminated with electrolyte materials, heavy metals, and other hazardous substances. This contaminated runoff may infiltrate groundwater systems or waterways, potentially causing long-term ecological damage to aquatic ecosystems and compromising drinking water supplies.

The carbon footprint associated with battery thermal runaway events must also be considered within a comprehensive environmental assessment. When batteries fail catastrophically, the embodied carbon from manufacturing is effectively wasted, and additional carbon emissions are generated through replacement production. This undermines the sustainability benefits that battery storage systems are intended to provide in renewable energy integration.

Land use impacts present further environmental challenges. Battery installations that experience thermal runaway events may contaminate surrounding soil with heavy metals and toxic chemicals, potentially rendering areas unusable for agricultural or residential purposes for extended periods. Remediation efforts often require extensive soil removal and treatment, creating additional environmental disturbances.

From a lifecycle perspective, thermal runaway incidents significantly reduce the operational lifespan of battery systems, necessitating premature replacement and increasing electronic waste generation. This accelerated turnover contradicts circular economy principles and places additional pressure on limited resources used in battery production, including lithium, cobalt, and nickel.

The environmental consequences of thermal runaway events also extend to biodiversity impacts. Toxic emissions and contaminated runoff can harm local flora and fauna, potentially disrupting ecosystems in proximity to battery installations. These effects may be particularly pronounced in ecologically sensitive areas where grid infrastructure expansion is occurring to accommodate renewable energy growth.

Water contamination represents another critical environmental concern. During thermal runaway incidents, firefighting efforts often utilize substantial water resources, which can become contaminated with electrolyte materials, heavy metals, and other hazardous substances. This contaminated runoff may infiltrate groundwater systems or waterways, potentially causing long-term ecological damage to aquatic ecosystems and compromising drinking water supplies.

The carbon footprint associated with battery thermal runaway events must also be considered within a comprehensive environmental assessment. When batteries fail catastrophically, the embodied carbon from manufacturing is effectively wasted, and additional carbon emissions are generated through replacement production. This undermines the sustainability benefits that battery storage systems are intended to provide in renewable energy integration.

Land use impacts present further environmental challenges. Battery installations that experience thermal runaway events may contaminate surrounding soil with heavy metals and toxic chemicals, potentially rendering areas unusable for agricultural or residential purposes for extended periods. Remediation efforts often require extensive soil removal and treatment, creating additional environmental disturbances.

From a lifecycle perspective, thermal runaway incidents significantly reduce the operational lifespan of battery systems, necessitating premature replacement and increasing electronic waste generation. This accelerated turnover contradicts circular economy principles and places additional pressure on limited resources used in battery production, including lithium, cobalt, and nickel.

The environmental consequences of thermal runaway events also extend to biodiversity impacts. Toxic emissions and contaminated runoff can harm local flora and fauna, potentially disrupting ecosystems in proximity to battery installations. These effects may be particularly pronounced in ecologically sensitive areas where grid infrastructure expansion is occurring to accommodate renewable energy growth.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!